GTC nose rebar concept

#1

GTC nose rebar concept

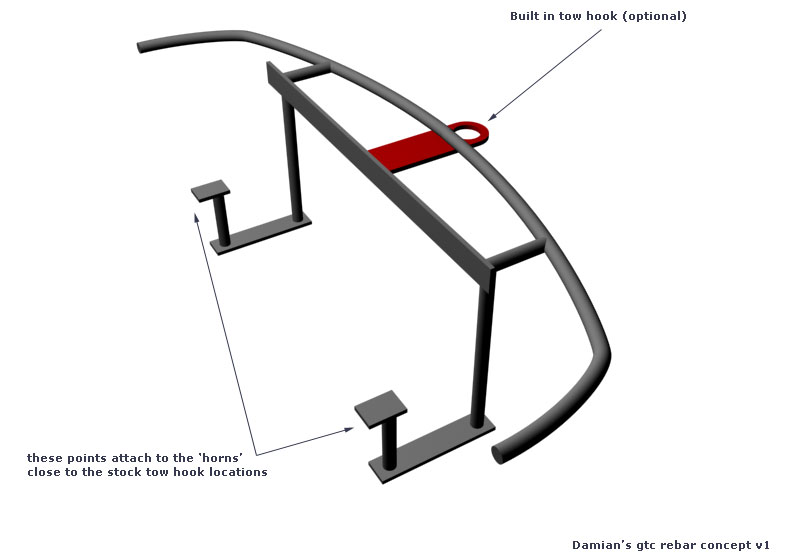

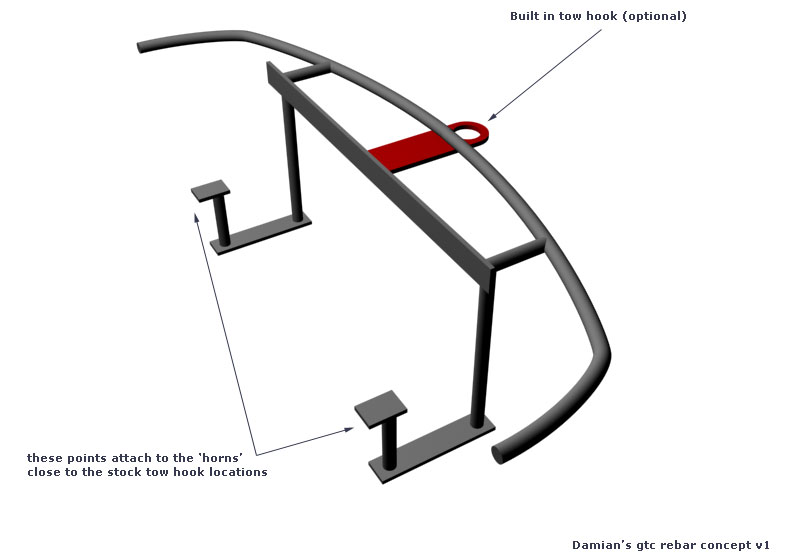

Ok, I mentioned in the GTC nose threads about a concept for a GTC rebar I had thought about a while back. Here are some notes and a first conceptual model for the gtc rebar. Keep in mind this is meant for track car use in mind.

Rebar Goals:

Tow Hook Support

The problem with my original toe hook position was that its hard to support properly and is not on the right axis. You want the toe hook to be horizontal, not vertical, as we learned from some real world experiences. I wont get in to all the gritty details here but the idea is that you can build in a tow hook that is positioned properly and supported properly. (This would be optional.)

Splitter/undertray support

Another goal is to provide support for a full undertray/splitter. The concept here is to allow the rebar to support the undertray/splitter rather than the nose itself supporting it. This will be even more important if the nose is made from a more flexible material like RFP rather than fiberglass.

'Bump' protection

In race car terms, this really is just a 'bumper bar'. In a race situation, you want a bumper bar to protect the nose from collapsing in the event of a small bump as well as protects what is behind the bar (oil coolers, radiator ducting, et). Also, in the unfortunate event of a harder impact, the rebar provides a structure for the impact energy to go into, hopefully bending up the rebar before it bends up the actual car frame. This may lead to making the short connecting bars at an angle instead of straight as they are now in the concept model.

Here is a 3D conceptual rendering I made:

For reference, here is a shot with the nose on:

a shot with the nose off:

a composite of my rebar concept in place:

I have a lot of details to think about and options to look into, but its a start.

Rebar Goals:

Tow Hook Support

The problem with my original toe hook position was that its hard to support properly and is not on the right axis. You want the toe hook to be horizontal, not vertical, as we learned from some real world experiences. I wont get in to all the gritty details here but the idea is that you can build in a tow hook that is positioned properly and supported properly. (This would be optional.)

Splitter/undertray support

Another goal is to provide support for a full undertray/splitter. The concept here is to allow the rebar to support the undertray/splitter rather than the nose itself supporting it. This will be even more important if the nose is made from a more flexible material like RFP rather than fiberglass.

'Bump' protection

In race car terms, this really is just a 'bumper bar'. In a race situation, you want a bumper bar to protect the nose from collapsing in the event of a small bump as well as protects what is behind the bar (oil coolers, radiator ducting, et). Also, in the unfortunate event of a harder impact, the rebar provides a structure for the impact energy to go into, hopefully bending up the rebar before it bends up the actual car frame. This may lead to making the short connecting bars at an angle instead of straight as they are now in the concept model.

Here is a 3D conceptual rendering I made:

For reference, here is a shot with the nose on:

a shot with the nose off:

a composite of my rebar concept in place:

I have a lot of details to think about and options to look into, but its a start.

#6

Rotary Freak

Join Date: Dec 2001

Location: Macungie, Pennsylvania

Posts: 1,802

Likes: 0

Received 0 Likes

on

0 Posts

It's a nice concept Damian. I know it's just a mock up but from the looks of it, you're going to have to bend the bar in more toward the car (at the corners of the bumper). Looks like it'll the bumper when installing. Also, I went back and forth looking at the pics and it looks like the bar may have to drop down a bit to clear the signal lights. I would be interested in one of these bars seeing I also have a GTC bumper. Do you think it will clear a front mount intercooler?......<<<<After further review, it looks like it could double as a nice support for a front mount!

#7

Place your ad here...

Looks good damian,

Couple of small points from a mechanical engineering perspective:

- Packaging/shipping. I assume that the goal is to eventually sell these to the public. This means that you need the ability to package and ship the product nationwide. In it's current design configuration, this would be extremely difficult and costly. Consider taking the drop-supports for the undertray and make them a bolt-on item, rather than welded. This would make for much easier/cheaper packaging.

- 'Bump' protection. Adequate analysis needs to be done in this area to find the right balance of stiffness. Obviously, you don't want it too stiff, as then it will simply transfer the energy to the chassis of the car. A basic idea of the stiffness can be given from hand calculations, but a good FEA program goes a looooong way here.

- You mentioned putting the support brackets in at an angle in order to help absorb impacts. Obviously this will work if the impact is at a different angle then the supports are mounted at. Putting them at an angle may help in the right situation, but keep in mind that impacts on the track are rarely head-on. Usually you impact another car or an object (wall) at various angles. A downward angle would probably be safest, but I can still think of scenarios where it would be bad to have a downward mounted support brace.

- There are various other methods of designing stiff structures that can absorb impacts that would probably be better to use. One quick example is to use a "V" style mounting bracket (think of your supporting brackets angling outward, and then back inward). There are countless other methods, so these other options should also be explored. Keep in mind, they will probably be a little more expensive, but something that I think would be worth it.

- In your current design configuration, is the tow hook welded to the curved bar? If so, this will further increase the rigidity and tendency for the bar to simply transfer impact energy rather than absorb it. Keep this in mind when doing stiffness analysis.

What program are you using for modeling? Solidworks?

-Rob

Couple of small points from a mechanical engineering perspective:

- Packaging/shipping. I assume that the goal is to eventually sell these to the public. This means that you need the ability to package and ship the product nationwide. In it's current design configuration, this would be extremely difficult and costly. Consider taking the drop-supports for the undertray and make them a bolt-on item, rather than welded. This would make for much easier/cheaper packaging.

- 'Bump' protection. Adequate analysis needs to be done in this area to find the right balance of stiffness. Obviously, you don't want it too stiff, as then it will simply transfer the energy to the chassis of the car. A basic idea of the stiffness can be given from hand calculations, but a good FEA program goes a looooong way here.

- You mentioned putting the support brackets in at an angle in order to help absorb impacts. Obviously this will work if the impact is at a different angle then the supports are mounted at. Putting them at an angle may help in the right situation, but keep in mind that impacts on the track are rarely head-on. Usually you impact another car or an object (wall) at various angles. A downward angle would probably be safest, but I can still think of scenarios where it would be bad to have a downward mounted support brace.

- There are various other methods of designing stiff structures that can absorb impacts that would probably be better to use. One quick example is to use a "V" style mounting bracket (think of your supporting brackets angling outward, and then back inward). There are countless other methods, so these other options should also be explored. Keep in mind, they will probably be a little more expensive, but something that I think would be worth it.

- In your current design configuration, is the tow hook welded to the curved bar? If so, this will further increase the rigidity and tendency for the bar to simply transfer impact energy rather than absorb it. Keep this in mind when doing stiffness analysis.

What program are you using for modeling? Solidworks?

-Rob

Trending Topics

#8

>>Also, I went back and forth looking at the pics and it looks like the bar may have to drop down a bit to clear the signal lights.

Yeah, its hard to see from the angel i did, but its meant to go below the blinker light area.

>>Do you think it will clear a front mount intercooler?......

that I do not know :-)

>>After further review, it looks like it could double as a nice support for a front mount!

possible :-)

Yeah, its hard to see from the angel i did, but its meant to go below the blinker light area.

>>Do you think it will clear a front mount intercooler?......

that I do not know :-)

>>After further review, it looks like it could double as a nice support for a front mount!

possible :-)

#10

great comments rob,

>>- Packaging/shipping. I assume that the goal is to eventually sell these to the public. ....Consider taking the drop-supports for the undertray and make them a bolt-on item, rather than welded. This would make for much easier/cheaper packaging.

Good point, with that in mind I would plan to have certain parts bolt together.

**********

>>- 'Bump' protection. Adequate analysis needs to be done in this area to find the right balance of stiffness. Obviously, you don't want it too stiff, as then it will simply transfer the energy to the chassis of the car. A basic idea of the stiffness can be given from hand calculations, but a good FEA program goes a looooong way here.

>> - You mentioned putting the support brackets in at an angle in order to help absorb impacts. Obviously this will work if the impact is at a different angle then the supports are mounted at. Putting them at an angle may help in the right situation, but keep in mind that impacts on the track are rarely head-on.

********

All gret ideas, but I think you are taking this bar to a place were it really is not meant to be. I mentioned that impact stuff as more of a side benefit, this bar is NOT meant to be a full on impact structure, that would take a lot more design work and analysis like you mentioned. Keep in mind that right now on most gtc nose cars, there is nothing there!!! Some maybe have a modified stock rebar, but that is not exaclty a stellar matchup to the gtc nose either :-(

I should have been more clear on that too, that its really just to manage fender bumping, where having no structure behind the nose means you will collapse the nose.

But, if anyone wants to take my idea a step further I am all for it!! But for my specific need, a simple support bar that can hold up the splitter/undertray, support a proper tow hook location, and proivides some bumper protection... is all I can put resources towards right now :-)

>> In your current design configuration, is the tow hook welded to the curved bar? If so, this will further increase the rigidity and tendency for the bar to simply transfer impact energy rather than absorb it. Keep this in mind when doing stiffness analysis.

Yea, well this is a catch 22, you NEED the tow hook solidly mounted or you will blow up your nose if/when you get towed, we have seen it happen. But you are right, you also put the frame at risk when the toe hook takes an impact. Maybe another solution will present itself, but right now its hard to see another way that will provide enough support for the tow hook and also place it in a good location.

>>What program are you using for modeling? Solidworks?

3d studio max :-)

all great comments, keep em coming!!!

>>- Packaging/shipping. I assume that the goal is to eventually sell these to the public. ....Consider taking the drop-supports for the undertray and make them a bolt-on item, rather than welded. This would make for much easier/cheaper packaging.

Good point, with that in mind I would plan to have certain parts bolt together.

**********

>>- 'Bump' protection. Adequate analysis needs to be done in this area to find the right balance of stiffness. Obviously, you don't want it too stiff, as then it will simply transfer the energy to the chassis of the car. A basic idea of the stiffness can be given from hand calculations, but a good FEA program goes a looooong way here.

>> - You mentioned putting the support brackets in at an angle in order to help absorb impacts. Obviously this will work if the impact is at a different angle then the supports are mounted at. Putting them at an angle may help in the right situation, but keep in mind that impacts on the track are rarely head-on.

********

All gret ideas, but I think you are taking this bar to a place were it really is not meant to be. I mentioned that impact stuff as more of a side benefit, this bar is NOT meant to be a full on impact structure, that would take a lot more design work and analysis like you mentioned. Keep in mind that right now on most gtc nose cars, there is nothing there!!! Some maybe have a modified stock rebar, but that is not exaclty a stellar matchup to the gtc nose either :-(

I should have been more clear on that too, that its really just to manage fender bumping, where having no structure behind the nose means you will collapse the nose.

But, if anyone wants to take my idea a step further I am all for it!! But for my specific need, a simple support bar that can hold up the splitter/undertray, support a proper tow hook location, and proivides some bumper protection... is all I can put resources towards right now :-)

>> In your current design configuration, is the tow hook welded to the curved bar? If so, this will further increase the rigidity and tendency for the bar to simply transfer impact energy rather than absorb it. Keep this in mind when doing stiffness analysis.

Yea, well this is a catch 22, you NEED the tow hook solidly mounted or you will blow up your nose if/when you get towed, we have seen it happen. But you are right, you also put the frame at risk when the toe hook takes an impact. Maybe another solution will present itself, but right now its hard to see another way that will provide enough support for the tow hook and also place it in a good location.

>>What program are you using for modeling? Solidworks?

3d studio max :-)

all great comments, keep em coming!!!

#13

Additional rebar support?

Any chance to have an additional side support to protect said oil coolers? and support for low ground clearance scrapes from tensioning plastics too far out to crack vs scrape/chip?

#14

Rotary Enthusiast

I have a front mount so i will hafto come up with a diffrent way to support the weight forward.

I will post some pics once im over the initial "proto type" construction. Right now it's beeing made in 4mm flat steel bars. But need to have it done by next weekend.

JT

Thread

Thread Starter

Forum

Replies

Last Post