Leaking oilpan - what to get and other advice

#26

Junior Member

Thread Starter

Join Date: Dec 2015

Location: Sweden

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for posting your guide in this thread as well Howard!I think its good to spread the same information (i.e. the right, and crucial information) in multiple threads.

New question:

My har has a complete Haltech PS1000 with a complete new loom. Because of this I'm unsure if the oil level sender is actually connected to anything. How do i test if the sender is being operational or not? I tried unplugging it, and the turning on the ignition (not starting the car), but no alarm or light went on.

Figured it would be a waste to buy a new one if its not being operational.

Thanks

New question:

My har has a complete Haltech PS1000 with a complete new loom. Because of this I'm unsure if the oil level sender is actually connected to anything. How do i test if the sender is being operational or not? I tried unplugging it, and the turning on the ignition (not starting the car), but no alarm or light went on.

Figured it would be a waste to buy a new one if its not being operational.

Thanks

#27

Rotary Enthusiast

iTrader: (32)

What do you do if running OEM motor mounts and a brace to deal with the extra 5mm of height? I have probably 10-12mm clearance between the engine intake and my strut brace now, I don't know how much the engine moves on acceleration but it could be a few mm. My OEM mounts are new, and I want to keep them.

#32

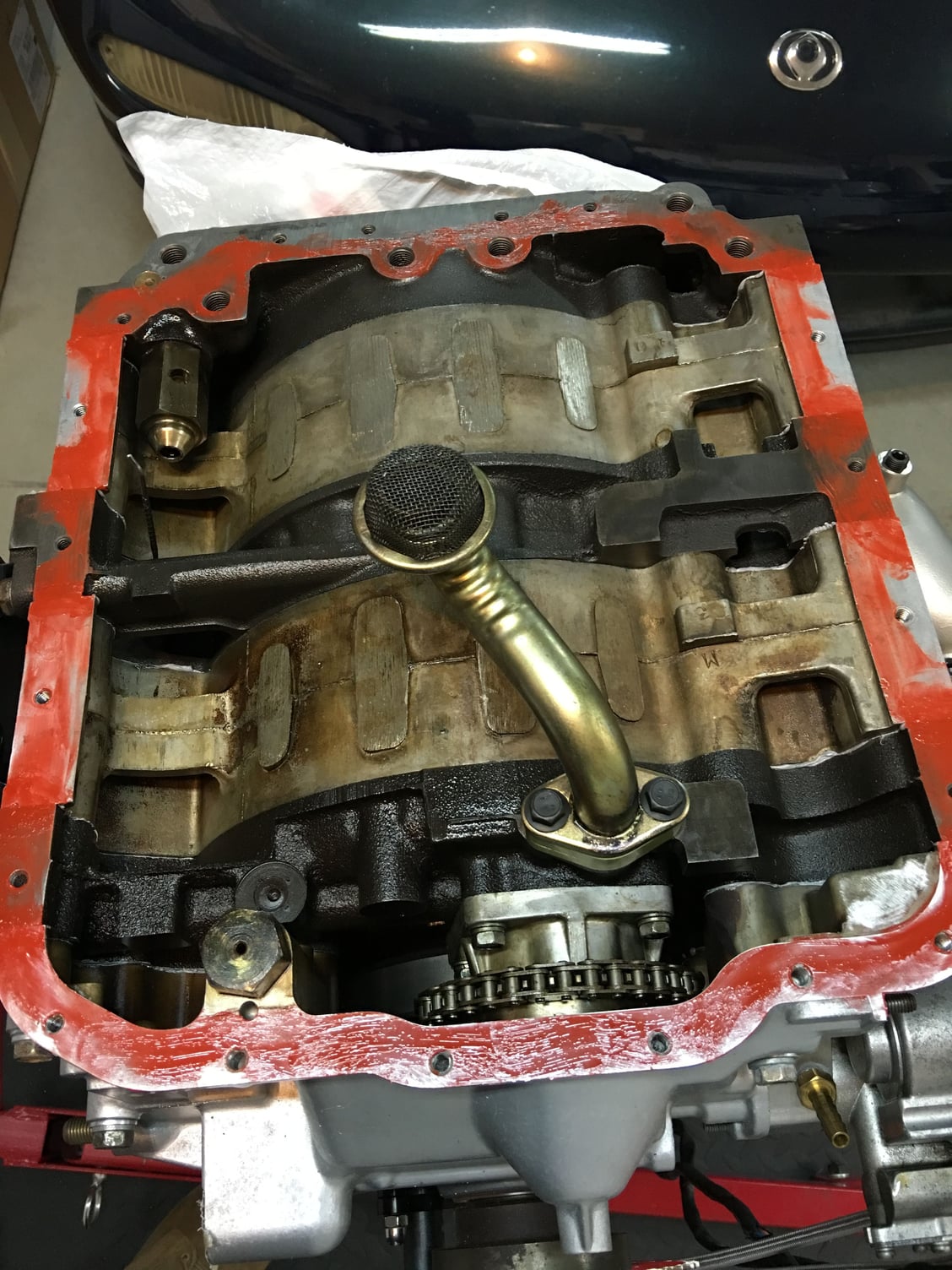

I bought in on it very early on and it was worth the wait. I had to hog out some of the main motor mount holes.

The O ring seems like it will seal well, but I have not filled the engine with oil yet. I also used a thin layer of gasket maker to assist at all the housing/plate joints.

#33

Spanking Pcars

iTrader: (4)

Join Date: Aug 2004

Location: DFW area

Posts: 1,084

Likes: 0

Received 0 Likes

on

0 Posts

How do those engine mounts attache to the subframe???

I must be missing something here, but the orientation is off, unless they connect to an adapter or these are just a jig for mock up, correct??

I must be missing something here, but the orientation is off, unless they connect to an adapter or these are just a jig for mock up, correct??

#37

Spanking Pcars

iTrader: (4)

Join Date: Aug 2004

Location: DFW area

Posts: 1,084

Likes: 0

Received 0 Likes

on

0 Posts

I don't think this oil pan provides more cooling, just prolong the heating of the oil due to more capacity and therefore takes a little longer for the rear rotor to get hot, not a significant effect IMHO.

#38

Junior Member

Thread Starter

Join Date: Dec 2015

Location: Sweden

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Just wanted to update you guys.

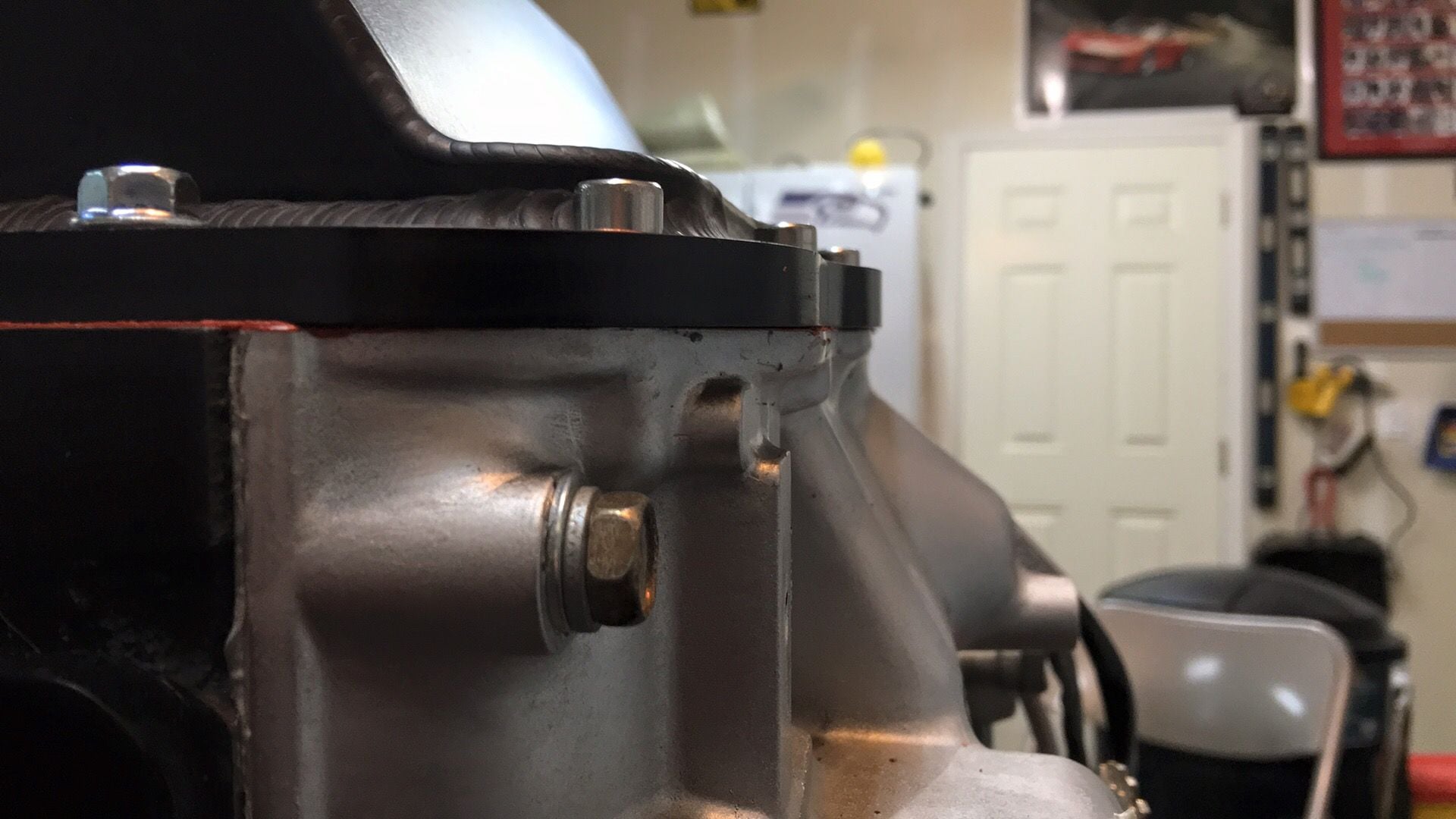

Did my oil pan last weekend. Dropped the subframe completely to gain the best access possible since i do now want to do this job again. Fitted a new pan with a locally made 6mm brace complete with all the hardware. Used Loctite 5910 as sealant. Next time ill use studs instead of bolts, less scary to torque down.

Im yet to put some 5w-50 synthetic oil in the engine, messing around with the catch can and other parts. Also installed a temp sender in the drain plug. I was going to tap the banjo bolt coming from the oil pump on the front cover, but i chickened out due to some sleepless nights over space and a possible failure of the modified banjo.

When messing around changing spark plugs i accidentally broke the wire, which was already bad, from the oil level sender. When disconnecting it before doing the pan, i didn't get a warning so i guess its not included in the new haltech harness. Shouldn't cause a leak should it?

Thanks everyone!

Did my oil pan last weekend. Dropped the subframe completely to gain the best access possible since i do now want to do this job again. Fitted a new pan with a locally made 6mm brace complete with all the hardware. Used Loctite 5910 as sealant. Next time ill use studs instead of bolts, less scary to torque down.

Im yet to put some 5w-50 synthetic oil in the engine, messing around with the catch can and other parts. Also installed a temp sender in the drain plug. I was going to tap the banjo bolt coming from the oil pump on the front cover, but i chickened out due to some sleepless nights over space and a possible failure of the modified banjo.

When messing around changing spark plugs i accidentally broke the wire, which was already bad, from the oil level sender. When disconnecting it before doing the pan, i didn't get a warning so i guess its not included in the new haltech harness. Shouldn't cause a leak should it?

Thanks everyone!

#39

So since our oil level is higher than the oil pan, why is the baffle plate even needed?

Also, does the high oil level provide a cooling measure to the bottom (hot side) of the rotor housings?

Also, does the high oil level provide a cooling measure to the bottom (hot side) of the rotor housings?

I have found that a baffled oil pan keeps your oil from sloshing all the way up your oil fill tube and into your catch can during heavy cornering and should also keep all your oil from going into your front cover during braking. It also keeps your low oil level light from flashing you all the time.

I haven't had such a problem with my FD and RX-8 that have baffled pans stock, but with the stock unbaffled pan in my FC it was ridiculous.

Thread

Thread Starter

Forum

Replies

Last Post

FourtyOunce

3rd Generation Specific (1993-2002)

37

09-01-20 08:22 PM

Tdskip

1st Generation Specific (1979-1985)

20

12-13-15 08:16 PM