FD Spark Plug Tech 2013

#53

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"So would it be safe to assume that a 13B making 350-400 whp would benefit from the Autolite "X" plugs in that they increase heat transfer taking heat away from the plug area?"

yes.

other Autolite options are the traditional, gappable ground strap AR3932 and a step warmer similar plug w a resistor... AR3923.

and of course there are other large ground strap NGK options.

i am going w Autolite.

howard

yes.

other Autolite options are the traditional, gappable ground strap AR3932 and a step warmer similar plug w a resistor... AR3923.

and of course there are other large ground strap NGK options.

i am going w Autolite.

howard

#54

Looks like I'm going with the AR3923 as a starting point. I may just order the "X" versions anyways and see what kind of differences I can feel. You can never have enough plugs laying around.

Edit: Oh I forgot, what about the trailing? Are we just using these in the leading only or both?

Edit: Oh I forgot, what about the trailing? Are we just using these in the leading only or both?

#55

Looks like I'm going with the AR3923 as a starting point. I may just order the "X" versions anyways and see what kind of differences I can feel. You can never have enough plugs laying around.

Edit oh I forgot, what about the trailing? Are we just using these in the leading only or both?

Edit oh I forgot, what about the trailing? Are we just using these in the leading only or both?

#57

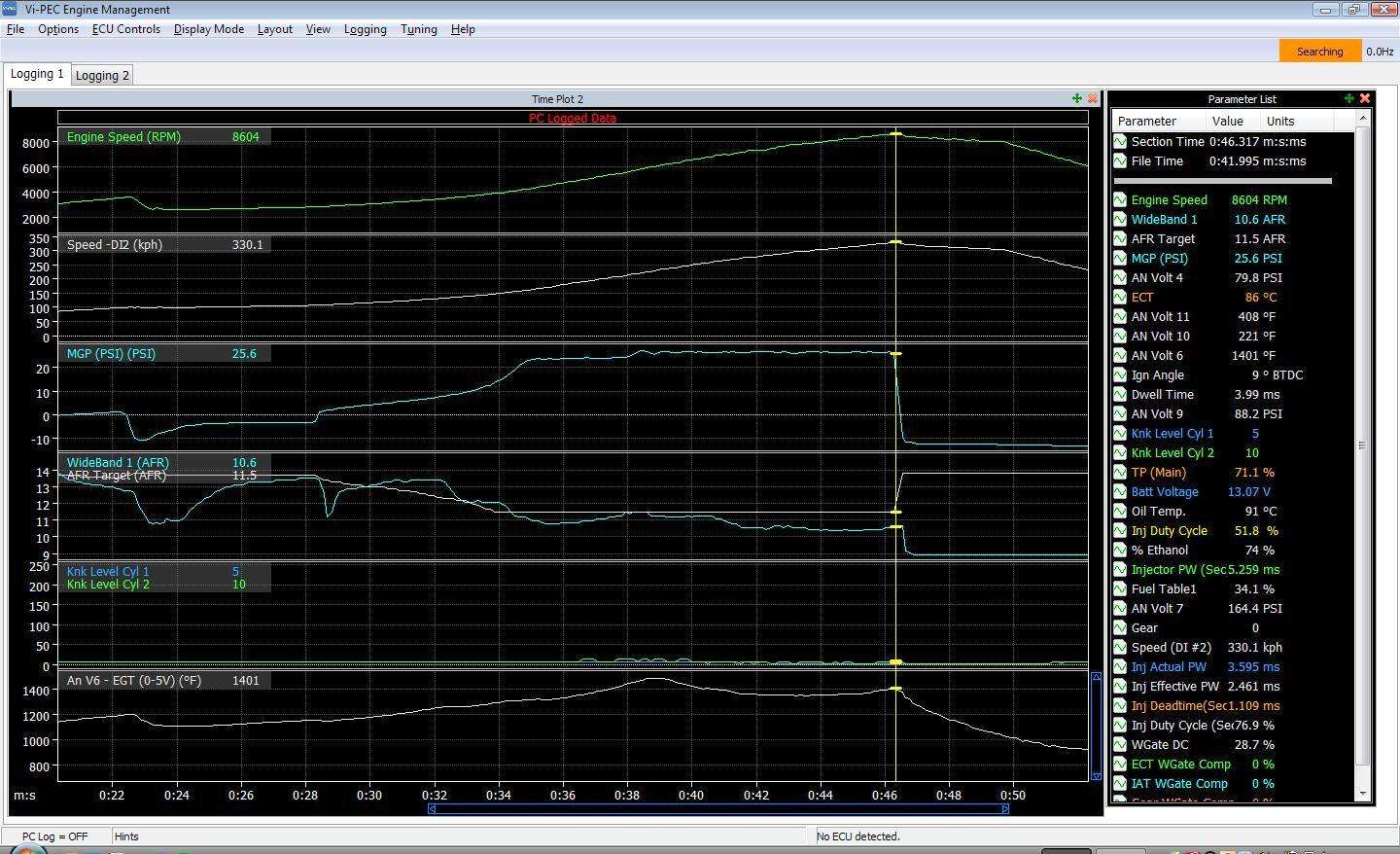

Howard, I am interested to know how your EGT trends on your pull through all the gears at WOT all the way to 5th gear at 8600 RPM. Does it level out,or continue to rise? If it continues to rise as mine does at WOT, what was your top number after that long duration pull?

#60

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

here's your answer, 2nd thru 5th to 186 mph

part of what we did yesterday was enable the gear based features of the V88.

the motor will blow the tires off in 1st, second and almost all of third around 25 psi.

Luke lowered the boost in the shorter gears...

second is 20.4 psi and top egt is 1553

third is the same boost and top egt was 1613

4th is 24.6 and was 1618

5th is less boost 23.2 1505 egt w rich AFRs as it is for 3/4 of a mile. rich AFRs lowered EGTs

so EGTs did not cumulate.

BTW, just bought some additional 3932s at NAPA for $3.49 each....

howard

part of what we did yesterday was enable the gear based features of the V88.

the motor will blow the tires off in 1st, second and almost all of third around 25 psi.

Luke lowered the boost in the shorter gears...

second is 20.4 psi and top egt is 1553

third is the same boost and top egt was 1613

4th is 24.6 and was 1618

5th is less boost 23.2 1505 egt w rich AFRs as it is for 3/4 of a mile. rich AFRs lowered EGTs

so EGTs did not cumulate.

BTW, just bought some additional 3932s at NAPA for $3.49 each....

howard

Last edited by Howard Coleman; 10-15-13 at 03:47 PM.

#64

547hp at the flywheel

iTrader: (30)

Join Date: Oct 2008

Location: Chicago

Posts: 1,223

Likes: 0

Received 0 Likes

on

0 Posts

Picked up a set this weekend since my greddy plugs decided they had enough of my pump+water injection setup (23 pulls on the dyno + 5k miles). They are smooooth. No hiccups, loss of power or any other indication of problems. Clear up to 8200rpm @ 22psi on my t04z setup. This is running the stock coils with a twin power.

#65

After reading what you wrote about the knock headphones...What are your thoughts about something like this? I am overly concerned about blowing my fresh motor while tuning it myself.

Could we utilize the factory knock sensor, and use this kind of system to detect knock?

Could we utilize the factory knock sensor, and use this kind of system to detect knock?

#67

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

i do think the gap setting is something that should be determined by the setup and application.

we set our gap at .02 so as to discourage exterior (under the boot to ground) discharge. we were losing the RPM signal due to electrical interference on the dyno.

as soon as we tightened the gap to .02 we had signal to 9000 w no problems. we also had no misfires and good power.

the same exact plugs that we used on the dyno from August thru the Texas Mile are currently in my motor. i don't mean the same type of plugs, i mean the the same plugs. they look perfect.

my guess is that if you aren't in the 500+ area power-wise the stock gap, which i think is around .03, would work fine.

BTW, the AR3932 is the largest selling plug within the Autolite Racing plug line...

hc

we set our gap at .02 so as to discourage exterior (under the boot to ground) discharge. we were losing the RPM signal due to electrical interference on the dyno.

as soon as we tightened the gap to .02 we had signal to 9000 w no problems. we also had no misfires and good power.

the same exact plugs that we used on the dyno from August thru the Texas Mile are currently in my motor. i don't mean the same type of plugs, i mean the the same plugs. they look perfect.

my guess is that if you aren't in the 500+ area power-wise the stock gap, which i think is around .03, would work fine.

BTW, the AR3932 is the largest selling plug within the Autolite Racing plug line...

hc

#69

wow that is some cheap plugs!

the standard bur9eq here in sweden is like $50 each!! :P

so have bought them on ebay all the time

but now running t04s at 20psi with pumpgas getting 480hp in the engine... should I go with the X version or the regular you think?

you were saying 350-400rwhp could have the X, and higher,550+, should hade the normal style?.. at 20psi I run 435rwhp... so in between?

have the bur9's on leading and ngk sd11a on trailing now without signs of any trouble yet.. but these is cheaper and seems like a good choice for next years track days

the standard bur9eq here in sweden is like $50 each!! :P

so have bought them on ebay all the time

but now running t04s at 20psi with pumpgas getting 480hp in the engine... should I go with the X version or the regular you think?

you were saying 350-400rwhp could have the X, and higher,550+, should hade the normal style?.. at 20psi I run 435rwhp... so in between?

have the bur9's on leading and ngk sd11a on trailing now without signs of any trouble yet.. but these is cheaper and seems like a good choice for next years track days

#70

After reading what you wrote about the knock headphones...What are your thoughts about something like this? I am overly concerned about blowing my fresh motor while tuning it myself.

Could we utilize the factory knock sensor, and use this kind of system to detect knock?

DIY Knock headphones for tuning standalone setups - YouTube

Could we utilize the factory knock sensor, and use this kind of system to detect knock?

DIY Knock headphones for tuning standalone setups - YouTube

#71

After reading what you wrote about the knock headphones...What are your thoughts about something like this? I am overly concerned about blowing my fresh motor while tuning it myself.

Could we utilize the factory knock sensor, and use this kind of system to detect knock?

DIY Knock headphones for tuning standalone setups - YouTube

Could we utilize the factory knock sensor, and use this kind of system to detect knock?

DIY Knock headphones for tuning standalone setups - YouTube

just noticed this post. You could run such a system, or other microphone-based setup. It still comes down to judgment call of what the signal means. Heavy knock is easy to judge, no knock isn't too hard to judge at lower engine speeds, but "borderline" conditions are very much open to interpretation.

Does anyone else use setups like this?

#72

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

there is an opportunity for someone to design/build/sell and knock system. they work. BTW, if you hammered the block and didn't hear anything you need to do some additional work.

i believe the CPS/HZ you are looking for is 3500 on the rotary.

i recommend the AR3932 rather than the AR3932X as they offer adj gap.

howard

i believe the CPS/HZ you are looking for is 3500 on the rotary.

i recommend the AR3932 rather than the AR3932X as they offer adj gap.

howard

Last edited by Howard Coleman; 11-17-13 at 07:11 PM.

#74

The stock sensor has an integrated band-pass filter. If you're not creating the correct frequency with your hammer, you won't hear it. Further, proper knock sensing needs to incorporate crank angle windowing. Without this, noise, outside of the narrow window of crank position where knock can actually occur, is interpreted as knock and counter measures are employed. Most systems do not employ this strategy and are therefore of limited value.