JB Weld (Quick) and Rotary Temperatures on intake elbow, any problems?

#1

JB Weld (Quick) and Rotary Temperatures on intake elbow, any problems?

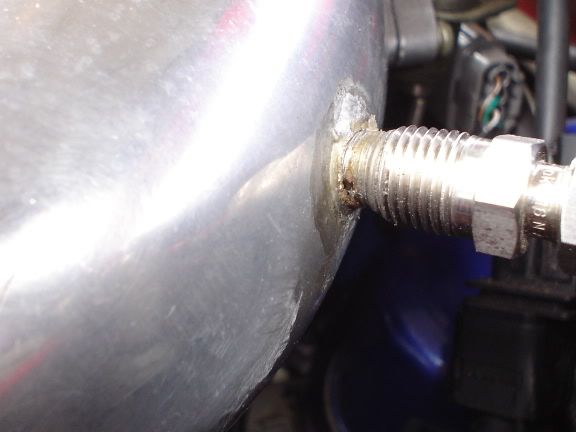

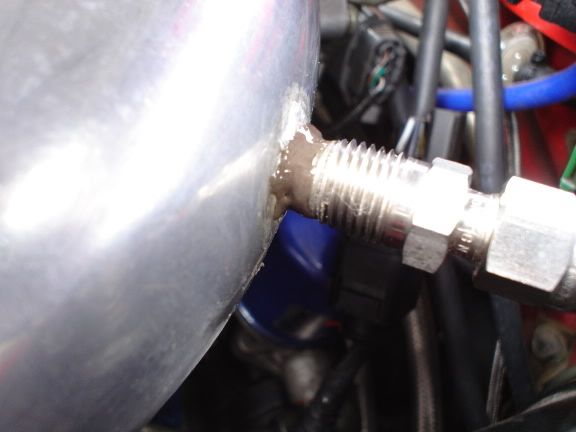

I had to go ghetto, I used some JB Qwik on the greddy elbow to seal up a leak.

I was just wondering if anyone has any experience with it being a problem? It'll support up to 300 degrees F, which is well under what the intake elbow will see.

Anyway, I plan on having my nozzles permanantely welded into place when i replace my bunged elbow with a non-bunged elbow.

I was just wondering if anyone has any experience with it being a problem? It'll support up to 300 degrees F, which is well under what the intake elbow will see.

Anyway, I plan on having my nozzles permanantely welded into place when i replace my bunged elbow with a non-bunged elbow.

Trending Topics

Thread

Thread Starter

Forum

Replies

Last Post