MotoIQ.com's - Project FD RX-7 "Restomod"

#177

Dropping the clutch at 700hp is worse than dropping the clutch at 200hp, even if the torque is equal. It's a relevant measurement for a non-moving part, the diff case doesn't care how fast the diff is spinning, it's only seeing HP. Gears do care how many teeth are taking that load per second, so torque is a better measurement for transmission strength.

yup, same for me. 8.8 is hard to source and expensive, wouldn't make sense to import a kit. A few people have moved on to Skyline diffs, but most just run a stock case with an aftermarket LSD. I've seen a quick change in a 4 rotor car, but that requires cutting out the center of the subframe and moving the gas tank. The fastest road raced FDs here are running stock cases, but with a cooler. Apparently the cooler is a very important part of making the stock diff last, spider gears generate a ton of heat.

So yeah, if you want to drag race your FD get a Quick Change with a 4 link rear

A while ago I asked about billet FD diff housings, seems nobody has made one. Popular in other platforms.

yup, same for me. 8.8 is hard to source and expensive, wouldn't make sense to import a kit. A few people have moved on to Skyline diffs, but most just run a stock case with an aftermarket LSD. I've seen a quick change in a 4 rotor car, but that requires cutting out the center of the subframe and moving the gas tank. The fastest road raced FDs here are running stock cases, but with a cooler. Apparently the cooler is a very important part of making the stock diff last, spider gears generate a ton of heat.

So yeah, if you want to drag race your FD get a Quick Change with a 4 link rear

A while ago I asked about billet FD diff housings, seems nobody has made one. Popular in other platforms.

Just...no. Horsepower is a function of power over time. The same amount of rotational force will be imparted on whatever part you're measuring.

Last edited by dguy; 04-19-24 at 03:58 PM. Reason: accidentally a word - power/force

#178

Full Member

Thread Starter

Again, no. Torque is a measurement of rotational force with no reference to time and can be directly attributed to the things you're describing whereas horsepower is power over time. The other things you're describing plug directly in to the use of torque (take it as ft/lbs or NM) as your unit of measurement, whereas they do not with regards to horsepower.

Horsepower is a dumb metric for drivetrain component longevity. Period.

Horsepower is a dumb metric for drivetrain component longevity. Period.

Failures are caused by far more than a singular dimension like torque.

#179

Age and fatigue is a completely separate conversation that I never weighed in on however again, force would be operating factor of fatigue.

#180

Full Member

Thread Starter

No, read what I've said originally and take into account the first part of your sentence. Force is what produces these issues and how one would measure their affects, horsepower is NOT force: it is a function of power (in this case force) over time. Period.

Age and fatigue is a completely separate conversation that I never weighed in on however again, force would be operating factor of fatigue.

Age and fatigue is a completely separate conversation that I never weighed in on however again, force would be operating factor of fatigue.

...unless you're a NASCAR or F1 team, no one does this. I get that the engine torque number is slightly more accurate than a HP figure, but you still need to know the rpm of the torque figure. I also get torque is the outright force that causes failures, but as I stated above, you need to do a lot of expensive calculations to come up with an accurate number that won't be relatable to the entire community.

Get off your high horse.

#181

So then you need to take the engine torque figure at the time of failure, multiplier by the transmission ratio and final drive ratio to get the total output torque that caused the failure and then quantity and add the force multiplication factor of wheel hop or a clutch drop, which can be determined in an isolated laboratory test to quantify the limit of a given component.

...unless you're a NASCAR or F1 team, no one does this. I get that the engine torque number is slightly more accurate than a HP figure, but you still need to know the rpm of the torque figure. I also get torque is the outright force that causes failures, but as I stated above, you need to do a lot of expensive calculations to come up with an accurate number that won't be relatable to the entire community.

Get off your high horse.

...unless you're a NASCAR or F1 team, no one does this. I get that the engine torque number is slightly more accurate than a HP figure, but you still need to know the rpm of the torque figure. I also get torque is the outright force that causes failures, but as I stated above, you need to do a lot of expensive calculations to come up with an accurate number that won't be relatable to the entire community.

Get off your high horse.

Stop being obtuse and focus on the words that I'm saying rather than trying to prove me wrong. You're conflating a law of physics with a unit of measurement that describe different things at a base level and then trying to throw in complexities (that are accurate by the way) to try and somehow prove your point. Horsepower is NOT force and the failure modes that you're trying to use an examples are caused by force. This is very simple physics.

#182

Full Member

Thread Starter

Stop being obtuse and focus on the words that I'm saying rather than trying to prove me wrong. You're conflating a law of physics with a unit of measurement that describe different things at a base level and then trying to throw in complexities (that are accurate by the way) to try and somehow prove your point. Horsepower is NOT force and the failure modes that you're trying to use an examples are caused by force. This is very simple physics.

Most people quote and mention failures at given HP levels, not TQ. There's not getting around that.

Quit trying to high road the conversation. If you want to really get into an accurate discussion of the force that causes failures, you need to discuss and consider all the factors I've mentioned. Not just the engine torque output, which is one degree and calculation away from a horsepower figure that youre hell bent on discrediting (which I addressed in part 14 if you even took the time to read it). The difference in torque vs HP (torque at a given RPM level) is far smaller than force multiplying variables like shock loading of clutch engagement, so the point you're trying to make is moot.

#183

Horsepower is a function of torque at a given RPM. Rotaries tend to have fairly flat torque curves.

Most people quote and mention failures at given HP levels, not TQ. There's not getting around that.

Quit trying to high road the conversation. If you want to really get into an accurate discussion of the force that causes failures, you need to discuss and consider all the factors I've mentioned. Not just the engine torque output, which is one degree and calculation away from a horsepower figure that youre hell bent on discrediting (which I addressed in part 14 if you even took the time to read it). The difference in torque vs HP (torque at a given RPM level) is far smaller than force multiplying variables like shock loading of clutch engagement, so the point you're trying to make is moot.

Most people quote and mention failures at given HP levels, not TQ. There's not getting around that.

Quit trying to high road the conversation. If you want to really get into an accurate discussion of the force that causes failures, you need to discuss and consider all the factors I've mentioned. Not just the engine torque output, which is one degree and calculation away from a horsepower figure that youre hell bent on discrediting (which I addressed in part 14 if you even took the time to read it). The difference in torque vs HP (torque at a given RPM level) is far smaller than force multiplying variables like shock loading of clutch engagement, so the point you're trying to make is moot.

K.

#184

Full Member

Thread Starter

I rarely do this on here, and previously I've really enjoyed your thread but if you can't even get on board with the fact that something that has historically been done in an automotive community is wrong after being given real information I'll just have to go ahead and do it:

K.

K.

The following users liked this post:

c0rbin9 (04-19-24)

#185

I think it's interesting that dguy obviously has a better understanding of physics and engineering and fabrication, but Billj747 is pulling the 'most people speak using laymans terms' card. That doesn't mean most people are correct, it just means that if you're trying to talk to most people without spending time to educate them you would need to speak their language.

Back to the subject of this RX7 project, I think there are some creative ideas discussed in this set of MotoIQ rotary RX7 articles. It's obvious that the perspective is to try a few new things based on what has worked for other brands (not Mazda), and I hope they work out well when the car is eventually finished and running. Hopefully it does get finished and running, unlike the previous MotoIQ rotary RX7 project.

Personally I dislike that so many changes are being made all at once, that makes it hard to quantify each change. For instance if the car's lap times improve, will that be due to the new engine or new turbo or new rear differential setup? Could it have been equally fast with the original differential and that money spent on brakes or aero or something else? My perspective is I like driving my car but don't have a lot of budget to spend modifying it. I want to know where it makes sense to spend money first, because there's no way I'm spending what it would cost to replicate this entire build at once. I bought my RX7 because it's a great car without needing tons of modifications.

Back to the subject of this RX7 project, I think there are some creative ideas discussed in this set of MotoIQ rotary RX7 articles. It's obvious that the perspective is to try a few new things based on what has worked for other brands (not Mazda), and I hope they work out well when the car is eventually finished and running. Hopefully it does get finished and running, unlike the previous MotoIQ rotary RX7 project.

Personally I dislike that so many changes are being made all at once, that makes it hard to quantify each change. For instance if the car's lap times improve, will that be due to the new engine or new turbo or new rear differential setup? Could it have been equally fast with the original differential and that money spent on brakes or aero or something else? My perspective is I like driving my car but don't have a lot of budget to spend modifying it. I want to know where it makes sense to spend money first, because there's no way I'm spending what it would cost to replicate this entire build at once. I bought my RX7 because it's a great car without needing tons of modifications.

Last edited by scotty305; 04-20-24 at 02:32 PM.

#186

Rotary Enthusiast

So 200hp at 200ft of torque, is the same driveline shock as 700hp at 200ft of torque? Only the torque matters to the driveline, wheels, frame etc?

#187

Arrogant Wankeler

The actual peak impulse torque will be higher with rpm on a clutch drop if it doesn't slip. Very difficult to measure unless you run are wireless strain guage on the tailshaft with very high frequency logging.

If something fails on load it doesn't matter, torque is torque but people think of it as a continuous level rather than a series of impulses. That's why you can make 50% more reliably on the same box with a 20b, the peak impulse isn't any higher. Same reason you need a lot more clutch and box on a 4 cylinder making the same power at the same rpm as a v8.

If something fails on load it doesn't matter, torque is torque but people think of it as a continuous level rather than a series of impulses. That's why you can make 50% more reliably on the same box with a 20b, the peak impulse isn't any higher. Same reason you need a lot more clutch and box on a 4 cylinder making the same power at the same rpm as a v8.

#188

Full Member

Thread Starter

I think it's interesting that dguy obviously has a better understanding of physics and engineering and fabrication, but Billj747 is pulling the 'most people speak using laymans terms' card. That doesn't mean most people are correct, it just means that if you're trying to talk to most people without spending time to educate them you would need to speak their language.

You and @dguy should really try reading the articles I wrote and consider that almost every failure point that I referenced are "quotes" compiled from posts on these forums, facebook, and talking to various sources. I quoted torque figures when they are known and provided, however the vast majority of people only mention the peak horsepower output of their engine when they break something (not torque). If I didn't quote horsepower figures, then there wouldn't be much documented information on the limitation of various drivetrain components.

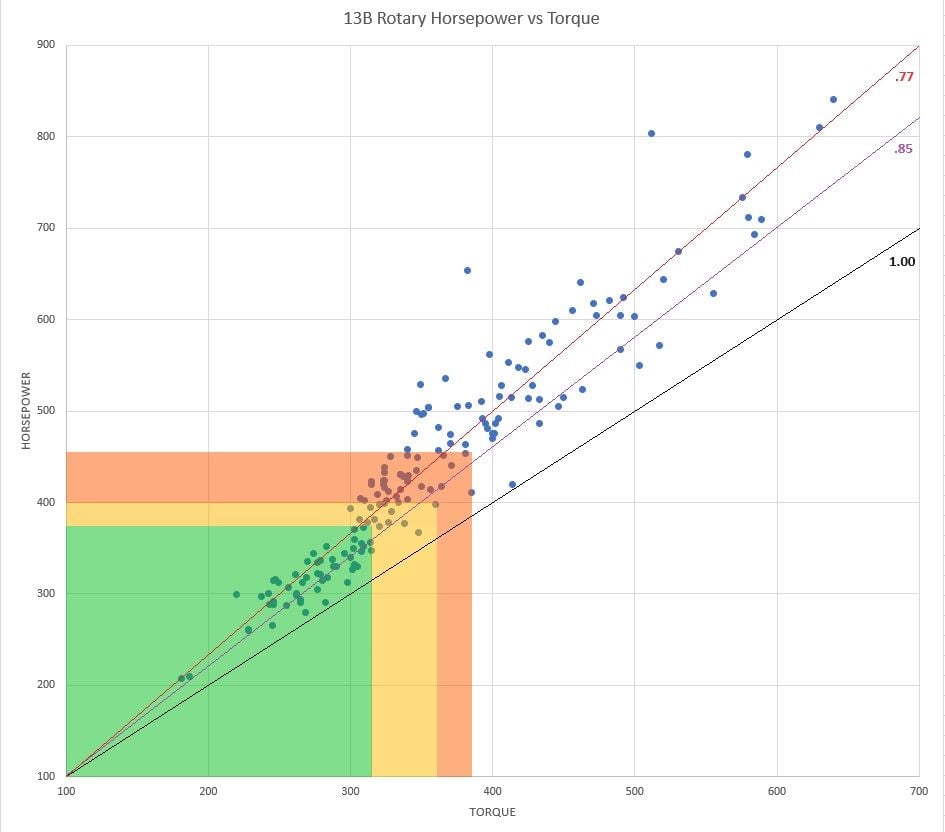

To expand on what I said earlier regarding 13Bs having relatively flat torque curves, and that knowing the horsepower of an engine is relevant to failures; I have compiled a scatter chart of over 150 known horsepower and torque figures of various turbocharged 13B rotary engines in order to see a correlation between horsepower and torque.

This will enable us to mathematically generalize a torque output range of known horsepower outputs when components fail.

Out of these 168 known horsepower/torque figures of various setups ranging from stock to 800hp+ builds, the average torque output is 82% of horsepower.

- In the 325-375whp range, the average torque output is 85% of horsepower.

- In the 375-425whp range, the average torque output is 83% of horsepower.

- In the 425-475whp range, the average torque output is 79% of horsepower.

- In the 475-525whp range, the average torque output is 79% of horsepower.

- In the 525-575whp range, the average torque output is 78% of horsepower.

- Horsepower generally increases at a greater rate then torque for the 13B rotary engine

1) From the MotoIQ article (Part 14) - When pushed aggressively at the drag strip, drifting, clutch-drops, etc... the stock drivetrain components can break around 350whp From the data above, this happens around ~300lb-ft of torque on average.

- Drag radials, aggressive clutches, and heavy shock to the drivetrain can cause failures at relatively low power/torque figures.

2) A lot of stock FD3S drivetrain components start to break around 400whp. From the data above, this generally happens around ~332lb-ft of torque on average.

- 90% of the dyno plots in the 375-425whp range fall between 300-360lb-ft of torque.

- The dangerous outlying examples are pushing the limits of the stock twin turbos or small single turbos like the EFR7670. When pushed on E85 or alcohol injection/meth, these turbos can make up to 400lb-ft of torque (or more), greatly increasing the risk of breaking drivetrain components

3) A lot of street cars can last with around 450whp or more. From the data above, this is generally around ~355lb-ft of torque on average.

- 100% of the dyno plots in the 425-475whp range fall between 324-401lb-ft of torque.

- Street cars do not push the drivetrain or experience Wide Open Throttle (WOT) nearly as often as cars that are tracked, drifted, or raced.

- Street cars tend to spin their tires, which is easy on the drivetrain, compared to a sticky track and sticky tires that cause more shock and load to the drivetrain.

4) At 500whp and above, for cars that are not dyno queens, it becomes more common to upgrade the stock diff and trans. From the data above, this generally happens around ~397lb-ft of torque on average.

- 90% of the dyno plots in the 475-525whp range fall between 346-446lb-ft of torque

From the above chart, we have put fairly accurate torque figures to the quoted horsepower figures documented in the MotoIQ article (which was taken from many threads on this forum, facebook posts, and conversations with many people who track and race RX-7s). The vast majority of engine builds have torque outputs fall within a consistent range of 85% of the horsepower output of the engine.

The 400-450whp range (and mid-high 300lb-ft of torque), starts to become the risky zone for the stock FD RX-7's drivetrain that doesn't does more than just play around on the street.

Staying below 365whp (310lb-ft of torque) seems to be a good rule of thumb to maintain reliability of the stock trans and diff when driving the car aggressively.

VARIABLES:

Having said all of this, as I have mentioned before, there are far greater variables than just the engine's torque output that affect the durability of the drivetrain.

- Wheel Hop is a killer, and can be a force multiplier by a factor of 3X.

- Shock from the tires (drag radials vs bias ply) can vary greatly depending on what tire is used.

- Shock from the clutch can vary greatly and many drag racers have determined through (expensive) trial and error, which combinations of friction material, number of discs, pressure plate clamping force, etc... breaks components vs 'cushions' the shock load.

- Age and fatigue. Heat cycled metal in the drivetrain weakens over time and continuous use, cracks propagate and can eventually lead to a failure at a power/torque output that it has survived for weeks/months/years.

- Rotational mass

- Etc..

The durability of any component will never be determined by a fixed torque figure for the reasons above.

Personally I dislike that so many changes are being made all at once, that makes it hard to quantify each change. For instance if the car's lap times improve, will that be due to the new engine or new turbo or new rear differential setup? Could it have been equally fast with the original differential and that money spent on brakes or aero or something else? My perspective is I like driving my car but don't have a lot of budget to spend modifying it. I want to know where it makes sense to spend money first, because there's no way I'm spending what it would cost to replicate this entire build at once. I bought my RX7 because it's a great car without needing tons of modifications.

Last edited by Billj747; 04-21-24 at 10:33 PM.

#189

Idk why we're getting hung up on this. People talk about general horsepower figures all the time and reference where things start to break. It's commonly known that torque is actually what makes the failures, but it's a much less commonly discussed metric. For every mention of achieving a torque figure for a given setup on this forum, there are 100+ mentions of horsepower as the metric instead. It might not be the most accurate to use in terms of breaking stuff, but horsepower is what most people benchmark to and therefore is most commonly referred to, especially in the rotary world. There are several over threads out there talking about horsepower levels that diffs/trans/axles break at. Do they all devolve into this pointless back and forth about torque? No

The following users liked this post:

SETaylor (04-22-24)

#191

Terminology debate aside.

I have to admit, rear end decisions have been top of my list recently and this article has really pushed me in this direction.

Regarding sourcing for the 8.8 diff - are there any other tell tale signs a late model 2006 will have the correct diff other than seeing it? There's a couple local junkyard with 07/06 and 12/06 build date on their 2007 Explorers and I'd rather not waste the trip if I don't have to.

I have to admit, rear end decisions have been top of my list recently and this article has really pushed me in this direction.

Regarding sourcing for the 8.8 diff - are there any other tell tale signs a late model 2006 will have the correct diff other than seeing it? There's a couple local junkyard with 07/06 and 12/06 build date on their 2007 Explorers and I'd rather not waste the trip if I don't have to.

#192

Full Member

Thread Starter

Terminology debate aside.

I have to admit, rear end decisions have been top of my list recently and this article has really pushed me in this direction.

Regarding sourcing for the 8.8 diff - are there any other tell tale signs a late model 2006 will have the correct diff other than seeing it? There's a couple local junkyard with 07/06 and 12/06 build date on their 2007 Explorers and I'd rather not waste the trip if I don't have to.

I have to admit, rear end decisions have been top of my list recently and this article has really pushed me in this direction.

Regarding sourcing for the 8.8 diff - are there any other tell tale signs a late model 2006 will have the correct diff other than seeing it? There's a couple local junkyard with 07/06 and 12/06 build date on their 2007 Explorers and I'd rather not waste the trip if I don't have to.

Be sure to grab the axle shafts as well if you want to go the less expensive route with the Ronin axle upgrade vs the bolt-in DSS "Direct-Fit" axles that I went with.

#193

Joel from Ronin Speedworks just clarified with me that 2006 was a transition year where most of the vehicles have the newer "dual mount" (from the 2007-2010 diffs) but there are some that have the 2005-older single-ear mounts. I'm sure between the two of them at least one will have the newer dual-ear mounts.

Be sure to grab the axle shafts as well if you want to go the less expensive route with the Ronin axle upgrade vs the bolt-in DSS "Direct-Fit" axles that I went with.

Be sure to grab the axle shafts as well if you want to go the less expensive route with the Ronin axle upgrade vs the bolt-in DSS "Direct-Fit" axles that I went with.

Oh! On the topic of 'Direct-Fit' DSS axles. There's nothing on the DSS site called 'Direct-Fit' axles - so I'm assuming you guys went with the Pro-Lexel Axle/Hub Kit specifically for the Ford Explorer 31 Spline 8.8 Rear (that's the 'Direct-Fit' part)? Extremely pricey at another $3000 and kinda puts a kink in the original value proposition. But I get it, that's for extreme power levels. The Ronin Grande should be good for big big power.

#194

Full Member

Thread Starter

Yep. That's why I was asking. Since 2006 is the transition year, I wasn't sure if there was a month cutoff or other specification that would signify the proper diff. I guess pictures will be worth 1000 words. =)

Oh! On the topic of 'Direct-Fit' DSS axles. There's nothing on the DSS site called 'Direct-Fit' axles - so I'm assuming you guys went with the Pro-Lexel Axle/Hub Kit specifically for the Ford Explorer 31 Spline 8.8 Rear (that's the 'Direct-Fit' part)? Extremely pricey at another $3000 and kinda puts a kink in the original value proposition. But I get it, that's for extreme power levels. The Ronin Grande should be good for big big power.

Oh! On the topic of 'Direct-Fit' DSS axles. There's nothing on the DSS site called 'Direct-Fit' axles - so I'm assuming you guys went with the Pro-Lexel Axle/Hub Kit specifically for the Ford Explorer 31 Spline 8.8 Rear (that's the 'Direct-Fit' part)? Extremely pricey at another $3000 and kinda puts a kink in the original value proposition. But I get it, that's for extreme power levels. The Ronin Grande should be good for big big power.

#195

Read Part 16. DSS offers a new "Direct-Fit" axle that uses the stock outer hubs, which makes it A LOT less expensive than the Pro series axles. They are giving this FD Direct Fit Axle kit a part number soon and I will update the article with the part number. For now you can call them, reference this article and get a price. The Ronin Grande is a good option and the base Ronin kit is by far the least expensive option if you want to build your axles.

I'll give DSS a call. 👍

#196

Full Member

Thread Starter

1993-1995 Mazda RX-7 (FD) Pro-Level Axle/Hub Kit (Pair)

SKU: 510321

PART# MZ56-V2

$3,567.93

-1,400hp+ rated

-Larger 33-spline outer hubs equipped with ARP extended studs

-108mm Porsche-style inner CV joints

-Aerospace-grade 300M Chromoly Bolt-on Inner Diff Stubs (OEM FD RX-7 spline)

-300M Axle Bar/shaft

-300M Outer Wheel Stub Splines (Larger 33-spline)

1993-1995 Mazda RX-7 (FD) Direct Fit Axle Set (Ronin Speedworks Ford Explorer 31 Spline 8.8 Diff Mount Kit) (Pair)

SKU: 510528

$1,999.99

-1,000hp Rated

-For use with stock FD outer hubs.

-108mm Porsche-style inner CV joints

-Aerospace-grade 300M Chromoly Bolt-on Inner Diff Stubs (31-spline Explorer 8.8)

-300M Axle Bar/shaft

-300M Outer Wheel Stub Splines (OEM FD RX-7 spline dimensions)

1993-1995 Mazda RX-7 (FD) Pro-Level Axle/Hub Kit (Ford Explorer 31 Spline 8.8 Differential Conversion) (Pair)

SKU: 510322

PART# MZFD56-E

$2,974.98

-1,400hp+ rated

-Larger 33-spline outer hubs equipped with ARP extended studs

-108mm Porsche-style inner CV joints

-Aerospace-grade 300M Chromoly Bolt-on Inner Diff Stubs (31-spline Explorer 8.8)

-300M Axle Bar/shaft

-300M Outer Wheel Stub Splines (Larger 33-spline)

1993-1995 Mazda RX-7 (FD) Pro-Level Axle/Hub Kit (Ford Cobra 8.8 Differential) (Pair)

SKU: 510324

PART# MZFD56-V2

$2,798.79

-Used with the Ford Cobra/Terminator 31 Spline Differential

-1,400hp+ rated

-Larger 33-spline outer hubs equipped with ARP extended studs

-108mm Porsche-style inner CV joints

-Aerospace-grade 300M Chromoly Bolt-on Inner Diff Stubs (31-spline Cobra/Terminator)

-300M Axle Bar/shaft

-300M Outer Wheel Stub Splines (Larger 33-spline)