AEM Tru Boost Problems....

#26

Quick update on my setup. I set the wastegate crack pressure (SPr) to 4psi and get good spool times. Pretty much instant 10 psi at 2.5 - 3k rpm. Duty cycle at 55 gave me an initial boost spike to 14.1 psi. I didn't see what it held to redline, I was busy passing an idiot on the road. Upon seeing it peak to 14 (don't want it that high right now), I lowered it back to 50% duty. Should be around 12 psi at WOT.

#28

I currently lowered my duty cycle back to 50% with 4 SPr. I had it set to 53% yesterday and did some WOT 3rd gear pulls and saw it spike up into the 14 psi range. Which is fine for some people, it's just a little too high for me right now. With my current settings (4 Spr and 50% duty) I'm getting 13psi held to red line with a minimal boost spike, which is to be expected.

When I moved my SPr to 4.1 I noticed a pretty big jump in boost spike. When I set it to 5, I got boost oscillations. When I set my SPr to 3.9 spool up times start to slow down. For me, 4.0 SPr is just right.

When I moved my SPr to 4.1 I noticed a pretty big jump in boost spike. When I set it to 5, I got boost oscillations. When I set my SPr to 3.9 spool up times start to slow down. For me, 4.0 SPr is just right.

#29

I think your playing with the wrong settings to achieve your goals. Spring pressure should be as close to your target boost as possible for best response. Usually around 4 psi under target boost. The sensitivity is what you should be changing. I usually start at zero and raise it until its doing what I like, usually only 5-10%

thewird

thewird

#30

I need to replace my bushings in my shifter before I got back out and fiddle with it again. When I had my SPr set to 6psi , assume stockish boost level, I got oscillations with a 40% duty cycle. I can lower the duty cycle way down to 5% and see what it does.

My current spool time should be slightly faster with the stock twins, but it's not really that slow with the SPr 4psi and duty cycle of 50% setting. If anyone is running a setting like 10 SPr with a lower duty cycle, I'd like to try out those specific settings.

AEM stats @ 5:58. "A good starting point is to set SPr to 3 psi less then your known wastegate spring pressure" ... adjust from there.

Time to go search for that bushing kit I had stashed away...

My current spool time should be slightly faster with the stock twins, but it's not really that slow with the SPr 4psi and duty cycle of 50% setting. If anyone is running a setting like 10 SPr with a lower duty cycle, I'd like to try out those specific settings.

AEM stats @ 5:58. "A good starting point is to set SPr to 3 psi less then your known wastegate spring pressure" ... adjust from there.

Time to go search for that bushing kit I had stashed away...

#31

I think your playing with the wrong settings to achieve your goals. Spring pressure should be as close to your target boost as possible for best response. Usually around 4 psi under target boost. The sensitivity is what you should be changing. I usually start at zero and raise it until its doing what I like, usually only 5-10%

thewird

thewird

#33

thewird

#34

Tangoshark, thanks but I found my bushing kit (in the mail via Ray Crowe lol). I had to order some upper spring mounts/insulators anyway.

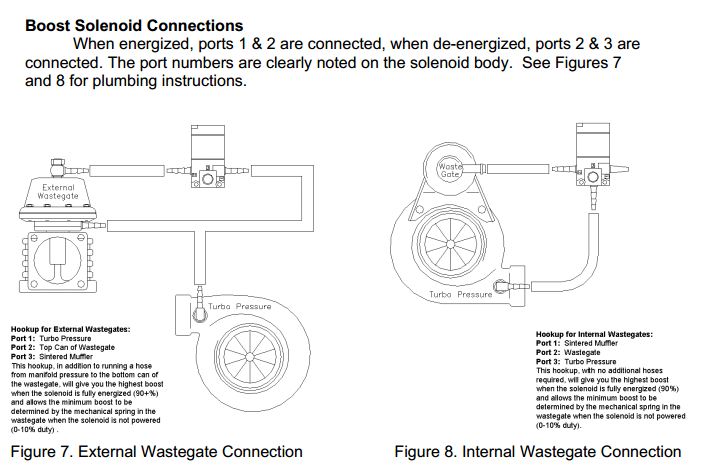

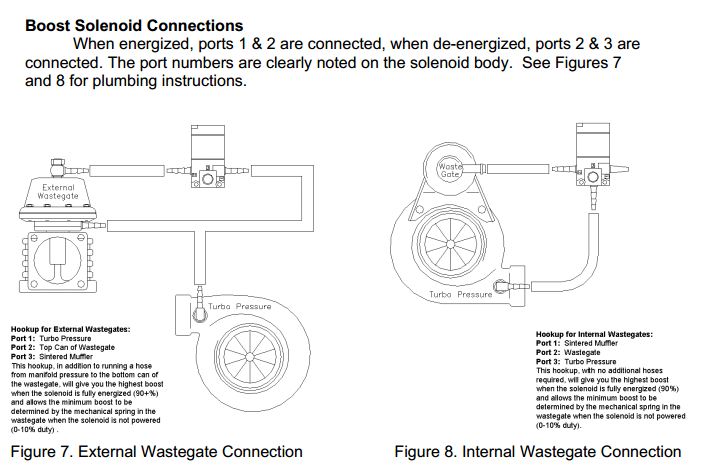

I would think that if you set the SPr value to a target boost level, say 12 psi, you'd just be bypassing the controller and just running off the mechanical wastegate (actuator). If I'm reading this correctly, if you use ports 2 (center) and 3 (bottom) you're routing pressurized air to the wastegate actuator when the solenoid is de-energized. So if you run 10-15% duty cycle, the majority of the time you're just using the mechanical wastegate spring to regulate boost. As you turn up the duty cycle, you're routing less pressurized air to the wastegate actuator and reducing the time the wastegate is open.

The oscillations come from a higher pressure boost (say 12 psi) getting to the wastegate actuator, forcing it fully open, dumping boost and then the Truboost solenoid stepping in and turning the wastegate actuator off again. That's when you see the boost spike, then the Truboost solenoid allows air to the wastegate actuator and dumps off boost. It just does that over and over again. See the definition of the SPr setting below, it states: "The Tru Boost will keep the boost solenoid open (I assume this means de-energized, i.e. open circuit) from 1 psi until boost exceeds the selected value."

Duty cycle explanation if anyone is unclear - from Wikipedia:

This is from the latest Tru Boost install manual online:

It's all in how you have the boost controller hooked up with the stock twins. An external wastegate is a different story. At least...this is how I read the document from AEM and see during testing. Please correct me if this is wrong.

I would think that if you set the SPr value to a target boost level, say 12 psi, you'd just be bypassing the controller and just running off the mechanical wastegate (actuator). If I'm reading this correctly, if you use ports 2 (center) and 3 (bottom) you're routing pressurized air to the wastegate actuator when the solenoid is de-energized. So if you run 10-15% duty cycle, the majority of the time you're just using the mechanical wastegate spring to regulate boost. As you turn up the duty cycle, you're routing less pressurized air to the wastegate actuator and reducing the time the wastegate is open.

The oscillations come from a higher pressure boost (say 12 psi) getting to the wastegate actuator, forcing it fully open, dumping boost and then the Truboost solenoid stepping in and turning the wastegate actuator off again. That's when you see the boost spike, then the Truboost solenoid allows air to the wastegate actuator and dumps off boost. It just does that over and over again. See the definition of the SPr setting below, it states: "The Tru Boost will keep the boost solenoid open (I assume this means de-energized, i.e. open circuit) from 1 psi until boost exceeds the selected value."

Duty cycle explanation if anyone is unclear - from Wikipedia:

A duty cycle is the time that an entity spends in an active state as a fraction of the total time under consideration.

Enter the waste gate spring pressure (3psi less then your spring). The Tru Boost

will keep the boost solenoid open from 1 psi until boost exceeds the selected value.

This value can be adjusted to reduce lead in boost spikes or reduce spool up time. If

the spring pressure is unknown, a conservative starting value of 5 is suggested.

will keep the boost solenoid open from 1 psi until boost exceeds the selected value.

This value can be adjusted to reduce lead in boost spikes or reduce spool up time. If

the spring pressure is unknown, a conservative starting value of 5 is suggested.

#35

It's important not to get the terminology confused. In this context, when they talk about the solenoid being "open" they literally mean that the valve is open and air is flowing through it. They don't mean that in the sense of an open electrical circuit. So "open" means maximum duty cycle for our purposes.

An oscillation could occur if the boost spikes and then drops very fast. It's hard to know 100% what's going on without using a current probe and a data acquisition system to calculate out duty cycle--which kind of defeats the purpose of a cheap boost controller. There's nothing unusual about the "SPr" setting in the AEM Tru Boost.

check out my boost controller comparison chart thread and you will see that other controllers have settings that work the same way:

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/electronic-boost-controller-comparison-chart-952767/

An oscillation could occur if the boost spikes and then drops very fast. It's hard to know 100% what's going on without using a current probe and a data acquisition system to calculate out duty cycle--which kind of defeats the purpose of a cheap boost controller. There's nothing unusual about the "SPr" setting in the AEM Tru Boost.

check out my boost controller comparison chart thread and you will see that other controllers have settings that work the same way:

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/electronic-boost-controller-comparison-chart-952767/

#36

Is it normal for the solenoid to make a soft clicking noise when the key is in the on position and car is not running?

I've been trying to test the controller by hooking a hand pump to the vacuum line on the gauge to simulate boost. When I pump the pressure up to the spr setting I can hear the solenoid start clicking loud. When I increase duty cycle, it clicks faster, and the scramble boost works for the preset duration. I just found it odd that when I turn the controller off, or depressurize the line, I can still hear a soft clicking from the solenoid. Does anyone else's do this?

I've been trying to test the controller by hooking a hand pump to the vacuum line on the gauge to simulate boost. When I pump the pressure up to the spr setting I can hear the solenoid start clicking loud. When I increase duty cycle, it clicks faster, and the scramble boost works for the preset duration. I just found it odd that when I turn the controller off, or depressurize the line, I can still hear a soft clicking from the solenoid. Does anyone else's do this?

Thread

Thread Starter

Forum

Replies

Last Post

Shainiac

Single Turbo RX-7's

12

07-17-19 02:20 PM

t-von

3rd Generation Specific (1993-2002)

9

09-10-15 01:56 PM