Leaking oilpan - what to get and other advice

#1

Junior Member

Thread Starter

Join Date: Dec 2015

Location: Sweden

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Leaking oilpan - what to get and other advice

Hi!

After buying my first FD back in November I've noticed my oil pan is leaking quite badly after a spirited drive. Not from the usual engine mounts, but from the middle left side, between the housings. Sadly there aren't just a few drops every time, but really pools up where the engine mount is mounted to the subframe, and then forms a spot on the floor about 8 inches in diameter.

My pan is a bit dented so i figured id get a new oil pan from Japan together with an oil pan brace from DM motorsports.

Im also considering a new oil level sender unit since the plastic cover piece is broken on the one currently installed. Or do i not need to worry about that?

Ive read multiple ways of doing this procedure, both with the subframe in place, and removed. Im debating wether its worth all the extra hassle with removing it completely to gain good access to the pan and engine, or just to drop it from the chassi and leaving it connected to the control arms etc.

Do you guys have any advice on what to expect when doing this, and what to plan ahead for? With the brace ill have my engine sit 5mm higher, maybe i can cut down the poly urethane engine mounts i have in the car...

Thanks!

After buying my first FD back in November I've noticed my oil pan is leaking quite badly after a spirited drive. Not from the usual engine mounts, but from the middle left side, between the housings. Sadly there aren't just a few drops every time, but really pools up where the engine mount is mounted to the subframe, and then forms a spot on the floor about 8 inches in diameter.

My pan is a bit dented so i figured id get a new oil pan from Japan together with an oil pan brace from DM motorsports.

Im also considering a new oil level sender unit since the plastic cover piece is broken on the one currently installed. Or do i not need to worry about that?

Ive read multiple ways of doing this procedure, both with the subframe in place, and removed. Im debating wether its worth all the extra hassle with removing it completely to gain good access to the pan and engine, or just to drop it from the chassi and leaving it connected to the control arms etc.

Do you guys have any advice on what to expect when doing this, and what to plan ahead for? With the brace ill have my engine sit 5mm higher, maybe i can cut down the poly urethane engine mounts i have in the car...

Thanks!

#2

Not familiar with DM Motorsports. IMHO get a proven brace from Banzai FD3s Oil Pan Brace if he ships internationally. Not a job I'd want to do twice.

I would order another oil level sender from MAZDA and replace it.

Personally I've never re-sealed a pan with the engine in the car. Those who have will have better advice, but would do what I needed to do to get the sealing surface hospital clean.

I would have a machine shop mill the steal mount arms down rather than trim the mounts themselves. There should be plenty of material to retain strength.

I would order another oil level sender from MAZDA and replace it.

Personally I've never re-sealed a pan with the engine in the car. Those who have will have better advice, but would do what I needed to do to get the sealing surface hospital clean.

I would have a machine shop mill the steal mount arms down rather than trim the mounts themselves. There should be plenty of material to retain strength.

Last edited by Sgtblue; 01-02-16 at 07:36 AM.

#3

international shipping can be a nightmare, a pan brace isn't rocket science. so if it looks similar to banzai's pan then i don't see why it wouldn't work.

i just leave the suspension attached and lower the subframe and prop it in the down position with a few blocks of wood while suspending the engine and tranny. it's really not that bad but an engine bay engine straddle lift is a good tool to have for this.

personally i don't see what the issue usually is about having the engine sit slightly higher, if you need the 5mm then you're already in trouble with space limitations. i guess if you're super freaking **** you could machine the mounts.

i just leave the suspension attached and lower the subframe and prop it in the down position with a few blocks of wood while suspending the engine and tranny. it's really not that bad but an engine bay engine straddle lift is a good tool to have for this.

personally i don't see what the issue usually is about having the engine sit slightly higher, if you need the 5mm then you're already in trouble with space limitations. i guess if you're super freaking **** you could machine the mounts.

Last edited by RotaryEvolution; 01-02-16 at 07:40 AM.

#4

The issue is having clearance from some aftermarket components like a Greddy elbow to the tower brace. Or even one of the dress-up things like an aftermarket oil filler cap to that same brace. If it's completely stock then no, it's not a big deal. But then it's also not a big deal or expense to have the arms milled either.

#5

Which ship internationally every day. FD3s Oil Pan Brace

Instructions FD OPB Brace Installation Instructions

In the car- Oil Pan Removal

Instructions FD OPB Brace Installation Instructions

In the car- Oil Pan Removal

#6

Racing Rotary Since 1983

iTrader: (6)

pls see this thread w an important 2016 update.

https://www.rx7club.com/3rd-generati.../#post11505799

howard

https://www.rx7club.com/3rd-generati.../#post11505799

howard

#7

Junior Member

Thread Starter

Join Date: Dec 2015

Location: Sweden

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Thanks a lot guys! Ill have to check hood clearance against my fuel reg which i think is my highest point on the engine. 5mm should be alright i suppose.

Regarding the engine lift, i don't have enough room in my cramped up garage to fit a engine lift. Maybe its possible to fabricate something and use the strut tower brace attachments ? Or I've read people supporting the engine with a jack as far forward as possible on the gearbox.

Howard Coleman CPR - The brace you mention in your post, does it happen to be cut from an old oil pan? It sure looks like it, but i may be wrong. Figured i could you my old dented pan as a brace if that was the case, but probably not!

Ill definitely have to find the right kind of silicone sold here in Sweden.

Regarding the engine lift, i don't have enough room in my cramped up garage to fit a engine lift. Maybe its possible to fabricate something and use the strut tower brace attachments ? Or I've read people supporting the engine with a jack as far forward as possible on the gearbox.

Howard Coleman CPR - The brace you mention in your post, does it happen to be cut from an old oil pan? It sure looks like it, but i may be wrong. Figured i could you my old dented pan as a brace if that was the case, but probably not!

Ill definitely have to find the right kind of silicone sold here in Sweden.

Trending Topics

#9

i do like garfinkles brace but i don't think has them anymore. i just do not prefer crushing the pan reliefs if possible.

something like this is what i was referring to, no need for an engine hoist in the garage. you may be able to find someplace to rent one:

sits on the fenders just beside the strut towers. a jackstand under the tranny is also a good extra safety measure.

something like this is what i was referring to, no need for an engine hoist in the garage. you may be able to find someplace to rent one:

sits on the fenders just beside the strut towers. a jackstand under the tranny is also a good extra safety measure.

Last edited by RotaryEvolution; 01-02-16 at 06:17 PM.

#10

Spanking Pcars

iTrader: (4)

Join Date: Aug 2004

Location: DFW area

Posts: 1,084

Likes: 0

Received 0 Likes

on

0 Posts

Don't like the idea of distorting the pan and enhancing the chances of an eventual leak.

The flatter the surface, the better distribution of even pressure.

#11

DM-motorsports is a UK based company, so no taxes and ****  I used theirs brace and have zero leaks

I used theirs brace and have zero leaks

I'll take this in swedish now =)

tja, som de skrev innan så en sån motorlyft som visas över här räcker, sätta i främre o bakre ögglan bara... sätts mot framskärmarna, funkar fint... jag lossade subframen nästan helt, o vek ner den i bakkant... i dagsläget hade ja valt o lossat den helt men låtit den sitta kvar i styrleder o så, bara hängt ner den för extra plats.

silikonet du behöver för o täta sen köper du på skruvat.se, https://www.skruvat.se/The-Right-Stuff-P29589.aspx

>Hondabond är sjukt trenvligt oxå men sjukt dyrt har ja hört, men ska finnas olika sorters hondabond, vet ej vilken Howard menar

värt o tänka på är o få bort allt befintligt silicon när du lossat på oljetråget, då rekomnederar ja crc stripper, även kallat gasket remover, finns på mekonomen, o sen en vass bladkniv, samt nån liten tandläkarliknande pet-krok, så du kan få bort skit i gängorna =)

tog mig cirka 3-4 timmar o få ner allt o upp igen.. good luck =)

should be fine

I'll take this in swedish now =)

tja, som de skrev innan så en sån motorlyft som visas över här räcker, sätta i främre o bakre ögglan bara... sätts mot framskärmarna, funkar fint... jag lossade subframen nästan helt, o vek ner den i bakkant... i dagsläget hade ja valt o lossat den helt men låtit den sitta kvar i styrleder o så, bara hängt ner den för extra plats.

silikonet du behöver för o täta sen köper du på skruvat.se, https://www.skruvat.se/The-Right-Stuff-P29589.aspx

>Hondabond är sjukt trenvligt oxå men sjukt dyrt har ja hört, men ska finnas olika sorters hondabond, vet ej vilken Howard menar

värt o tänka på är o få bort allt befintligt silicon när du lossat på oljetråget, då rekomnederar ja crc stripper, även kallat gasket remover, finns på mekonomen, o sen en vass bladkniv, samt nån liten tandläkarliknande pet-krok, så du kan få bort skit i gängorna =)

tog mig cirka 3-4 timmar o få ner allt o upp igen.. good luck =)

should be fine

Last edited by Wolf_; 01-03-16 at 04:45 AM.

#14

Junior Member

Thread Starter

Join Date: Dec 2015

Location: Sweden

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Thanks again! Nice to see some other Swede's on here

Will start to order parts and hopefully i can get this done rather soon.

Indeed DM-motorsports sells new/lower pucks, but 60 UK pounds each feels rather expensive when my current ones aren't bad.

Just need to find a place that rents out that kind of hoist.

Will start to order parts and hopefully i can get this done rather soon.

Indeed DM-motorsports sells new/lower pucks, but 60 UK pounds each feels rather expensive when my current ones aren't bad.

Just need to find a place that rents out that kind of hoist.

#19

http://www.biltema.se/sv/Bil---MC/Verktyg-och-Verkstadsutrustning/Lyftverktyg/Motorok-500-kg-2000021465/

Last edited by Wolf_; 01-04-16 at 09:24 AM.

#20

Spanking Pcars

iTrader: (4)

Join Date: Aug 2004

Location: DFW area

Posts: 1,084

Likes: 0

Received 0 Likes

on

0 Posts

You can get one at biltema, kind of expensive but a god thing to have I'd say, or buy it, make sure to keep it clean, fix the leak and return it för full refund, 30days open buy is a good fakking thing! :-)

Motorok, 500 kg - Motorok - Biltema

Motorok, 500 kg - Motorok - Biltema

We all know your character or lack of thereof with that comment.

#21

Junior Member

Thread Starter

Join Date: Dec 2015

Location: Sweden

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Again, great to have an discussion with people of great knowledge helping us beginners having a good first encounter with rotary's and Mazda's !

That Len Bacon pan sure looks great, but i think its quite over the top for my particular situation. Was I building a pure race car with all kinds of chassi mods, sure!

That Len Bacon pan sure looks great, but i think its quite over the top for my particular situation. Was I building a pure race car with all kinds of chassi mods, sure!

#22

Sponsor

iTrader: (41)

I recommend a new Mada oem oil pan for most cars. Aftermarket pans like Len Bacon's are great for track cars because they have significantly better baffling.

If using a stock oil pan definitely install a brace such as Banzai's. I don't have any experience with the DM motorsports brace.

New Mazda oem oil level sender and o-ring.

I use Permatex "the right stuff" to seal the pan. You need to have both the pan and bottom of the motor 100% clean of any oil or silicone. I like to use a 90 degree die grinder with a mild sanding wheel to roughen up the surfaces so the silicone adheres better. Clean everything with brake cleaner or acetone and wipe dry. I run an even layer across the entire oil pan mating surface. Put it up against the motor and snug it until silicone starts to squeeze out. Wait an hour, then torque all the hardware to spec. Wait 24 hours before filling the motor with oil so the sealant can cure.

This is also a good time to upgrade your motor mounts. I cut my IRP polyurethane motor mounts to clear with an oil pan brace. I currently have them on sale in my winter specials link in my signature.

If using a stock oil pan definitely install a brace such as Banzai's. I don't have any experience with the DM motorsports brace.

New Mazda oem oil level sender and o-ring.

I use Permatex "the right stuff" to seal the pan. You need to have both the pan and bottom of the motor 100% clean of any oil or silicone. I like to use a 90 degree die grinder with a mild sanding wheel to roughen up the surfaces so the silicone adheres better. Clean everything with brake cleaner or acetone and wipe dry. I run an even layer across the entire oil pan mating surface. Put it up against the motor and snug it until silicone starts to squeeze out. Wait an hour, then torque all the hardware to spec. Wait 24 hours before filling the motor with oil so the sealant can cure.

This is also a good time to upgrade your motor mounts. I cut my IRP polyurethane motor mounts to clear with an oil pan brace. I currently have them on sale in my winter specials link in my signature.

#23

Racing Rotary Since 1983

iTrader: (6)

this is one scary photo...

if you look carefully you will see that the "Full" level on the dipstick

is approx an inch above the pan rail!

in order to lower the CG of the FD Mazda chose to run a shallow pan necessitating the oil level to be above the pan rail. yikes!

combine this w the higher oil temps of the rotary and is it any wonder that there are lots and lots of "my oil pan is leaking" threads?

over 40% of the motors i disassemble have leaking oilpans. and all of them leak because of build errors. the FD pan, if properly installed doesn't have to leak.

i present no magic bullet here and there are numerous ways to get it done properly but my system works so i thought i would present it. others are very welcome to add here as the primary purpose of the thread is to help eliminate leaking pans.

first off a bit about preparation and supplies. i find a simple tool that holds a boxcutter blade laterally greatly speeds scraping the engine pan flange. once i have it mostly clean i grab a can of Walmart's wonderful Carb Cleaner and a piece of 3M Scotch Brite pictured below. this cleans all the residual silicone from the flange.

i then place the pan in a box of 2 X 4s 10 5/8 square interior dimension and attack it first w the scraper. at that point the remaining silicone is in the pan flutes. i use a wire wheel on a drill and it completely cleans the 19 flutes.

next up are the 18 bolt holes in the block and front cover. i find that 90% of my motors have an incredible amount of silicone accumulation in the holes so i tap each bolt hole. while it might sound like a lot of work after you see what comes out you will have no problem gaining the resolve to do them all. see pic

while you are at it, don't forget the motor mount bolt holes. most have a half inch of silicone at the bottom. grab a pick and remove it. there is, of course no reason to use silicone on the motor mount bolts as they are not in communication with oil.

so now both surfaces are clean, the bolt holes are tapped and it is time to not even think about using a gasket. gaskets are appropriate for certain things but not the oilpan. the newer silicones do the job and why try to seal two faces when you can just seal one?

i use and recommend Permatex's "The Right Stuff." if ever a name was properly descriptive of a product...

///2016 UPDATE....... RE specific silicone recommendation, see bottom of Post One.../////////////

coat both surfaces sparingly and you are ready to reach for the bolts...

know this however on the subject of silicone/The Right Stuff....

it takes the better part of a WEEK to fully cure. and when i say the better part i am talking probably 7 days at room temp and longer if it is a bit chilly in your garage in October.

sure, the outer part of the silicone on the exterior of the engine cures in a couple of days.

not on the inside where it counts.

so you do your pan job, you are tuckered out... you come back to the car in a couple of days, fill it w oil and go for a drive-- warming up the oil which, incidentally is ABOVE the silicone.

and the silicone isn't completely cured.

back to that handful of grimy silicone encased bunch of pan bolts...

run them thru the parts washer and clean the threads on your bench grinder's wire wheel. you want them looking shiny.

these are tiny bolts w a big job. the reason you tapped the bolt holes and cleaned the bolt threads was so you could get an accurate torque reading. and the number is 100 inch pounds.. there are loads of bolts on the FD that have 10 mm heads and an inch pound torque wrench is the proper tool for the job and not expensive.

after you have all the bolts secure grab your two motor mounts and mount them to the motor at 55 ft pounds. they will help set the silicone in the rear area..

finally, i wrap the outer pan lip to the motor w a band around the entire motor.

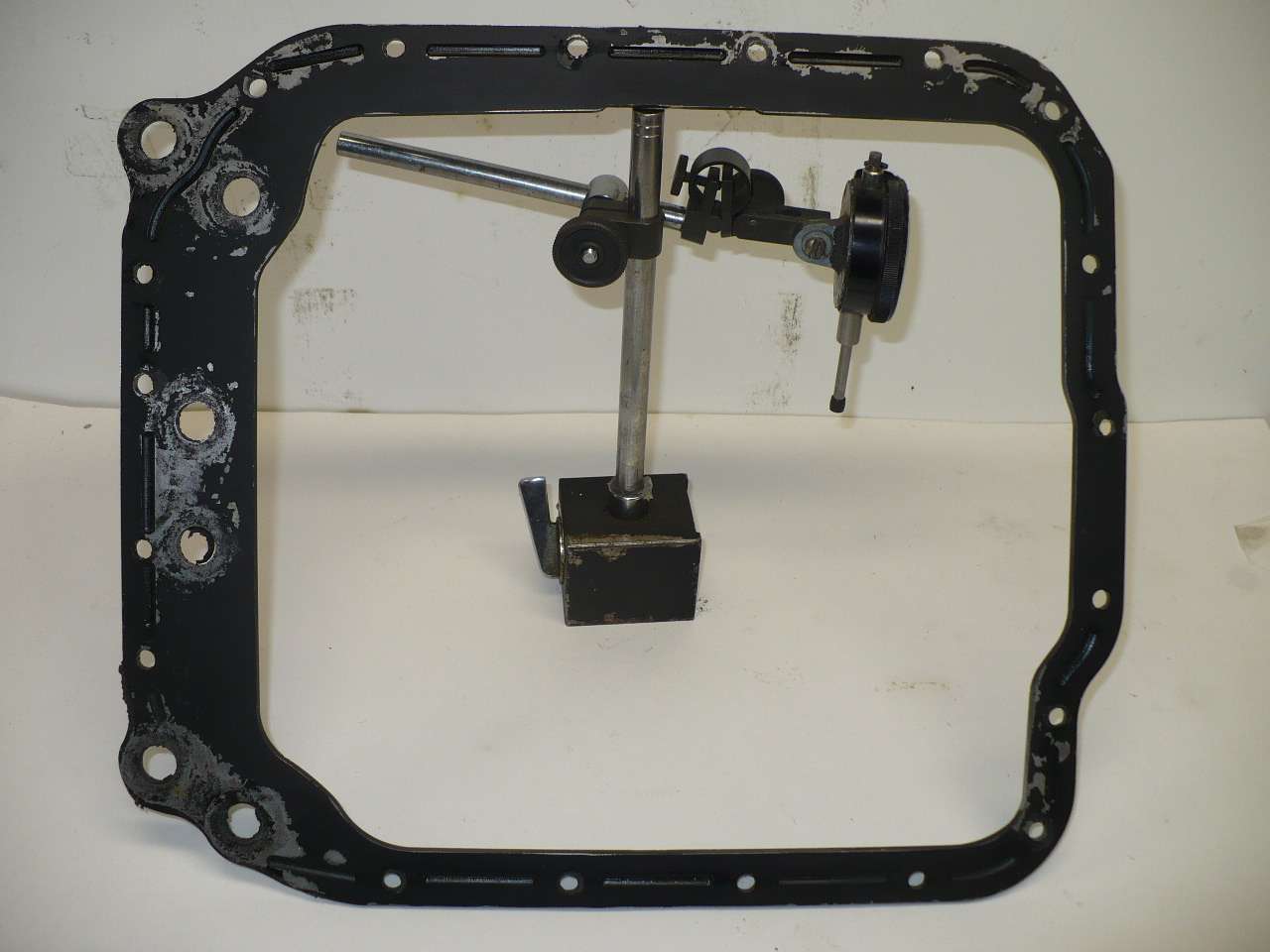

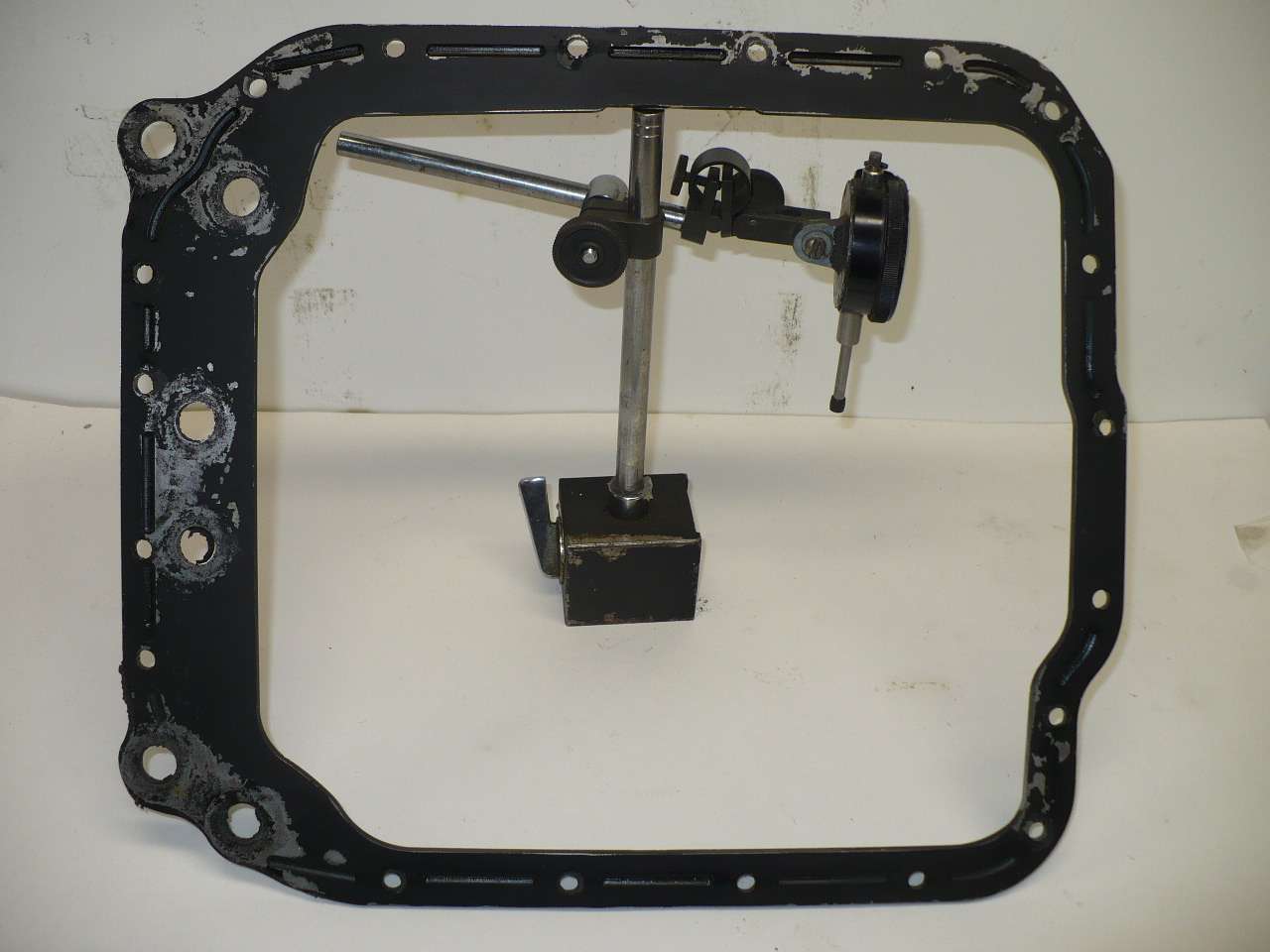

an additional item that i have ran for the better part of ten years and that i install on almost all the motors i build is David Garfinkle's excellent engine block and oilpan brace. it is exquisitely engineered. just look carefully at the following two pics.

FD oilpans have 19 raised flutes for additional rigidity. David's brace perfectly fits over the the flutes so when you crank down on the 18 pan bolts you are pressing only flat surfaces together. the braces are only sporadically available so i bought a bunch and am a stocking dealer.

so that's about all i have for you on oilpans... they are a major issue but if installed correctly should not leak. i invite and welcome any additional comments on the subject. no doubt much of what is here you may already know but this may be of help to some.

Jan 2, 2016 UPDATE.

the correct silicone sealer MATTERS. all Permatex silicone sealers including The RIGHT STUFF (going forward to be known as The Wrong Stuff) have updated packaging and ALL carry a larger warning statement.... Not to be used with gasoline..

gas gets in our oil. period.

i did a study of 7 silicone sealers. i allowed each to cure for a week and tested them w my durometer. a durometer is used in racing to test hardness of tires. it is a probe on a spring w a dial.

most silicones registered about 60. higher is harder.

i then placed them in gasoline and another batch in E85 for a week. most reacted similarly. those placed in E85 lost approx 5 points. those placed in gasoline lost 25 points and the material seemed changed. sort of spongy.

all but HondaBond.

HB maybe lost 5 points. ThreeBond make most silicone sealers( including ToyotaBond, YamahaBond, MazdaBond) that compete w Permatex. i have spent more than an hour on the phone w them (as well as Permatex) and have tested a couple of their products that are very close to HB. they set up similar to HB but i find them a bit runny to apply. they are also about half the cost.

so it is HondaBond for me. i don't think there is any question that some pans leak because they are sealed w a Permatex product and it has become porous.

howard

if you look carefully you will see that the "Full" level on the dipstick

is approx an inch above the pan rail!

in order to lower the CG of the FD Mazda chose to run a shallow pan necessitating the oil level to be above the pan rail. yikes!

combine this w the higher oil temps of the rotary and is it any wonder that there are lots and lots of "my oil pan is leaking" threads?

over 40% of the motors i disassemble have leaking oilpans. and all of them leak because of build errors. the FD pan, if properly installed doesn't have to leak.

i present no magic bullet here and there are numerous ways to get it done properly but my system works so i thought i would present it. others are very welcome to add here as the primary purpose of the thread is to help eliminate leaking pans.

first off a bit about preparation and supplies. i find a simple tool that holds a boxcutter blade laterally greatly speeds scraping the engine pan flange. once i have it mostly clean i grab a can of Walmart's wonderful Carb Cleaner and a piece of 3M Scotch Brite pictured below. this cleans all the residual silicone from the flange.

i then place the pan in a box of 2 X 4s 10 5/8 square interior dimension and attack it first w the scraper. at that point the remaining silicone is in the pan flutes. i use a wire wheel on a drill and it completely cleans the 19 flutes.

next up are the 18 bolt holes in the block and front cover. i find that 90% of my motors have an incredible amount of silicone accumulation in the holes so i tap each bolt hole. while it might sound like a lot of work after you see what comes out you will have no problem gaining the resolve to do them all. see pic

while you are at it, don't forget the motor mount bolt holes. most have a half inch of silicone at the bottom. grab a pick and remove it. there is, of course no reason to use silicone on the motor mount bolts as they are not in communication with oil.

so now both surfaces are clean, the bolt holes are tapped and it is time to not even think about using a gasket. gaskets are appropriate for certain things but not the oilpan. the newer silicones do the job and why try to seal two faces when you can just seal one?

i use and recommend Permatex's "The Right Stuff." if ever a name was properly descriptive of a product...

///2016 UPDATE....... RE specific silicone recommendation, see bottom of Post One.../////////////

coat both surfaces sparingly and you are ready to reach for the bolts...

know this however on the subject of silicone/The Right Stuff....

it takes the better part of a WEEK to fully cure. and when i say the better part i am talking probably 7 days at room temp and longer if it is a bit chilly in your garage in October.

sure, the outer part of the silicone on the exterior of the engine cures in a couple of days.

not on the inside where it counts.

so you do your pan job, you are tuckered out... you come back to the car in a couple of days, fill it w oil and go for a drive-- warming up the oil which, incidentally is ABOVE the silicone.

and the silicone isn't completely cured.

back to that handful of grimy silicone encased bunch of pan bolts...

run them thru the parts washer and clean the threads on your bench grinder's wire wheel. you want them looking shiny.

these are tiny bolts w a big job. the reason you tapped the bolt holes and cleaned the bolt threads was so you could get an accurate torque reading. and the number is 100 inch pounds.. there are loads of bolts on the FD that have 10 mm heads and an inch pound torque wrench is the proper tool for the job and not expensive.

after you have all the bolts secure grab your two motor mounts and mount them to the motor at 55 ft pounds. they will help set the silicone in the rear area..

finally, i wrap the outer pan lip to the motor w a band around the entire motor.

an additional item that i have ran for the better part of ten years and that i install on almost all the motors i build is David Garfinkle's excellent engine block and oilpan brace. it is exquisitely engineered. just look carefully at the following two pics.

FD oilpans have 19 raised flutes for additional rigidity. David's brace perfectly fits over the the flutes so when you crank down on the 18 pan bolts you are pressing only flat surfaces together. the braces are only sporadically available so i bought a bunch and am a stocking dealer.

so that's about all i have for you on oilpans... they are a major issue but if installed correctly should not leak. i invite and welcome any additional comments on the subject. no doubt much of what is here you may already know but this may be of help to some.

Jan 2, 2016 UPDATE.

the correct silicone sealer MATTERS. all Permatex silicone sealers including The RIGHT STUFF (going forward to be known as The Wrong Stuff) have updated packaging and ALL carry a larger warning statement.... Not to be used with gasoline..

gas gets in our oil. period.

i did a study of 7 silicone sealers. i allowed each to cure for a week and tested them w my durometer. a durometer is used in racing to test hardness of tires. it is a probe on a spring w a dial.

most silicones registered about 60. higher is harder.

i then placed them in gasoline and another batch in E85 for a week. most reacted similarly. those placed in E85 lost approx 5 points. those placed in gasoline lost 25 points and the material seemed changed. sort of spongy.

all but HondaBond.

HB maybe lost 5 points. ThreeBond make most silicone sealers( including ToyotaBond, YamahaBond, MazdaBond) that compete w Permatex. i have spent more than an hour on the phone w them (as well as Permatex) and have tested a couple of their products that are very close to HB. they set up similar to HB but i find them a bit runny to apply. they are also about half the cost.

so it is HondaBond for me. i don't think there is any question that some pans leak because they are sealed w a Permatex product and it has become porous.

howard

#24

Sponsor

iTrader: (41)

*CORRECTION* Howard is right about the "right stuff". They recently changed the packaging and I believe the formulation. The silicone seems thinner and dries faster. I have had a few leak on me since. I'm having pretty good results with Permatex Ultra Black right now. If you get hondabond be careful. There are a few different formulations and some is only semi-hardening and only intended to be used as a gasket dressing.