Electric Turbo Control Actuator

#1

Senior Member

Thread Starter

Electric Turbo Control Actuator

I searched and didn't find anything on this. . .I'm wondering if anyone who has a sequential setup has replaced the pressure/vacuum controled TCA with an electric controled TCA? With newer technology out there, seems like this might be possible at reasonable cost and provide for a more reliable system. I'm not an electrical expert, but it seems if you could find an actuator that would work, you could control it with the same electrical leads that control our current solenoid operations. Any thoughts?

#5

Senior Member

Thread Starter

Hi arghx (sorry, not sure your name). I know you've posted on many turbo threads. Isn't the TCA just an on/off situation? if you had a motor with the correct throw (I've seen them with 1", 2", etc. I was thinking a relay control or something to engage and disengage the motor.

Thanks for your thoughts. May be more hassle than its worth unless you could source the exact parts.

--Jeff

Thanks for your thoughts. May be more hassle than its worth unless you could source the exact parts.

--Jeff

#7

and here:

You can't just have that signal run the motor continuously. It'll never last.

Now consider 3 systems:

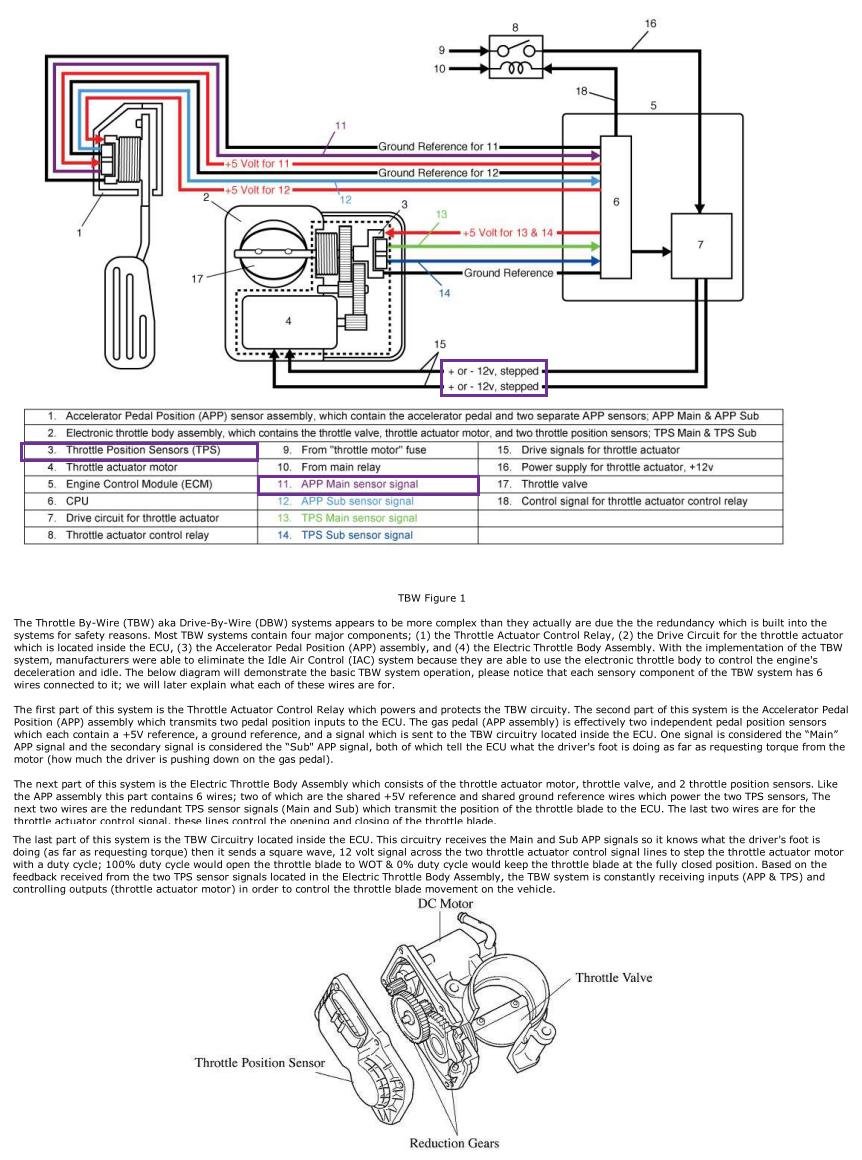

1) Subaru drive-by-wire

You can see that there are two TPS's. Now the throttlebody is a very critical component and you would expect that level of redundancy for it, but it demonstrates the kind of engineering that goes into systems with electric motors. It's also duty controlled of course.

2) Ford drive-by-wire

You can see in these diagrams of Ford drive-by-wire that the motor is duty controlled. There are a number of mechanical components that come into play in the event of a failure.

Of course an electric TCA is not as complicated as a drive-by-wire, but some of the basic engineering principles remain (redundancy, failure mode, feedback/position sensing). So let's look at something that's a little bit closer to what you're trying to do.

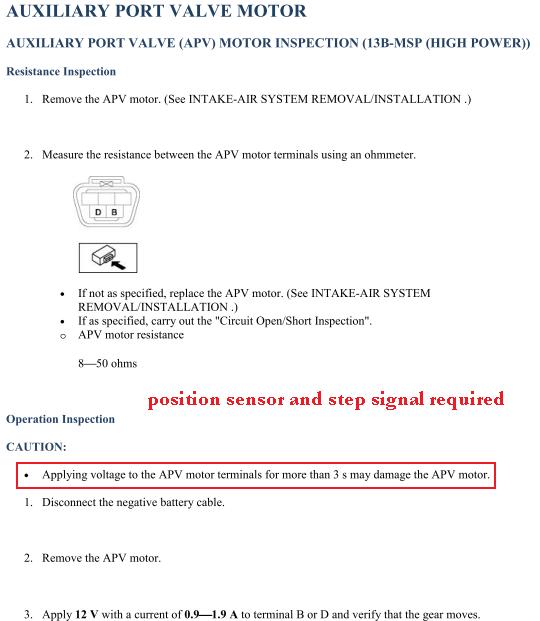

3)

That's the Auxiliary Port Valve motor on the Rx-8's. It's closer to what you're trying to do--it's mostly open or closed and isn't as complicated as a drive-by-wire system. But it has a position sensor at least, and it has some sort of pulsewidth modulation or something, otherwise it wouldn't burn out if +12V were applied for more than 3 seconds.

I'm not saying it can't be done, and I'm not saying you shouldn't try. It's not my job to **** in somebody's cornflakes. But I question how reliable it would be and how long it would last without recreating the elements of OEM design that maximize consistency and longevity. 2nd gen Rx-7 owners have attempted to convert from pressure actuated auxiliary port sleeves (stock design until the Rx-8's came out) to an electric motor. Nobody has ever gotten a system like that to run consistently over time due to the quality of the motors normally used and an inability to compensate for any changes or degradation. It wasn't until Mazda engineered the auxiliary port motors on the Rx-8 that it was done relatively reliably (compared to DIY systems at least).

If you can integrate a position sensor and some kind of control logic it would improve the chances of it working over the long haul. But if it were as simple as just supplying +12V to something continuously for a few seconds Mazda would've done it. Whatever motor you pick would have to stand up to a lot of heat... and you would need a TCA position sensor to monitor that it's working properly.

Last edited by arghx; 08-29-09 at 09:28 AM. Reason: fixed pic

Trending Topics

#8

Ah, I see.

I was thinking you meant some kind of controlled-opening electric solenoid rather than a servomotor type of thing. (And I apologize if I get the terminology wrong, I'm not a controls guy).

Based on what's out there, is there an electric-powered on-off device that can move a rod with the same throw force as the stock actuator?

David

I was thinking you meant some kind of controlled-opening electric solenoid rather than a servomotor type of thing. (And I apologize if I get the terminology wrong, I'm not a controls guy).

Based on what's out there, is there an electric-powered on-off device that can move a rod with the same throw force as the stock actuator?

David

#11

Senior Member

Thread Starter

Would something like this work electrically?

http://www.firgelliauto.com/product_...roducts_id=104

--Jeff

#13

Well the TCA is probably your best location for regulating heat damage. It's down low, in the airstream, and you could probably extend the piston rod to allow the actuator to locate further ahead in the engine bay. Good heat shielding should help immensely.

Really those actuators are interesting. My only initial question is whether 1.5"/sec is suitably quick. Since those particular pieces are for automating doors and stuff I'm sure they aren't the fastest thing out there.

Dave

Really those actuators are interesting. My only initial question is whether 1.5"/sec is suitably quick. Since those particular pieces are for automating doors and stuff I'm sure they aren't the fastest thing out there.

Dave

#14

Just found this thread while looking for information into TCAs (because the pressure side on mine is melted).

This is definitely a good idea, and likely could be built to actuate faster than the pneumatic system.

An electric motor is not the right actuator, though. Instead, it could be designed around a high force, long throw tubular pull solenoid with a spring return. This

shows the architecture. One of the existing solenoid harness connections would drive a solid state (or mechanical) relay that would switch power to the pull solenoid (it would be much higher current draw than the existing TCA control solenoids so likely couldn't be driven directly from the ECU).

No, a home-brew aftermarket design implementing this idea probably wouldn't be as reliable as the existing system. But only because, like every other aftermarket part, it won't have gone through the extensive reliability testing that automotive companies do. The technology involved is quite well understood and robust, and electrical windings can withstand extreme temperatures (umm, unlike the plastic in the existing TCA). I'd guess Mazda didn't do it this way because it costs more in volume, not because it couldn't be as reliable, and not because it wouldn't work better.

Note new TCAs are NLA.... someone with more time than I have should make one.

This is definitely a good idea, and likely could be built to actuate faster than the pneumatic system.

An electric motor is not the right actuator, though. Instead, it could be designed around a high force, long throw tubular pull solenoid with a spring return. This

No, a home-brew aftermarket design implementing this idea probably wouldn't be as reliable as the existing system. But only because, like every other aftermarket part, it won't have gone through the extensive reliability testing that automotive companies do. The technology involved is quite well understood and robust, and electrical windings can withstand extreme temperatures (umm, unlike the plastic in the existing TCA). I'd guess Mazda didn't do it this way because it costs more in volume, not because it couldn't be as reliable, and not because it wouldn't work better.

Note new TCAs are NLA.... someone with more time than I have should make one.

Last edited by primerGrey; 08-26-17 at 07:48 PM.

#15

RX-7 Bad Ass

iTrader: (55)

The tricky thing though is the TCA generally does its job fairly well. They are also available used for a dime a dozen.

If you went for something aftermarket it would need to be able to stand up to a LOT of heat, the TCA is right there on the exhaust manifold, which is the hottest part of the whole system.

Doing the charge control actuator with a solenoid would probably be a bit easier as it's out of the super-hot part of the engine.

Would be cool if you could replace both with a solenoid - that would negate a lot of the pneumatic plumbing. Could save some weight too. But, it would need to be dead reliable, no sense replacing the not-too-relaible system with something less so.

Dale

If you went for something aftermarket it would need to be able to stand up to a LOT of heat, the TCA is right there on the exhaust manifold, which is the hottest part of the whole system.

Doing the charge control actuator with a solenoid would probably be a bit easier as it's out of the super-hot part of the engine.

Would be cool if you could replace both with a solenoid - that would negate a lot of the pneumatic plumbing. Could save some weight too. But, it would need to be dead reliable, no sense replacing the not-too-relaible system with something less so.

Dale

#16

Thanks Dale. I think the motivation behind something like this would be a substantially quicker actuation, minimizing boost dip at transition.

I have to disagree about the heat concern associated with electric solenoids. I've pulled the OEM TCA apart out of curiosity - it contains a plastic bellows on the pressure side that definitely won't withstand as much heat as an electric coil would. And that plastic bellows is sealed on the actuator end with an rubber o-ring. My plastic bellows had melted (not in normal use though - it got blasted with hot exhaust after an exhaust gasket failed).

Even with a good bellows, many of the used units I've seen have pressure side leaks, because the o-ring has worn, or become embrittled from age or heat.

But you are right, I'm replacing mine with a used unit because that is the easiest path forward.

I have to disagree about the heat concern associated with electric solenoids. I've pulled the OEM TCA apart out of curiosity - it contains a plastic bellows on the pressure side that definitely won't withstand as much heat as an electric coil would. And that plastic bellows is sealed on the actuator end with an rubber o-ring. My plastic bellows had melted (not in normal use though - it got blasted with hot exhaust after an exhaust gasket failed).

Even with a good bellows, many of the used units I've seen have pressure side leaks, because the o-ring has worn, or become embrittled from age or heat.

But you are right, I'm replacing mine with a used unit because that is the easiest path forward.

#17

RX-7 Bad Ass

iTrader: (55)

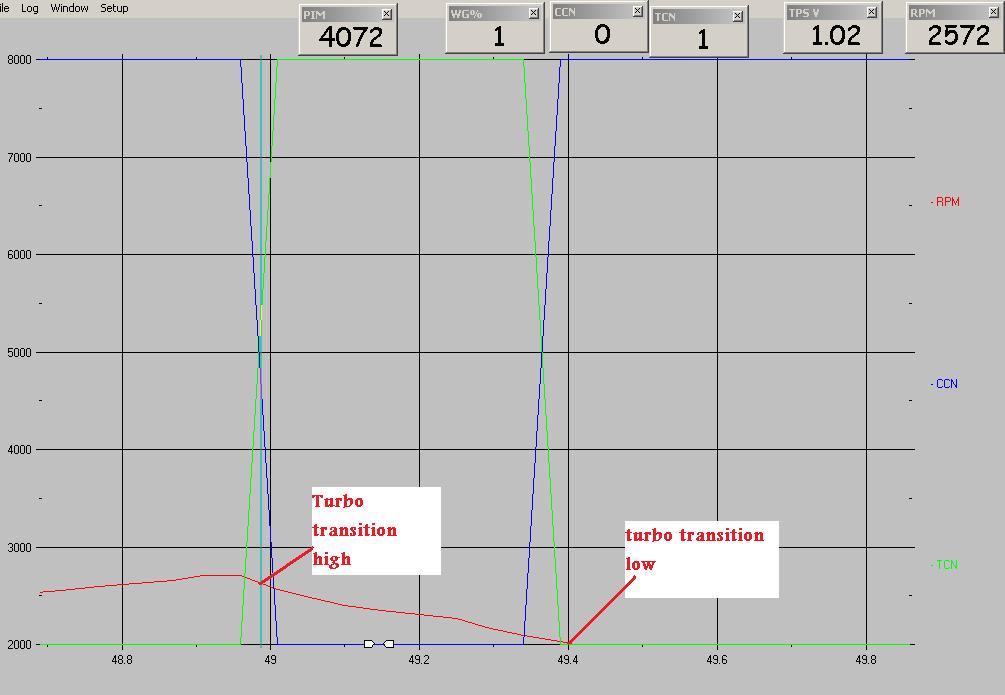

The TCA isn't the cause of the boost dip, tuning is. My car has no noticeable transition whatsoever.

You can change the transition point with the Datalogit on a PowerFC, if you drop the RPM a bit you can find a sweet spot where you don't have a transition delay. Stock ECU, you're pretty stuck with it, unless you use an AVC-R or a boost controller that can adjust boost by RPM.

IMHO, Mazda put the transition in there purely for marketing. Go to the dealer, test drive the car, salesman says "boy you can feel when that second turbo kicks in!" and you whip out the checkbook. If it was a smooth, linear power band you wouldn't notice it.

Dale

You can change the transition point with the Datalogit on a PowerFC, if you drop the RPM a bit you can find a sweet spot where you don't have a transition delay. Stock ECU, you're pretty stuck with it, unless you use an AVC-R or a boost controller that can adjust boost by RPM.

IMHO, Mazda put the transition in there purely for marketing. Go to the dealer, test drive the car, salesman says "boy you can feel when that second turbo kicks in!" and you whip out the checkbook. If it was a smooth, linear power band you wouldn't notice it.

Dale

Thread

Thread Starter

Forum

Replies

Last Post

sherff

Adaptronic Engine Mgmt - AUS

9

02-24-19 12:09 PM

CaptainKRM

2nd Generation Specific (1986-1992)

14

08-26-15 09:52 PM

82streetracer

1st Generation Specific (1979-1985)

7

08-23-15 09:28 AM