FD A/C system oil charge capaciity question

#1

FD A/C system oil charge capaciity question

Long story short, I'm restoring the A/C system in my FD, but the end result will be something of a custom mutt. I'm using the existing Denso evaporator core, which I flushed and installed a new OEM Denso expansion valve on, a used Denso compressor, which will be drained & bench flushed with new lube until clean and drained completely. The condenser and dryer I picked up are generic aftermarket parts that fit the OEM installation well - condenser is a multi-pass parallel flow unit, core size about 12"x24", and the dryer is the typical cylinder, about 2.5" diameter X 6" high that fits well in the OEM bracket I got. Plumbing will be all custom/DIY fabricated as the OEM bits won't clear the turbo.

The A/C system sticker under the hood in my FD is long gone, and I could not find any specs for the full A/C system lubricant capacity anywhere in the FSM for either Denso or MANA A/C systems. In the '94 Body Electrical manual HVAC system, they specify oil amounts to add to each A/C component when replacing it with a new/dry component. Using that info, I derived the total system oil charge, for an R134a charged system:

Compressor = 170cc oil

Condenser = 40cc

Dryer = 10cc

Evap. Core = 40cc

All in, that's 260cc or about 8.8 ounces lube for the total A/C system. Can anyone that still has their A/C sticker under the hood confirm that I'm at least in the ballpark?

The A/C system sticker under the hood in my FD is long gone, and I could not find any specs for the full A/C system lubricant capacity anywhere in the FSM for either Denso or MANA A/C systems. In the '94 Body Electrical manual HVAC system, they specify oil amounts to add to each A/C component when replacing it with a new/dry component. Using that info, I derived the total system oil charge, for an R134a charged system:

Compressor = 170cc oil

Condenser = 40cc

Dryer = 10cc

Evap. Core = 40cc

All in, that's 260cc or about 8.8 ounces lube for the total A/C system. Can anyone that still has their A/C sticker under the hood confirm that I'm at least in the ballpark?

#3

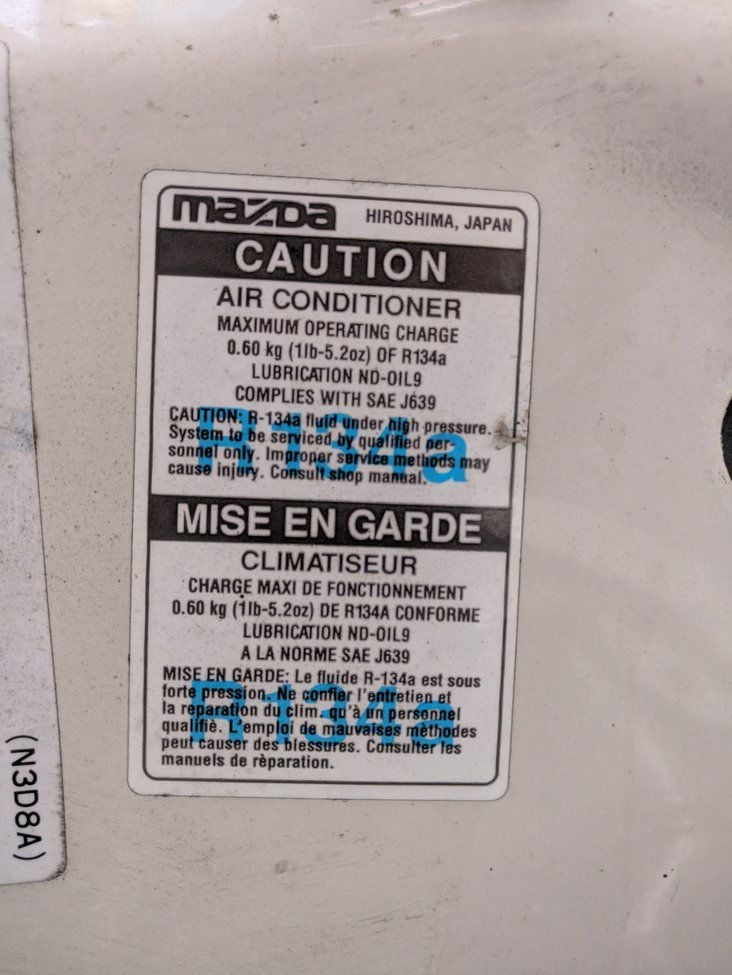

Interesting - that sticker specifies how much R134a refrigerant to charge by weight, and the type/grade of lubricant (ND9) to use, but it doesn't specify the capacity/amount of lubricant for the system. IIRC, the sticker in my FC has info for lube capacity and type, will need to take a peek under the hood to confirm.

#4

Pete,

My sticker is illegible. I finished this last year on mine tho. Denso r-12 that I completely restored. I’m going to assume since you’re using a new Denso expansion valve you are going to stay with R-12? Like you I looked up the stats in the fms. It does state in the technical data section a variance of 3.7oz - 8.5oz. Starting from a completely redone system like you’ve done, I can tell you that you will not get over 6 oz ( and some change ) in the dry compressor when filling the discharge port and spinning the compressor over by hand. I spoke to a guy who only does Vehicle AC repair ( 26 years now ) and he told me it’s better to be on the lighter side than the heavier side. You want enough to keep the compressor happy, but too much will sludge the compressor and have diminishing returns. If you do put too much oil in there, for instance pouring some in the condenser/evaporator etc. you will reduce the total volume of gas the system can except. Same goes for how much gas you put in. It’s better to have slightly less than slightly more. It’s all a balancing act. From my dry system I used 6oz and 26 oz of r-12. This is off my notes from then. No issues all summer and enjoyed 36* vent temps while driving down the hwy. You may have to play with the gas amount due to your slightly different condenser. If you need any help, I’m down in Millersville. I have all the stuff you’ll need if you run into trouble.

~ GW

My sticker is illegible. I finished this last year on mine tho. Denso r-12 that I completely restored. I’m going to assume since you’re using a new Denso expansion valve you are going to stay with R-12? Like you I looked up the stats in the fms. It does state in the technical data section a variance of 3.7oz - 8.5oz. Starting from a completely redone system like you’ve done, I can tell you that you will not get over 6 oz ( and some change ) in the dry compressor when filling the discharge port and spinning the compressor over by hand. I spoke to a guy who only does Vehicle AC repair ( 26 years now ) and he told me it’s better to be on the lighter side than the heavier side. You want enough to keep the compressor happy, but too much will sludge the compressor and have diminishing returns. If you do put too much oil in there, for instance pouring some in the condenser/evaporator etc. you will reduce the total volume of gas the system can except. Same goes for how much gas you put in. It’s better to have slightly less than slightly more. It’s all a balancing act. From my dry system I used 6oz and 26 oz of r-12. This is off my notes from then. No issues all summer and enjoyed 36* vent temps while driving down the hwy. You may have to play with the gas amount due to your slightly different condenser. If you need any help, I’m down in Millersville. I have all the stuff you’ll need if you run into trouble.

~ GW

Last edited by gdub29e; 10-31-20 at 08:57 AM.

#5

Interesting - that sticker specifies how much R134a refrigerant to charge by weight, and the type/grade of lubricant (ND9) to use, but it doesn't specify the capacity/amount of lubricant for the system. IIRC, the sticker in my FC has info for lube capacity and type, will need to take a peek under the hood to confirm.

Here's some info, although with GM compressor and toward the end of the thread another recommendation.

https://www.norotors.com/index.php?t...2947#msg302947

#6

Interesting - that sticker specifies how much R134a refrigerant to charge by weight, and the type/grade of lubricant (ND9) to use, but it doesn't specify the capacity/amount of lubricant for the system. IIRC, the sticker in my FC has info for lube capacity and type, will need to take a peek under the hood to confirm.

Here's some info, although with a GM compressor and toward the end of the thread another recommendation.

https://www.norotors.com/index.php?t...2947#msg302947

#7

My sticker is illegible. I finished this last year on mine tho. Denso r-12 that I completely restored. Iím going to assume since youíre using a new Denso expansion valve you are going to stay with R-12? Like you I looked up the stats in the fms. It does state in the technical data section a variance of 3.7oz - 8.5oz. Starting from a completely redone system like youíve done, I can tell you that you will not get over 6 oz ( and some change ) in the dry compressor when filling the discharge port and spinning the compressor over by hand. I spoke to a guy who only does Vehicle AC repair ( 26 years now ) and he told me itís better to be on the lighter side than the heavier side. You want enough to keep the compressor happy, but too much will sludge the compressor and have diminishing returns. If you do put too much oil in there, for instance pouring some in the condenser/evaporator etc. you will reduce the total volume of gas the system can except. Same goes for how much gas you put in. Itís better to have slightly less than slightly more. Itís all a balancing act. From my dry system I used 6oz and 26 oz of r-12. This is off my notes from then. No issues all summer and enjoyed 36* vent temps while driving down the hwy. You may have to play with the gas amount due to your slightly different condenser. If you need any help, Iím down in Millersville. I have all the stuff youíll need if you run into trouble.

The other interesting thing I learned is other than changing out to the green HBNR O-rings, the Denso expansion valves are otherwise identical for R12 and R134A systems, so you can buy the Denso part # specified for R134A and it will work for both refrigerants - it will come with green HBNR O-rings instead of the black rubber O-rings. I got mine from Rockauto for around $15.

Initially I'm going to charge the system with the R152A duster gas - that stuff is dirt cheap (~ $11 for 4 cans at Walmart), so if I have a leak that only shows up under pressure it's no big loss. Testing for leaks by holding a vacuum isn't always conclusive, since the differential test pressure is only 1 atmosphere or about 14.7 psi. When I did the restoration on my FC, the duster gas performed so well that I never bothered to switch back to R12 or try R134A - the air coming out of the center vents using the duster gas was in the 36*~40*F range, the same as it was with R12. A year after doing the FC restoration I found I have an extremely slow leak though, so I need to evacuate & recharge at the beginning of each season with the duster gas. Can't find the leak with UV dye anywhere, so I'm guessing its just slowly permeating out from the 31 year old non-barrier rubber hoses as the system runs over the course of the summer. Those are the only original parts I didn't replace on the FC project.

If the duster gas performs equally well in the FD as it did in my FC, and none of it leaks out over a full season or two, I might just evacuate & recharge with R134A to see how the system performs. This isn't a collector FD, so there's no need to keep everything original, and I'll end up using what works best and doesn't cost me stupid money - which will probably make charging with R12 unlikely.

Did you happen to find any shops in MD that can crimp the beadlock fittings on your AC hoses for you? After evaluating all my plumbing options for the hoses, I settled on using reduced barrier hose (same inside diameter, smaller OD = more flexible, take up less space) with the appropriate beadlock hose end fittings. That's what all the OEMs are using today for AC lines, so it should be a reliable choice. To finish the job and build the hoses, I have 2 options - buy the crimping tool for about $150 ~ $300 and DIY the crimps, or find a local shop to do it for me. So far I'm having zero luck finding a local shop that can crimp the reduced barrier AC hoses. There are a couple of hydraulics shops by me that say they can do it, but only on the condition that I buy all my hose & fittings from them, at about 3~5 times what I'd be paying for the same stuff online. And then they charge a fortune for each crimp, screw that!

Here's some info, although with a GM compressor and toward the end of the thread another recommendation.

https://www.norotors.com/index.php?t...2947#msg302947

https://www.norotors.com/index.php?t...2947#msg302947

Trending Topics

#8

Yes, the OP is aware of the mounting orientation. He had stated he had mounted the condenser in both configurations.

with respect to your leak on the FC, I had a leak that was difficult to detect using the dye. After several times checking all the o-ring locations, I noticed it leaking at the seam on the compressor body.

with respect to your leak on the FC, I had a leak that was difficult to detect using the dye. After several times checking all the o-ring locations, I noticed it leaking at the seam on the compressor body.

#9

the ND mineral oil specified for R12.

The other interesting thing I learned is other than changing out to the green HBNR O-rings, the Denso expansion valves are otherwise identical for R12 and R134A systems, so you can buy the Denso part # specified for R134A and it will work for both refrigerants - it will come with green HBNR O-rings instead of the black rubber O-rings. I got mine from Rockauto for around $15.

A year after doing the FC restoration I found I have an extremely slow leak though, so I need to

Did you happen to find any shops in MD that can crimp the beadlock fittings on your AC hoses for you? After evaluating all my plumbing options for the hoses, I settled on using reduced barrier hose (same inside diameter, smaller OD = more flexible, take up less space) with the appropriate beadlock hose end fittings. That's what all the OEMs are using today for AC lines, so it should be a reliable choice. To finish the job and build the hoses, I have 2 options - buy the crimping tool for about $150 ~ $300 and DIY the crimps, or find a local shop to do it for me. So far I'm having zero luck finding a local shop that can crimp the reduced barrier AC hoses. There are a couple of hydraulics shops by me that say they can do it, but only on the condition that I buy all my hose & fittings from them, at about 3~5 times what I'd be paying for the same stuff online. And then they charge a fortune for each crimp, screw that!

.

The other interesting thing I learned is other than changing out to the green HBNR O-rings, the Denso expansion valves are otherwise identical for R12 and R134A systems, so you can buy the Denso part # specified for R134A and it will work for both refrigerants - it will come with green HBNR O-rings instead of the black rubber O-rings. I got mine from Rockauto for around $15.

A year after doing the FC restoration I found I have an extremely slow leak though, so I need to

Did you happen to find any shops in MD that can crimp the beadlock fittings on your AC hoses for you? After evaluating all my plumbing options for the hoses, I settled on using reduced barrier hose (same inside diameter, smaller OD = more flexible, take up less space) with the appropriate beadlock hose end fittings. That's what all the OEMs are using today for AC lines, so it should be a reliable choice. To finish the job and build the hoses, I have 2 options - buy the crimping tool for about $150 ~ $300 and DIY the crimps, or find a local shop to do it for me. So far I'm having zero luck finding a local shop that can crimp the reduced barrier AC hoses. There are a couple of hydraulics shops by me that say they can do it, but only on the condition that I buy all my hose & fittings from them, at about 3~5 times what I'd be paying for the same stuff online. And then they charge a fortune for each crimp, screw that!

.

Couple things~ The oil for the r12 system is ND-6, which for love or money you can’t find anymore. I used r12 mineral oil from napa. You’re correct about the r134a oil. I actually read that thread you posted and a ton of others. One on this forum that was very informative. Plus chatting with people who are slightly more experienced than I am.

The best way I have found to test for leaks prior to filling the system is to purge the system with nitrogen to remove all the air and pressurize it to about 100 psi. I leave it sit for an hour or two with my manifold gauges hooked up and then come back and check to see if it’s leaked down. If it’s good I continue. If not I re-pressurize and take soapy water spraying down that the lines, fittings and compressor ( my latest one had a leak where the compressor splits). After that holds, I hook up the vac pump to the gauges and start vacuuming it down. If it pulls right down that a good sign, but I leave it running for 30-45 minutes. I then let that sit an hour or two and recheck. If it’s good I move on to filling. The reason I do both is I’ve heard that sometimes only vacuuming it can pull the leak close. I know some people may agree doing it this way and some people will definitely disagree. But it’s worked for me really well.

I will have to check on the ac crimps. I believe they’re was a place off of route 1 called tubes and hoses of Elkridge. I had some stuff done there years back, but I don’t know if they’re still around. I’ll check with the local place by me called cauliflower and see if they can. I’m not surprised they want you to buy the fittings there. Everybody’s trying to make a dollar.

~ GW

#10

What does a tank of pressurized tank of nitrogen go for these days? Agree that's the best way to leak test the system before charging with refrigerant. Since I didn't have that handy when I did the FC, I just tested for leaks by seeing if it would hold a vacuum overnight. Since it did, I just charged it up with the duster gas, and periodically checked system performance (center vent thermometer test + manifold gauge H/L pressure readings in operation, and static H/L gauge readings before starting) over the course of that first summer using it. Figured that would give me a good indication if anything was leaking out.

Back to the original oil capacity question, I checked my notes from the FC, and it looks like a total of 6~7.5 oz. will be enough for my FD. I'll get about 6oz of that in the compressor, and the remainder in the dryer, condenser & evaporator. The FC FSM does specify a total system dry capacity, as well as the per component replacement capacities the FD FSM references. Based on proportions between the two FC sets of numbers, it looks like Mazda specified a little extra lube for the per-component replacement scenario - probably to account for a little lost oil during service procedures. I'm guessing they did the same for the FD.

Back to the original oil capacity question, I checked my notes from the FC, and it looks like a total of 6~7.5 oz. will be enough for my FD. I'll get about 6oz of that in the compressor, and the remainder in the dryer, condenser & evaporator. The FC FSM does specify a total system dry capacity, as well as the per component replacement capacities the FD FSM references. Based on proportions between the two FC sets of numbers, it looks like Mazda specified a little extra lube for the per-component replacement scenario - probably to account for a little lost oil during service procedures. I'm guessing they did the same for the FD.

#11

That’s a great question. I haven’t bought that stuff in a while. A quick Google search yielded a bunch of little kits you can buy called AC flush. The big thing is to not over oil. Been there, done that. Pain to redo something you just did. But you live and learn. I think you will be fine with 6 and change. Oh, I almost forgot to mention, The Denso expansion valve for r134 may work for both but the orifice size is very different. For what you’re doing it makes sense to use the R134 but for others who are going to stick with r12 they should buy the specific one. I’ll check on the AC stuff and let you know if they can crimp that.

~ GW

~ GW

#12

Senior Member

iTrader: (2)

I fitted RX8 compressor with a Denso compressor in my FD with some custom lines. The 1994 Body and Electrical Troubleshooting Guide, Section G, shows the capacity for both R134 and R12 along with the recommended high/low side pressure. I would use the low side of the recommended capacity and charge with proper manifold gauges. DO NOT rely on those AC recharge cans that only show low side pressure. This the **** way to charge and those things are notoriously not accurate. I did that at first totally over charged and blew a compressor. As for pulling a vac to check for leaks, let it run for a 20-30 min but let it sit OVERNIGHT before you fill. A slow leak could take hours to show. Again, I tried to go fast and it made may life way more difficult. It just took me half a summer to figure all my **** out after totally messing it up the first time. Also, if you mess up and have to crack the system open, replace the drier. Don't reuse it. I tried that with my RX8 condenser (has replaceable desiccant) and my AC was on the water side of cool. Replaced it...cold as ice.

Last edited by Djseto; 11-01-20 at 05:29 PM.

#13

RX-7 Bad Ass

iTrader: (55)

I think the shop manual has some stuff on the AC system and refrigerant oil. It's in the Body Electrical Manual, that guide isn't on many of the sites with a copy of the shop manual. I posted a link to it recently, it goes in depth on the AC system.

Typically it has a whole process - pull the compressor, drain the oil out, see how much drains out, then put that much back in with a certain extra, put in so much extra if you replace the drier, etc. I don't think it's very much. The amount you were talking (8.8) about seems high.

I redid the AC recently in my RX-8 during the rebuild process. Had to guess on the amount in the compressor as a bunch got lost when it was pulled from the car and left on its side in the driveway . I think I only put like 3-4 oz in and that seemed too much. But, it's a smaller (physically) compressor and it's a different system. The AC is blowing cold and happy, though, so there's that.

. I think I only put like 3-4 oz in and that seemed too much. But, it's a smaller (physically) compressor and it's a different system. The AC is blowing cold and happy, though, so there's that.

Also ND-9 oil (I bought the real deal stuff) smells like Band-Aids and the smell sticks to you like CRAZY. Barf.

The long thread in the FC section on 152a does talk some about compressor oil, that may be worth another read through and take notes.

Dale

Typically it has a whole process - pull the compressor, drain the oil out, see how much drains out, then put that much back in with a certain extra, put in so much extra if you replace the drier, etc. I don't think it's very much. The amount you were talking (8.8) about seems high.

I redid the AC recently in my RX-8 during the rebuild process. Had to guess on the amount in the compressor as a bunch got lost when it was pulled from the car and left on its side in the driveway

. I think I only put like 3-4 oz in and that seemed too much. But, it's a smaller (physically) compressor and it's a different system. The AC is blowing cold and happy, though, so there's that.

. I think I only put like 3-4 oz in and that seemed too much. But, it's a smaller (physically) compressor and it's a different system. The AC is blowing cold and happy, though, so there's that.Also ND-9 oil (I bought the real deal stuff) smells like Band-Aids and the smell sticks to you like CRAZY. Barf.

The long thread in the FC section on 152a does talk some about compressor oil, that may be worth another read through and take notes.

Dale

#14

I think the shop manual has some stuff on the AC system and refrigerant oil. It's in the Body Electrical Manual, that guide isn't on many of the sites with a copy of the shop manual. I posted a link to it recently, it goes in depth on the AC system.

Typically it has a whole process - pull the compressor, drain the oil out, see how much drains out, then put that much back in with a certain extra, put in so much extra if you replace the drier, etc. I don't think it's very much. The amount you were talking (8.8) about seems high.

Typically it has a whole process - pull the compressor, drain the oil out, see how much drains out, then put that much back in with a certain extra, put in so much extra if you replace the drier, etc. I don't think it's very much. The amount you were talking (8.8) about seems high.

I redid the AC recently in my RX-8 during the rebuild process. Had to guess on the amount in the compressor as a bunch got lost when it was pulled from the car and left on its side in the driveway  . I think I only put like 3-4 oz in and that seemed too much. But, it's a smaller (physically) compressor and it's a different system. The AC is blowing cold and happy, though, so there's that.

. I think I only put like 3-4 oz in and that seemed too much. But, it's a smaller (physically) compressor and it's a different system. The AC is blowing cold and happy, though, so there's that.

Also ND-9 oil (I bought the real deal stuff) smells like Band-Aids and the smell sticks to you like CRAZY. Barf.

The long thread in the FC section on 152a does talk some about compressor oil, that may be worth another read through and take notes.

Dale

. I think I only put like 3-4 oz in and that seemed too much. But, it's a smaller (physically) compressor and it's a different system. The AC is blowing cold and happy, though, so there's that.

. I think I only put like 3-4 oz in and that seemed too much. But, it's a smaller (physically) compressor and it's a different system. The AC is blowing cold and happy, though, so there's that.Also ND-9 oil (I bought the real deal stuff) smells like Band-Aids and the smell sticks to you like CRAZY. Barf.

The long thread in the FC section on 152a does talk some about compressor oil, that may be worth another read through and take notes.

Dale

I "bench flushed" the compressor yesterday with the fresh lube. My used compressor was already drained out almost completely dry when I got it. It would take only about 6.5oz of lube to fill it completely, and that's after rotating the compressor clockwise about a dozen times to work it all through. Drain, rinse & repeat a few times until nothing but clean new lube drains out.

#15

RX-7 Bad Ass

iTrader: (55)

I think adding compressor oil is a bit of a black art. I don't think you want the compressor to be full per se when installed, just needs the right amount. Too much and you can gum up the works with oil everywhere in the system.

Dale

Dale

Thread

Thread Starter

Forum

Replies

Last Post

moconnor

3rd Generation Specific (1993-2002)

16

01-04-11 06:43 PM

sbelyo

3rd Generation Specific (1993-2002)

4

04-23-09 07:20 PM

slo

2nd Generation Specific (1986-1992)

4

03-22-08 04:26 PM

BATMAN

3rd Generation Specific (1993-2002)

14

06-28-04 06:45 PM