FD Spark Plug Tech 2013

#1

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

FD Spark Plug Tech 2013

FD engines, being only 80 cubic inches or 1.3 liters are SMALL.

when combined w a turbo system, the unique flow capability of the rotary can make BIG POWER easily.

at the OE power rating, 255 flywheel hp, the engine is making over 3.18 hp per cubic inch!

thinking more in today's metric world:

using the same output per displacement a 2 liter motor would make 387 hp!

and that's stock.

a quick search reveals a recent article re a new Mercedes- Benz AMG 2 liter 4 cyl turbo'd to 26 psi, direct injected etc with an expected power rating of 345 hp flywheel.

345 from 2 liters cranked to the max from MB AMG in 2013.

stock output FD at 2 liters 387.

and that's STOCK.

on our board we think that a GT35 mod is on the modest side...

a Borg Warner S363, a GT500, PT67 is considered medium, and a GT42 or BW 475 is considered large.

so we are thinking

400 to 450 RWhp is modest

500 is medium

600+ large.

and we are still talking about a 1.3 liter 80 cubic inch motor!

Combustion Chamber Pressure (CCP) is pretty linear with output per displacement.

enter the spark plug. not only does it have to FIRE the highly compressed mixture but it also does not get an every other TDC rest as do its piston buddies.

pressure and heat go hand in hand. lots of pressure, lots of heat. the heat needs to get transferred pronto. otherwise you get this:

i call the lateral carbon tracks around the lead plug hole "wings" and they are on every motor i dis-assemble. anywhere on the housing where carbon exists there is no apex seal to housing contact. so how come the apex seal is not on the housing?

of course apex seals ride on springs and so they can move in and out. the motivating force is because of Spark Plug Mountain (SPM).

as the heat builds within the sparkplug the surrounding area also becomes hotter than its neighborhood. when heat increases metals expand at the molecular level. and when they expand they need somewhere to go and that direction is always the easiest path which is up to form:

Spark Plug Mountain.

SPM rises from the flat plain of the housing surface and pushes the apex seal off the surface. note the immediate lateral area at the plug is wiped clean of carbon because it rose and WAS in contact w the apex seal.

not good for power and not good because adjoining rotor faces become in communication.

another effect ARE the inevitable cracks that form in the same direction.

so what does this all have to do w the spark plug?

the cooler the plug you run the lower becomes SPM. a cooler plug transfers more heat away from the problem area.

you need to run as cold a plug as you can. 10s are a good start and if your system can handle more, do it.

i chamfer the hole a bit to reduce SPM which does help.

of course running AI is a big help, even in the one bar boost area.

the plug options for our motors are wide ranged. from $4 to $35. some require special sockets.

previously i was in the CD camp running a couple of boxes and monster coils. a couple of years ago Lance Nist (PanteraEFI) and i were chatting and Lance is a really persuasive guy. when it comes to ignitions you'd best tread carefully and take notes.

Lance is an inductive guy... he had a hand in the design of the all conquering Mercury Marine coil which is now re-badged as the AEM Smart Coil, IGN-1A etc etc.

so i rolled the dice and made the switch.

WOW.

inductive, just like Mazda fixtured on the FD, sure is simple and deadly. it also is relatively cheap as no other boxes are needed and nickel plugs, often priced closer to a nickle than $35, work great. no need for the platinum items.

Lance suggested, w my Merc coils, that i try what he termed the "NASCAR" plugs.

turns out that they are an Autolite Racing plug:

AR3932X

i suggest you write that down.

i bought a bunch from my NAPA, around $5 per. slipped them into my motor in March and i haven't removed them other than to do a couple of plug checks. they are a 10 heat range and the rumor is they are closer to 11.

they cold start fine and are well mannered around town. no special wrench required. i am personally happy to be back w Autolite as i used them in my racecar for 17 seasons and considered the Autolite Racing plug to be of superior quality.

how do they run?

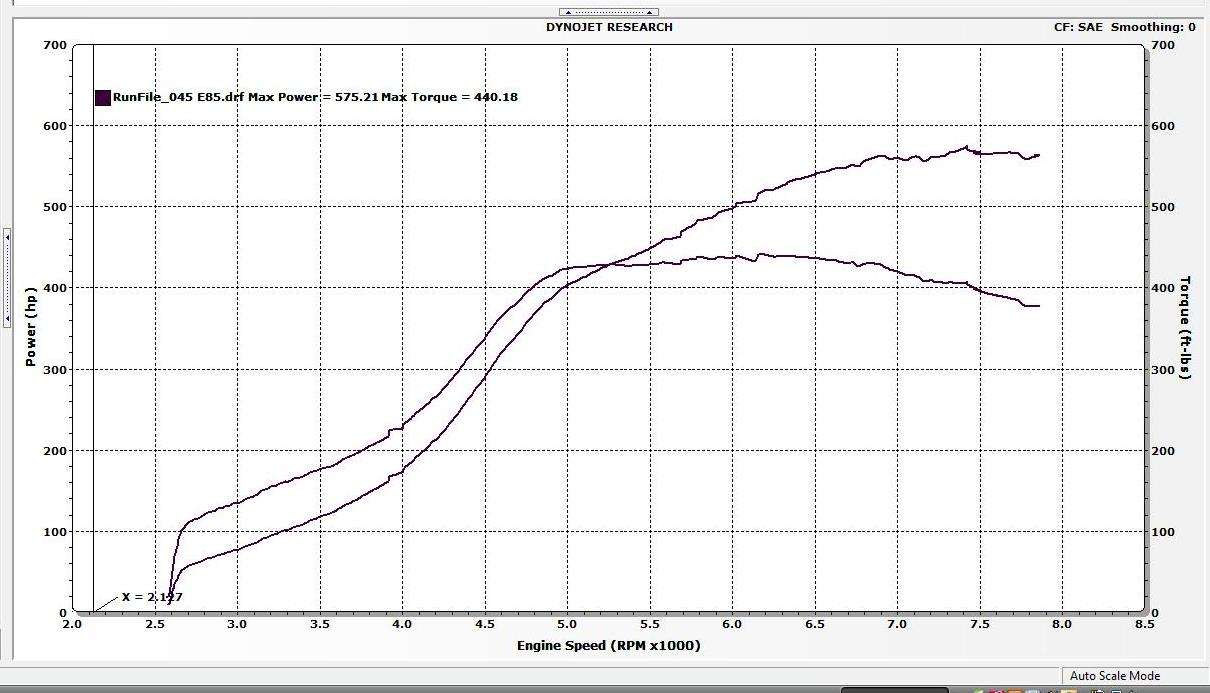

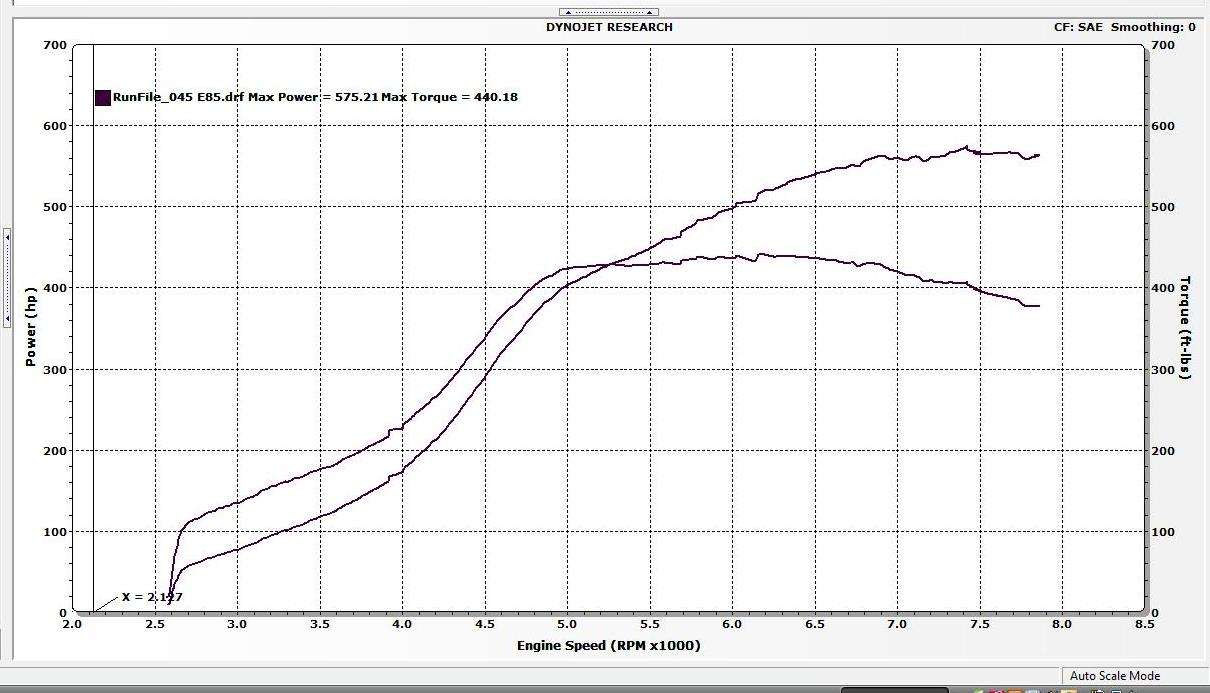

here's my dyno chart from saturday...

another excellent aspect of the AR3932X is that it does not have a welded ground strap. ground straps have been known to fly thru motors producing an unhappy ending. nothing is going to come off this plug..

so what's in your motor? plugs are especially important.

howard

when combined w a turbo system, the unique flow capability of the rotary can make BIG POWER easily.

at the OE power rating, 255 flywheel hp, the engine is making over 3.18 hp per cubic inch!

thinking more in today's metric world:

using the same output per displacement a 2 liter motor would make 387 hp!

and that's stock.

a quick search reveals a recent article re a new Mercedes- Benz AMG 2 liter 4 cyl turbo'd to 26 psi, direct injected etc with an expected power rating of 345 hp flywheel.

345 from 2 liters cranked to the max from MB AMG in 2013.

stock output FD at 2 liters 387.

and that's STOCK.

on our board we think that a GT35 mod is on the modest side...

a Borg Warner S363, a GT500, PT67 is considered medium, and a GT42 or BW 475 is considered large.

so we are thinking

400 to 450 RWhp is modest

500 is medium

600+ large.

and we are still talking about a 1.3 liter 80 cubic inch motor!

Combustion Chamber Pressure (CCP) is pretty linear with output per displacement.

enter the spark plug. not only does it have to FIRE the highly compressed mixture but it also does not get an every other TDC rest as do its piston buddies.

pressure and heat go hand in hand. lots of pressure, lots of heat. the heat needs to get transferred pronto. otherwise you get this:

i call the lateral carbon tracks around the lead plug hole "wings" and they are on every motor i dis-assemble. anywhere on the housing where carbon exists there is no apex seal to housing contact. so how come the apex seal is not on the housing?

of course apex seals ride on springs and so they can move in and out. the motivating force is because of Spark Plug Mountain (SPM).

as the heat builds within the sparkplug the surrounding area also becomes hotter than its neighborhood. when heat increases metals expand at the molecular level. and when they expand they need somewhere to go and that direction is always the easiest path which is up to form:

Spark Plug Mountain.

SPM rises from the flat plain of the housing surface and pushes the apex seal off the surface. note the immediate lateral area at the plug is wiped clean of carbon because it rose and WAS in contact w the apex seal.

not good for power and not good because adjoining rotor faces become in communication.

another effect ARE the inevitable cracks that form in the same direction.

so what does this all have to do w the spark plug?

the cooler the plug you run the lower becomes SPM. a cooler plug transfers more heat away from the problem area.

you need to run as cold a plug as you can. 10s are a good start and if your system can handle more, do it.

i chamfer the hole a bit to reduce SPM which does help.

of course running AI is a big help, even in the one bar boost area.

the plug options for our motors are wide ranged. from $4 to $35. some require special sockets.

previously i was in the CD camp running a couple of boxes and monster coils. a couple of years ago Lance Nist (PanteraEFI) and i were chatting and Lance is a really persuasive guy. when it comes to ignitions you'd best tread carefully and take notes.

Lance is an inductive guy... he had a hand in the design of the all conquering Mercury Marine coil which is now re-badged as the AEM Smart Coil, IGN-1A etc etc.

so i rolled the dice and made the switch.

WOW.

inductive, just like Mazda fixtured on the FD, sure is simple and deadly. it also is relatively cheap as no other boxes are needed and nickel plugs, often priced closer to a nickle than $35, work great. no need for the platinum items.

Lance suggested, w my Merc coils, that i try what he termed the "NASCAR" plugs.

turns out that they are an Autolite Racing plug:

AR3932X

i suggest you write that down.

i bought a bunch from my NAPA, around $5 per. slipped them into my motor in March and i haven't removed them other than to do a couple of plug checks. they are a 10 heat range and the rumor is they are closer to 11.

they cold start fine and are well mannered around town. no special wrench required. i am personally happy to be back w Autolite as i used them in my racecar for 17 seasons and considered the Autolite Racing plug to be of superior quality.

how do they run?

here's my dyno chart from saturday...

another excellent aspect of the AR3932X is that it does not have a welded ground strap. ground straps have been known to fly thru motors producing an unhappy ending. nothing is going to come off this plug..

so what's in your motor? plugs are especially important.

howard

Last edited by Howard Coleman; 09-20-13 at 01:55 PM.

#5

Howard, on my 3 rotor I've got the AEM coils as well and have swapping between the NGK 9s ($7 per plug) and the $35 per plug race ones. Would love to find an option that is better on the wallet and also one that doesn't require swapping out the plugs. I just had the engine pulled apart and didn't have any of the telltale signs of spark plug problems like in the pic you posted.

Would you recommend these for a 3 rotor? Not sure there would be any difference but I thought I'd ask. I take the car up to only 18-20 PSI.

Did you note any ignition issues with your setup and as I recall, you went up to 26 PSI or so with your dyno run? Finally, what is the your dwell time setting for the AEM coils?

Would you recommend these for a 3 rotor? Not sure there would be any difference but I thought I'd ask. I take the car up to only 18-20 PSI.

Did you note any ignition issues with your setup and as I recall, you went up to 26 PSI or so with your dyno run? Finally, what is the your dwell time setting for the AEM coils?

#6

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"are you saying that changing from oem coils to the AEM coils and autolite plugs will make the carbon area around the plug hole go away?"

no, i am saying that running a cold (10 or higher) plug will help transfer more heat from SPM.

turn SPM into SPm (Spark Plug molehill)....... along w AI which i consider necessary for any of our cars.

Hi David,

sure, a 3 rotor doesn't know it is "different" inside

maybe no tracks due to proper tuning and AI?

while the dyno sheet stops just before 8000 due to loss of signal up top most runs were to 8900 with no ignition issues whatsoever. dwell was a conservative 4.5 maximum. the coils can accept more dwell if necessary for short periods.

no, i am saying that running a cold (10 or higher) plug will help transfer more heat from SPM.

turn SPM into SPm (Spark Plug molehill)....... along w AI which i consider necessary for any of our cars.

Hi David,

sure, a 3 rotor doesn't know it is "different" inside

maybe no tracks due to proper tuning and AI?

while the dyno sheet stops just before 8000 due to loss of signal up top most runs were to 8900 with no ignition issues whatsoever. dwell was a conservative 4.5 maximum. the coils can accept more dwell if necessary for short periods.

Trending Topics

#8

^Thanks Howard. I'd concur on the good tuning and AI = no spark plug tracks.

I'll give these a shot and see how they perform. I'm due at the dyno in about one month so it will be a good test. I've got a set of the 9s and the 10.5 race plugs so I'll compare them all.

I'll give these a shot and see how they perform. I'm due at the dyno in about one month so it will be a good test. I've got a set of the 9s and the 10.5 race plugs so I'll compare them all.

#9

Interesting. I like the price. Looks like they're non-resistor plugs, which seems to have caused EMI issues in some applications. Also, the reach is shorter than that on the R7420s (.750" vs .846").

Have you experimented with other non-resistor plugs? Other short-reach plugs? Issues?

Have you experimented with other non-resistor plugs? Other short-reach plugs? Issues?

#12

The NGKs in 7s and 9s are not transferring enough heat out of the area.

Surely you guys, being "car guys" understand what plug heat ranges are all about? Its the most basic of basic tech. Go read some Hot Rod Magazine if you dont understand how plug heat ranges work.

I always thought that mazda ran such hot plugs to meet emissions. Your grandma's buick would run 7s or a similar heat range as she pootles around town at 20mph. Hot heat range plugs are for the low performance daily driver, because they resist fouling.

Colder plugs are more prone to fouling, but the porcelain design transfers more heat away from the surrounding area. You put 10s in your stock daily FD and it will reduce SPM, but increase the chances of fouled plugs. You dont get something for nothing in the performance world.

Surely you guys, being "car guys" understand what plug heat ranges are all about? Its the most basic of basic tech. Go read some Hot Rod Magazine if you dont understand how plug heat ranges work.

I always thought that mazda ran such hot plugs to meet emissions. Your grandma's buick would run 7s or a similar heat range as she pootles around town at 20mph. Hot heat range plugs are for the low performance daily driver, because they resist fouling.

Colder plugs are more prone to fouling, but the porcelain design transfers more heat away from the surrounding area. You put 10s in your stock daily FD and it will reduce SPM, but increase the chances of fouled plugs. You dont get something for nothing in the performance world.

#13

^ And I'm basing my plug knowledge on having read about plugs in some Holley tuning books, then gone online and researched it for a while on Car Craft/Hot Rod magazine, and talking to my dad about the subject, and putting it into theory in my previous cars.

Nothing like being 18, and in the middle of a carpark and the car doesnt want to run on all 8. It runs on 7, and half an hour ago you bought some sets of colder plugs, and you got to the point you went too cold and you fouled some and now it runs like a pig.

Following phone conversation goes like:

Me: "Hey Dad, would you mind bringing me that other set of J8 plugs I had on the bench at home? I'm in the carpark of Kmart and the b#$%^& fouled some plugs on me. I went to Kmart to try a colder set, and the things fouled. I need the J8's, not the J9's. I f$%^ed up."

Dad: "Jesus Christ, stop fiddling with that car. It goes well enough as it is. I told you not to go too cold or it would foul. Give me 15 minutes, I'm busy in the lathe."

I'll always remember that part of growing up. I'm 26 now, and I feel like I went through enough of that stage of my life in traffic and at the track, to be able to reasonably talk about plug heat ranges with at least some confidence.

I ran a 440 cubic inch V8 Chrysler engine, and an Australian Hemi 6 cylinder engine, stepping the plugs colder and colder (8's, 9's, 10's) until those engines began fouling plugs. I then went back one warmer, and that was the coldest plug for that engine, in its circumstances.

If you look at a plug, without knowing the heat range, you can see if its hot or cold, based on the design of the porcelain on the electrode. It will either absorb and extract combustion heat from the chamber, or retain the heat in the chamber and not transmit it out of the surrounding material based on how far up the porcelain extends.

In this phenomena, it is possible to select a colder plug for the 13B-REW, which will absorb more heat out of the surrounding housing material, acting as a heat sink, and transmit it away. Less heat means less deformation of the housing, which leads to Howard's "Spark Plug Mountain" description. Its very simple.

If you wanted to, you could run a 10 plug in the REW, and then if it worked well on the street, in the most testing environment possible (idling in traffic, engine just warm, with some quick boost in traffic) without fouling, you could try a colder plug, move towards an 11. Eventually you will find a plug that runs too cold, and cannot "flash off" the combustion fuel/oil and carbon that can foul the plug tip. You would then go back to the last coldest plug number that worked well and stay there.

Mazda had two considerations when choosing plugs-

1. How easy it would foul (cant have customers bringing the cars back with fouled plugs every month).

2. Emissions. The hotter the plug, the better the combustion and less leftovers for the cat converter to have to deal with.

The factory did not go colder than 9's, because they did not want fouling and customer complaints. Also, they used 7's because they needed a complete hot burn to help emissions. There are other timing considerations that go into it too, but its not worth covering it here.

Also of note, hotter plugs can encourage pre-ignition (the nose of the plug acts as a glowplug) in high performance engines or when running dodgy low octane fuel. Thats why race engines tend to run colder plugs. They will make more power and reduce pre-ignition but they will foul more readily. (Not an issue in a race engine, just whack a new set of plugs in, before you head out to the track again.)

Some racers would read plugs (high rpm, high load, then neutral and shut her off, pull over and check the plugs) but that was always something I did if I was fine tuning jet sizes on a new Holley carburetor.

Some people (piston engine guys) would index the plugs (mark the electrode position on the porcelain, then screw it in and see if the electrode points toward the valve, and if not, add shims til it screws in and points the right way) hoping to make more power by very fine tuning that sort of thing. It is irrelevant in a rotary, because the REW uses a "Surface Discharge" type of plug nose- IE no welded electrode as Howard mentioned, but a flat nose with four slots. No electrode to index.

Disclaimer: I apologize for writing when I'm angry. My tone goes bad very quickly. I am not angry at anything to do with the forum. I just had a bad day.

You could probably run a 10 (one step colder) in a stock FD3S. My feeling is that they foul their plugs enough already that a 10 would be about the limit before you start to get pissed off with it fouling its plugs more frequently in normal use. A "hot" 11 might be okay, but each car needs the heat range tailored, as they are all different, and the environment and driving styles are very different from one owner to the next.

Howard, do you noticed the pronounced "SPM" as you coined it, more on the leading or trailing plug apertures in a stock engine running 9's and 7's?

My feeling is that the 7's will show more pronounced "wing" effect than around the 9's on a stripped REW?

Nothing like being 18, and in the middle of a carpark and the car doesnt want to run on all 8. It runs on 7, and half an hour ago you bought some sets of colder plugs, and you got to the point you went too cold and you fouled some and now it runs like a pig.

Following phone conversation goes like:

Me: "Hey Dad, would you mind bringing me that other set of J8 plugs I had on the bench at home? I'm in the carpark of Kmart and the b#$%^& fouled some plugs on me. I went to Kmart to try a colder set, and the things fouled. I need the J8's, not the J9's. I f$%^ed up."

Dad: "Jesus Christ, stop fiddling with that car. It goes well enough as it is. I told you not to go too cold or it would foul. Give me 15 minutes, I'm busy in the lathe."

I'll always remember that part of growing up. I'm 26 now, and I feel like I went through enough of that stage of my life in traffic and at the track, to be able to reasonably talk about plug heat ranges with at least some confidence.

I ran a 440 cubic inch V8 Chrysler engine, and an Australian Hemi 6 cylinder engine, stepping the plugs colder and colder (8's, 9's, 10's) until those engines began fouling plugs. I then went back one warmer, and that was the coldest plug for that engine, in its circumstances.

If you look at a plug, without knowing the heat range, you can see if its hot or cold, based on the design of the porcelain on the electrode. It will either absorb and extract combustion heat from the chamber, or retain the heat in the chamber and not transmit it out of the surrounding material based on how far up the porcelain extends.

In this phenomena, it is possible to select a colder plug for the 13B-REW, which will absorb more heat out of the surrounding housing material, acting as a heat sink, and transmit it away. Less heat means less deformation of the housing, which leads to Howard's "Spark Plug Mountain" description. Its very simple.

If you wanted to, you could run a 10 plug in the REW, and then if it worked well on the street, in the most testing environment possible (idling in traffic, engine just warm, with some quick boost in traffic) without fouling, you could try a colder plug, move towards an 11. Eventually you will find a plug that runs too cold, and cannot "flash off" the combustion fuel/oil and carbon that can foul the plug tip. You would then go back to the last coldest plug number that worked well and stay there.

Mazda had two considerations when choosing plugs-

1. How easy it would foul (cant have customers bringing the cars back with fouled plugs every month).

2. Emissions. The hotter the plug, the better the combustion and less leftovers for the cat converter to have to deal with.

The factory did not go colder than 9's, because they did not want fouling and customer complaints. Also, they used 7's because they needed a complete hot burn to help emissions. There are other timing considerations that go into it too, but its not worth covering it here.

Also of note, hotter plugs can encourage pre-ignition (the nose of the plug acts as a glowplug) in high performance engines or when running dodgy low octane fuel. Thats why race engines tend to run colder plugs. They will make more power and reduce pre-ignition but they will foul more readily. (Not an issue in a race engine, just whack a new set of plugs in, before you head out to the track again.)

Some racers would read plugs (high rpm, high load, then neutral and shut her off, pull over and check the plugs) but that was always something I did if I was fine tuning jet sizes on a new Holley carburetor.

Some people (piston engine guys) would index the plugs (mark the electrode position on the porcelain, then screw it in and see if the electrode points toward the valve, and if not, add shims til it screws in and points the right way) hoping to make more power by very fine tuning that sort of thing. It is irrelevant in a rotary, because the REW uses a "Surface Discharge" type of plug nose- IE no welded electrode as Howard mentioned, but a flat nose with four slots. No electrode to index.

Disclaimer: I apologize for writing when I'm angry. My tone goes bad very quickly. I am not angry at anything to do with the forum. I just had a bad day.

You could probably run a 10 (one step colder) in a stock FD3S. My feeling is that they foul their plugs enough already that a 10 would be about the limit before you start to get pissed off with it fouling its plugs more frequently in normal use. A "hot" 11 might be okay, but each car needs the heat range tailored, as they are all different, and the environment and driving styles are very different from one owner to the next.

Howard, do you noticed the pronounced "SPM" as you coined it, more on the leading or trailing plug apertures in a stock engine running 9's and 7's?

My feeling is that the 7's will show more pronounced "wing" effect than around the 9's on a stripped REW?

The following users liked this post:

EZAS (10-02-17)

#14

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,815

Received 2,585 Likes

on

1,836 Posts

here is a pic of a ~100,000 mile 12A rotor housing. as you can see every wear aspect is worse than the REW, despite the REW making 2.5 times more power.

#17

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"so you're saying I can run those with my 500+hp on a twin power instead of eating 39+ bux per plug for the NGK?"

i have no experience w the plugs other than what i have set forth. i do consider it a low risk ($20) speculation to give them a try. my guess is that if your current setup, the more expensive plugs, works the nickel plugs should work. i don't see any significant motor risk especially if you turn down the boost a bit and sneak up on it.

i believe others on the board are running them and would welcome additional comments.

"so what exactly is wrong with stock NGKs in the proper heat range?"

nothing.

my post is about a NEW OPTION for the FD. it may be worth noting that some people have lost NGK ground straps. there are no ground straps on the AR3932X. the really stock NGKs are designed like the AR3932X with no ground straps but are only available in a 9 heat range.

howard

i have no experience w the plugs other than what i have set forth. i do consider it a low risk ($20) speculation to give them a try. my guess is that if your current setup, the more expensive plugs, works the nickel plugs should work. i don't see any significant motor risk especially if you turn down the boost a bit and sneak up on it.

i believe others on the board are running them and would welcome additional comments.

"so what exactly is wrong with stock NGKs in the proper heat range?"

nothing.

my post is about a NEW OPTION for the FD. it may be worth noting that some people have lost NGK ground straps. there are no ground straps on the AR3932X. the really stock NGKs are designed like the AR3932X with no ground straps but are only available in a 9 heat range.

howard

Last edited by Howard Coleman; 09-19-13 at 12:32 PM.

#18

Rotary Enthusiast

good deal.

i had a question on these months ago. there are a few threads about them around here, but not hard data.

like everything else on here everything is hidden away.

i had a question on these months ago. there are a few threads about them around here, but not hard data.

like everything else on here everything is hidden away.

#21

First off, nice dyno Howard.

I will also '2nd' Autolite plugs as an option for our engines. I have used their plugs for years with good results (in my FC and FD as well as all types of engines).

Your point about power density and the correct heat ranges is also well taken; moreover, the importance of AI and why it should be standard equipment.

Ever the engineer, I wanted to ask you for clarification as to the mechanism causing the SPM, as you call it:

The reason I ask, is that a hotter plug actually transfers less heat to the shell--and thus, the surrounding chamber (and heat is transferred deeper in the shell, somewhat further from the combustion chamber surface). The plug retains more heat in the core, which is why it is characterized as hotter. The shell of the plug is not generally characterized in the heat range and is going to be close to the temp of the material it's screwed into (in this case, the housings).

Or put another way, a cold plug should actually transfer more heat into the housing.

So what else could be causing the SPM effect?

I don't doubt that a correlation to heat range may exist; others have made similar observations. I am just not convinced thermal conduction is your mechanism.

A couple of other things that also enter into the equation:

Aluminum's coefficient of expansion is much greater than steel;

Aluminum's thermal conductivity is much greater than steel; and,

when a material expands, the holes in the material expand larger.

I recall reading a mazda paper, posted somewhere on the forum, that says they chose a aluminum for the housing material because cast iron could not conduct heat away from some areas (spark plug?) fast enough, resulting in localized overheating. Aluminum, with its superior thermal conductivity, apparently mitigated these concerns--but with the astronomical power densities that we can achieve--perhaps we're just hitting the limitations of the materials and/or design.

Your thoughts?

I will also '2nd' Autolite plugs as an option for our engines. I have used their plugs for years with good results (in my FC and FD as well as all types of engines).

Your point about power density and the correct heat ranges is also well taken; moreover, the importance of AI and why it should be standard equipment.

Ever the engineer, I wanted to ask you for clarification as to the mechanism causing the SPM, as you call it:

....so what does this all have to do w the spark plug?

the cooler the plug you run the lower becomes SPM. a cooler plug transfers more heat away from the problem area.

you need to run as cold a plug as you can. 10s are a good start and if your system can handle more, do it. ....

howard

the cooler the plug you run the lower becomes SPM. a cooler plug transfers more heat away from the problem area.

you need to run as cold a plug as you can. 10s are a good start and if your system can handle more, do it. ....

howard

Or put another way, a cold plug should actually transfer more heat into the housing.

So what else could be causing the SPM effect?

I don't doubt that a correlation to heat range may exist; others have made similar observations. I am just not convinced thermal conduction is your mechanism.

A couple of other things that also enter into the equation:

Aluminum's coefficient of expansion is much greater than steel;

Aluminum's thermal conductivity is much greater than steel; and,

when a material expands, the holes in the material expand larger.

I recall reading a mazda paper, posted somewhere on the forum, that says they chose a aluminum for the housing material because cast iron could not conduct heat away from some areas (spark plug?) fast enough, resulting in localized overheating. Aluminum, with its superior thermal conductivity, apparently mitigated these concerns--but with the astronomical power densities that we can achieve--perhaps we're just hitting the limitations of the materials and/or design.

Your thoughts?

#23

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"cold plug should actually transfer more heat into the housing."

yes and therefore the cold plug, itself, remains... colder. a hot plug retains more heat within the plug and therefore the immediate aluminum contact. as you mentioned aluminum is one of the top substances for heat transfer.

hold one end of a 1/8th inch aluminum welding rod, hit the other end w a torch and you will almost immediately not be able to hold it.

do the same w a stainless steel rod or even a mild steel rod and you will feel almost no increase in heat on your end.

aluminum is crazy good w re to heat transfer.... and it works w the rotary, transferring (more) heat away from SPM.

since a cold plug transfers more heat to the aluminum housing that heat spreads quite well over the housing and into the coolant creating less immediate heat at SPM.

let's assume the heat total is a constant... it is spread out over a larger area w the cold plug which reduces the uplift at SPM. that's why a cold plug runs at a colder temp, as the heat is better conducted away from the spark plug boss.

immediate heat around the spark plug boss IS a challenge for the rotary and cannot be completely eliminated but can be reduced.

i can say that taking apart an engine that has run cold plugs does support my, uh, theory

another interesting off topic consideration is the effect of SPM on the apex seal. (not good).

"shorter reach and non - resistor"

all i can say is they work well for me. i realize there have been a lot of questions re how the plugs work w a more typical setup and i do know that a bunch of people on our board are running them. maybe we will get some comments.

howard

yes and therefore the cold plug, itself, remains... colder. a hot plug retains more heat within the plug and therefore the immediate aluminum contact. as you mentioned aluminum is one of the top substances for heat transfer.

hold one end of a 1/8th inch aluminum welding rod, hit the other end w a torch and you will almost immediately not be able to hold it.

do the same w a stainless steel rod or even a mild steel rod and you will feel almost no increase in heat on your end.

aluminum is crazy good w re to heat transfer.... and it works w the rotary, transferring (more) heat away from SPM.

since a cold plug transfers more heat to the aluminum housing that heat spreads quite well over the housing and into the coolant creating less immediate heat at SPM.

let's assume the heat total is a constant... it is spread out over a larger area w the cold plug which reduces the uplift at SPM. that's why a cold plug runs at a colder temp, as the heat is better conducted away from the spark plug boss.

immediate heat around the spark plug boss IS a challenge for the rotary and cannot be completely eliminated but can be reduced.

i can say that taking apart an engine that has run cold plugs does support my, uh, theory

another interesting off topic consideration is the effect of SPM on the apex seal. (not good).

"shorter reach and non - resistor"

all i can say is they work well for me. i realize there have been a lot of questions re how the plugs work w a more typical setup and i do know that a bunch of people on our board are running them. maybe we will get some comments.

howard