Intermittent Stalling and Rough Idle

#1

Junior Member

Thread Starter

Join Date: Apr 2017

Location: Japan, Aomori Prefecture

Posts: 27

Received 0 Likes

on

0 Posts

Intermittent Stalling and Rough Idle

I'll preface this by saying I've been troubleshooting this issue for a week now with all my free time after work, I finally decided it was time to consolidate my info and try to get a spirit bomb of advice going of my own.

There are countless threads on here with lots of good info, but none have quite matched the gremlin I'm chasing.

This problem started about 2 weeks ago. I got back from a 2 month trip and since then the weather has changed a lot (Humidity). Got back and drove the car for a few days; went to start it up on like the 5th day and while it was warming up it just died. No history of this with the car so i started it up again and it stayed running so I left to go cruise with a friend. An hour into this we pull over and the car starts Idling high... like 1,300 accompanied by backfires in sets of 3 every time I let off the gas. I let it cool off a bit and it died again while idling. Wasn't having this so I took it home. (End Prologue)

Those are the two symptoms I've been dealing with, and they've gotten worse respectively during troubleshooting. The idle is sometimes high, sometime low and rough, but always very rich (backfires while revving at any RPM, although I tried to stay below 3k). And the stalling is random but frequent.

I started looking for obvious vacuum leaks and found nothing. Tried using some carb cleaner on the hard to reach areas to see if it affected the idle, nothing. Changed clamps and added some legit clamps in placed that there was cheap ones, nothing. Gave up on vacuum leaks.

Skimming the FAQ section of the Gen 3 forums I found this thread on adjusting the TPS https://www.rx7club.com/3rd-generati...g-more-170731/ FULL OF GREAT INFO Half way through there's even a dude with a similar problem but he never followed up with a fix. I looked into it and my TPS is out of tolerance while the TB is closed. Readings are as follows:

I tried getting this adjusted, Alas the screws on the TPS were already stripped, and are made of soft metal. not even Easy grip could save me here. I managed to get the top one easily with vice grips, but the bottom is beyond reach behind the oil filter in the way.

Not having what I needed to move the filter and deal with the mess last night; I went back to look for other indications of a problem. I eventually found a loose vacuum line, basically unattached from the the rats nest. I have yet to look in the FSM to see what it was responsible for. Juggling work duties, sleep, and troubleshooting this hasn't left me the time. I started the car after fixing the leak and it made almost no difference. Today still unable to deal with the TPS I decided to reset the ECU (Disconnecting battery and hitting the Brake) Started the car this time and it sounded good! idle dropped down to like 500 after warming a bit but it wasn't rough and wasn't nearly as rich. I figured this was because I zeroed out the air adjusting screw on the bottom of the TB while reading the thread I linked earlier. I went to raise the idle with the screw..... and somehow that stalled the engine. Barely moved the screw at all. And me being me I managed to flood the engine trying to get it to start again... that was fun.

Deflooded the engine, reset the Air screw I messed with back to zero, cleaned and I mean CLEANED the spark plugs. Reset the ECU again (just because?) and it started back up. Idled great for 15 mins while I cleaned up... died.. no longer runs rich (Because of the vacuum line?), but now stalls randomly and instantly. Doesn't sputter to death, it just turns off. I noticed three different times that after the engine dies there is a rapid Ticking noise coming from the ISC solenoid. And it will not stop ticking unless I unplug it....

Apologies for the long winded post.

The TPS and ISC are the next two things on my list; If anyone has second opinions or advice on other things to look at please feel free to share. I'm an aircraft mechanic not an automotive mechanic, and I live in japan so the RX7 community is small with a language barrier.

That's what I've got so far, Thanks for your time.

1993 JDM FD:

Stock ECU.

Cat Delete. (Sort of)

Battery Relocation. (Sort of)

Trust intakes.

Just about everything else is stock.

There are countless threads on here with lots of good info, but none have quite matched the gremlin I'm chasing.

This problem started about 2 weeks ago. I got back from a 2 month trip and since then the weather has changed a lot (Humidity). Got back and drove the car for a few days; went to start it up on like the 5th day and while it was warming up it just died. No history of this with the car so i started it up again and it stayed running so I left to go cruise with a friend. An hour into this we pull over and the car starts Idling high... like 1,300 accompanied by backfires in sets of 3 every time I let off the gas. I let it cool off a bit and it died again while idling. Wasn't having this so I took it home. (End Prologue)

Those are the two symptoms I've been dealing with, and they've gotten worse respectively during troubleshooting. The idle is sometimes high, sometime low and rough, but always very rich (backfires while revving at any RPM, although I tried to stay below 3k). And the stalling is random but frequent.

I started looking for obvious vacuum leaks and found nothing. Tried using some carb cleaner on the hard to reach areas to see if it affected the idle, nothing. Changed clamps and added some legit clamps in placed that there was cheap ones, nothing. Gave up on vacuum leaks.

Skimming the FAQ section of the Gen 3 forums I found this thread on adjusting the TPS https://www.rx7club.com/3rd-generati...g-more-170731/ FULL OF GREAT INFO Half way through there's even a dude with a similar problem but he never followed up with a fix. I looked into it and my TPS is out of tolerance while the TB is closed. Readings are as follows:

Green and Red wire

1.5V with TB closed.

4.9V with throttle wide open

Black and Green Wire

.5V with TB closed.

4.9V with TB open.

1.5V with TB closed.

4.9V with throttle wide open

Black and Green Wire

.5V with TB closed.

4.9V with TB open.

I tried getting this adjusted, Alas the screws on the TPS were already stripped, and are made of soft metal. not even Easy grip could save me here. I managed to get the top one easily with vice grips, but the bottom is beyond reach behind the oil filter in the way.

Not having what I needed to move the filter and deal with the mess last night; I went back to look for other indications of a problem. I eventually found a loose vacuum line, basically unattached from the the rats nest. I have yet to look in the FSM to see what it was responsible for. Juggling work duties, sleep, and troubleshooting this hasn't left me the time. I started the car after fixing the leak and it made almost no difference. Today still unable to deal with the TPS I decided to reset the ECU (Disconnecting battery and hitting the Brake) Started the car this time and it sounded good! idle dropped down to like 500 after warming a bit but it wasn't rough and wasn't nearly as rich. I figured this was because I zeroed out the air adjusting screw on the bottom of the TB while reading the thread I linked earlier. I went to raise the idle with the screw..... and somehow that stalled the engine. Barely moved the screw at all. And me being me I managed to flood the engine trying to get it to start again... that was fun.

Deflooded the engine, reset the Air screw I messed with back to zero, cleaned and I mean CLEANED the spark plugs. Reset the ECU again (just because?) and it started back up. Idled great for 15 mins while I cleaned up... died.. no longer runs rich (Because of the vacuum line?), but now stalls randomly and instantly. Doesn't sputter to death, it just turns off. I noticed three different times that after the engine dies there is a rapid Ticking noise coming from the ISC solenoid. And it will not stop ticking unless I unplug it....

Apologies for the long winded post.

The TPS and ISC are the next two things on my list; If anyone has second opinions or advice on other things to look at please feel free to share. I'm an aircraft mechanic not an automotive mechanic, and I live in japan so the RX7 community is small with a language barrier.

That's what I've got so far, Thanks for your time.

1993 JDM FD:

Stock ECU.

Cat Delete. (Sort of)

Battery Relocation. (Sort of)

Trust intakes.

Just about everything else is stock.

#2

I just did this today, and I think you will find it is the TPS. Replace the bolts with stainless allen head cap screws. It makes it easier to adjust when hot (it has to be hot).

You want:

Green and Red wire

1V with TB closed.

Black and Green Wire

0.45V with TB closed.

Fully warm up the car, then set the idle to 850rpm. Adjust the TPS to get the 0.45v. If you move the idle, you have to readjust the TPS. They work in conjunction. Don't overtighten the new bolts.

My car idles, accelerates, and decelerates so much smoother now.

You want:

Green and Red wire

1V with TB closed.

Black and Green Wire

0.45V with TB closed.

Fully warm up the car, then set the idle to 850rpm. Adjust the TPS to get the 0.45v. If you move the idle, you have to readjust the TPS. They work in conjunction. Don't overtighten the new bolts.

My car idles, accelerates, and decelerates so much smoother now.

The following users liked this post:

IGermanDudeI (07-30-17)

#3

Junior Member

Thread Starter

Join Date: Apr 2017

Location: Japan, Aomori Prefecture

Posts: 27

Received 0 Likes

on

0 Posts

Update

Didn't have as much time to work the problem this week, sleep deprived myself a little too much. However I did get the TPS off and replaced the screws, and cleaned the throttle body while I was at it. I adjusted the TPS to about where it should be and let the car run for a bit. It still stalls randomly though about 5 - 8 minutes after it's started, every time. Allowing it to run with the ISC unplugged doesn't keep it from stalling, so i guess I can rule that out as the problem. After it stalled I went to finish adjusting the TPS with the engine warm, and while TB is closed pins 1 and 4 no longer had voltage outputs? The wires have continuity to ground though. Maybe the TPS is bad, I'll try and open it up to take a look. If i don't find anything there I'll move on to the fuel system.

#4

Junior Member

Thread Starter

Join Date: Apr 2017

Location: Japan, Aomori Prefecture

Posts: 27

Received 0 Likes

on

0 Posts

Update

I've been in and out of the country a bit with not much time to work this, but I have made progress. I shot the TPS bad as it gave no voltage output when throttle was closed. I changed this along with the fuel filter as it hadn't been changed since 2005; I also changed the ISC and the car seemed to be fixed as it idled fine and didn't stall for a couple days. I went to drive it and it died in the driveway again. I have a fuel pressure regulator on hand because the FSM calls it out as a potential cause. I'll be changing that next. otherwise I'm going to be looking at the injectors to see if they look wonky. I'm going to try and rig up an LED so I can see if the ECU has any codes as well, if not I have a power FC on order with some new spark plugs and I'll use the input data on the commander to help with troubleshooting.

#5

Full Member

iTrader: (2)

tps and things

Just a heads up, the PowerFC may not be a cure-all resolution. It'll give you a way to check TPS voltage a bit easier but other than that, mine didn't help at all with my hunting idle.

Have you checked compression? I was running on one rotor (due to a stuck primary injector) and the symptoms were similar to your initial issues. This is a worst case scenario but it's easy to do since you're already removing plugs and de-flooding.

I would also check spark by arcing them against some grounded metal on the car.

A note on the TPS, if your car is not warmed up, the fast idle cam will cause the voltages to be high. When testing voltages on a cold car, make sure you actuate the cam.

i would also suggest replacing the stripped screws with little hex or sockets if you've already got the UIM off. I can adjust TPS just by taking off the intake elbow with those installed.

The FSM , Section F, includes a resistance check on the solenoid in the ISC (BAC). For a '94, the resistance should be 10.7-12.3 Ohms at 68 degrees F.

What's the idle like with it disconnected?

Good luck man

Have you checked compression? I was running on one rotor (due to a stuck primary injector) and the symptoms were similar to your initial issues. This is a worst case scenario but it's easy to do since you're already removing plugs and de-flooding.

I would also check spark by arcing them against some grounded metal on the car.

A note on the TPS, if your car is not warmed up, the fast idle cam will cause the voltages to be high. When testing voltages on a cold car, make sure you actuate the cam.

i would also suggest replacing the stripped screws with little hex or sockets if you've already got the UIM off. I can adjust TPS just by taking off the intake elbow with those installed.

The FSM , Section F, includes a resistance check on the solenoid in the ISC (BAC). For a '94, the resistance should be 10.7-12.3 Ohms at 68 degrees F.

What's the idle like with it disconnected?

Good luck man

The following users liked this post:

IGermanDudeI (10-08-17)

#6

The Power FC is notorious for having its own set of idling concerns. I should know, I wrote a series of procedures and work-arounds for them. https://www.rx7club.com/3rd-generati...needed-841706/

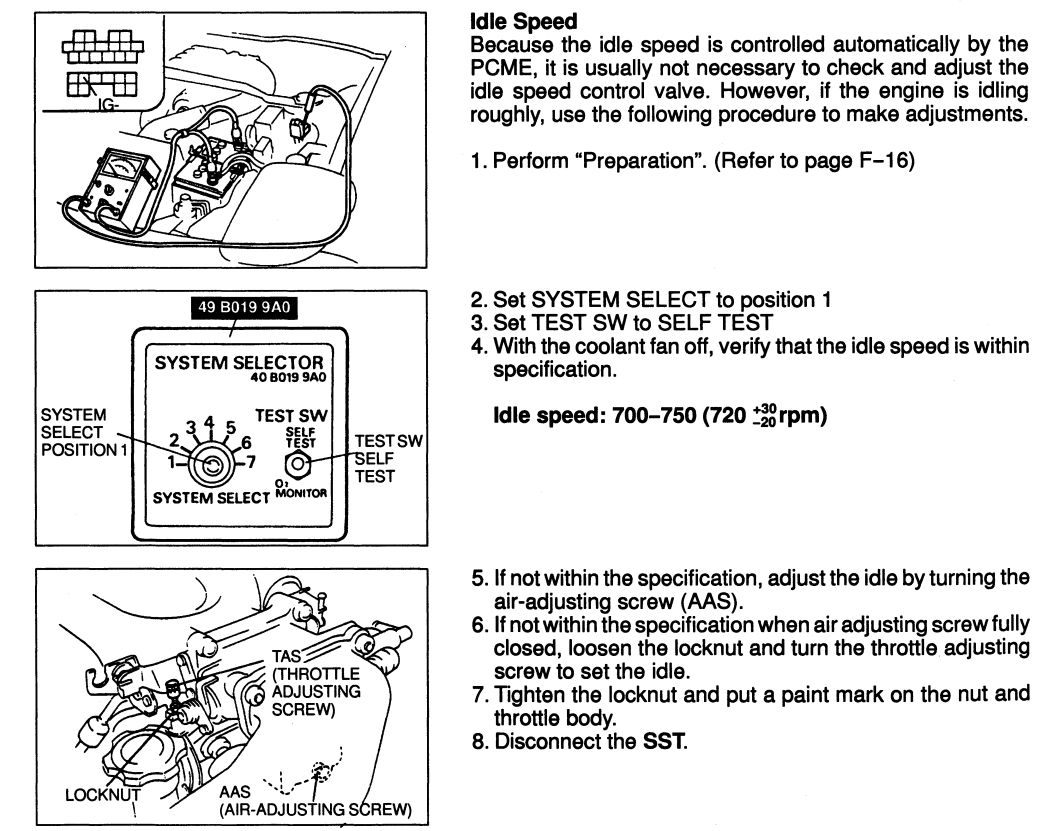

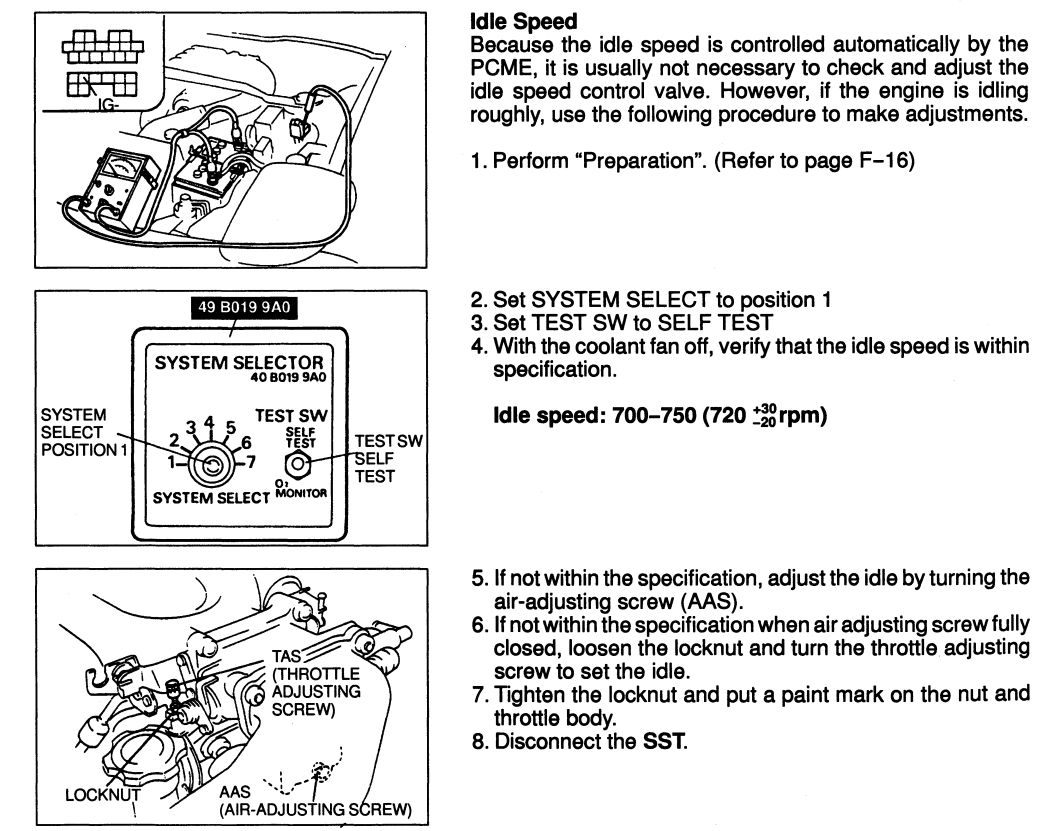

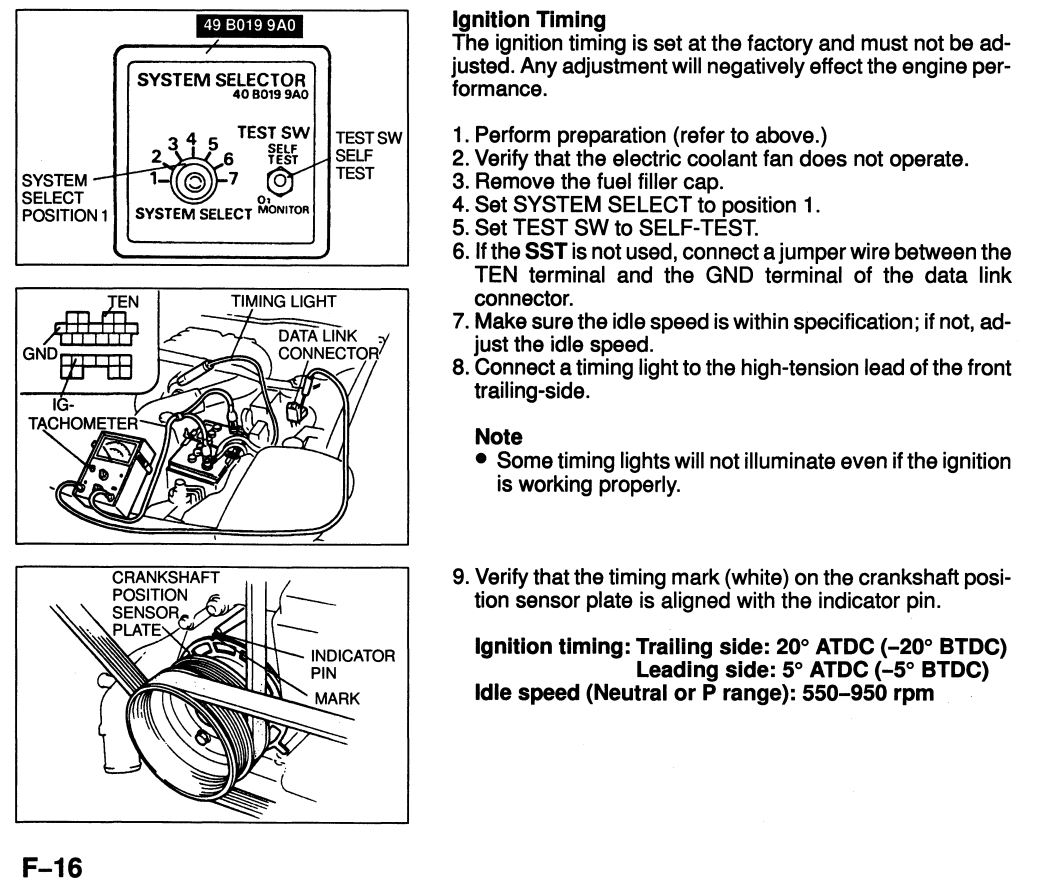

One thing I did not see is how you are adjusting the air bleed screw. Here is the procedure from the service manual:

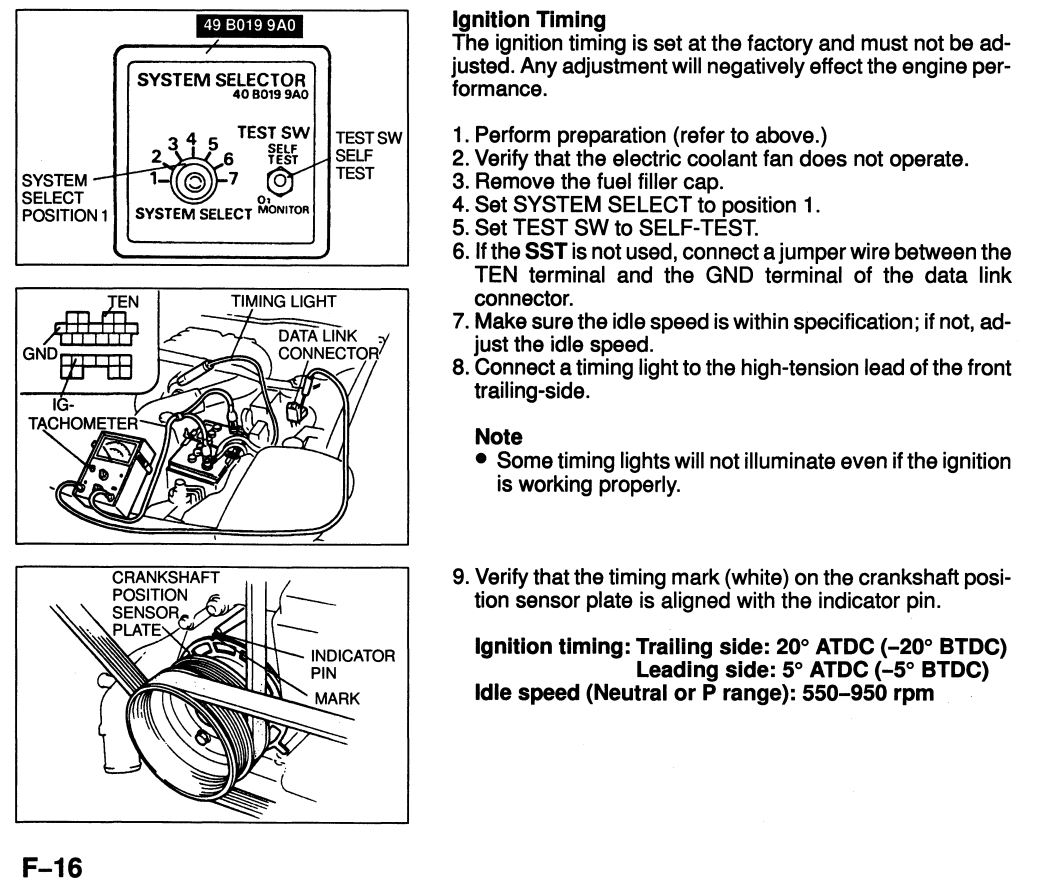

Notice the first thing it tells you to do is the "preparation" procedure, which I will post here:

This is checking the ignition timing with a timing light. In your case, that is probably not necessary. On the older rotaries the base ignition timing was adjustable, due to having a distributor or a crank angle sensor that drops in like a distributor. The FD crank angle sensor is different. FYI It has a signal plate and two sensors.

One is equivalent to the crank position sensor on a piston engine ("Ne" signal, Ne being common Japanese notation for engine speed).

One is equivalent to the cam position sensor on a piston engine ("G" signal).

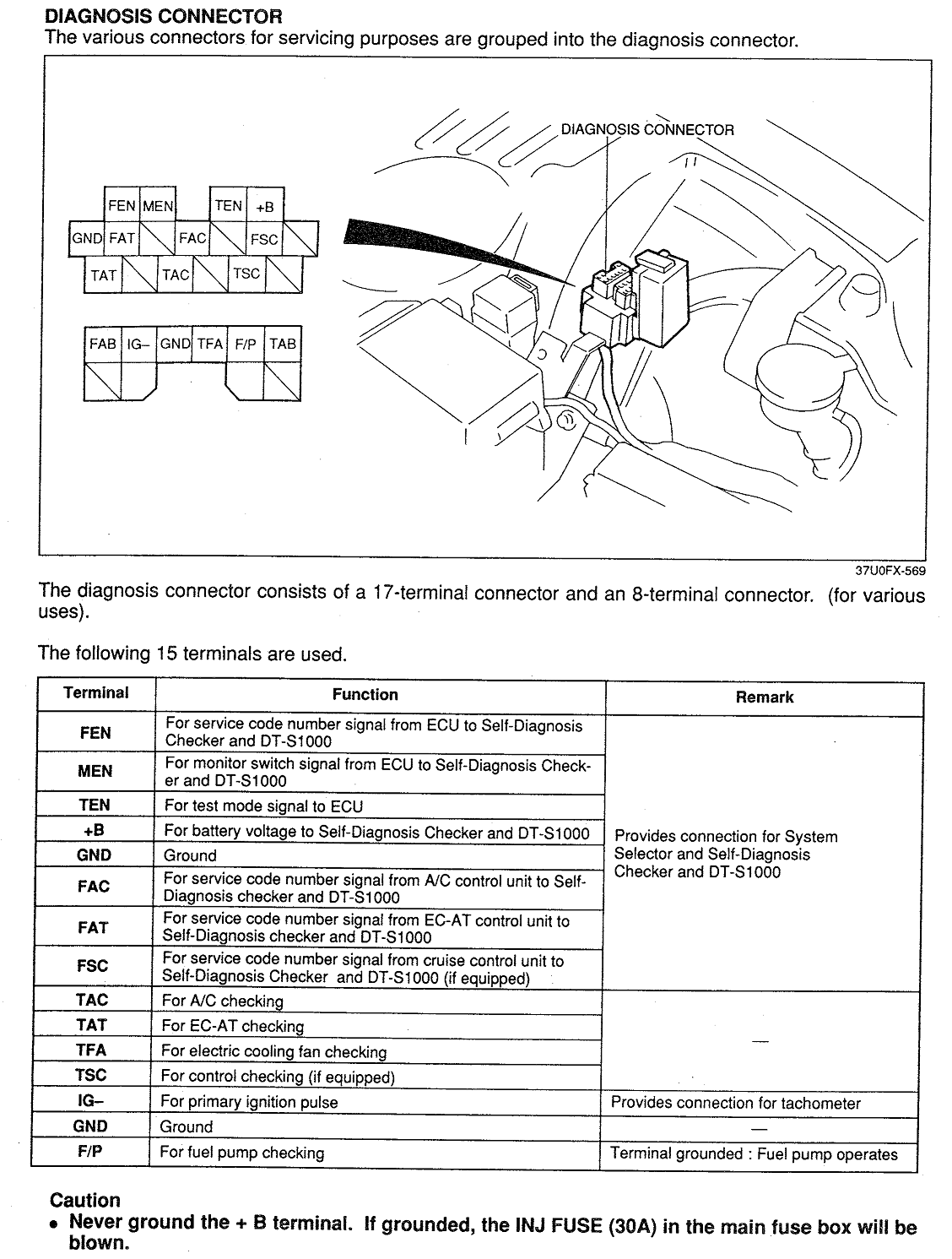

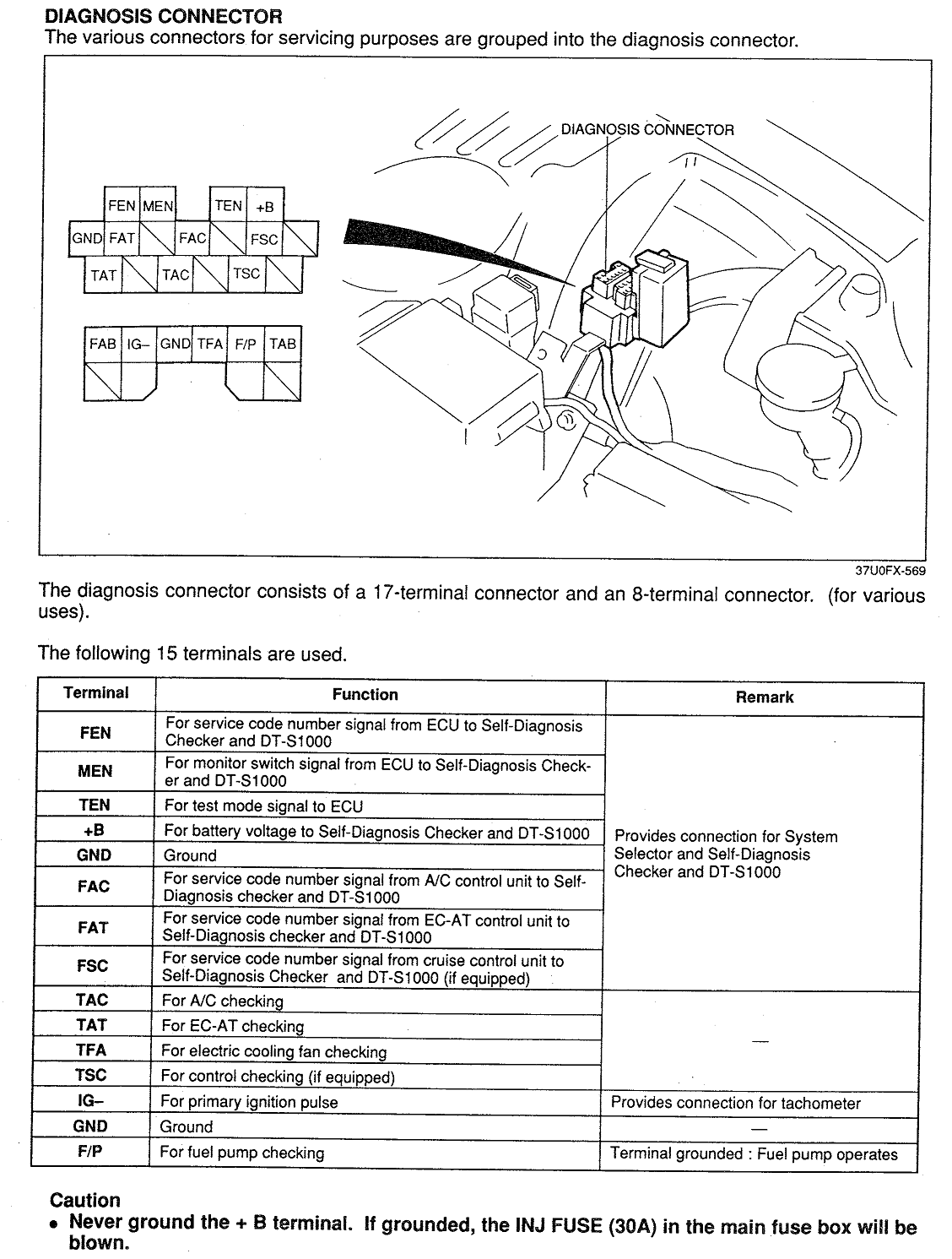

Now if you look at the procedure it tells you to jumper the TEN and GND terminals in the diagnostic box. Now what are those terminals?

Those put the engine into "test mode." I don't have the page handy, but if you dig around the various documents, you will see that you must jumper TEN and GND to disable the idle speed feedback system. With that system disabled your ignition timing is locked to -5L and -20T, and the idle speed solenoid duty cycle is fixed. If you don't have this jumpered you won't be able to set the air adjusting screw correctly ("AAS"). The ECU will fight you by changing the ignition timing and idle speed duty as you are turning the screw. Note, for Power FC cars this does not apply. You may need to turn off "Idle IG Control" in the Commander and adjust the idle speed & fuel cut settings. Read the thread I linked above.

So, did you jumper the GND and TEN terminals?

One thing I did not see is how you are adjusting the air bleed screw. Here is the procedure from the service manual:

Notice the first thing it tells you to do is the "preparation" procedure, which I will post here:

This is checking the ignition timing with a timing light. In your case, that is probably not necessary. On the older rotaries the base ignition timing was adjustable, due to having a distributor or a crank angle sensor that drops in like a distributor. The FD crank angle sensor is different. FYI It has a signal plate and two sensors.

One is equivalent to the crank position sensor on a piston engine ("Ne" signal, Ne being common Japanese notation for engine speed).

One is equivalent to the cam position sensor on a piston engine ("G" signal).

Now if you look at the procedure it tells you to jumper the TEN and GND terminals in the diagnostic box. Now what are those terminals?

Those put the engine into "test mode." I don't have the page handy, but if you dig around the various documents, you will see that you must jumper TEN and GND to disable the idle speed feedback system. With that system disabled your ignition timing is locked to -5L and -20T, and the idle speed solenoid duty cycle is fixed. If you don't have this jumpered you won't be able to set the air adjusting screw correctly ("AAS"). The ECU will fight you by changing the ignition timing and idle speed duty as you are turning the screw. Note, for Power FC cars this does not apply. You may need to turn off "Idle IG Control" in the Commander and adjust the idle speed & fuel cut settings. Read the thread I linked above.

So, did you jumper the GND and TEN terminals?

Last edited by arghx; 10-02-17 at 11:25 AM. Reason: concerns

#7

All the advice you read about closing the air adjusting screw down to near closed (half a turn, 1 turn open)... does NOT apply to stock ECU or chipped ECU. It is a work around for some of idle issues the Power FC has that involves surging idle or a sticking idle.

For a mostly stock car using a stock ECU or chipped ECU, follow the service manual procedure shown above. From memory, the air adjusting screw is open several turns in a factory state, i want to say like 4 or 5. Things get messed up though when you start turning throttle plate screws ("TAS" throttle adjusting screw), then adjusting the air adjusting screw under the throttlebody, then doing other stuff to compensate for a bad TPS or an improper setting procedure (not jumpering the TEN and GND terminals, not having the car warmed up, adjusting the screw when the fans are on).

What I'm saying is, if you closed off the air adjusting screw (or closed it to like half a turn) in an effort to fix the idle, you probably made it worse. And... this is why electronic throttle is so great on modern cars. You don't have to deal with any of this.

For a mostly stock car using a stock ECU or chipped ECU, follow the service manual procedure shown above. From memory, the air adjusting screw is open several turns in a factory state, i want to say like 4 or 5. Things get messed up though when you start turning throttle plate screws ("TAS" throttle adjusting screw), then adjusting the air adjusting screw under the throttlebody, then doing other stuff to compensate for a bad TPS or an improper setting procedure (not jumpering the TEN and GND terminals, not having the car warmed up, adjusting the screw when the fans are on).

What I'm saying is, if you closed off the air adjusting screw (or closed it to like half a turn) in an effort to fix the idle, you probably made it worse. And... this is why electronic throttle is so great on modern cars. You don't have to deal with any of this.

Trending Topics

#8

Junior Member

Thread Starter

Join Date: Apr 2017

Location: Japan, Aomori Prefecture

Posts: 27

Received 0 Likes

on

0 Posts

All the advice you read about closing the air adjusting screw down to near closed (half a turn, 1 turn open)... does NOT apply to stock ECU or chipped ECU. It is a work around for some of idle issues the Power FC has that involves surging idle or a sticking idle.

For a mostly stock car using a stock ECU or chipped ECU, follow the service manual procedure shown above. From memory, the air adjusting screw is open several turns in a factory state, i want to say like 4 or 5. Things get messed up though when you start turning throttle plate screws ("TAS" throttle adjusting screw), then adjusting the air adjusting screw under the throttlebody, then doing other stuff to compensate for a bad TPS or an improper setting procedure (not jumpering the TEN and GND terminals, not having the car warmed up, adjusting the screw when the fans are on).

What I'm saying is, if you closed off the air adjusting screw (or closed it to like half a turn) in an effort to fix the idle, you probably made it worse. And... this is why electronic throttle is so great on modern cars. You don't have to deal with any of this.

For a mostly stock car using a stock ECU or chipped ECU, follow the service manual procedure shown above. From memory, the air adjusting screw is open several turns in a factory state, i want to say like 4 or 5. Things get messed up though when you start turning throttle plate screws ("TAS" throttle adjusting screw), then adjusting the air adjusting screw under the throttlebody, then doing other stuff to compensate for a bad TPS or an improper setting procedure (not jumpering the TEN and GND terminals, not having the car warmed up, adjusting the screw when the fans are on).

What I'm saying is, if you closed off the air adjusting screw (or closed it to like half a turn) in an effort to fix the idle, you probably made it worse. And... this is why electronic throttle is so great on modern cars. You don't have to deal with any of this.

#9

Junior Member

Thread Starter

Join Date: Apr 2017

Location: Japan, Aomori Prefecture

Posts: 27

Received 0 Likes

on

0 Posts

So today; after being out of the country for 3 weeks I re-accomplished some things since the post office is closed and I can't pick up my Power FC.

I started with a compression: Using my friends "Rotory Compression Tester.com" Tester @ 235 RPM Both housings have values of approx. 105-110 PSI. (Plugs are black again even after cleaning them completely)

Next: I have been noticing some white-ish smoke for two seconds from the exhaust on startup. It never smells sweet like coolant would, but I'm suspicious anyway. I haven't been driving the car enough to notice a drop in coolant levels if there is in fact a leak, and I tried a geyser test to see if maybe those coolant seals are bad but nothing happened. I've heard that's an easy way to check but It seemed alright as no coolant spewed out.

lastly I started to re adjust the idle by jumpering TEN to ground but didn't have time to finish because my friend needed help with his Nissan; the car still runs like crap below 1k rpm, absolute crap.

Should be picking up the new ECU and some new spark plugs tomorrow, will probably end up getting a new battery too since the one I got with the car is pretty old.

I started with a compression: Using my friends "Rotory Compression Tester.com" Tester @ 235 RPM Both housings have values of approx. 105-110 PSI. (Plugs are black again even after cleaning them completely)

Next: I have been noticing some white-ish smoke for two seconds from the exhaust on startup. It never smells sweet like coolant would, but I'm suspicious anyway. I haven't been driving the car enough to notice a drop in coolant levels if there is in fact a leak, and I tried a geyser test to see if maybe those coolant seals are bad but nothing happened. I've heard that's an easy way to check but It seemed alright as no coolant spewed out.

lastly I started to re adjust the idle by jumpering TEN to ground but didn't have time to finish because my friend needed help with his Nissan; the car still runs like crap below 1k rpm, absolute crap.

Should be picking up the new ECU and some new spark plugs tomorrow, will probably end up getting a new battery too since the one I got with the car is pretty old.

#10

Junior Member

Thread Starter

Join Date: Apr 2017

Location: Japan, Aomori Prefecture

Posts: 27

Received 0 Likes

on

0 Posts

Engine codes

So the Power FC never showed. I ended up just pulling engine codes with an LED, I got a 9, 12, and 18. The 12 and 18 are for TPS but those were likely from before I changed the sensor. I reset the ECU and let the car run till it stalled and only the 9 stuck...... coolant thermo sensor. Kinda makes sense and explains why my radiator fans spin for absolutely no reason.

Funny enough following a similar thread, this guy had the same problem/fix. https://www.rx7club.com/3rd-generati...tarts-1047832/

Funny enough following a similar thread, this guy had the same problem/fix. https://www.rx7club.com/3rd-generati...tarts-1047832/