Updated 2nd gen Power FC document now on Google Docs

#1

Updated 2nd gen Power FC document now on Google Docs

Some of you may know that I have been maintaining a Power FC guide for 2nd gen owners for a while now. The old links to it are dead, so I have decided to host it on Google Docs:

https://docs.google.com/fileview?id=...MTkxODA2&hl=en

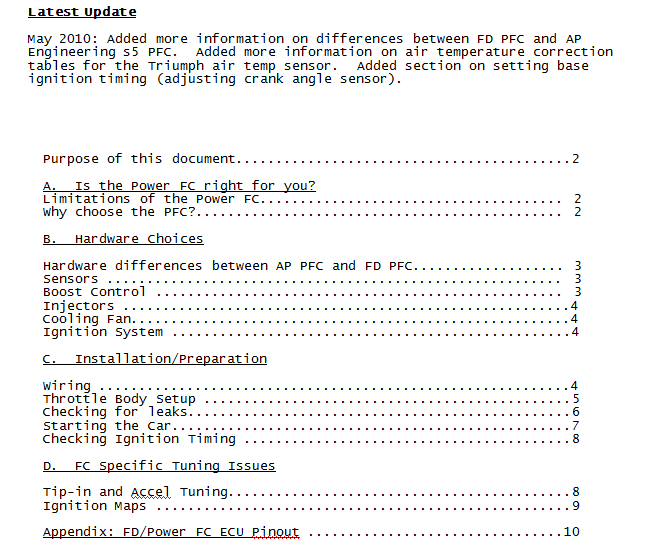

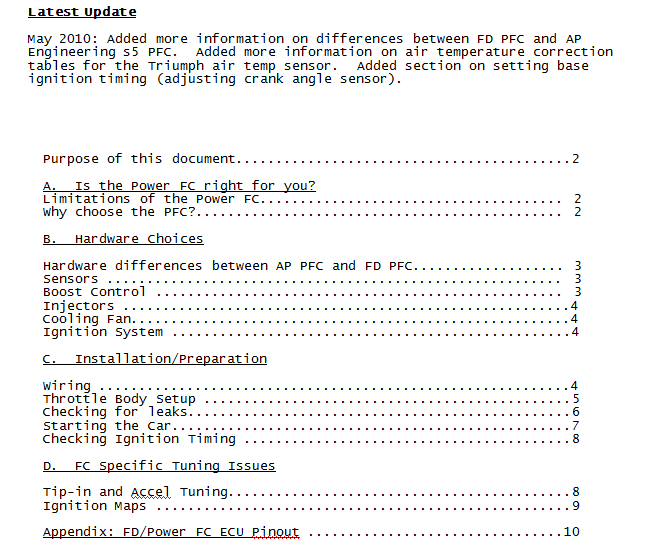

the formatting is slightly off from the conversion but it is plenty readable. This document is aimed towards people who are considering purchasing a Power FC for their 2nd gen and those who have one but want some additional background information. It also gives wiring advice and a Power FC pinout for things like the TPS, vehicle speed sensor, boost control signal, etc. The document also contains a few miscellaneous sections on FC specific tuning issues for those of you who are DIY-oriented. Here is the current table of contents:

Here is another thread I made in the 3rd gen section on basic Power FC tuning adjustments using only the Commander:

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/how-make-your-untuned-pfc-basemap-safer-idle-better-no-datalogit-needed-841706/

There are a few FD specific things in there (like the throttlebody adjustments and the default FD timing map) but it gives a good background to get you familiar with the system. It also has detailed discussion of idle tuning on the Power FC.

https://docs.google.com/fileview?id=...MTkxODA2&hl=en

the formatting is slightly off from the conversion but it is plenty readable. This document is aimed towards people who are considering purchasing a Power FC for their 2nd gen and those who have one but want some additional background information. It also gives wiring advice and a Power FC pinout for things like the TPS, vehicle speed sensor, boost control signal, etc. The document also contains a few miscellaneous sections on FC specific tuning issues for those of you who are DIY-oriented. Here is the current table of contents:

Here is another thread I made in the 3rd gen section on basic Power FC tuning adjustments using only the Commander:

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/how-make-your-untuned-pfc-basemap-safer-idle-better-no-datalogit-needed-841706/

There are a few FD specific things in there (like the throttlebody adjustments and the default FD timing map) but it gives a good background to get you familiar with the system. It also has detailed discussion of idle tuning on the Power FC.

#2

Good info. I have a question though as I don't know how the PFC software works (I run a simple haltech).

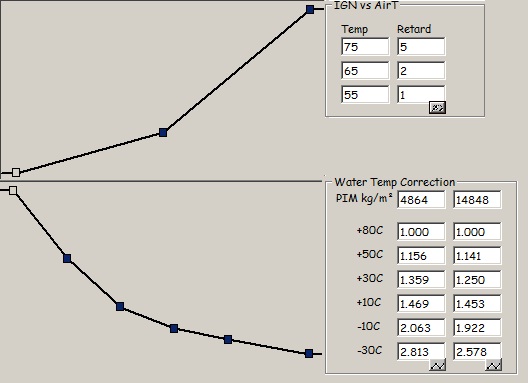

Page 10 of your document has those correction tables. The numbers in those tables, are they multipliers on top of the base injection times?

IE: 1.156 is adding 15.6%?

Page 10 of your document has those correction tables. The numbers in those tables, are they multipliers on top of the base injection times?

IE: 1.156 is adding 15.6%?

#3

re-amemiya body vert

iTrader: (2)

Join Date: Oct 2003

Location: Calgary, Canada

Posts: 503

Likes: 0

Received 0 Likes

on

0 Posts

Dude, you're the man. It's one thing to read the manual that comes with the PFC and it's another to get someone's insight and experience into using the product. Thanks for putting in the effort!

#4

So base is 10msec * 1.20 INJ correction = 12msec commanded pulsewidth , same as base being 12.0 msec and INJ being 1.00

12 msec * 1.156 air temp correction is a commanded pulsewidth of 13.872 msec.

There may be other corrections on top of that (like injector lag compensation), as well as tip-in correction or water temp correction if applicable.

#5

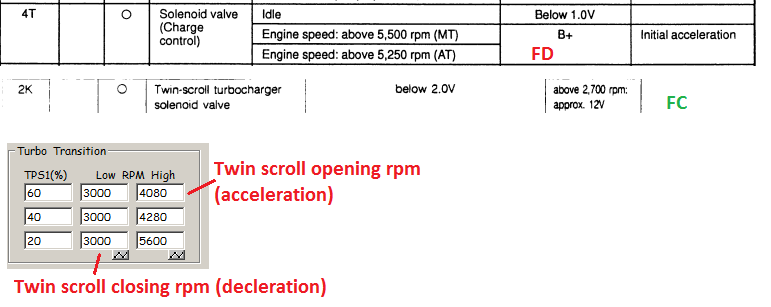

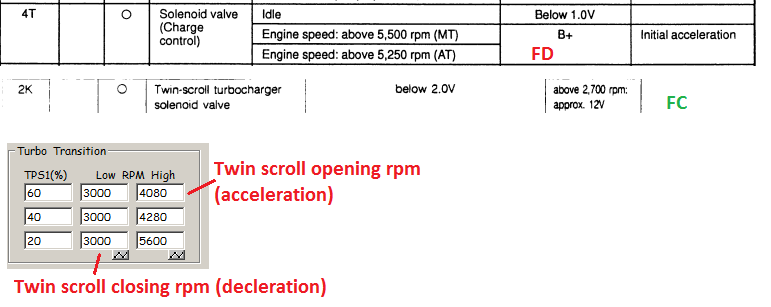

Just another random note that is not included in the document: I think you can control the s4 twin scroll solenoid with the Power FC. Just use pin FD 4T on the harness, it is normally used as the charge control solenoid output on an FD. The corresponding pin for the twin scroll solenoid is s4 pin 2K.

So on an FD pin 4T is ON (ground is supplied) until the trigger rpm that has been set in the Power FC "turbo transition" options available in the settings 1 tab of the Datalogit software. This works the same way as pin 2K on the s4 ECU:

Pictured above is the factory sequential turbo transition logic on an FD. If you are running an FC with a twin scroll solenoid you can set the "high" value to 2800 rpm and the "low" value to about 2500 if you want the same control logic Mazda used from the factory. If you are ordering an s4 harness adapter from Banzai Racing you may be able to request that they connect FD pin 4T to FC pin 2K, then you would have twin scroll solenoid functionality provided that you have a Datalogit box to adjust those settings with a laptop. Then you can also request that pin 4U be installed and left as an unterminated wire. That's your wire for the boost control output, something that the s5 already has but the s4 does not. You can use that to wire up an inexpensive boost control solenoid, like this one here:

http://www.frightprops.com/FrightPro...ID=A-0013-0082 1/8" NPT, $26.50 . Same as the AEM and Haltech solenoids but without the markup.

So on an FD pin 4T is ON (ground is supplied) until the trigger rpm that has been set in the Power FC "turbo transition" options available in the settings 1 tab of the Datalogit software. This works the same way as pin 2K on the s4 ECU:

Pictured above is the factory sequential turbo transition logic on an FD. If you are running an FC with a twin scroll solenoid you can set the "high" value to 2800 rpm and the "low" value to about 2500 if you want the same control logic Mazda used from the factory. If you are ordering an s4 harness adapter from Banzai Racing you may be able to request that they connect FD pin 4T to FC pin 2K, then you would have twin scroll solenoid functionality provided that you have a Datalogit box to adjust those settings with a laptop. Then you can also request that pin 4U be installed and left as an unterminated wire. That's your wire for the boost control output, something that the s5 already has but the s4 does not. You can use that to wire up an inexpensive boost control solenoid, like this one here:

http://www.frightprops.com/FrightPro...ID=A-0013-0082 1/8" NPT, $26.50 . Same as the AEM and Haltech solenoids but without the markup.

#6

I am comparing percentages and trying to get a feel for what I should be aiming for (I know all modified engines are different though) as far as my own map. When it's cooler out and the car is warming up, I tend to lean out and the engine doesn't seem happy. Other times when it's a little warmer it's fine. Something I need to play with. Should I be taking out a little timing in the air temperature vs ignition map if it's leaning out in the cold? Throw more fuel into the air temp map? Any info is appreciated.

#7

Air temp fuel correction first. Focus on how the engine runs when fully warmed up, especially as the engine heatsoaks or as the weather changes. The location of the air temp sensor affects this. I presume you are using a Haltech/GM style sensor in the elbow.

Water temp fuel correction second. If the car runs fine when warm, you can make it run ok when cold by just throwing more fuel at it. FYI, retarding the timing during warm up can sometimes help with the popping sounds you may get. You don't always have that luxury when you don't have a BAC valve though, as idle stability is especially sensitive when you don't have a BAC.

Air temp ignition correction third. Retarding ignition under cooler air temps is not a common way of doing things. Usually once air temps heat up to a particular threshold you begin to retard ignition from whatever your normal value is. I have mine set to begin pulling timing at 55 C air temps I think. From my experience the engine can tolerate more timing at cooler intake temps.

As far as over WOT fueling vs air temp changes, well that does come down to preference to an extent. I actually run a little leaner as it gets colder out. 10-25C intake temps are usually around 11.5:1 AFR. 25C - 40C AFR is low 11's. intake temps over 40C are 11:1 or richer. This is intentional. But AFR's will still deviate within some range no matter what you do: that's why modern factory computers have a learning strategy (fuel trims) based on feedback from factory wideband o2 sensors.

This is with a s4 rotors, large streetport, T04R turbo, 720/1680 injectors, 43.5psi base fuel pressure, open element air temp sensor in Greddy elbow, Greddy 3 row FMIC, max boost 17psi.

Water temp fuel correction second. If the car runs fine when warm, you can make it run ok when cold by just throwing more fuel at it. FYI, retarding the timing during warm up can sometimes help with the popping sounds you may get. You don't always have that luxury when you don't have a BAC valve though, as idle stability is especially sensitive when you don't have a BAC.

Air temp ignition correction third. Retarding ignition under cooler air temps is not a common way of doing things. Usually once air temps heat up to a particular threshold you begin to retard ignition from whatever your normal value is. I have mine set to begin pulling timing at 55 C air temps I think. From my experience the engine can tolerate more timing at cooler intake temps.

As far as over WOT fueling vs air temp changes, well that does come down to preference to an extent. I actually run a little leaner as it gets colder out. 10-25C intake temps are usually around 11.5:1 AFR. 25C - 40C AFR is low 11's. intake temps over 40C are 11:1 or richer. This is intentional. But AFR's will still deviate within some range no matter what you do: that's why modern factory computers have a learning strategy (fuel trims) based on feedback from factory wideband o2 sensors.

This is with a s4 rotors, large streetport, T04R turbo, 720/1680 injectors, 43.5psi base fuel pressure, open element air temp sensor in Greddy elbow, Greddy 3 row FMIC, max boost 17psi.

Trending Topics

#8

Thanks for the info!

I am using the stock IAT sensor location, with the haltech/gm piece.

Retarding timing for coolant temps under warm up. I will try that as I get lots of popping on the engine.

As far as intake timing, I am not running any correction. I haven't read much about it.

I do run a BAC, I use it to bump my idle when cold (under 140 coolant). I have been playing with it quite a deal, and seem to have it doing what I want, but I fear it's a losing battle. I've looked at other maps people run, and I seem to be running tons more fuel as far as coolant correction goes. But that's because my BAC lets extra air in. Then I add more fuel. I keep repeating this and now I'm sure I need to start over as I am fighting the BAC settings against my coolant correction. I'm going to disable the BAC valve, and see how the car warms up without it. I imagine I'll be taking lots of fuel out.

At what point would you say the fuel vs coolant no longer needs correction?

I am using the stock IAT sensor location, with the haltech/gm piece.

Retarding timing for coolant temps under warm up. I will try that as I get lots of popping on the engine.

As far as intake timing, I am not running any correction. I haven't read much about it.

I do run a BAC, I use it to bump my idle when cold (under 140 coolant). I have been playing with it quite a deal, and seem to have it doing what I want, but I fear it's a losing battle. I've looked at other maps people run, and I seem to be running tons more fuel as far as coolant correction goes. But that's because my BAC lets extra air in. Then I add more fuel. I keep repeating this and now I'm sure I need to start over as I am fighting the BAC settings against my coolant correction. I'm going to disable the BAC valve, and see how the car warms up without it. I imagine I'll be taking lots of fuel out.

At what point would you say the fuel vs coolant no longer needs correction?

#9

Thanks for the info!

I am using the stock IAT sensor location, with the haltech/gm piece.

Retarding timing for coolant temps under warm up. I will try that as I get lots of popping on the engine.

As far as intake timing, I am not running any correction. I haven't read much about it.

I am using the stock IAT sensor location, with the haltech/gm piece.

Retarding timing for coolant temps under warm up. I will try that as I get lots of popping on the engine.

As far as intake timing, I am not running any correction. I haven't read much about it.

At what point would you say the fuel vs coolant no longer needs correction?

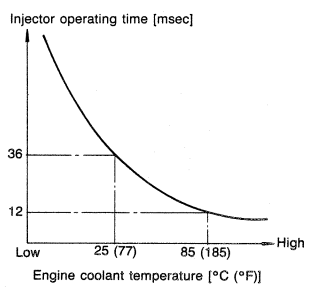

You can see how the fuel correction decays as the engine warms up. It's not linear. That graph is for the right column. Right column is for 7psi boost, left column is for 14" vac, and the PFC interpolates between the two columns as manifold pressure changes. My warmup AFR is usually around 12.2-12.5:1 at idle and then my warm idle AFR is between 12.8:1-13.3:1 at an idle speed of 900rpm and vacuum of about 13" from the big streetport.

I do run a BAC, I use it to bump my idle when cold (under 140 coolant). I have been playing with it quite a deal, and seem to have it doing what I want, but I fear it's a losing battle. I've looked at other maps people run, and I seem to be running tons more fuel as far as coolant correction goes. But that's because my BAC lets extra air in. Then I add more fuel. I keep repeating this and now I'm sure I need to start over as I am fighting the BAC settings against my coolant correction. I'm going to disable the BAC valve, and see how the car warms up without it. I imagine I'll be taking lots of fuel out.

Try this: Raise your cold BAC duty cycle and dial back your timing. Set your cold opening % and cold minimum position % higher. Pulling timing should help with the popping some while the BAC will keep the idle speed stable. Do the fuel last. I don't want to give you specific values to try without more information on your current map, because they may be way off for your particular engine. Also, you may need to adjust your BAC air adjusting screw some. Try to achieve your target warm idle with BAC valve duty between 40 - 70%.

#11

^That one I've seen before, it's the priming map. I have mine pretty much where I need it. It starts when heat soaked (185+ water, 125+ air), and in the cold winter temps I got it starting with no trouble in the 20's.

My haltech is an old one, still uses DOS mode! It's very primative, but it works well and is easy to use. I don't have load based warm up/corrections like you have though with the power FC.

I do not run correction as far as hot/cold coolant and air temps in regards to timing. My first concern was getting the fuel corrections for those 2 variables. My base idle timing is 4 degree advance with a 12 degree split. Like mentioned, I don't have correction added. When warmed up, my AFR's are around 12.5 - 13, and it's very stable around 900RPM. A lot of people crank the timing, but I am happy with my settings.

During warm up, especially in much colder temps I was aiming for 11.5-12 AFR's as the engine seemed happier.

My BAC doesn't seem to have an adjusting screw. I used to not have one at all, and the car would idle OK when cold, sometimes I needed to put my foot on the gas when it was below 40 outside. I plan to drive the car when it's cold, just not in crappy weather, hence I went this route to help idle up (instead of my foot).

I am happy with the way the car starts/runs, but it's inconsitent depending on the weather. I am just looking to make things more stable. Thanks for all the help so far.

FYI I run a street ported S4 TII motor, but it must not be too big. My idle vacuum is 17" at 900RPM.

My haltech is an old one, still uses DOS mode! It's very primative, but it works well and is easy to use. I don't have load based warm up/corrections like you have though with the power FC.

I do not run correction as far as hot/cold coolant and air temps in regards to timing. My first concern was getting the fuel corrections for those 2 variables. My base idle timing is 4 degree advance with a 12 degree split. Like mentioned, I don't have correction added. When warmed up, my AFR's are around 12.5 - 13, and it's very stable around 900RPM. A lot of people crank the timing, but I am happy with my settings.

During warm up, especially in much colder temps I was aiming for 11.5-12 AFR's as the engine seemed happier.

My BAC doesn't seem to have an adjusting screw. I used to not have one at all, and the car would idle OK when cold, sometimes I needed to put my foot on the gas when it was below 40 outside. I plan to drive the car when it's cold, just not in crappy weather, hence I went this route to help idle up (instead of my foot).

I am happy with the way the car starts/runs, but it's inconsitent depending on the weather. I am just looking to make things more stable. Thanks for all the help so far.

FYI I run a street ported S4 TII motor, but it must not be too big. My idle vacuum is 17" at 900RPM.

Thread

Thread Starter

Forum

Replies

Last Post

Skeese

Adaptronic Engine Mgmt - AUS

65

03-28-17 03:30 PM

1156, 156, 2nd, bac, corrections, documentation, duty, fc, gen, genpower, gtp50, power, split, table, temperature