Modernizing the FD?

#1

First off, I love my FD, and no I'm not going around in circles, thinking my FD is outdated. But, I've come across some systems that were never available on the FD, and was curious what you guys think of these, WRT worthwhile, feasable, etc? Some of this is serious consideration, others is plain curiosity. Point being, many of these systems are available on cars nowadays, and others have been available for decades - long before the FD came along.

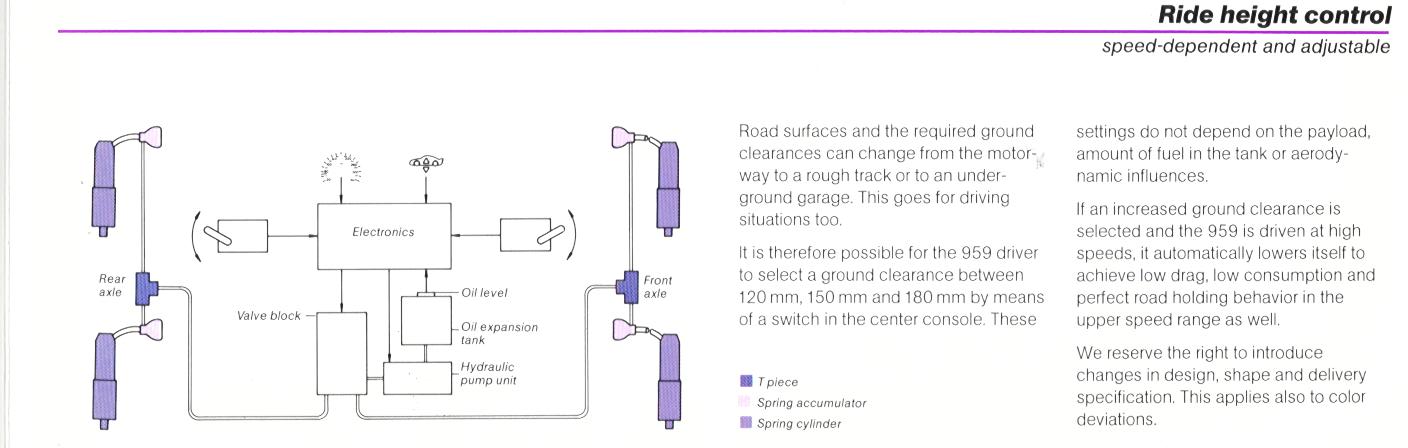

- Ride height control. I inquired about this maybe two years ago, and everyone I spoke to told me ride height is adjustable manually, ONLY. Not electronically, unless you go w/ an airbag suspension, in which case your handling goes kaput. But here I was, reading through the Porsche 959 brochure I have, and lo and behold, the 1980s Supercar came w/ electronically controlled ride height! (see below for description & diagram).

Please note, this IS actually changing the ride HEIGHT, as the section immediately above this discusses shock absorber regulation (also speed-dependent and adjustable). Again, I know many coilovers come w/ the capability to adjust the shock absorbers electonically, but I was told ride height couldn't be changed electronically.

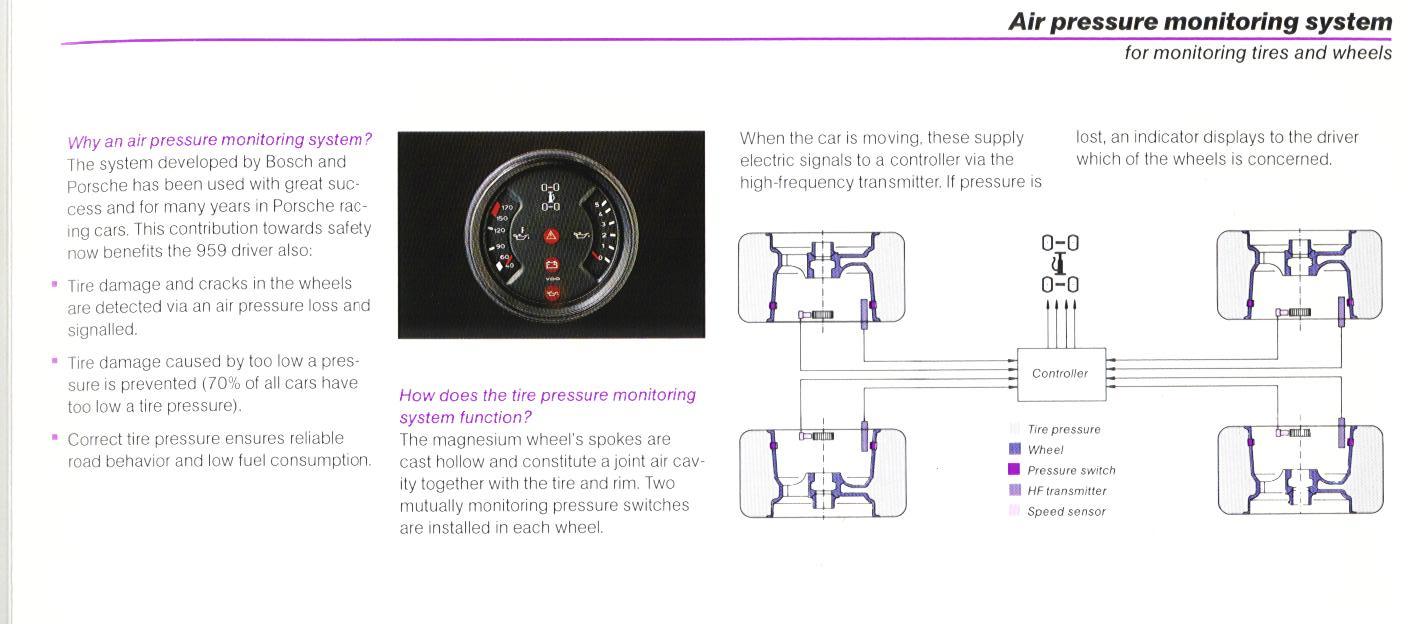

- Air Pressure Monitoring System. The 959 also came w/ an air pressure monitoring system, ensuring the tires weren't over- or underinflated. Yes, this can be taken care of w/ routine maintenance, but it has it's advantages as well. Many newer cars are coming w/ these systems, along w/ NeverFlat tires, etc. Again, see below for description & diagram.

- Traction Control. I'm not talking about going crazy, going AWD, w/ Porsche's dyanamic stability and what not (80/20 split going to a 60/40 split, etc). But traction control could be very useful and safe (I don't want to get into a debate about this, there are quite a few threads about it as is). But I think either way, it's not a bad idea if you have a very high hp FD which will spin throughout gears. Racelogic seems to offer an excellent system, and I've heard nothing but positive feedback regarding it, so I think that point's taken care of.

- Sequential Twins. I'm going to tread lightly on this one, given that we have 99specs, Knightsports, Borders, and the BNRs. But I'd love someone to take a look at the description & diagram below of the 959's sequential twins. Yes, the info isn't THAT detailed, but does it look like it was an electronically-based system, or purely mechanical? I dunno if this is of any use to anyone, but I'm including it nonetheless.

- Underbody Design. I know Damian's currently working on this, so I won't make this too long. My question is a simple noob question. I see GT spoilers stick to the same basic teardrop design; there really isn't much difference between the major 2 made by RE Amemiya and C-West. So (here's the noob idea lol) if an aerodynamic design in it of itself could be successfully used on other applications (same wing, different cars), could you do the same with underbody trays? The 959 had an underbody tray, and it was close in size to the FD. Many modern high-end cars like the Enzo and Carerra GT have underbody trays as well. I'm curious if one can pretty much mold an existing underbody tray that is been track and windtunnel tested, and reuse it on an FD? That way we're not shooting in the dark when it comes to it's aerodynamic function? Because I don't know anyone on this forum who's gonna spend $50K an hour to windtunnel test anything we have...

Thankfully, I think those are really the only things I think the FD could use to make it just a little bit better - obviously the FD is incredible as is. I dunno if any of you have further suggesstions as to what other systems we could possibly benefit from. Yes, this post is about getting info, but I'm all for a bit of brainstorming as well - and I'd love to hear from some of the Big List guys and their feedback re: what is and isn't worthwhile, feasible, useful, etc.

Oh and guys, plz keep from the "yea it needs cupholders too" kinda comments. I'm keeping absolute performance in mind, not creature comforts here

Thanks

~Ramy

PS: Here's something humerous I found in the brochure lol. I thought some of you would get a kick out of this

- Ride height control. I inquired about this maybe two years ago, and everyone I spoke to told me ride height is adjustable manually, ONLY. Not electronically, unless you go w/ an airbag suspension, in which case your handling goes kaput. But here I was, reading through the Porsche 959 brochure I have, and lo and behold, the 1980s Supercar came w/ electronically controlled ride height! (see below for description & diagram).

Please note, this IS actually changing the ride HEIGHT, as the section immediately above this discusses shock absorber regulation (also speed-dependent and adjustable). Again, I know many coilovers come w/ the capability to adjust the shock absorbers electonically, but I was told ride height couldn't be changed electronically.

- Air Pressure Monitoring System. The 959 also came w/ an air pressure monitoring system, ensuring the tires weren't over- or underinflated. Yes, this can be taken care of w/ routine maintenance, but it has it's advantages as well. Many newer cars are coming w/ these systems, along w/ NeverFlat tires, etc. Again, see below for description & diagram.

- Traction Control. I'm not talking about going crazy, going AWD, w/ Porsche's dyanamic stability and what not (80/20 split going to a 60/40 split, etc). But traction control could be very useful and safe (I don't want to get into a debate about this, there are quite a few threads about it as is). But I think either way, it's not a bad idea if you have a very high hp FD which will spin throughout gears. Racelogic seems to offer an excellent system, and I've heard nothing but positive feedback regarding it, so I think that point's taken care of.

- Sequential Twins. I'm going to tread lightly on this one, given that we have 99specs, Knightsports, Borders, and the BNRs. But I'd love someone to take a look at the description & diagram below of the 959's sequential twins. Yes, the info isn't THAT detailed, but does it look like it was an electronically-based system, or purely mechanical? I dunno if this is of any use to anyone, but I'm including it nonetheless.

- Underbody Design. I know Damian's currently working on this, so I won't make this too long. My question is a simple noob question. I see GT spoilers stick to the same basic teardrop design; there really isn't much difference between the major 2 made by RE Amemiya and C-West. So (here's the noob idea lol) if an aerodynamic design in it of itself could be successfully used on other applications (same wing, different cars), could you do the same with underbody trays? The 959 had an underbody tray, and it was close in size to the FD. Many modern high-end cars like the Enzo and Carerra GT have underbody trays as well. I'm curious if one can pretty much mold an existing underbody tray that is been track and windtunnel tested, and reuse it on an FD? That way we're not shooting in the dark when it comes to it's aerodynamic function? Because I don't know anyone on this forum who's gonna spend $50K an hour to windtunnel test anything we have...

Thankfully, I think those are really the only things I think the FD could use to make it just a little bit better - obviously the FD is incredible as is. I dunno if any of you have further suggesstions as to what other systems we could possibly benefit from. Yes, this post is about getting info, but I'm all for a bit of brainstorming as well - and I'd love to hear from some of the Big List guys and their feedback re: what is and isn't worthwhile, feasible, useful, etc.

Oh and guys, plz keep from the "yea it needs cupholders too" kinda comments. I'm keeping absolute performance in mind, not creature comforts here

Thanks

~Ramy

PS: Here's something humerous I found in the brochure lol. I thought some of you would get a kick out of this

Last edited by FDNewbie; 09-10-05 at 06:47 PM.

#3

Ramy,

In the case of traction control, quite a few members of not only this site, but also the supra and other forums have it equipped on their vehicles. Racelogic seems to be the popular choice for any others who aren't in the know- below is some reading for further information on the product and accesories available.

http://www.racelogic.co.uk/?show=Traction_Control

Tire pressure monitors are also available on the aftermarket. I personally haven't had any experience with them, or seen how they functioned on anyones vehicle to give any real information though. Below is a link to tireracks site conerning TPM's.

http://www.tirerack.com/accessories/.../smartire2.jsp

In the case of traction control, quite a few members of not only this site, but also the supra and other forums have it equipped on their vehicles. Racelogic seems to be the popular choice for any others who aren't in the know- below is some reading for further information on the product and accesories available.

http://www.racelogic.co.uk/?show=Traction_Control

Tire pressure monitors are also available on the aftermarket. I personally haven't had any experience with them, or seen how they functioned on anyones vehicle to give any real information though. Below is a link to tireracks site conerning TPM's.

http://www.tirerack.com/accessories/.../smartire2.jsp

Last edited by Shinobi-X; 09-10-05 at 06:54 PM.

#4

Kayin, thanks for the info. I think I mentioned the Racelogic system as being the system of choice (from what I've read as well) in the first post. I think the Beemer guys swear by it too. They just came out w/ a new display unit too.

Re: the tire pressure monitors, I had no idea TireRack sold them, but most importantly, I'm curious if it's worthwhile or is it one of those things that's "nice to have" and that's it?

Re: the tire pressure monitors, I had no idea TireRack sold them, but most importantly, I'm curious if it's worthwhile or is it one of those things that's "nice to have" and that's it?

#5

I wouldn't change much to modernize the FD. Just better materials, and be damned with our difficult air quality laws. That means use the upgraded ECU technology, better solenoids, better vacuum hoses, better radiator and overflow tank construction, etc. And a bigger intercooler would be nice.

I wouldn't sweat the ride height control - I believe the 959 was developed for both paved and unpaved roads, which in rally racing means that clearance compromises pavement performance. (I could be full of s**t on this point, but I don't think I'm making this up)

Tire pressure monitors - are they that important for track use? (when you say performance, I assume you mean road course driving)

Traction control would be nice as an option, or at least be able to disable it.

Based on the provided picture of the 959 sequential turbos, I see nothing notably different from the FD, except that the dual header layout of the engine makes the y-pipe almost seamless. I don't see a prespool mechanism, however it may be left out for illustrations' sake. The single-line diagram of the control system could be pneumatic, electronic, or hydraulic.

Dave

I wouldn't sweat the ride height control - I believe the 959 was developed for both paved and unpaved roads, which in rally racing means that clearance compromises pavement performance. (I could be full of s**t on this point, but I don't think I'm making this up)

Tire pressure monitors - are they that important for track use? (when you say performance, I assume you mean road course driving)

Traction control would be nice as an option, or at least be able to disable it.

Based on the provided picture of the 959 sequential turbos, I see nothing notably different from the FD, except that the dual header layout of the engine makes the y-pipe almost seamless. I don't see a prespool mechanism, however it may be left out for illustrations' sake. The single-line diagram of the control system could be pneumatic, electronic, or hydraulic.

Dave

#6

Senior Member

Join Date: Dec 2003

Location: Lexington, IL

Posts: 292

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the nice thread. Quite thought provoking.

The issue of underbody aerodynamics had me thinking a couple of weeks ago, as well.

I was covering a story about the solar powered car race when one of the cars that

finished (from Illinois State University) was exhibited for the public. The body designs of

these things always sort of bothered me. They didn't seem right. Then, I got a look at

one up close and talked to the engineering team that raced it. Upon close inspection, I

looked at the bottom of the car and realized that they had formed the car to be an

inverted wing. Yep, bernouli's principle in reverse - designed to create maximum

downforce. The top of the car is almost flat while the bottom was quite rounded. We

all know how that works. What I was thinking, was whether the flow of air under our

sevens couldn't be sped up, creating a near negative pressure zone. Air passing over

our cars would result in a higher pressure area, forcing the car into the ground and

reduce the high speed instability some of us feel at speeds over 130 mpg. This

would require some sort of ducting and just maybe, lessen the need to keep the

car built so low to the ground. Right now, the bottom of the car is relatively flat, which

is a bad thing. We ttend to lower the car and install front air dams to prevent air from going

underneath the car as a means to keep air pressure up top higher. We could instead

gain more by allowing more air underneath at a higher speed. This was the theory

behind the famous CANAM Chaparral cars of the 1960s. They were so successful, they

were virtually outlawed after the first couple of seasons Jim Hall ran them.

The issue of underbody aerodynamics had me thinking a couple of weeks ago, as well.

I was covering a story about the solar powered car race when one of the cars that

finished (from Illinois State University) was exhibited for the public. The body designs of

these things always sort of bothered me. They didn't seem right. Then, I got a look at

one up close and talked to the engineering team that raced it. Upon close inspection, I

looked at the bottom of the car and realized that they had formed the car to be an

inverted wing. Yep, bernouli's principle in reverse - designed to create maximum

downforce. The top of the car is almost flat while the bottom was quite rounded. We

all know how that works. What I was thinking, was whether the flow of air under our

sevens couldn't be sped up, creating a near negative pressure zone. Air passing over

our cars would result in a higher pressure area, forcing the car into the ground and

reduce the high speed instability some of us feel at speeds over 130 mpg. This

would require some sort of ducting and just maybe, lessen the need to keep the

car built so low to the ground. Right now, the bottom of the car is relatively flat, which

is a bad thing. We ttend to lower the car and install front air dams to prevent air from going

underneath the car as a means to keep air pressure up top higher. We could instead

gain more by allowing more air underneath at a higher speed. This was the theory

behind the famous CANAM Chaparral cars of the 1960s. They were so successful, they

were virtually outlawed after the first couple of seasons Jim Hall ran them.

#7

I check my tire pressures often enough, that it probably wouldn't justify the added cost of purchasing and installation for the TPM system. I think above all, checking the tires regularly should be standard practice for anyone trying to drive the FD often or hard. However, below is another link you may take interest in.

http://www.conti-online.com/generato...g_1103_en.html

Not to stray too far away from where you're trying to take the thread, but at this point, the most beneficial piece of technology my FD could recieve now, would be an electric hybrid motor.

Edit:

BTW, is your purpose for looking into adjustable ride height for aerodynamic purposes? Or is it for something similar to the murcielago where you can raise the front end so as to clear bumps and other inclines?

http://www.conti-online.com/generato...g_1103_en.html

Not to stray too far away from where you're trying to take the thread, but at this point, the most beneficial piece of technology my FD could recieve now, would be an electric hybrid motor.

Edit:

BTW, is your purpose for looking into adjustable ride height for aerodynamic purposes? Or is it for something similar to the murcielago where you can raise the front end so as to clear bumps and other inclines?

Last edited by Shinobi-X; 09-10-05 at 07:38 PM.

Trending Topics

#8

Originally Posted by FDNewbie

- Sequential Twins. I'm going to tread lightly on this one, given that we have 99specs, Knightsports, Borders, and the BNRs. But I'd love someone to take a look at the description & diagram below of the 959's sequential twins. Yes, the info isn't THAT detailed, but does it look like it was an electronically-based system, or purely mechanical? I dunno if this is of any use to anyone, but I'm including it nonetheless.

J/K

J/KAre you referring to pneumatic actuators as opposed to solenoids or stepping motors? I don't know that one.

It does look very similar to our system. They use a valve (4) on the right turbo as a wastegate/prespool device.

#9

Dave, I'm w/ you about the main & major reliability upgrades; those are no-brainers. I'm talking about taking it a step past that, when you've pretty much upgraded everything you can. What worthwhile things are we missing? Or could we add? Indeed, and I said it earlier, I think the FD is an amazing machine in every sence of the word. The mere fact that I can't come up w/ a whole laundry list of things that MUST be completely added says a lot IMO.

Re: the ride height control, I've always liked it for the mere fact that it would be quite convenient to be able to have the ride raised a bit for around the town driving, speed bumps, dirt/gravel/driveway entrances etc, and be able to quickly drop it when you want to scoot fast. So Kayin, it's uses are two-fold.

And yes, I'm speaking of road courses.

Thanks for your input re: the twins diagram...I read it, looked at the diagram, and read it some more, but it's simply beyond me. I do remember speaking with one of the more popular tuners once - and at length - and he telling me an idea he had laying in the back of his head for designing a purely mechanical sequential setup. What he described seemed so simple and ingenious...

Mazda99Nikon, thanks for the compliment. I'm just the type that when I see something better or useful, I wanna know "hey, can I do that to my car?" Cuz I simply don't see any other better platform than the FD. Really. Of course, I'm just a wee bit biased

About your idea, wow...I heard of that once VERY briefly, and it was actually on this forum - but it was in relation to wings I believe, not the underside of the car. My noob commentary would be the top of our car is already designed and fixed, non-modifyable (save a wing, etc). It's round(ed). So I think that's why ppl choose the smooth flat surface undertray method, since half of the equation is non-modifyable. No one's gonna redesign the body lines of the car Damian's been working on a front undertray that extends back past the oilpan, and we already have a RE diffuser. All what's left is to design (or copy, if possible) the middle portion, which would consist of the loading ramps to direct the airflow to the diffuser in the rear.

Damian's been working on a front undertray that extends back past the oilpan, and we already have a RE diffuser. All what's left is to design (or copy, if possible) the middle portion, which would consist of the loading ramps to direct the airflow to the diffuser in the rear.

Gosh...  Lately I've been a

Lately I've been a  LOL.

LOL.

See the idea I mentioned above. In short, the gist of it was to have the primary turbo's external wastegate vent directly to the inlet of the secondary turbo. The wastegate's spring is set at the desired psi level to have the secondary turbo spool. Once that psi level was reached, the excess gases vented would provide prespool to the secondary, and since that air was hot, it carries heat, and would spool the wheel even faster. That's what I remember...it was a year or so ago. So basically the secondary turbo fed off the primary turbo. I can't remember if it was doing so exclusively, or in addition to receiving air supply from the engine as well (forgive me...I'm not Mr. Technical when it comes to mechanics lol. I'm more of Mr. Ideas lol)

~Ramy

Re: the ride height control, I've always liked it for the mere fact that it would be quite convenient to be able to have the ride raised a bit for around the town driving, speed bumps, dirt/gravel/driveway entrances etc, and be able to quickly drop it when you want to scoot fast. So Kayin, it's uses are two-fold.

And yes, I'm speaking of road courses.

Thanks for your input re: the twins diagram...I read it, looked at the diagram, and read it some more, but it's simply beyond me. I do remember speaking with one of the more popular tuners once - and at length - and he telling me an idea he had laying in the back of his head for designing a purely mechanical sequential setup. What he described seemed so simple and ingenious...

Mazda99Nikon, thanks for the compliment. I'm just the type that when I see something better or useful, I wanna know "hey, can I do that to my car?" Cuz I simply don't see any other better platform than the FD. Really. Of course, I'm just a wee bit biased

About your idea, wow...I heard of that once VERY briefly, and it was actually on this forum - but it was in relation to wings I believe, not the underside of the car. My noob commentary would be the top of our car is already designed and fixed, non-modifyable (save a wing, etc). It's round(ed). So I think that's why ppl choose the smooth flat surface undertray method, since half of the equation is non-modifyable. No one's gonna redesign the body lines of the car

Damian's been working on a front undertray that extends back past the oilpan, and we already have a RE diffuser. All what's left is to design (or copy, if possible) the middle portion, which would consist of the loading ramps to direct the airflow to the diffuser in the rear.

Damian's been working on a front undertray that extends back past the oilpan, and we already have a RE diffuser. All what's left is to design (or copy, if possible) the middle portion, which would consist of the loading ramps to direct the airflow to the diffuser in the rear.

Originally Posted by poss

Apparently you missed the part where it said "all these operations are controlled my a microprocessor"  J/K

J/K

J/K

J/K Lately I've been a

Lately I've been a  LOL.

LOL.

Are you referring to pneumatic actuators as opposed to solenoids or stepping motors? I don't know that one.

~Ramy

Last edited by FDNewbie; 09-10-05 at 07:57 PM.

#10

Senior Member

Join Date: Jul 2005

Location: Clearwater, FL

Posts: 364

Likes: 0

Received 0 Likes

on

0 Posts

Traction Control would be nice for launching. The rest of the stuff just doesn't seem worth the effort or weight. The car is stable to at least 160 in stock trim. I'm not sure that I would drive an FD much above 180 even on a salt flat have seen one totaled the unibody was made for those speed like the 959. At 200 mph without a good cage they would need a DNA test to identfy the body

#11

2/4 wheel cornering fiend

Originally Posted by dgeesaman

I wouldn't sweat the ride height control - I believe the 959 was developed for both paved and unpaved roads, which in rally racing means that clearance compromises pavement performance. (I could be full of s**t on this point, but I don't think I'm making this up)

It could be done on the FD, but you would add weight because of the hydraulic pump and valves necessary to run the system. I agree, not worth it IMO.

Originally Posted by FDNewbie

In short, the gist of it was to have the primary turbo's external wastegate vent directly to the inlet of the secondary turbo. The wastegate's spring is set at the desired psi level to have the secondary turbo spool. Once that psi level was reached, the excess gases vented would provide prespool to the secondary, and since that air was hot, it carries heat, and would spool the wheel even faster. That's what I remember...it was a year or so ago. So basically the secondary turbo fed off the primary turbo. I can't remember if it was doing so exclusively, or in addition to receiving air supply from the engine as well.

Originally Posted by FDNewbie

Damian's been working on a front undertray that extends back past the oilpan, and we already have a RE diffuser. All what's left is to design (or copy, if possible) the middle portion, which would consist of the loading ramps to direct the airflow to the diffuser in the rear.

It's not just a matter of making the bottom smooth and then reaping the rewards of Bernoulli's Principle because the "air slows down over the car". You have to keep that airflow under the car and undisturbed to reap the full benefits; you have to keep the underbody airflow away from the tires and wheel wells, as they create a lot of turbulence. There's also the overall ride attitude and angle of the car that plays a role here. Aerodynamics is not as simple as a lot of people think.

#12

Kento, I was in no way trying to oversimplify aerodynamics, which is why I clearly stated it was a noob question/idea. I'm sure a LOT more goes into it than that. What do you think about the whole "copy the undertray design" idea? Maybe I am indeed way off, but the tunneling I've seen under some high end cars + the stock ground clearance the FD has makes it look very feasible IMO. I could def. see it becoming an issue when driving on uneven surfaces and around town, but on a track or paved road (highway etc) I think it looks as if ground clearance wouldn't be that big of an issue. No?

#13

Personally, I wouldn't bother with the variable ride height or tire-pressure monitoring systems. If anything, an infra-red tire temperature monitoring system would be nice, similar to what F1 cars use. Most people don't care to monitor tire temps, you've got to be a serious racer or suspension tuner to care about monitoring them on the fly.

With regard to the turbo control system, I've never been too fond of the complexity of our sequential setup. A relatively simple modernization would be to use electronic controls instead of vacuum-controls, while retaining the mechanical components (wastegate, prespool valve(s), solenoids, etc...). The cost and knowledge base for electronics have improved greatly in the past decade.

Thinking a little further out of the box, I would like to try Variable Geometry Turbochargers ( http://www.bankspower.com/sidewinder-turbochargers.cfm ).

I also really like the idea of centrifugal superchargers, possibly in a twin supercharger setup, similar to the Koenigsegg ( http://www.koenigsegg.com/thecars/en...?engineering=2 ). I think superchargers would be a better setup for track racing and street driving, while the VGT turbocharger should make more power.

Electronics has improved immensely since the early 90's, and you can make a ton of improvement to our car using modern electronics technology. Electric water pump. Electric air pump (a la RX-8 , Corvette). All of the relays on the car can be replaced with power transistors, reducing a lot of weight and decreasing packaging size. As we already know, the stock ECU is archaic and needs replacing. The engine bay wiring routing is pretty crappy as well. The headlights need be upgraded if you're doing any driving at night. HID is not required, but a modern projector or reflector design is.

If you want some luxury, a climate-controlled HVAC system wouldn't add significant weight, and would be convenient. Same goes for keyless entry and remote start. I'm personally a fan of GPS navigation systems, but your habits and schedule will dictate if you need this or not.

Aerodynamically speaking, there is a lot of trial and error involved, even when a proper Aero Engineer is designing something. The calculations are very complex, and it's nearly impossible to account for all the variables that will come into play. Here's an oversimplification: they build a lot of prototypes and perform many experiments based on rough simulations involving proven theories (such as the Bernoulli's principles, underbody tunnels, general wing shape, etc...), and generally zero in on what works best based on the test data.

As you mentioned, imitating Ferrarri and other race teams sounds like a good place to start, assuming your goals are similar. The main problem I can forsee (for aero improvements) is quantifying your results. How will you prove that your new Underbody Channel design works better than the previous version?

I hope this doesn't ramble too much, I'm a bit sleepy...

-s-

With regard to the turbo control system, I've never been too fond of the complexity of our sequential setup. A relatively simple modernization would be to use electronic controls instead of vacuum-controls, while retaining the mechanical components (wastegate, prespool valve(s), solenoids, etc...). The cost and knowledge base for electronics have improved greatly in the past decade.

Thinking a little further out of the box, I would like to try Variable Geometry Turbochargers ( http://www.bankspower.com/sidewinder-turbochargers.cfm ).

I also really like the idea of centrifugal superchargers, possibly in a twin supercharger setup, similar to the Koenigsegg ( http://www.koenigsegg.com/thecars/en...?engineering=2 ). I think superchargers would be a better setup for track racing and street driving, while the VGT turbocharger should make more power.

Electronics has improved immensely since the early 90's, and you can make a ton of improvement to our car using modern electronics technology. Electric water pump. Electric air pump (a la RX-8 , Corvette). All of the relays on the car can be replaced with power transistors, reducing a lot of weight and decreasing packaging size. As we already know, the stock ECU is archaic and needs replacing. The engine bay wiring routing is pretty crappy as well. The headlights need be upgraded if you're doing any driving at night. HID is not required, but a modern projector or reflector design is.

If you want some luxury, a climate-controlled HVAC system wouldn't add significant weight, and would be convenient. Same goes for keyless entry and remote start. I'm personally a fan of GPS navigation systems, but your habits and schedule will dictate if you need this or not.

Aerodynamically speaking, there is a lot of trial and error involved, even when a proper Aero Engineer is designing something. The calculations are very complex, and it's nearly impossible to account for all the variables that will come into play. Here's an oversimplification: they build a lot of prototypes and perform many experiments based on rough simulations involving proven theories (such as the Bernoulli's principles, underbody tunnels, general wing shape, etc...), and generally zero in on what works best based on the test data.

As you mentioned, imitating Ferrarri and other race teams sounds like a good place to start, assuming your goals are similar. The main problem I can forsee (for aero improvements) is quantifying your results. How will you prove that your new Underbody Channel design works better than the previous version?

I hope this doesn't ramble too much, I'm a bit sleepy...

-s-

Last edited by scotty305; 09-11-05 at 02:50 AM.

#14

Originally Posted by scotty305

Electronics has improved immensely since the early 90's, and you can make a ton of improvement to our car using modern electronics technology. Electric water pump. Electric air pump (a la RX-8 , Corvette). All of the relays on the car can be replaced with power transistors, reducing a lot of weight and decreasing packaging size. As we already know, the stock ECU is archaic and needs replacing. The engine bay wiring routing is pretty crappy as well. The headlights need be upgraded if you're doing any driving at night. HID is not required, but a modern projector or reflector design is.

All of the things that FDNewbie mentioned can be taken care of (to some extent) with currently available aftermarket products (except the underbelly design). There are lots of adjustable/tunable suspensions out there, traction control is more or less covered by racelogic, air pressure monitoring systems are not of great concern to most people (but its a nice luxury

), and there is really no easy "modern" way to have sequential turbos that perform as good as the stock system (maybe a few less mechanical things for reliabilities sake).

), and there is really no easy "modern" way to have sequential turbos that perform as good as the stock system (maybe a few less mechanical things for reliabilities sake). What I find most interesting about this thread, is that it seems too be concluding that there are relatively few performance alterations that the FD needs to become modernized. So a car that was designed roughly 15 years ago maybe has an outdated electronic system, but that's about it

.

.

#15

Senior Member

Join Date: Dec 2003

Location: Lexington, IL

Posts: 292

Likes: 0

Received 0 Likes

on

0 Posts

Scotty 305 wrote: "The main problem I can forsee (for aero improvements) is quantifying your results. How will you prove that your new Underbody Channel design works better than the previous version?"

That's a fair question. But it's really pretty easy. The issue is to measure the rise and fall of barometric pressure at various points along the top and bottom of the car. A simple of system of plastic tubes (another rats nest YEEK!) could be taped along the countour of the car. Pressure transducers would be installed inside the cockpit and recorded by a laptop. Not extactly rocket science any more. I've seen kids do this with wind tunnels at science fairs. Your idea to steal existing concepts from other car makers is a good idea, because your observation about trial and error is correct. Even NASA has to adjust wing and body mouldings of experimental aircraft by gut feel after initial wind tunnel tests show errors in initial computer modeling. One car worth looking at, that's mass produced, is the underbody aerodynamic kit Infinity introduced for the G35. See ://www.infiniti.com/content/0,,cid-75237_sctid-32005,00.html

"To reduce drag under the G35 Coupe, openings are sealed, the floor pan is smoothed, and brake lines are countersunk into the chassis so as not to trap air. Diffusers create low-pressure areas that reduce lift. Hot air is drawn from the engine and cool air directed through the brakes. "

That's a fair question. But it's really pretty easy. The issue is to measure the rise and fall of barometric pressure at various points along the top and bottom of the car. A simple of system of plastic tubes (another rats nest YEEK!) could be taped along the countour of the car. Pressure transducers would be installed inside the cockpit and recorded by a laptop. Not extactly rocket science any more. I've seen kids do this with wind tunnels at science fairs. Your idea to steal existing concepts from other car makers is a good idea, because your observation about trial and error is correct. Even NASA has to adjust wing and body mouldings of experimental aircraft by gut feel after initial wind tunnel tests show errors in initial computer modeling. One car worth looking at, that's mass produced, is the underbody aerodynamic kit Infinity introduced for the G35. See ://www.infiniti.com/content/0,,cid-75237_sctid-32005,00.html

"To reduce drag under the G35 Coupe, openings are sealed, the floor pan is smoothed, and brake lines are countersunk into the chassis so as not to trap air. Diffusers create low-pressure areas that reduce lift. Hot air is drawn from the engine and cool air directed through the brakes. "

#16

2/4 wheel cornering fiend

Originally Posted by FDNewbie

Kento, I was in no way trying to oversimplify aerodynamics, which is why I clearly stated it was a noob question/idea.

Originally Posted by FDNewbie

What do you think about the whole "copy the undertray design" idea? Maybe I am indeed way off, but the tunneling I've seen under some high end cars + the stock ground clearance the FD has makes it look very feasible IMO. I could def. see it becoming an issue when driving on uneven surfaces and around town, but on a track or paved road (highway etc) I think it looks as if ground clearance wouldn't be that big of an issue. No?

Originally Posted by scotty305

Thinking a little further out of the box, I would like to try Variable Geometry Turbochargers ( http://www.bankspower.com/sidewinder-turbochargers.cfm ).

I also really like the idea of centrifugal superchargers, possibly in a twin supercharger setup, similar to the Koenigsegg ( http://www.koenigsegg.com/thecars/e...p?engineering=2 ). I think superchargers would be a better setup for track racing and street driving, while the VGT turbocharger should make more power.

I also really like the idea of centrifugal superchargers, possibly in a twin supercharger setup, similar to the Koenigsegg ( http://www.koenigsegg.com/thecars/e...p?engineering=2 ). I think superchargers would be a better setup for track racing and street driving, while the VGT turbocharger should make more power.

Superchargers are good for no lag, but their limitations include being able to properly cool the intake charge (both screw and Roots-type superchargers require the closest placement to the intake as possible to avoid boost issues, which negates the ability to use an air/air IC) and the mechanical drag imposed by driving the SC.

#17

Originally Posted by scotty305

Electronics has improved immensely since the early 90's, and you can make a ton of improvement to our car using modern electronics technology. Electric water pump. Electric air pump (a la RX-8 , Corvette). All of the relays on the car can be replaced with power transistors, reducing a lot of weight and decreasing packaging size. As we already know, the stock ECU is archaic and needs replacing. The engine bay wiring routing is pretty crappy as well. The headlights need be upgraded if you're doing any driving at night. HID is not required, but a modern projector or reflector design is.

And again, I'm very curious as to the difficulty and intricacy of doing such an upgrade is (I wouldn't be doing it obviously lol). But for example, when a certain someone is on the verge of having his motor pulled

it seems that a lot of this could be done at such an opportune time, along w/ changes to the wiring harness, etc. Lights are already taken care of.

it seems that a lot of this could be done at such an opportune time, along w/ changes to the wiring harness, etc. Lights are already taken care of.

If you want some luxury, a climate-controlled HVAC system wouldn't add significant weight, and would be convenient. Same goes for keyless entry and remote start. I'm personally a fan of GPS navigation systems, but your habits and schedule will dictate if you need this or not.

Originally Posted by moehler

There are lots of adjustable/tunable suspensions out there

What I find most interesting about this thread, is that it seems too be concluding that there are relatively few performance alterations that the FD needs to become modernized. So a car that was designed roughly 15 years ago maybe has an outdated electronic system, but that's about it  .

.

.

.

Originally Posted by Mazda99Nikon

One car worth looking at, that's mass produced, is the underbody aerodynamic kit Infinity introduced for the G35. See ://www.infiniti.com/content/0,,cid-75237_sctid-32005,00.html

"To reduce drag under the G35 Coupe, openings are sealed, the floor pan is smoothed, and brake lines are countersunk into the chassis so as not to trap air. Diffusers create low-pressure areas that reduce lift. Hot air is drawn from the engine and cool air directed through the brakes. "

"To reduce drag under the G35 Coupe, openings are sealed, the floor pan is smoothed, and brake lines are countersunk into the chassis so as not to trap air. Diffusers create low-pressure areas that reduce lift. Hot air is drawn from the engine and cool air directed through the brakes. "

Originally Posted by Kento

Calm down, Ramy. I wasn't attacking your idea or intentions, just stating an answer to the questions posed in your original post. Don't be so defensive.

Maybe I need to think twice about my writing style hehe

Maybe I need to think twice about my writing style hehe

As Scott stated, it's not as simple as copying another underbody design and applying it to the FD. There's a lot of other factors, least of which (if you get it to function) includes the matter of where the downforce is applied and how much. These and many other aspects are all well-researched and tested when they're fitted to an OEM application.

So essentially, we're playing in the dark, hoping to make some improvement, and hoping even furthermore that it doesn't upset the entire aerodynamics of the car, right? Kinda makes you wonder if it's worthwhile if not done w/ the data to back it up...

~Ramy

#18

Originally Posted by FDNewbie

So essentially, we're playing in the dark, hoping to make some improvement, and hoping even furthermore that it doesn't upset the entire aerodynamics of the car, right? Kinda makes you wonder if it's worthwhile if not done w/ the data to back it up...

~Ramy

~Ramy

Dave

#19

2/4 wheel cornering fiend

Originally Posted by Mazda99Nikon

Your idea to steal existing concepts from other car makers is a good idea, because your observation about trial and error is correct. Even NASA has to adjust wing and body mouldings of experimental aircraft by gut feel after initial wind tunnel tests show errors in initial computer modeling.

At least with experimental aircraft, you have some altitude to recover if the "gut feel" was wrong...

Originally Posted by Mazda99Nikon

One car worth looking at, that's mass produced, is the underbody aerodynamic kit Infinity introduced for the G35. See ://www.infiniti.com/content/0,,cid-75237_sctid-32005,00.html

"To reduce drag under the G35 Coupe, openings are sealed, the floor pan is smoothed, and brake lines are countersunk into the chassis so as not to trap air. Diffusers create low-pressure areas that reduce lift. Hot air is drawn from the engine and cool air directed through the brakes. "

"To reduce drag under the G35 Coupe, openings are sealed, the floor pan is smoothed, and brake lines are countersunk into the chassis so as not to trap air. Diffusers create low-pressure areas that reduce lift. Hot air is drawn from the engine and cool air directed through the brakes. "

While better than the majority of automobiles out there, I think you should look at the underside of a Lotus Elise to see a smooth underpan. Typical adspeak smoke & mirrors...

While better than the majority of automobiles out there, I think you should look at the underside of a Lotus Elise to see a smooth underpan. Typical adspeak smoke & mirrors...

#20

Ramy,

The RX-8 uses an electric air pump. You could remove theirs and fit it to our car. Controlling it should be relatively simple (on/off), but it could be complex also (changing the power to the pump, varying the amount of air that is being introduced to the cat).

When I mention transistors, I'm talking about replacing the relays that are being used to remotely switch a high-current device (for instance, the 4 fan control relays on the passenger side of the engine). I'm personally looking into replacing the fan control relays with four TO-220 size transistors. The setup would take up less space than one of these 4 relays and weigh considerably less. I've got a few other projects that are higher priorities, but I'll be sure to post the results and how-to on here.

Kento, I've heard of variable vane turbos, but that's not the exact same technology that I've got in mind. The system I'm thinking of is installed on some factory diesel engines, and uses a hydraulic valve to vary the volume of the exhaust turbine housing:

http://www.everytime.cummins.com/every/misc/vgt.jsp

-scott-

The RX-8 uses an electric air pump. You could remove theirs and fit it to our car. Controlling it should be relatively simple (on/off), but it could be complex also (changing the power to the pump, varying the amount of air that is being introduced to the cat).

When I mention transistors, I'm talking about replacing the relays that are being used to remotely switch a high-current device (for instance, the 4 fan control relays on the passenger side of the engine). I'm personally looking into replacing the fan control relays with four TO-220 size transistors. The setup would take up less space than one of these 4 relays and weigh considerably less. I've got a few other projects that are higher priorities, but I'll be sure to post the results and how-to on here.

Kento, I've heard of variable vane turbos, but that's not the exact same technology that I've got in mind. The system I'm thinking of is installed on some factory diesel engines, and uses a hydraulic valve to vary the volume of the exhaust turbine housing:

http://www.everytime.cummins.com/every/misc/vgt.jsp

-scott-

#21

Senior Member

Join Date: Oct 2002

Location: Portland, OR

Posts: 336

Likes: 0

Received 0 Likes

on

0 Posts

Without the aid of a windtunnel, there are still ways to develop the aerodynamics a vehicle.

The best way is to fully instrument the car with a MOTEC or simlar system that has pots at each corner. This gives you a way to measure the lift and downforce as well as the distribution of these forces.

Another, less objective way is to simply do track testing with a good car and a good driver who can communicate what he feels on the track. Then, iterate changes from there.

Look to race cars for ideas. Compare the race versions of cars to their production versions. A good series to look at is Speed World Challenge.

Basic aero tweaks you'll see:

Splitter, Diveplanes, Diffuser, Wing, Louvered Hood (to reduce underhood pressure), Seal around the radiator, Push out fascia/fenders in front of tires, Pull in fascia fenders behind wheels, Underbody kickups, Side Sill extensions.

The best way is to fully instrument the car with a MOTEC or simlar system that has pots at each corner. This gives you a way to measure the lift and downforce as well as the distribution of these forces.

Another, less objective way is to simply do track testing with a good car and a good driver who can communicate what he feels on the track. Then, iterate changes from there.

Look to race cars for ideas. Compare the race versions of cars to their production versions. A good series to look at is Speed World Challenge.

Basic aero tweaks you'll see:

Splitter, Diveplanes, Diffuser, Wing, Louvered Hood (to reduce underhood pressure), Seal around the radiator, Push out fascia/fenders in front of tires, Pull in fascia fenders behind wheels, Underbody kickups, Side Sill extensions.

#22

2/4 wheel cornering fiend

Originally Posted by scotty305

Kento, I've heard of variable vane turbos, but that's not the exact same technology that I've got in mind. The system I'm thinking of is installed on some factory diesel engines, and uses a hydraulic valve to vary the volume of the exhaust turbine housing:

http://www.everytime.cummins.com/every/misc/vgt.jsp

-scott-

http://www.everytime.cummins.com/every/misc/vgt.jsp

-scott-

. I'd heard of the Holset axial VGT turbos, but never followed up on them. I think the reasons you haven't seen these in an automotive gasoline engine application are:

. I'd heard of the Holset axial VGT turbos, but never followed up on them. I think the reasons you haven't seen these in an automotive gasoline engine application are:1. You can help spool up a turbine by increasing exhaust gas velocity, but remember that you still have to overcome inertia. This requires a thinner, lighter turbine blade setup that will still provide decent boost levels at lower rpms; that limits its ability at higher rpms, which means that extremely precise control of the shaft speed is required. I see that the Cummins setup uses an electronic controller for the hydraulics; you'll need that to keep the turbine setup in the optimum range without overrevving the shaft.

2. The EGTs of a gasoline engine are much higher than a diesel. That puts additional stress on the alloy turbine assembly that is spinning at 100,000 rpm or more. You'd need a very durable and strong yet lightweight alloy that could withstand high temps for long periods of time without coming apart at high speed.

3. The slower rev characteristics of a diesel engine assist the Holset's electronic controller in keeping the shaft speeds from overrevving. A quick-revving, 8000 rpm gasoline engine would require a lot of computing power to keep things from getting out of hand in the numerous situations likely to be encountered during hard use.

Not saying this isn't possible in the future; it's probably only a matter of time. And it'll mean a big step forward for turbo technology with gasoline performance when it does.

#23

2/4 wheel cornering fiend

Originally Posted by ExpensiveHobby22

Without the aid of a windtunnel, there are still ways to develop the aerodynamics a vehicle.

The best way is to fully instrument the car with a MOTEC or simlar system that has pots at each corner. This gives you a way to measure the lift and downforce as well as the distribution of these forces.

Another, less objective way is to simply do track testing with a good car and a good driver who can communicate what he feels on the track. Then, iterate changes from there.

The best way is to fully instrument the car with a MOTEC or simlar system that has pots at each corner. This gives you a way to measure the lift and downforce as well as the distribution of these forces.

Another, less objective way is to simply do track testing with a good car and a good driver who can communicate what he feels on the track. Then, iterate changes from there.

I just want to avoid the typical situation of someone posting on this forum and saying, "I've tested my underbody/diffuser setup at Joe Blow Raceway, and it works", and then a whole herd of people taking that as gospel. Proving that a reliability mod, IC setup, fueling mod, etc. works is easy; demonstrating that an aerodynamic design really does is not.

#24

Originally Posted by Kento

Proving that a reliability mod, IC setup, fueling mod, etc. works is easy; demonstrating that an aerodynamic design really does is not.

Kento, if you don't mind me asking, what's your day job? Your automotive background seems much broader than rotary cars.

Dave

#25

Rotary Freak

Join Date: Aug 2002

Location: nyc+li, ny

Posts: 2,690

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by FDNewbie

But it seems no one knows of an aftermarket unit/system that could be used to electronically control the ride height. What can I say...I'm kinda stuck on that one. I just really see it as being useful...but as many others have mentioned, it may very well be less than worthwhile. I'm curious nonetheless if anyone knows of such a system??

They've been tested on Subaru's and more recently BMW - google for "praxis air suspension"