HOW TO: Make your untuned PFC basemap safer/idle better (no Datalogit needed)

#27

Advanced Idle Troubleshooting - Idle IG control

Based on your settings in the etc. --> function select menu, the PFC controls idle with the following logic:

1. O2 feedback and Idle IG Control ON (default): PFC controls idle fuel based on factory O2 sensor signal, PFC uses closed loop idle control. Neither fuel nor timing are directly adjustable by the user.

2. O2 feedback OFF, Idle IG control ON: User can control fuel, closed loop fuel is disabled completely, PFC varies idle timing in an effort to reach target idle speeds. Turning off O2 feedback is usually necessary on cars without an airpump.

3. O2 feedback OFF, Idle IG control OFF: Ignition timing is fixed at

-5 L, -20 T for no load idle, same as the FC and FD service manual spec and same as the yellow and red timing marks on the FC crank pulley

4 L, -6 T for electrical load idle. electrical load is triggered by either engaging the fans (fan output) or by the PFC receiving a signal from the electrical load detection computer (ELD input)

I don't know the fixed A/C ignition timing values off the top of my head.

The ignition timing is completely static for the three idle conditions (no load, fans or electrical load applied, A/C load). The PFC manual specifically states that turning off Idle IG control was intended for checking ignition timing with a timing light. On an FD that's not normally necessary, although it is on an FC because the crank angle sensor is installed like a distributor.

4. O2 feedback OFF, Idle IG control OFF, idle speeds set to 0. This is what many refer to as "manual idle control," and can only be enabled with a Datalogit. The user has complete control over idle ignition timing but the ISC valve no longer functions for A/C or E/L idle up or improved cold starting. There are advantages and disadvantages to this configuration, and all I will say is that using this depends on your setup and your personal preferences. PM Chuck Westbrook (cewrx7r1) about tuning notes, I won't go into it much because this thread is all about Commander tuning.

With an ISC installed and no airpump, I personally prefer to have O2 feedback OFF and Idle IG control ON. Now let's discuss steady state (not decelerating or free revving) idle speed control before we get to the very thorny issue of deceleration idle problems.

With Idle IG control ON, the PFC calculates ignition timing in this basic way:

base idle ignition timing (a separate value for no load, electrical load, or A/C) + closed loop correction factor

The closed loop correction factor is somehow calculated by measuring how far the current speed differs from its target, or the "error" term for those of you with any knowledge of closed loop jargon. With idle IG control on, the PFC will vary the ignition timing within some range of authority in order to stabilize engine vacuum and get closer to the target idle speed. The PFC will also add more idle air through the ISC valve when electrical or A/C load are applied, even if they have the exact same target idle speeds.

The PFC will advance ignition timing to raise the idle speed or retard ignition timing to lower the idle speed. While it is not possible to directly set idle ignition timing without full manual idle control, a little fiddling with the idle settings will accomplish the same goal. As counterintuitive as it may seem, my current idle speeds are:

1000rpm no load

950 rpm E/L

950 rpm A/C (no A/C is installed on my 2nd gen but I have tuned A/C idle before)

Yet with my throttlebody adjustments, I actually idle at around 900rpm with no load or electrical load applied. Basically I adjusted the idle through the TB down (in order to prevent idle sticking on decel) then effectively raised the base idle speed through indirectly manipulating the PFC's ignition timing logic. Note that this is on an engine with large intake and exhaust ports that pulls very little vacuum for a non-bridge engine. The work-arounds and manipulations I have done are probably not necessary on most people's setups. You need to remember that The PFC and the throttlebody adjustment all work together to control idle speed under various driving conditions.

Based on your settings in the etc. --> function select menu, the PFC controls idle with the following logic:

1. O2 feedback and Idle IG Control ON (default): PFC controls idle fuel based on factory O2 sensor signal, PFC uses closed loop idle control. Neither fuel nor timing are directly adjustable by the user.

2. O2 feedback OFF, Idle IG control ON: User can control fuel, closed loop fuel is disabled completely, PFC varies idle timing in an effort to reach target idle speeds. Turning off O2 feedback is usually necessary on cars without an airpump.

3. O2 feedback OFF, Idle IG control OFF: Ignition timing is fixed at

-5 L, -20 T for no load idle, same as the FC and FD service manual spec and same as the yellow and red timing marks on the FC crank pulley

4 L, -6 T for electrical load idle. electrical load is triggered by either engaging the fans (fan output) or by the PFC receiving a signal from the electrical load detection computer (ELD input)

I don't know the fixed A/C ignition timing values off the top of my head.

The ignition timing is completely static for the three idle conditions (no load, fans or electrical load applied, A/C load). The PFC manual specifically states that turning off Idle IG control was intended for checking ignition timing with a timing light. On an FD that's not normally necessary, although it is on an FC because the crank angle sensor is installed like a distributor.

4. O2 feedback OFF, Idle IG control OFF, idle speeds set to 0. This is what many refer to as "manual idle control," and can only be enabled with a Datalogit. The user has complete control over idle ignition timing but the ISC valve no longer functions for A/C or E/L idle up or improved cold starting. There are advantages and disadvantages to this configuration, and all I will say is that using this depends on your setup and your personal preferences. PM Chuck Westbrook (cewrx7r1) about tuning notes, I won't go into it much because this thread is all about Commander tuning.

With an ISC installed and no airpump, I personally prefer to have O2 feedback OFF and Idle IG control ON. Now let's discuss steady state (not decelerating or free revving) idle speed control before we get to the very thorny issue of deceleration idle problems.

With Idle IG control ON, the PFC calculates ignition timing in this basic way:

base idle ignition timing (a separate value for no load, electrical load, or A/C) + closed loop correction factor

The closed loop correction factor is somehow calculated by measuring how far the current speed differs from its target, or the "error" term for those of you with any knowledge of closed loop jargon. With idle IG control on, the PFC will vary the ignition timing within some range of authority in order to stabilize engine vacuum and get closer to the target idle speed. The PFC will also add more idle air through the ISC valve when electrical or A/C load are applied, even if they have the exact same target idle speeds.

The PFC will advance ignition timing to raise the idle speed or retard ignition timing to lower the idle speed. While it is not possible to directly set idle ignition timing without full manual idle control, a little fiddling with the idle settings will accomplish the same goal. As counterintuitive as it may seem, my current idle speeds are:

1000rpm no load

950 rpm E/L

950 rpm A/C (no A/C is installed on my 2nd gen but I have tuned A/C idle before)

Yet with my throttlebody adjustments, I actually idle at around 900rpm with no load or electrical load applied. Basically I adjusted the idle through the TB down (in order to prevent idle sticking on decel) then effectively raised the base idle speed through indirectly manipulating the PFC's ignition timing logic. Note that this is on an engine with large intake and exhaust ports that pulls very little vacuum for a non-bridge engine. The work-arounds and manipulations I have done are probably not necessary on most people's setups. You need to remember that The PFC and the throttlebody adjustment all work together to control idle speed under various driving conditions.

#28

Advanced Idle Troubleshooting -- The Dreaded Sticking/Surging Idle

This section will focus on a troubleshooting process. It's not going to just give you some settings that you can mindlessly enter into your PFC you can go off on your merry way--if only it were that simple. Fixing these deceleration idle problems could take as little as 5 minutes (just a quick change in the PFC) or as much as 10 hours (testing all sorts of combinations of PFC settings and TB adjustments).

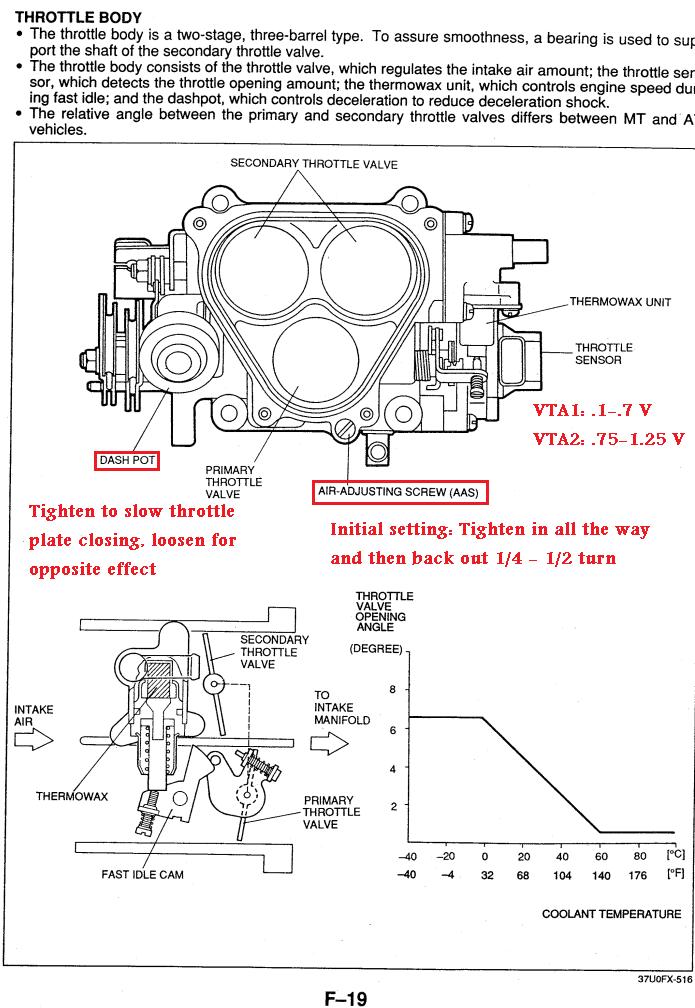

For those of you with an ISC valve installed, this is one of the most common and frustrating problems with the Power FC. I have covered this in another thread: https://www.rx7club.com/3rd-generation-specific-1993-2002-16/new-pfc-idle-sticking-problem-solving-strategy-isc-installed-853278/ but I want to update, condense, and simplify the information here. You should have already checked the obvious stuff (throttle cable etc), you should have tried adjusting the air adjusting screw under the TB elbow, and you should have set up everything else properly in the PFC (O2 feedback for example).

Now here are the typical symptoms: You start the car up, and properly perform the idle learning procedure. Everything idles fine and the car is at operating temperature. Then you go drive the car. Eventually you get to a stop sign or a traffic light and one of these three things may happen:

1. The idle sticks at 1200-1500rpm and just stays there.

2. The idle sticks at 1200-1500rpm and eventually drops.

3. The idle drops too fast, the engine stumbles, then surges as the PFC struggles to keep it alive. It may just surge once and settle down, or may be hunting up and down for a while, making you look like a complete idiot to anyone else in traffic.

You may not be able to make the car idle like it did brand new off the showroom floor, but there are a number of strategies you can employ to mitigate those problems. First, here's a little background on the idle speed control system.

Sources of Idle Air for the FD

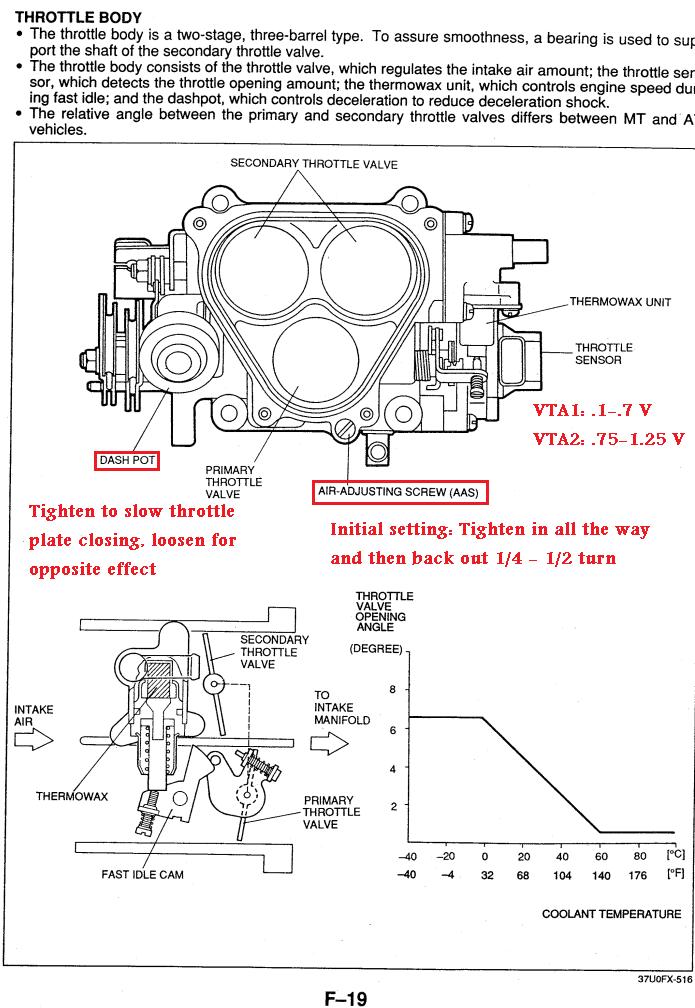

1. the throttle plate opening angle. This is controlled by the fast idle cam, which I've already covered. It's also controlled by the throttle adjust screw, which acts as a stopped for the primary throttle plates. Finally, extra tension in the the throttle and cruise cables can open the throttle plate. Both should have 1-2mm of freeplay)

2. a vacuum leak

3. air bypassing the throttle plates, controlled by the air adjust screw

4. duty controlled bypass air from the ISC valve, controlled by PFC target idle speed (and the learning process) and the fuel cut settings, which indirectly determine ISC behavior on decel.

On deceleration, the dashpot function of the idle control system controls the amount of air entering the engine as you release the accelerator pedal. There are two components to the dashpot function:

1. an electronic dashpot based on how much air enters the engine through the ISC valve.

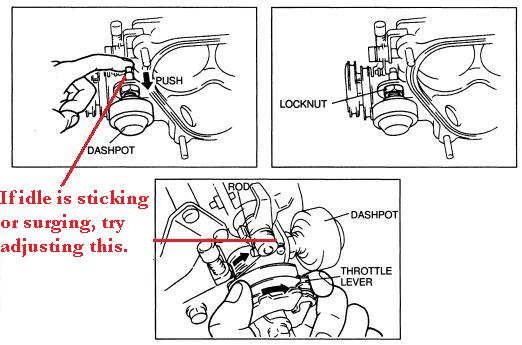

2. an actual damper on the throttlebody which slows the closing of the throttle plates

The PFC gives us somewhat crude control over the electronic dashpot function (other standalones like the AEM EMS are more adjustable but also more complicated). Adjusting the PFC can often mitigate the problem to the point that the car drives a lot better and thus TB dashpot adjustment would be unnecessary.

Dashpot function--Electronic

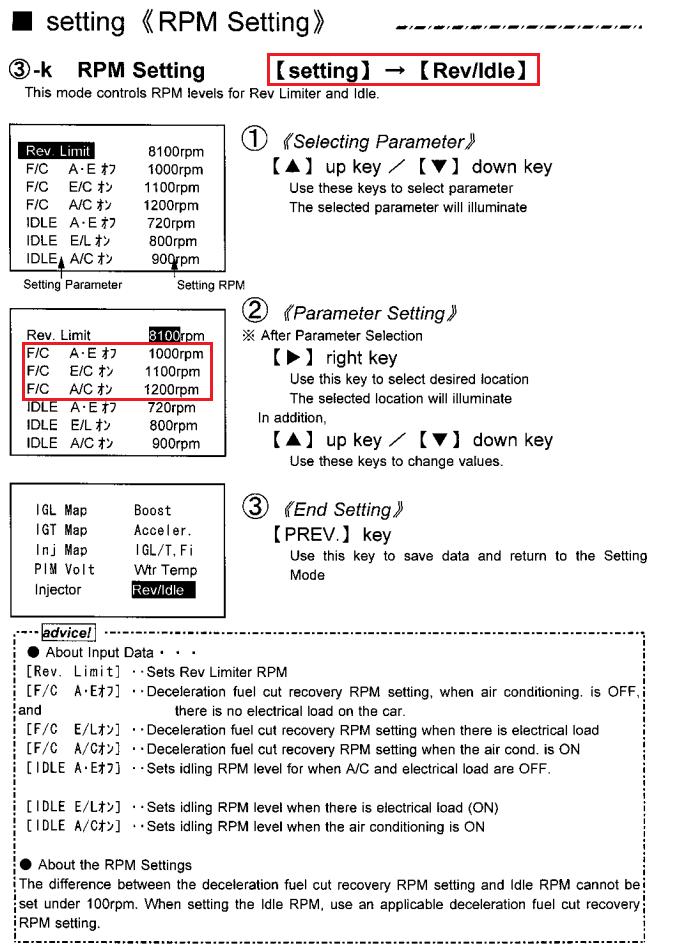

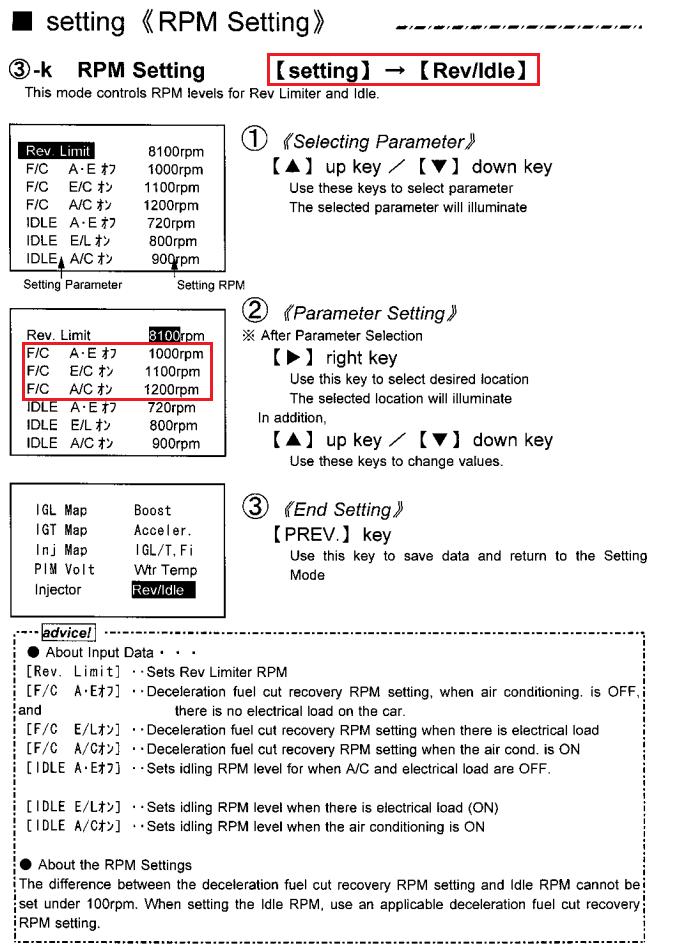

The PFC controls the ISC valve dashpot function based on the target idle speed and especially the target fuel cut recovery speeds (we'll call them "fuel cut" or "F/C" settings). The fuel cut recovery speeds are here:

When you let off the gas, the fuel injectors stop firing. The F/C settings control two things:

1. They control the rpm at which the fuel injectors come back on line after deceleration. So if you come to a stop light and push the clutch in, the mixture will go super lean until the rpms drop near this setting.

2. They indirectly control how much air is supplied by the ISC during deceleration and how long it will be supplied. I wish I could give some breakdown of the ISC control logic here, but I just don't know exactly and neither does anybody else. I will say this: different idle speed settings and ambient conditions seem to have some effect on how the PFC determines the amount of air supplied for the dashpot function. Different clutches/flywheels, and different adjustments of the TB can all make a difference in what kind of settings may be required. You just have to fiddle with the thing.

Here are the two fundamental rules of the fuel cut settings.

The higher the F/C rpm settings, the more air will be supplied as engine rpms drop. Higher F/C settings will hopefully help address stumbling and subsequent surging. If you raise the F/C speeds too high, you may get a sticking idle.

The lower the F/C rpm settings, the less air will be supplied as engine rpms drop. Lower F/C settings should hopefully help address many instances of a sticking idle. Note that the F/C rpm settings must be at least 100 rpm higher than the target idle speeds. If you lower the F/C speeds too much, you may experience stumbling, surging, or stalling.

An example of Decel Idle Troubleshooting With the PFC Fuel Cut Settings

1. Park the car with the engine running, in a place that will tolerate you revving the engine. Start by setting all your F/C settings to the same value. In the end they don't all have to be the same, but again this is a basic approach to start with. Here's an example.

F/C A.E. 1200

F/C E/L 1200

F/C A/C 1200

Rev the car multiple times. Give it some small throttle movements and see what happens as you let off the gas. Give it some larger throttle movements and higher revs.

If you notice stumbling, raise all the F/C speeds and continue to test with free revving. Try it in 50rpm increments at first, and then you may have to make 20 or 10rpm changes. The PFC can be very sensitive. Remember, if you over compensate you will have the opposite problem (sticking idle).

If you notice the idle hanging up for a significant period of time, lower all the F/C speeds and continue to test with free revving. As you let off the gas, you want the rpms to drop to maybe 1200 rpm and then slowly fall. Try making changes in 50rpm increments at first, and then you may have to make 20 or 10rpm changes. The PFC can be very sensitive. Remember, if you over compensate you will have the opposite problem (stumbles, surges, stalling). This is something you have to tune by 'feel'. Later on you may have to adjust the dashpot on the throttlebody to improve this further, which I am still going to cover. Hopefully at this point you have made some kind of improvement in the way the ISC behaves during free revving.

Now take the car out for some city driving. As you slow for a stop sign, pop the clutch in while the vehicle is still rolling. On many cars the rpms should stay anywhere from 1000-1200 rpms until the vehicle comes to a complete stop. The PFC is designed to raise the idle speed if the vehicle is moving, in order the prevent stalling. Unfortunately you don't have direct control over this. Lowering the fuel cut speeds will reduce this behavior, but again you can overcompensate and compromise idle stability.

If you come to a complete stop at a traffic light with the clutch in, and the idle takes a very long time to drop down near the target speed, you can adjust the PFC fuel cut settings down further. But you may actually have to adjust the mechanical dashpot on the throttlebody for further improvement.

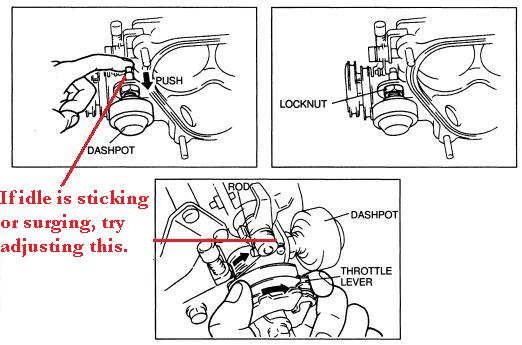

Dashpot function--Throttlebody

I'm going to be more succinct in this section, as you are using the same basic tuning principles as adjusting the PFC F/C settings. The dashpot is this plunger looking thing that slows the closing of the throttle plates.

Increasing the plunger's contact with the throttle has a lot of the same effects as raising the fuel cut speeds in the PFC. My car has a lightish flywheel and a sprung 6 puck clutch. I found that dashpot adjustments made the car a lot less prone to stalling in low speed parking lot maneuvers. The fuel cut settings couldn't completely cure that issue.

Decreasing the plunger's contact with the throttle has a lot of the same effects as lowering the fuel cut speeds in the PFC. Try that if the idle is taking too long to drop down as you decelerate no matter what adjustments you try in the PFC. Note that any adjustments to any part of the TB may necessitate further adjustment in to PFC settings. Your car may run worse before it runs better, but that's just the nature of driveability tuning.

I want to conclude by saying that you just need to keep fiddling until you're satisfied with the way the car drives. Use whatever combination of throttle body and PFC adjustments you need to make the car run the best. Focus on incremental improvements and don't expect the car to idle exactly like it did stock, especially if you have a 6 puck clutch and a 9 pound flywheel.

This section will focus on a troubleshooting process. It's not going to just give you some settings that you can mindlessly enter into your PFC you can go off on your merry way--if only it were that simple. Fixing these deceleration idle problems could take as little as 5 minutes (just a quick change in the PFC) or as much as 10 hours (testing all sorts of combinations of PFC settings and TB adjustments).

For those of you with an ISC valve installed, this is one of the most common and frustrating problems with the Power FC. I have covered this in another thread: https://www.rx7club.com/3rd-generation-specific-1993-2002-16/new-pfc-idle-sticking-problem-solving-strategy-isc-installed-853278/ but I want to update, condense, and simplify the information here. You should have already checked the obvious stuff (throttle cable etc), you should have tried adjusting the air adjusting screw under the TB elbow, and you should have set up everything else properly in the PFC (O2 feedback for example).

Now here are the typical symptoms: You start the car up, and properly perform the idle learning procedure. Everything idles fine and the car is at operating temperature. Then you go drive the car. Eventually you get to a stop sign or a traffic light and one of these three things may happen:

1. The idle sticks at 1200-1500rpm and just stays there.

2. The idle sticks at 1200-1500rpm and eventually drops.

3. The idle drops too fast, the engine stumbles, then surges as the PFC struggles to keep it alive. It may just surge once and settle down, or may be hunting up and down for a while, making you look like a complete idiot to anyone else in traffic.

You may not be able to make the car idle like it did brand new off the showroom floor, but there are a number of strategies you can employ to mitigate those problems. First, here's a little background on the idle speed control system.

Sources of Idle Air for the FD

1. the throttle plate opening angle. This is controlled by the fast idle cam, which I've already covered. It's also controlled by the throttle adjust screw, which acts as a stopped for the primary throttle plates. Finally, extra tension in the the throttle and cruise cables can open the throttle plate. Both should have 1-2mm of freeplay)

2. a vacuum leak

3. air bypassing the throttle plates, controlled by the air adjust screw

4. duty controlled bypass air from the ISC valve, controlled by PFC target idle speed (and the learning process) and the fuel cut settings, which indirectly determine ISC behavior on decel.

On deceleration, the dashpot function of the idle control system controls the amount of air entering the engine as you release the accelerator pedal. There are two components to the dashpot function:

1. an electronic dashpot based on how much air enters the engine through the ISC valve.

2. an actual damper on the throttlebody which slows the closing of the throttle plates

The PFC gives us somewhat crude control over the electronic dashpot function (other standalones like the AEM EMS are more adjustable but also more complicated). Adjusting the PFC can often mitigate the problem to the point that the car drives a lot better and thus TB dashpot adjustment would be unnecessary.

Dashpot function--Electronic

The PFC controls the ISC valve dashpot function based on the target idle speed and especially the target fuel cut recovery speeds (we'll call them "fuel cut" or "F/C" settings). The fuel cut recovery speeds are here:

When you let off the gas, the fuel injectors stop firing. The F/C settings control two things:

1. They control the rpm at which the fuel injectors come back on line after deceleration. So if you come to a stop light and push the clutch in, the mixture will go super lean until the rpms drop near this setting.

2. They indirectly control how much air is supplied by the ISC during deceleration and how long it will be supplied. I wish I could give some breakdown of the ISC control logic here, but I just don't know exactly and neither does anybody else. I will say this: different idle speed settings and ambient conditions seem to have some effect on how the PFC determines the amount of air supplied for the dashpot function. Different clutches/flywheels, and different adjustments of the TB can all make a difference in what kind of settings may be required. You just have to fiddle with the thing.

Here are the two fundamental rules of the fuel cut settings.

The higher the F/C rpm settings, the more air will be supplied as engine rpms drop. Higher F/C settings will hopefully help address stumbling and subsequent surging. If you raise the F/C speeds too high, you may get a sticking idle.

The lower the F/C rpm settings, the less air will be supplied as engine rpms drop. Lower F/C settings should hopefully help address many instances of a sticking idle. Note that the F/C rpm settings must be at least 100 rpm higher than the target idle speeds. If you lower the F/C speeds too much, you may experience stumbling, surging, or stalling.

An example of Decel Idle Troubleshooting With the PFC Fuel Cut Settings

1. Park the car with the engine running, in a place that will tolerate you revving the engine. Start by setting all your F/C settings to the same value. In the end they don't all have to be the same, but again this is a basic approach to start with. Here's an example.

F/C A.E. 1200

F/C E/L 1200

F/C A/C 1200

Rev the car multiple times. Give it some small throttle movements and see what happens as you let off the gas. Give it some larger throttle movements and higher revs.

If you notice stumbling, raise all the F/C speeds and continue to test with free revving. Try it in 50rpm increments at first, and then you may have to make 20 or 10rpm changes. The PFC can be very sensitive. Remember, if you over compensate you will have the opposite problem (sticking idle).

If you notice the idle hanging up for a significant period of time, lower all the F/C speeds and continue to test with free revving. As you let off the gas, you want the rpms to drop to maybe 1200 rpm and then slowly fall. Try making changes in 50rpm increments at first, and then you may have to make 20 or 10rpm changes. The PFC can be very sensitive. Remember, if you over compensate you will have the opposite problem (stumbles, surges, stalling). This is something you have to tune by 'feel'. Later on you may have to adjust the dashpot on the throttlebody to improve this further, which I am still going to cover. Hopefully at this point you have made some kind of improvement in the way the ISC behaves during free revving.

Now take the car out for some city driving. As you slow for a stop sign, pop the clutch in while the vehicle is still rolling. On many cars the rpms should stay anywhere from 1000-1200 rpms until the vehicle comes to a complete stop. The PFC is designed to raise the idle speed if the vehicle is moving, in order the prevent stalling. Unfortunately you don't have direct control over this. Lowering the fuel cut speeds will reduce this behavior, but again you can overcompensate and compromise idle stability.

If you come to a complete stop at a traffic light with the clutch in, and the idle takes a very long time to drop down near the target speed, you can adjust the PFC fuel cut settings down further. But you may actually have to adjust the mechanical dashpot on the throttlebody for further improvement.

Dashpot function--Throttlebody

I'm going to be more succinct in this section, as you are using the same basic tuning principles as adjusting the PFC F/C settings. The dashpot is this plunger looking thing that slows the closing of the throttle plates.

Increasing the plunger's contact with the throttle has a lot of the same effects as raising the fuel cut speeds in the PFC. My car has a lightish flywheel and a sprung 6 puck clutch. I found that dashpot adjustments made the car a lot less prone to stalling in low speed parking lot maneuvers. The fuel cut settings couldn't completely cure that issue.

Decreasing the plunger's contact with the throttle has a lot of the same effects as lowering the fuel cut speeds in the PFC. Try that if the idle is taking too long to drop down as you decelerate no matter what adjustments you try in the PFC. Note that any adjustments to any part of the TB may necessitate further adjustment in to PFC settings. Your car may run worse before it runs better, but that's just the nature of driveability tuning.

I want to conclude by saying that you just need to keep fiddling until you're satisfied with the way the car drives. Use whatever combination of throttle body and PFC adjustments you need to make the car run the best. Focus on incremental improvements and don't expect the car to idle exactly like it did stock, especially if you have a 6 puck clutch and a 9 pound flywheel.

#30

Guys,

At the time of this writing the Power FC Commander manual is not available on the Apex'i website. They're not that hard to find from Google searches however.

Right now you can get the Commander manual here: http://bagpuss.swan.ac.uk/200sx/apex...der_manual.pdf . this link may eventually stop working but a search for "Power FC Commander Manual" works well enough

At the time of this writing the Power FC Commander manual is not available on the Apex'i website. They're not that hard to find from Google searches however.

Right now you can get the Commander manual here: http://bagpuss.swan.ac.uk/200sx/apex...der_manual.pdf . this link may eventually stop working but a search for "Power FC Commander Manual" works well enough

#31

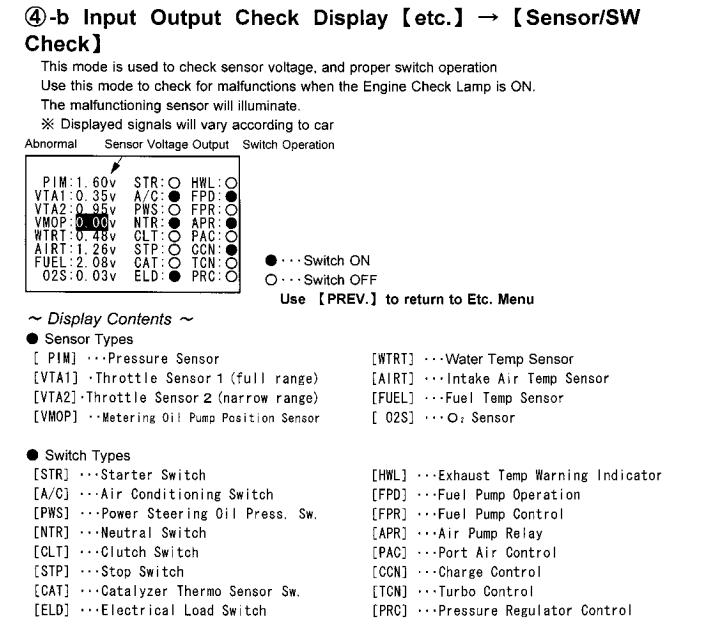

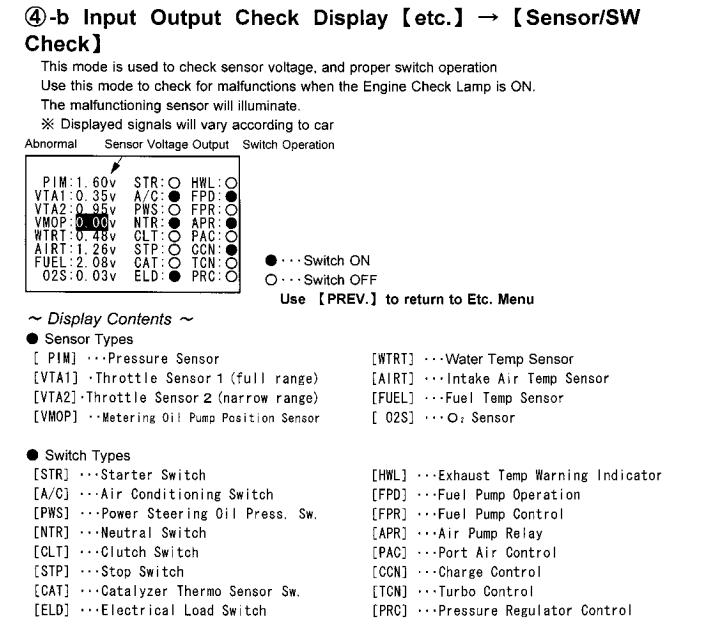

I've seen a few posts of people trying to diagnose problems by looking at the Power FC etc.-->Sensor/Sw check screen but not understanding what they are looking at. The description of each symbol is buried in the PFC manual and also buried in a less important section of this thread, so I'll post again here:

#34

Hard or Slow Starts

When you start removing idle control components or changing primary injectors you may find that the car takes longer to start, or won't start without using the accelerator pedal. This problem can often be improved with fuel and timing changes, although not necessarily eliminated.

Factors that affect cranking and starting:

-- Cranking speed, which is affected by battery voltage, the health of the starter, oil temperature, and oil viscosity

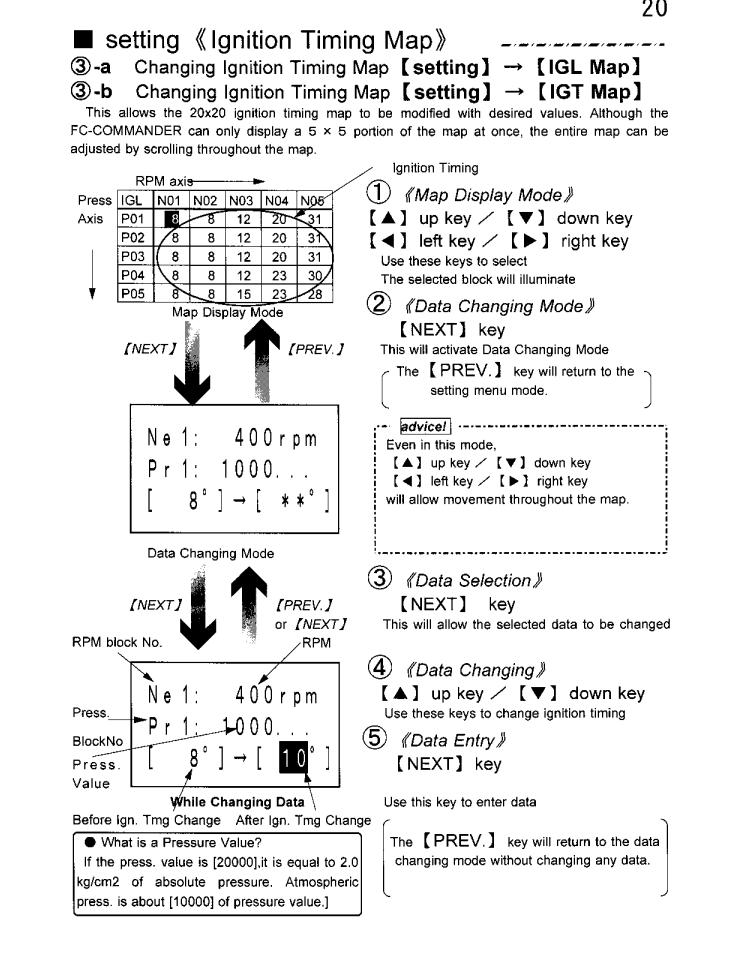

-- Cranking ignition timing, a function of the N1-P2, P9-P10 cells of the IGL and IGT maps and [unconfirmed] the ignition timing retard setting in the Datalogit

-- Fuel pressure

-- Throttle plate opening angle (VTA1 and VTA2 tps voltages), affected by the fast idle cam position (if still installed), the primary throttle plate adjust screw, and whether the accelerator pedal is being pressed

-- ISC valve duty cycle (if still installed), which will be 100% during cranking and then taper down

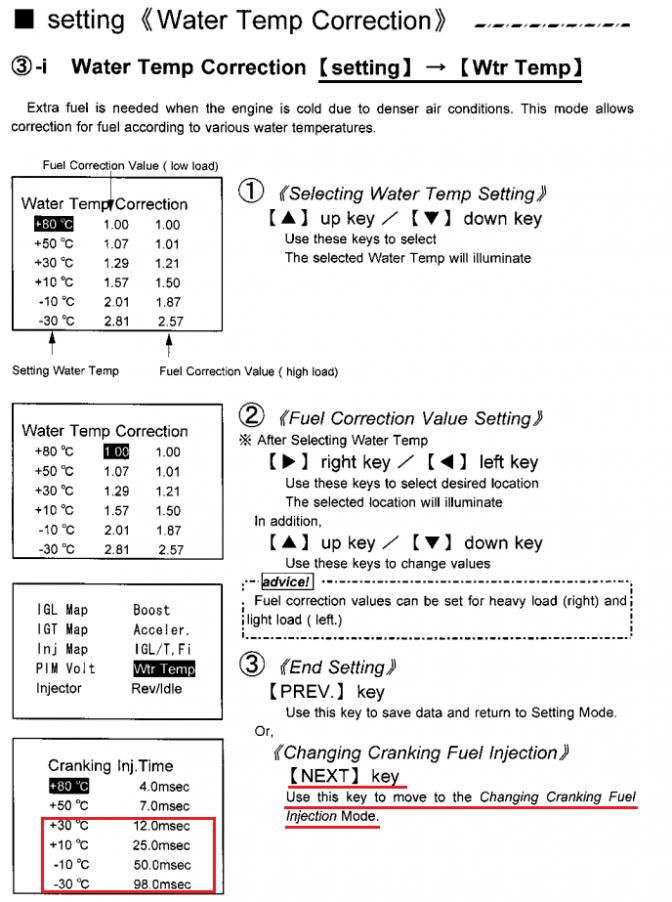

My latest testing indicates that even with Idle IG control on, the PFC will use the values from the IGL and IGT map until the engine is partially warmed up (about 60C ?). I will have to verify this, but it should also apply a warm up timing retard correction on top of the values in the maps. The warm up timing retard is 15 degrees by default until water temp reaches 60C. It is only adjustable with a Datalogit. A lot of tuners disable it, but there are times when it can be useful for smoothing out idle during warmup.

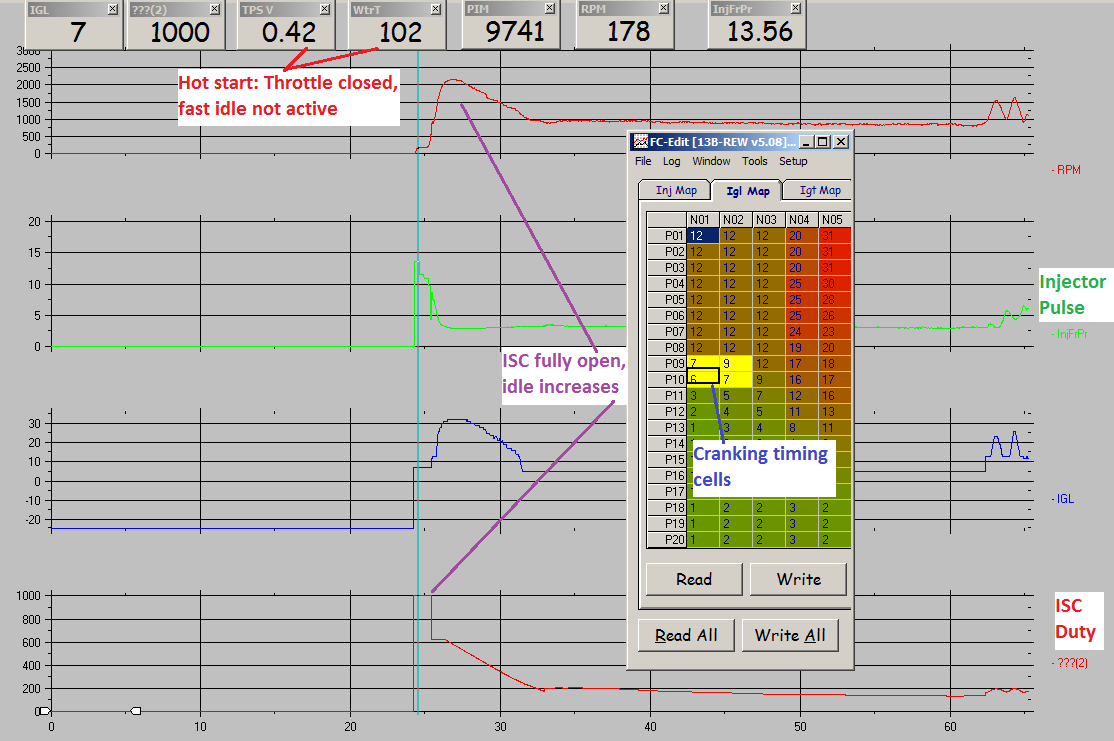

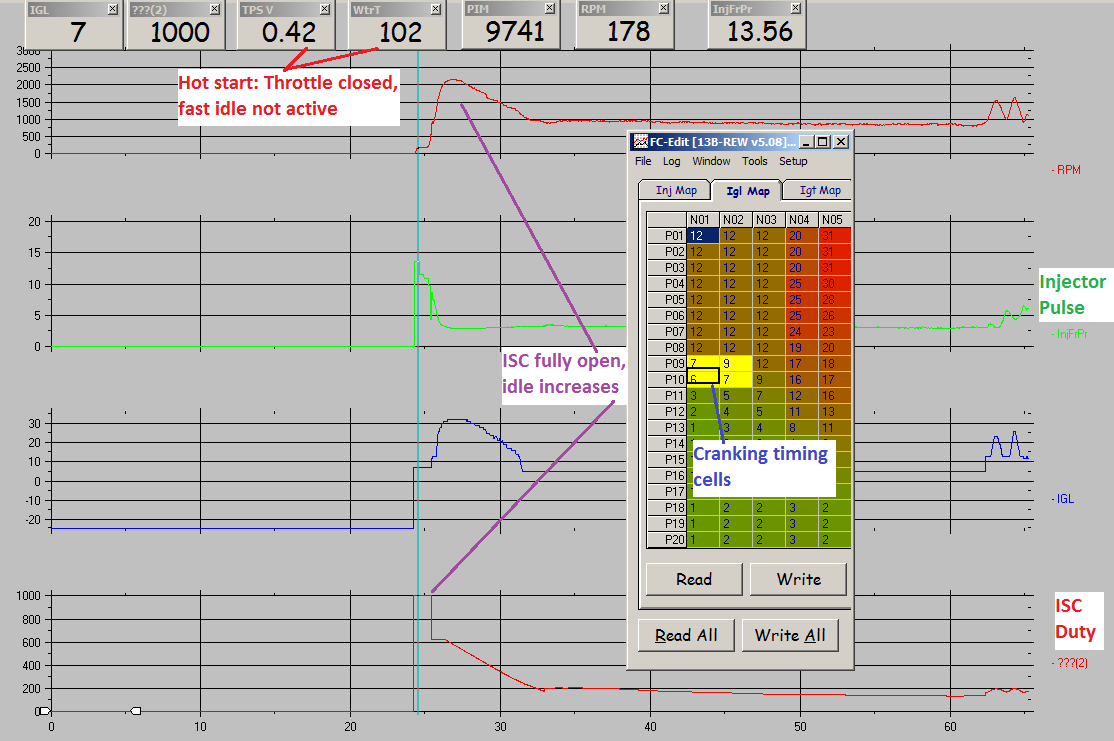

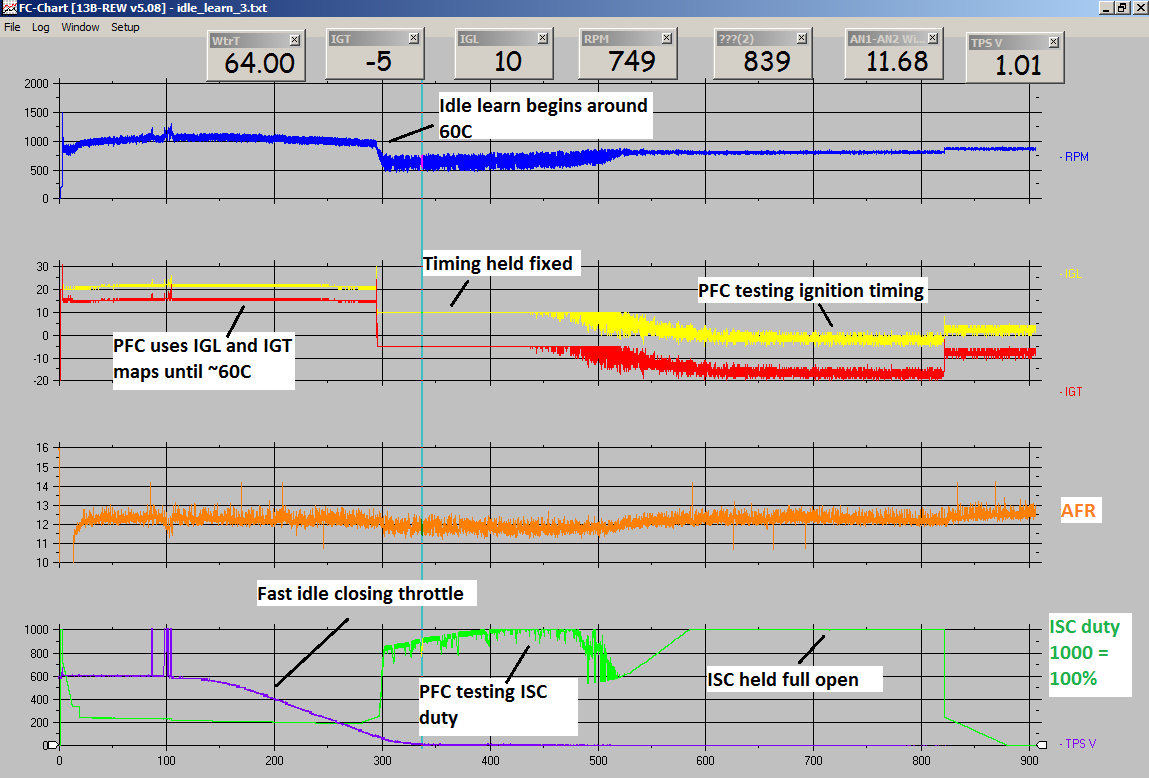

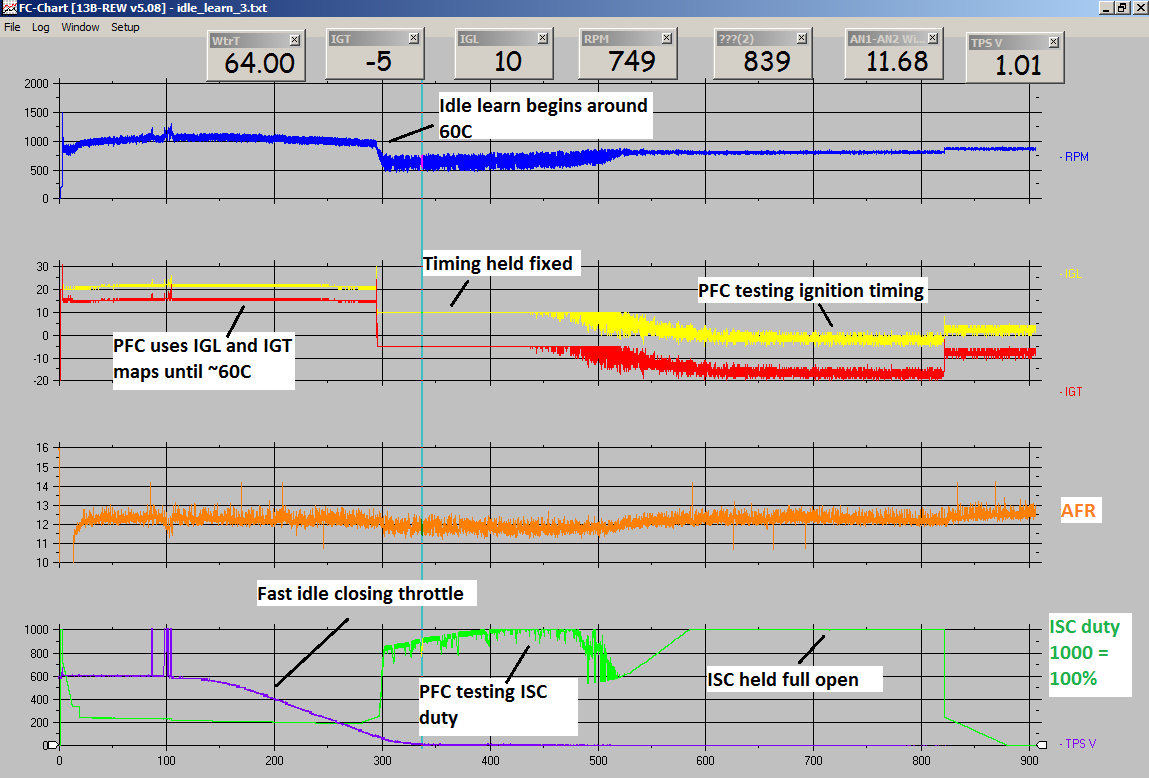

I recently figured out how to log ISC valve duty cycle with the Datalogit, shown as the bottom chart in the log below. Who would've thought that it's labeled with 3 question marks, parentheses, and the number 2? aka Advanced ??? (2). Here is a log of a street ported FD with stock sequential twins, 550/1300 injectors, and stock rats nest (ISC valve and fast idle cam). The FD is hot starting (which is normally not problematic on most healthy engines). The fast idle is not active and the accelerator pedal is not being pressed. Idle IG control is not on and idle speed is set to 850, so ignition timing is fixed during normal idle depending on electrical load etc.

Here are a few things to notice in this log. As I said, it is a hot start with coolant temperature heat soaking at 102C. Fast idle cam is down due to the temperature; if it were active, TPS voltage (VTA1 under Commander sensor/sw select) would be closer to 1 volt and narrow range TPS voltage (VTA2) would likely be over 1 volt. This is because the fast idle cam is the same as you hitting the gas pedal a little bit during cranking.

In this log the cranking speed is around 180rpm which is a little slow, but the battery was a bit discharged on this car. The four yellow cells in the IGL map trace the cells that the PFC is falling into when determining ignition timing during cranking . On default PFC calibrations there is a 15 degree ignition retard value for water temps below 60 C. I believe applies to cranking ignition timing as well, but I don't have a log which verifies that.

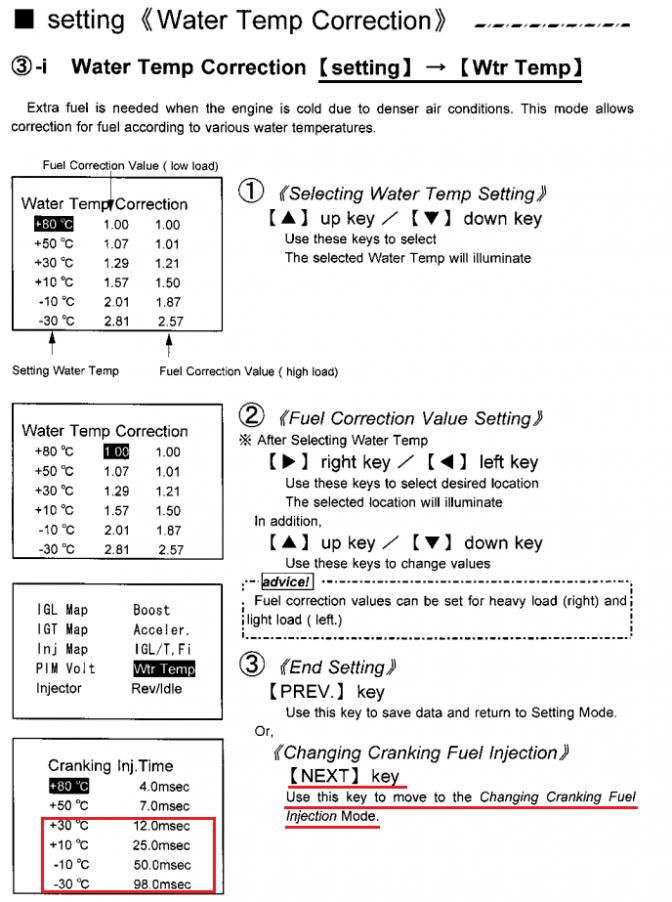

Cranking fuel injection, which is labeled here as InjFrPR (Advance InjFrPr, only loggable with a Datalogit), is initially at 13.56 msec and then tapers down. The 80C value for cranking fuel is 12 msec by default, so there must be some unseen correction added in there to increase the fuel. Cranking fuel is NOT determined by the INJ map, don't get confused.

The bottom chart is ISC valve duty. As soon as the engine begins to turn over, the ISC valve goes to full open (100%, labeled as 1000 in the PFC). As the engine fires up, engine speed rises over 2000rpm as a result of the ISC duty and the ignition timing values (throttle plate is closed the whole time). The ISC duty tapers down and idle speed falls.

Cranking Ignition Timing

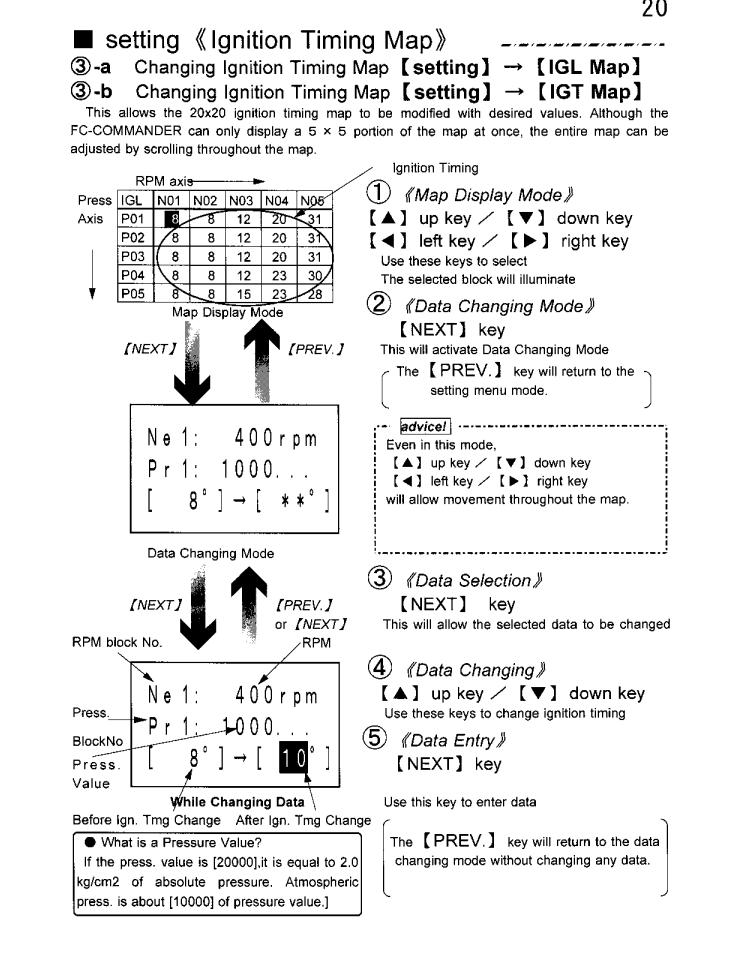

To adjust cranking ignition timing, use the IGL and IGT screens:

Locate the matrix of N1-N2, P9-P10. Go to the IGL screen and try advancing the leading timing in increments of 5 degrees. So take the value that's in there and add 5 to it. Then try setting the corresponding trailing cell to the same value, resulting in a trailing split of zero degrees. So for example, if our IGL N1-P10 value is 6 degrees, set that to 11. Find the same cell in the IGT map and set it to 11 degrees as well. Do this for the whole cranking matrix. I wouldn't increase the leading cranking timing any more than 15 degrees over the original value.

Cranking Fuel

Note: some aftermarket FPR's don't hold fuel pressure as well when the engine is turned off. This in itself can make cold starts a little slower despite changes to the cranking fuel map.

The 50C and 80C settings rarely need to be changed, I wouldn't touch them. For the other temperatures you can try multiplying the cranking values by an adjustment percentage. For example, at 30C I may want to increase my cranking fuel by 10%. Say I had a value of 15 msec. I multiply by 1.10 for a final value of 16.5. I input this value (or whatever number closest that the PFC will allow). Then I apply the same percentage correction to the 10C, -10C, and -30C values. On most setups I would not add any more than 15% additional cold start cranking fuel. It might flood or (more likely) just not help any more.

So to review: Changing porting or injectors, removal of the ISC valve/fast idle, or changing the FPR may result in slower cranking times. Startability can be improved in many cases by advancing the timing (increase IGL values and set IGT value to match IGL) or increasing fuel through by a percentage. You probably won't need to adjust fuel and timing on setups with stock primary injectors and FPR that also retain the ISC valve and fast idle cam.

When you start removing idle control components or changing primary injectors you may find that the car takes longer to start, or won't start without using the accelerator pedal. This problem can often be improved with fuel and timing changes, although not necessarily eliminated.

Factors that affect cranking and starting:

-- Cranking speed, which is affected by battery voltage, the health of the starter, oil temperature, and oil viscosity

-- Cranking ignition timing, a function of the N1-P2, P9-P10 cells of the IGL and IGT maps and [unconfirmed] the ignition timing retard setting in the Datalogit

-- Fuel pressure

-- Throttle plate opening angle (VTA1 and VTA2 tps voltages), affected by the fast idle cam position (if still installed), the primary throttle plate adjust screw, and whether the accelerator pedal is being pressed

-- ISC valve duty cycle (if still installed), which will be 100% during cranking and then taper down

My latest testing indicates that even with Idle IG control on, the PFC will use the values from the IGL and IGT map until the engine is partially warmed up (about 60C ?). I will have to verify this, but it should also apply a warm up timing retard correction on top of the values in the maps. The warm up timing retard is 15 degrees by default until water temp reaches 60C. It is only adjustable with a Datalogit. A lot of tuners disable it, but there are times when it can be useful for smoothing out idle during warmup.

I recently figured out how to log ISC valve duty cycle with the Datalogit, shown as the bottom chart in the log below. Who would've thought that it's labeled with 3 question marks, parentheses, and the number 2? aka Advanced ??? (2). Here is a log of a street ported FD with stock sequential twins, 550/1300 injectors, and stock rats nest (ISC valve and fast idle cam). The FD is hot starting (which is normally not problematic on most healthy engines). The fast idle is not active and the accelerator pedal is not being pressed. Idle IG control is not on and idle speed is set to 850, so ignition timing is fixed during normal idle depending on electrical load etc.

Here are a few things to notice in this log. As I said, it is a hot start with coolant temperature heat soaking at 102C. Fast idle cam is down due to the temperature; if it were active, TPS voltage (VTA1 under Commander sensor/sw select) would be closer to 1 volt and narrow range TPS voltage (VTA2) would likely be over 1 volt. This is because the fast idle cam is the same as you hitting the gas pedal a little bit during cranking.

In this log the cranking speed is around 180rpm which is a little slow, but the battery was a bit discharged on this car. The four yellow cells in the IGL map trace the cells that the PFC is falling into when determining ignition timing during cranking . On default PFC calibrations there is a 15 degree ignition retard value for water temps below 60 C. I believe applies to cranking ignition timing as well, but I don't have a log which verifies that.

Cranking fuel injection, which is labeled here as InjFrPR (Advance InjFrPr, only loggable with a Datalogit), is initially at 13.56 msec and then tapers down. The 80C value for cranking fuel is 12 msec by default, so there must be some unseen correction added in there to increase the fuel. Cranking fuel is NOT determined by the INJ map, don't get confused.

The bottom chart is ISC valve duty. As soon as the engine begins to turn over, the ISC valve goes to full open (100%, labeled as 1000 in the PFC). As the engine fires up, engine speed rises over 2000rpm as a result of the ISC duty and the ignition timing values (throttle plate is closed the whole time). The ISC duty tapers down and idle speed falls.

Cranking Ignition Timing

To adjust cranking ignition timing, use the IGL and IGT screens:

Locate the matrix of N1-N2, P9-P10. Go to the IGL screen and try advancing the leading timing in increments of 5 degrees. So take the value that's in there and add 5 to it. Then try setting the corresponding trailing cell to the same value, resulting in a trailing split of zero degrees. So for example, if our IGL N1-P10 value is 6 degrees, set that to 11. Find the same cell in the IGT map and set it to 11 degrees as well. Do this for the whole cranking matrix. I wouldn't increase the leading cranking timing any more than 15 degrees over the original value.

Cranking Fuel

Note: some aftermarket FPR's don't hold fuel pressure as well when the engine is turned off. This in itself can make cold starts a little slower despite changes to the cranking fuel map.

The 50C and 80C settings rarely need to be changed, I wouldn't touch them. For the other temperatures you can try multiplying the cranking values by an adjustment percentage. For example, at 30C I may want to increase my cranking fuel by 10%. Say I had a value of 15 msec. I multiply by 1.10 for a final value of 16.5. I input this value (or whatever number closest that the PFC will allow). Then I apply the same percentage correction to the 10C, -10C, and -30C values. On most setups I would not add any more than 15% additional cold start cranking fuel. It might flood or (more likely) just not help any more.

So to review: Changing porting or injectors, removal of the ISC valve/fast idle, or changing the FPR may result in slower cranking times. Startability can be improved in many cases by advancing the timing (increase IGL values and set IGT value to match IGL) or increasing fuel through by a percentage. You probably won't need to adjust fuel and timing on setups with stock primary injectors and FPR that also retain the ISC valve and fast idle cam.

#36

Idle learn Procedure explained

Below is a partial log of an idle learn procedure being performed on a cold engine. This engine is running an ISC valve, fast idle system, PFC controlled idle with o2 feedback off. doing. The log is from over a year ago so I don't have the actual map I was running with it.

In this log the engine starts and up until 60C the idle control is in open loop. The PFC uses the timing values in the IGL and IGT maps. ISC duty is mostly fixed at 20%. The TPS voltage slowly drops as the hot coolant flows through the fast idle system. The voltage drop is somewhat exaggerated here due to the scaling I have chosen to illustrate it.

As the learning procedure begins, the PFC sets the leading and trailing timing to fixed values. It then varies the ISC duty as part of the learning process. Then the ISC duty is held fixed and the PFC tests ignition. At the very end of the log the idle speed has begun to stabilize as the engine fully warms up. I do not have a log of the electrical load and A/C portions of the learning procedure, but they may work in a similar way.

So does it matter whether the engine is cold or warm when performing the learning procedure? From what I've seen, I don't think so. I have tried it both ways and the PFC still tests ISC duty and timing.

In this log the engine starts and up until 60C the idle control is in open loop. The PFC uses the timing values in the IGL and IGT maps. ISC duty is mostly fixed at 20%. The TPS voltage slowly drops as the hot coolant flows through the fast idle system. The voltage drop is somewhat exaggerated here due to the scaling I have chosen to illustrate it.

As the learning procedure begins, the PFC sets the leading and trailing timing to fixed values. It then varies the ISC duty as part of the learning process. Then the ISC duty is held fixed and the PFC tests ignition. At the very end of the log the idle speed has begun to stabilize as the engine fully warms up. I do not have a log of the electrical load and A/C portions of the learning procedure, but they may work in a similar way.

So does it matter whether the engine is cold or warm when performing the learning procedure? From what I've seen, I don't think so. I have tried it both ways and the PFC still tests ISC duty and timing.

#38

WOW... yes.

great new Information here..

from my point of view I can give some additional informations, too.

This might be some information tuners could have made alot of money with...

but for you, its for free!

A DAMN!Nice motorsports gift.

First of all some informations about my circumstances to understand why and how I did what I did.

As I bought my car, it already had 850 primaries installed.

I never had issues with the 850s in terms of driveability etc.

Now that I have my parts together to go for tuning (Datalogit, wideband, EGT, etc.) I started out improving every part of the map.

One of those is the idle.

Idle was High and rich (so smelly) all the time.

I had two problems with this fact:

1. my girlsfriend always talked bad about my smelly car

2. emmision tests here in germany are really really strict.

So I tried some things, already posted on this forum to lean it out:

- change lag-time to negative values

- lower idle rpm

- negative split.

As arghx showed on his posts, is the Idle controlled by the PFC:

- fuel wise if you turn on "O2 control"

- Ignition wise, if you turn on "IG control"

If you turn out both, it uses a fixed idle Ignition timing.

So yesterday I tried to set idle rpm to 0 to achieve the negative split on idle.

To my surprise. there wasn`t to much change. so it seemed that my idle (skrews) was set real nicely (mechanically).

then I started to tinker around with the timing. leading and trailling.

Here to sum up for you:

1. It is not that important which coil fires first (leading or trailling). there is one thing you should know.

the first one is responsible for the torque.

so I tested some things.

I used the standard PFC - fixed ignition times.

so leading = -5

trailling = -20

and then I switched those two.

The result was, the idle began to change in terms of sound, completely. It wasn´t that smooth as before but still accapteable.

Big difference was AFR: they changed from 12,7 to around 13,2

so i advanced trailling idle to around 0 to get a smoother more strong idle.

AFRs dropped a bit by doing so, but I was able to get a smooth idle.

then I realized that the great AFRs are because of the late firing of the leading plug which seems to work perfect as a waste ignition. (ignition all of the fuel rest)

by tinkering around some more with the idle adjust skrew and trailling timing, I was able to get a idle @ 700rpm @ 14AFR with 850 primaries which was also stable when I swiched on every electrical load by using those values:

(please keep in mind that it worked on my car. It might not work on yours!)

lag time: -0.26

timing:

when I´ve tested it under different conditions (it was 35°C yesterday [95°F])

I´ll post some logs.

Maybe I have to play with my idle adjust skrews some more to keep idle where I want it to be. But I think it is possible.

One more thing is startup of the engine.

Arghx is right.

When ISC isn´t working you probably will have the need to start up with throttle pushed in.

On my car it was able to start without, but alot worse then before!

Good luck to you all finding the perfect way.

I hope my information could help some people heaving problems with emission tests.

lean Idle is key on those tests...

regards

Marc

great new Information here..

from my point of view I can give some additional informations, too.

This might be some information tuners could have made alot of money with...

but for you, its for free!

A DAMN!Nice motorsports gift.

First of all some informations about my circumstances to understand why and how I did what I did.

As I bought my car, it already had 850 primaries installed.

I never had issues with the 850s in terms of driveability etc.

Now that I have my parts together to go for tuning (Datalogit, wideband, EGT, etc.) I started out improving every part of the map.

One of those is the idle.

Idle was High and rich (so smelly) all the time.

I had two problems with this fact:

1. my girlsfriend always talked bad about my smelly car

2. emmision tests here in germany are really really strict.

So I tried some things, already posted on this forum to lean it out:

- change lag-time to negative values

- lower idle rpm

- negative split.

As arghx showed on his posts, is the Idle controlled by the PFC:

- fuel wise if you turn on "O2 control"

- Ignition wise, if you turn on "IG control"

If you turn out both, it uses a fixed idle Ignition timing.

So yesterday I tried to set idle rpm to 0 to achieve the negative split on idle.

To my surprise. there wasn`t to much change. so it seemed that my idle (skrews) was set real nicely (mechanically).

then I started to tinker around with the timing. leading and trailling.

Here to sum up for you:

1. It is not that important which coil fires first (leading or trailling). there is one thing you should know.

the first one is responsible for the torque.

so I tested some things.

I used the standard PFC - fixed ignition times.

so leading = -5

trailling = -20

and then I switched those two.

The result was, the idle began to change in terms of sound, completely. It wasn´t that smooth as before but still accapteable.

Big difference was AFR: they changed from 12,7 to around 13,2

so i advanced trailling idle to around 0 to get a smoother more strong idle.

AFRs dropped a bit by doing so, but I was able to get a smooth idle.

then I realized that the great AFRs are because of the late firing of the leading plug which seems to work perfect as a waste ignition. (ignition all of the fuel rest)

by tinkering around some more with the idle adjust skrew and trailling timing, I was able to get a idle @ 700rpm @ 14AFR with 850 primaries which was also stable when I swiched on every electrical load by using those values:

(please keep in mind that it worked on my car. It might not work on yours!)

lag time: -0.26

timing:

when I´ve tested it under different conditions (it was 35°C yesterday [95°F])

I´ll post some logs.

Maybe I have to play with my idle adjust skrews some more to keep idle where I want it to be. But I think it is possible.

One more thing is startup of the engine.

Arghx is right.

When ISC isn´t working you probably will have the need to start up with throttle pushed in.

On my car it was able to start without, but alot worse then before!

Good luck to you all finding the perfect way.

I hope my information could help some people heaving problems with emission tests.

lean Idle is key on those tests...

regards

Marc

#40

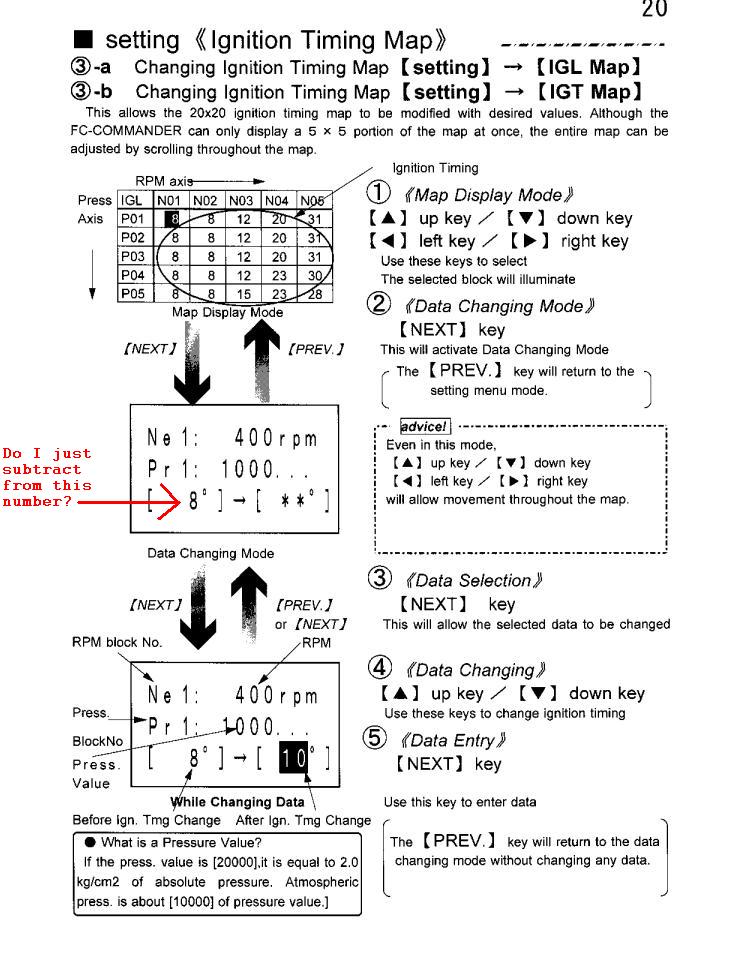

The basemap trailing timing on the PFC model #414-Z004 , the model that most people have, is less safe once you get over about 10psi (and the timing progression is sloppy). But the safety aspect is correctable even with a Commander just by tediously going through the IGT screen, rows P16-P18 (8.5psi to 14 psi range), and retarding the timing (decrease the timing value) by about 4 degrees in every cell over say 2400 rpm (N7 and higher columns in the commander). So take whatever value is in a particular cell, subtract 4 from it, and then input that new value in the cell.

I have. P16

(N7=2) (N8=3) (N9=4) (N10=4) (N11-4) (N12=5) (N13=5) (N14=5) (N15=4) (N16=5) (N17=6) (N18=9) (N19=13) (N20=14)

So if I fallow your intructions I shuld change it to this? P16

(N7= -2) (N8= -1) (N9= 0) (N10=0) (N11=0) (N12=1) (N13=1) (N14=1) (N15=0) (N16=1) (N17=2) (N18=5) (N19=9) (N20=10)

One othere thing please check out the pic. Do I just subtract from that number and leave the rest as is?

#41

Sorry for being dump but i am new to my power fc. If I follow your timing how to for the power fc.

I have. P16

(N7=2) (N8=3) (N9=4) (N10=4) (N11-4) (N12=5) (N13=5) (N14=5) (N15=4) (N16=5) (N17=6) (N18=9) (N19=13) (N20=14)

So if I fallow your intructions I shuld change it to this? P16

(N7= -2) (N8= -1) (N9= 0) (N10=0) (N11=0) (N12=1) (N13=1) (N14=1) (N15=0) (N16=1) (N17=2) (N18=5) (N19=9) (N20=10)

I have. P16

(N7=2) (N8=3) (N9=4) (N10=4) (N11-4) (N12=5) (N13=5) (N14=5) (N15=4) (N16=5) (N17=6) (N18=9) (N19=13) (N20=14)

So if I fallow your intructions I shuld change it to this? P16

(N7= -2) (N8= -1) (N9= 0) (N10=0) (N11=0) (N12=1) (N13=1) (N14=1) (N15=0) (N16=1) (N17=2) (N18=5) (N19=9) (N20=10)

One othere thing please check out the pic. Do I just subtract from that number and leave the rest as is?

I'm not exactly sure what you mean by "the rest" but yes that number on the left is the number you are starting with, and the number on the right is the number you will be changing it to.

#42

So for example in the picture provided. I leave the 8 number alone and subtract 4 from it which equals 4 and input the # 4 on the right and leave the 8 alone as is? What I mean by the rest is that if I hit left, right, up or down the numbers at the top also change. I think I saw that if I hit up it gives me a different number at the top then when I hit the right botton.

#43

I leave the 8 number alone and subtract 4 from it which equals 4 and input the # 4 on the right

What I mean by the rest is that if I hit left, right, up or down the numbers at the top also change. I think I saw that if I hit up it gives me a different number at the top then when I hit the right botton.

#45

Acceleration Enrichment and Stumbling

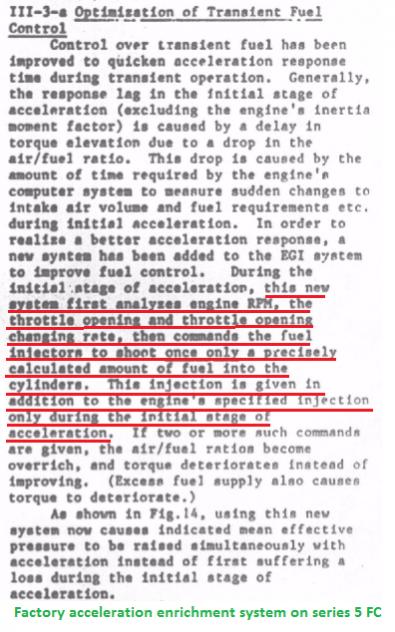

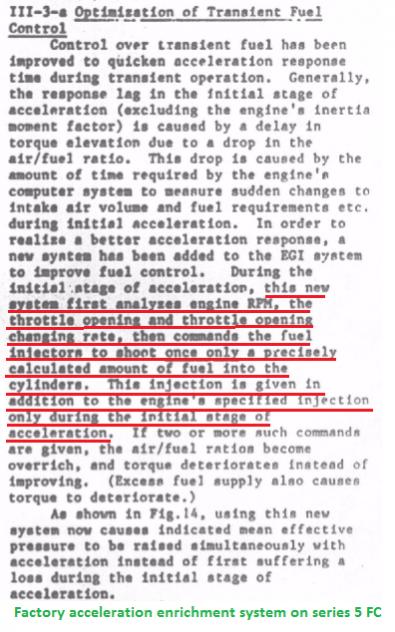

One of the common problems on these engines, especially ones that are ported, is a stumble as the throttle opens. At one point I doubted this, but I now believe that the PFC delivers one major shot of fuel as the throttle opens. It is most likely "asynchronous," where the primary injectors fire at the same time and the normal injector firing order is ignored. Normally the injector firing order would go F primary, R primary, essentially synchronized with the top dead center signal ("G" signal) from the crank angle sensor. The tip-in fuel ignores the crank angle sensor. Just about every modern port injected gas engine does it that way, and Mazda actually describes it in an SAE paper for the series 5 FC3S Rx-7:

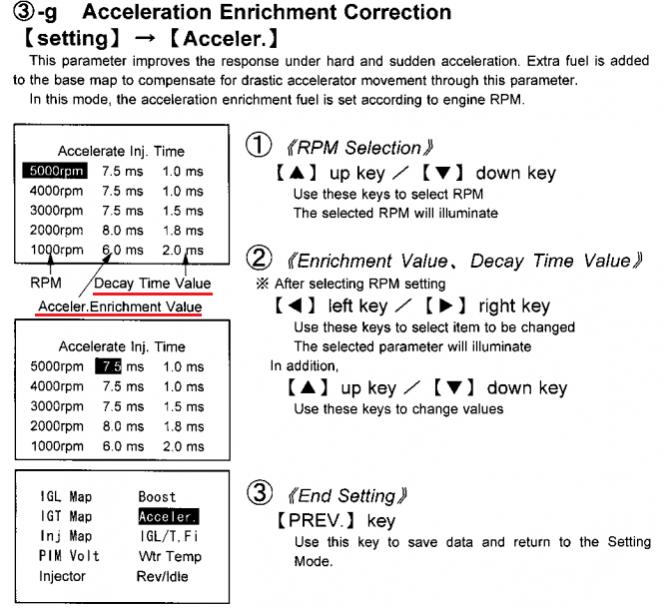

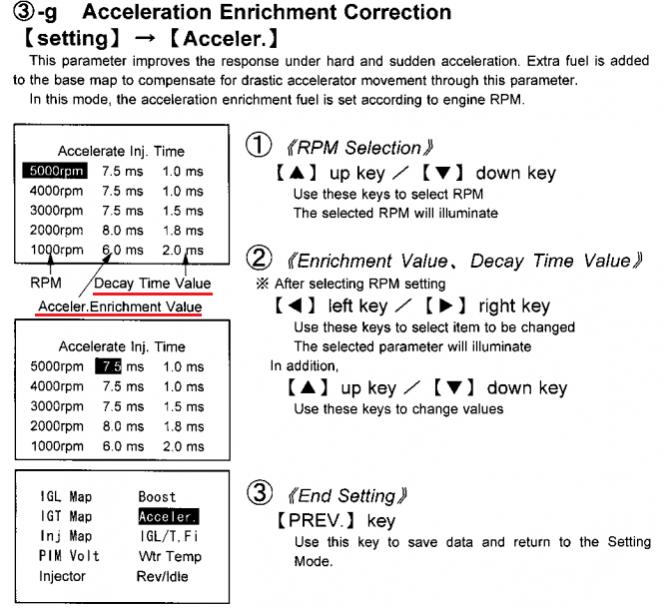

The Power FC has two main tables for this "accelerator pump" system (like on a carb) which is supposed to prevent/reduce stumbles as the throttle opens. The first one is the "Acceleration Enrichment" table, accessible in the Commander:

"Accelerate injector" is a max amount of injector pulsewidth that can be added at a given rpm, and I assume it interpolates between the rpm breakpoints. The middle column sets the max allowable pulsewidth for this extra shot of fuel at a given rpm. From what I've seen the rightmost "decay" setting has to do with how the fuel tapers off after that initial shot. The setting isn't very important and is best left alone. Playing around with that rightmost column will most likely just hurt your fuel economy in my experience.

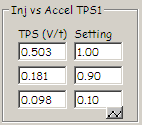

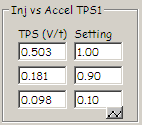

So in the Commander we can set the max allowable fuel for the "accelerator pump" in the PFC. But what if you are only moving the throttle open a little bit? If you need very fine adjustment of this type of fueling you will need a Datalogit unfortunately. The Inj vs Accel TPS1 table determines what % of this max value (Accelerate injector "amount") will actually be delivered:

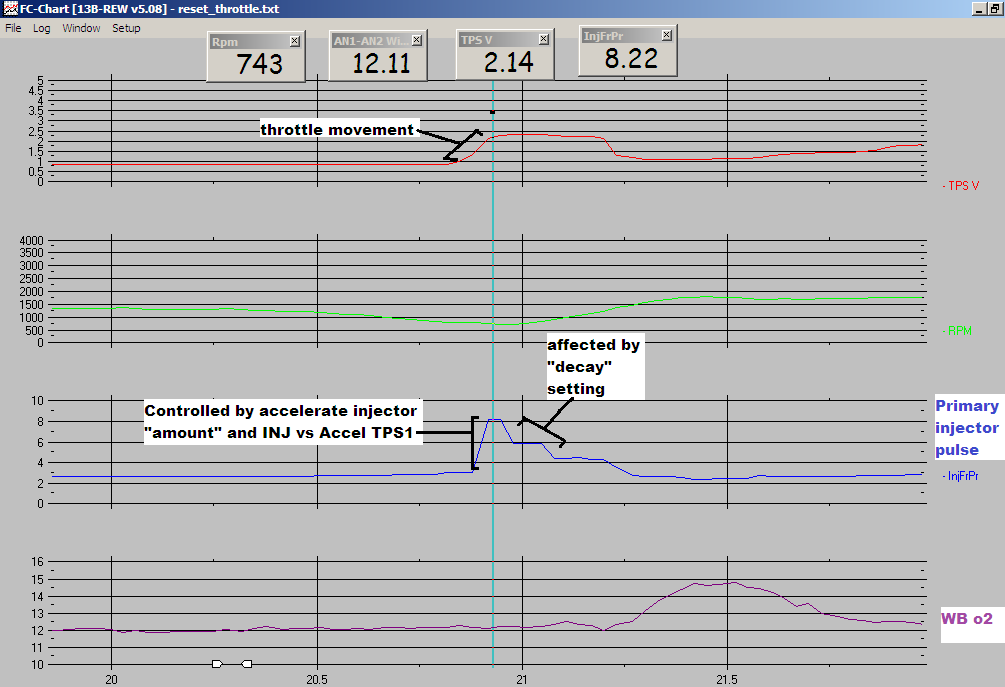

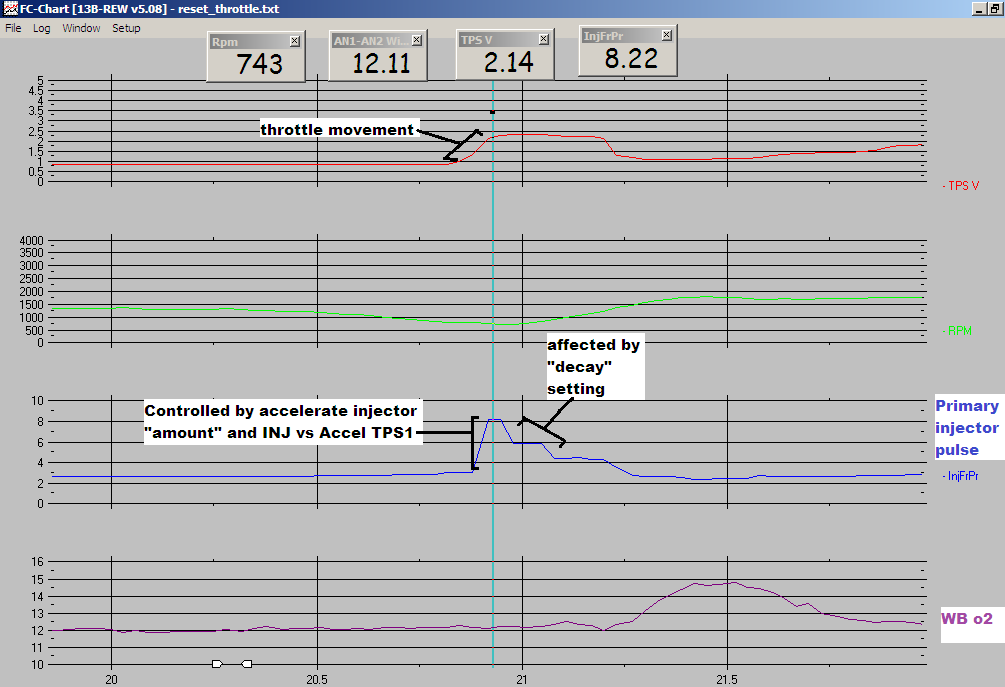

That is the factory table (viewed in the latest 2.128 FC-Edit software). On the left is the rate of change of TPS voltage (the speed at which the throttle is opening), based on change of voltage over time. On the right appears to be a multiplier of the "amount" (middle column) of the PFC Accelerate Injector/Acceleration Enrichment table. Basically the faster you stab the throttle, the more additional fuel (from the Accelerate Injector table) will be injected. This Datalogit log illustrates how these settings come into play:

As the throttle opens quickly (top red line), the PFC calculates the total amount of fuel (blue red line) it could inject based on rpm (Accelerate Injector table). Then it uses the INJ vs Accel TPS1 table to figure out what % of that maximum fuel to use based on the rate of change of TPS voltage. Finally, the "decay" value is used to taper off the fuel after the initial shot.

For those of you who don't want to get deep into tuning your own car, you could attempt to increase the values in the middle column of the "Accelerate Injector" table in the commander. It might help reduce stumbling a little, or it might just hurt your fuel economy. Most people will try to increase the millisecond values in this table by some fixed percentage, say 10%.

The Power FC has two main tables for this "accelerator pump" system (like on a carb) which is supposed to prevent/reduce stumbles as the throttle opens. The first one is the "Acceleration Enrichment" table, accessible in the Commander:

"Accelerate injector" is a max amount of injector pulsewidth that can be added at a given rpm, and I assume it interpolates between the rpm breakpoints. The middle column sets the max allowable pulsewidth for this extra shot of fuel at a given rpm. From what I've seen the rightmost "decay" setting has to do with how the fuel tapers off after that initial shot. The setting isn't very important and is best left alone. Playing around with that rightmost column will most likely just hurt your fuel economy in my experience.

So in the Commander we can set the max allowable fuel for the "accelerator pump" in the PFC. But what if you are only moving the throttle open a little bit? If you need very fine adjustment of this type of fueling you will need a Datalogit unfortunately. The Inj vs Accel TPS1 table determines what % of this max value (Accelerate injector "amount") will actually be delivered:

That is the factory table (viewed in the latest 2.128 FC-Edit software). On the left is the rate of change of TPS voltage (the speed at which the throttle is opening), based on change of voltage over time. On the right appears to be a multiplier of the "amount" (middle column) of the PFC Accelerate Injector/Acceleration Enrichment table. Basically the faster you stab the throttle, the more additional fuel (from the Accelerate Injector table) will be injected. This Datalogit log illustrates how these settings come into play:

As the throttle opens quickly (top red line), the PFC calculates the total amount of fuel (blue red line) it could inject based on rpm (Accelerate Injector table). Then it uses the INJ vs Accel TPS1 table to figure out what % of that maximum fuel to use based on the rate of change of TPS voltage. Finally, the "decay" value is used to taper off the fuel after the initial shot.

For those of you who don't want to get deep into tuning your own car, you could attempt to increase the values in the middle column of the "Accelerate Injector" table in the commander. It might help reduce stumbling a little, or it might just hurt your fuel economy. Most people will try to increase the millisecond values in this table by some fixed percentage, say 10%.

#46

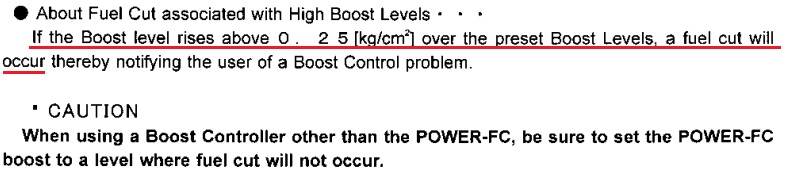

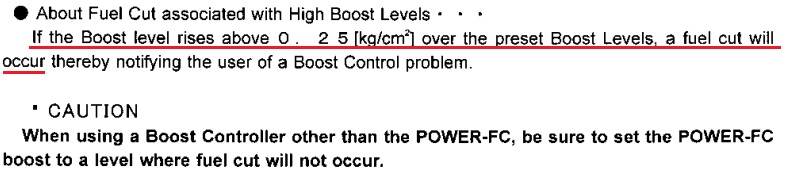

Overboost Fuel Cut with External Boost Controllers

Note: revised 11/22/2010 to correct/clarify certain points per Raymond's request by Gracer7-rx7

If you are using an external boost controller, you must adjust the Power FC overboost fuel cut. You have two options:

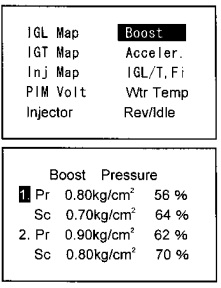

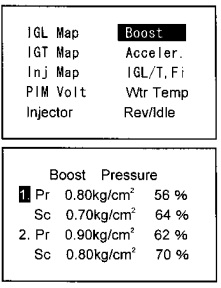

-- You can disable the overboost fuel cut entirely. The main advantage of this choice is that you can very quickly raise boost with your separate boost controller without being concerned about the Power FC interfering. Without any "last resort" overboost protection you could blow your motor if boost control fails. This overboost fuel cut isn't the only way to protect the motor in the event of a boost control failure, but it is the simplest to implement. Now to effectively disable the overboost fuel cut, go into the boost control screen on the Commander:

Select option 1 and adjust the boost setting to 2.00 kg/cm^2. So you want option 1 to read

Pr 2.00

Sc 2.00

the duty % settings don't matter because you are using a separate controller.

-- You can set an overboost fuel cut relative to your intended boost level. So if/when you raise the boost on your external controller you will probably need to raise the fuel cut in the PFC. There are two boost/fuel cut settings allowed in the PFC, so you could have option 1 be your low boost fuel cut setting and option 2 be your high boost fuel cut setting.

Configuring Overboost Fuel Cut -- Stock MAP Sensor With Default Calibration

The PFC instructions mention that overboost fuel cut occurs .25 kg/cm^2 higher than the boost setting in the Commander. My own testing says it can sometimes kick in at a little less boost than that, maybe .22 kg/cm^2 higher than the target boost. This section will show you how to set up the boost settings correctly for overboost fuel cut. Many/most people reading this guide are running the stock MAP sensor with the Apex'i default calibration. The default MAP sensor calibration reads boost slightly low so I have added an additional step to account for this.

1) Figure out what you want your fuel cut to be in psi and then convert to kg/cm^2. One guideline to follow is to set fuel cut about 2psi higher than your normal intended boost. So if I want to run 10psi I could set my fuel cut to 12psi.

To convert 12psi to kg/cm^2, divide it by 14.22 and then round up. 12 / 14.22 = .84 kg/cm^2, then round up to .85 kg/cm^2 .

2) Subtract .05 kg/cm^2 from the value in step 1. This is a rough compensation for the fact that the default MAP sensor calibration reads low. .85 kg/cm^2 - .05 kg/cm^2 = .80 kg/cm^2 . You will skip step 2 if you are not using the stock MAP sensor with default calibration.

3. Subtract .25 kg/cm^2 from the value you just calculated to get the final boost setting you will be using. So .80 kg/cm^2 - .25 kg/cm^2 = .55 kg/cm^2

4. Go to the boost control screen in your commander. Select the option you want to use, and set Pr and Sc boost setting to that final value you just calculated. So in this case if you wanted to use option 1 with a ~12psi fuel cut, you would want your setting to be:

Pr .55

Sc .55

This is a guideline value. Decreasing this number will make the fuel cut kick in sooner, while increasing this number will allow more overboosting before the fuel cut kicks in. You could also set option 2 to higher values, and then switch to it when you raise the boost on your external controller.

Configuring Overboost Fuel Cut -- other MAP sensor/calibration

If you have recalibrated the factory sensor or you are using some other MAP sensor such as a GM 3 bar, the calibration should read more accurately. Setting up the fuel cut is the same basic process, we are just going to skip step 2 above. So for a ~12psi fuel cut:

12 psi / 14.22 = .843 --> .85 kg/cm^2 . Subtract .25 kg/cm^2 and you get a setting of .60 kg/cm^2 . So set your boost control to Pr .60 Sc .60 and you're done.

If you are using an external boost controller, you must adjust the Power FC overboost fuel cut. You have two options:

-- You can disable the overboost fuel cut entirely. The main advantage of this choice is that you can very quickly raise boost with your separate boost controller without being concerned about the Power FC interfering. Without any "last resort" overboost protection you could blow your motor if boost control fails. This overboost fuel cut isn't the only way to protect the motor in the event of a boost control failure, but it is the simplest to implement. Now to effectively disable the overboost fuel cut, go into the boost control screen on the Commander:

Select option 1 and adjust the boost setting to 2.00 kg/cm^2. So you want option 1 to read

Pr 2.00

Sc 2.00

the duty % settings don't matter because you are using a separate controller.

-- You can set an overboost fuel cut relative to your intended boost level. So if/when you raise the boost on your external controller you will probably need to raise the fuel cut in the PFC. There are two boost/fuel cut settings allowed in the PFC, so you could have option 1 be your low boost fuel cut setting and option 2 be your high boost fuel cut setting.

Configuring Overboost Fuel Cut -- Stock MAP Sensor With Default Calibration

The PFC instructions mention that overboost fuel cut occurs .25 kg/cm^2 higher than the boost setting in the Commander. My own testing says it can sometimes kick in at a little less boost than that, maybe .22 kg/cm^2 higher than the target boost. This section will show you how to set up the boost settings correctly for overboost fuel cut. Many/most people reading this guide are running the stock MAP sensor with the Apex'i default calibration. The default MAP sensor calibration reads boost slightly low so I have added an additional step to account for this.

1) Figure out what you want your fuel cut to be in psi and then convert to kg/cm^2. One guideline to follow is to set fuel cut about 2psi higher than your normal intended boost. So if I want to run 10psi I could set my fuel cut to 12psi.

To convert 12psi to kg/cm^2, divide it by 14.22 and then round up. 12 / 14.22 = .84 kg/cm^2, then round up to .85 kg/cm^2 .

2) Subtract .05 kg/cm^2 from the value in step 1. This is a rough compensation for the fact that the default MAP sensor calibration reads low. .85 kg/cm^2 - .05 kg/cm^2 = .80 kg/cm^2 . You will skip step 2 if you are not using the stock MAP sensor with default calibration.

3. Subtract .25 kg/cm^2 from the value you just calculated to get the final boost setting you will be using. So .80 kg/cm^2 - .25 kg/cm^2 = .55 kg/cm^2

4. Go to the boost control screen in your commander. Select the option you want to use, and set Pr and Sc boost setting to that final value you just calculated. So in this case if you wanted to use option 1 with a ~12psi fuel cut, you would want your setting to be:

Pr .55

Sc .55

This is a guideline value. Decreasing this number will make the fuel cut kick in sooner, while increasing this number will allow more overboosting before the fuel cut kicks in. You could also set option 2 to higher values, and then switch to it when you raise the boost on your external controller.

Configuring Overboost Fuel Cut -- other MAP sensor/calibration

If you have recalibrated the factory sensor or you are using some other MAP sensor such as a GM 3 bar, the calibration should read more accurately. Setting up the fuel cut is the same basic process, we are just going to skip step 2 above. So for a ~12psi fuel cut:

12 psi / 14.22 = .843 --> .85 kg/cm^2 . Subtract .25 kg/cm^2 and you get a setting of .60 kg/cm^2 . So set your boost control to Pr .60 Sc .60 and you're done.

Last edited by gracer7-rx7; 11-22-10 at 01:53 AM. Reason: revised 11/22/2010 per Raymond's request by Gracer7-rx7

#48

Planning my come back

iTrader: (7)

Join Date: Feb 2003

Location: Austin, Tx

Posts: 3,393

Likes: 0

Received 0 Likes

on

0 Posts

Okay I went ahead and changed my Ign Map to the older version using datalogit. If I understand it, it is a better map than the older version, correct?

Now I want to make my fuel maps safer, any tips?

I'm just want to be extra careful when doing this since I never dealt with this before.

Now I want to make my fuel maps safer, any tips?

I'm just want to be extra careful when doing this since I never dealt with this before.

#49

Now I want to make my fuel maps safer, any tips?

I'm just want to be extra careful when doing this since I never dealt with this before.

#50

Planning my come back

iTrader: (7)

Join Date: Feb 2003

Location: Austin, Tx

Posts: 3,393

Likes: 0

Received 0 Likes

on

0 Posts

What I did was changed my 5.08 ignition map to the 2.01 map thinking it was the changes you commented on. I just realized what the changes are for the 5.08 map. I'm going now to change the ignition map to the original then retard the ignition like you posted. My car has all the bolts ons and I went ahead and increase my fuel to 110% on all RPMS.