thermo wax/fast idle/tps

#1

Yo dawg, Im happy for you

Thread Starter

iTrader: (2)

Join Date: Jan 2006

Location: Corvallis, Oregon

Posts: 574

Likes: 0

Received 0 Likes

on

0 Posts

thermo wax/fast idle/tps

All of a sudden this week the fast idle cam and tps have been on the fritz. I have been doing research on how to correct the problems, and got most of the information that I need. But when I go to put this info to work I'm not getting successful results. Here are my problems.

Fast Idle cam:

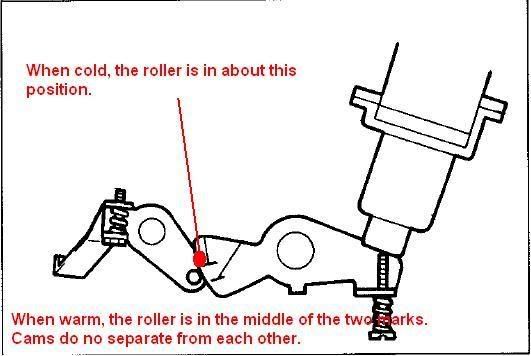

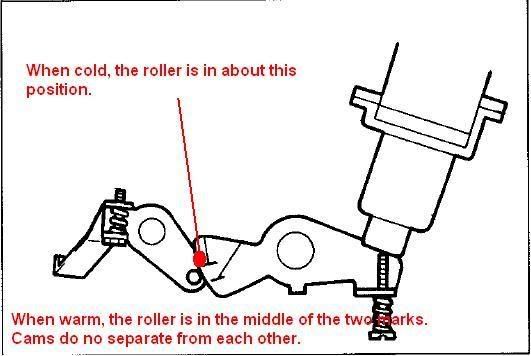

I took of the TB and ran hot water through the thermo wax and the piston did extend, but the linkage did not separate. When hot I adjusted the cam so the roller is in between the 2 marks(I have 3 marks, but put the roller between the two with the largest gap). When thermo wax is cold the roller is outside of the lines all together, looks something like this:

Also right now my AWS is revving to about 4K and the fast idle is at about 2-2.5k. Are these linked through the fast idle cam not being set right?

TPS:

I tried to rig up a checker lamp and test the green connector near the air box, but when i turn the keys into the on position, the lights just immediately blink and never come back on. So next I tried to to use a DMM in the same area, but that did not work either. I next tried to use a DMM at the tps connector where it meets with the harness, the red needle testing the green wire, and the black needle testing the black wire. By doing this I started about 1.79ohms, and would have to turn the screw clockwise to get to 1ohm. But by the time I got to 1.3ohms the screw spring was all the way compressed and could not turn clock wise any more, and now believe I was either getting bad readings, or was testing the wrong wires. It is also possible that my dmm is not good as it is quite old. Any thoughts on that?

And also the idle screw on top of the UIM has been tampered with, but I figured I could adjust this once the fast idle/tps were set.

I do own a haynes manual, and been reading through online FSMs and old threads, but thought it was possible I am off just a little bit.

Any help will be much appreciated!

Fast Idle cam:

I took of the TB and ran hot water through the thermo wax and the piston did extend, but the linkage did not separate. When hot I adjusted the cam so the roller is in between the 2 marks(I have 3 marks, but put the roller between the two with the largest gap). When thermo wax is cold the roller is outside of the lines all together, looks something like this:

Also right now my AWS is revving to about 4K and the fast idle is at about 2-2.5k. Are these linked through the fast idle cam not being set right?

TPS:

I tried to rig up a checker lamp and test the green connector near the air box, but when i turn the keys into the on position, the lights just immediately blink and never come back on. So next I tried to to use a DMM in the same area, but that did not work either. I next tried to use a DMM at the tps connector where it meets with the harness, the red needle testing the green wire, and the black needle testing the black wire. By doing this I started about 1.79ohms, and would have to turn the screw clockwise to get to 1ohm. But by the time I got to 1.3ohms the screw spring was all the way compressed and could not turn clock wise any more, and now believe I was either getting bad readings, or was testing the wrong wires. It is also possible that my dmm is not good as it is quite old. Any thoughts on that?

And also the idle screw on top of the UIM has been tampered with, but I figured I could adjust this once the fast idle/tps were set.

I do own a haynes manual, and been reading through online FSMs and old threads, but thought it was possible I am off just a little bit.

Any help will be much appreciated!

Last edited by RyosukeD; 11-24-07 at 05:52 PM.

#2

HAILERS

Join Date: May 2001

Location: FORT WORTH, TEXAS,USA

Posts: 20,563

Likes: 0

Received 21 Likes

on

19 Posts

How 'bout adjusting the screw *on the fly* just to make it fall off the cam??????

I'm suggesting DEVIATING a bit with the marks shown in the book. Just adjust it's cold setting closer to where it will fall off the cam instead of at the marks. Yes?

OR you could have one of those MAZDATRIX 160* thermostats and the water isn't getting hot enough to fully extend the piston. Hmmm. No you said you used boiling water. Forget the thermostat then.

EDIT: Usually if the cam has not come off the rollpin, to me that means the throttle shaft is not fully closed, which in turn means the TPS setting is PROBABLY off.

The TPS is to be set with a fully closed throttle and the engine fully hot. Remember, the tps plunger is directly connected to the throttle shaft that is directly related to where that cam/roll pin arrangement is. Heck, that confused me too.

Yeah, turn the waterthermowax screw a bit. OFFRIGG it a touch to where it favors YOU.

I'm suggesting DEVIATING a bit with the marks shown in the book. Just adjust it's cold setting closer to where it will fall off the cam instead of at the marks. Yes?

OR you could have one of those MAZDATRIX 160* thermostats and the water isn't getting hot enough to fully extend the piston. Hmmm. No you said you used boiling water. Forget the thermostat then.

EDIT: Usually if the cam has not come off the rollpin, to me that means the throttle shaft is not fully closed, which in turn means the TPS setting is PROBABLY off.

The TPS is to be set with a fully closed throttle and the engine fully hot. Remember, the tps plunger is directly connected to the throttle shaft that is directly related to where that cam/roll pin arrangement is. Heck, that confused me too.

Yeah, turn the waterthermowax screw a bit. OFFRIGG it a touch to where it favors YOU.

#3

I'm a boost creep...

Join Date: Jan 2002

Location: Auckland, New Zealand

Posts: 15,608

Likes: 0

Received 8 Likes

on

8 Posts

How hot? Hailers thinks you used boiling water but you didn't actually say that. You do need to use boiling water because water from the hot tap is quite a bit cooling that the coolant in a warmed-up engine. I believe the cam and roller should separate at ~150degF, and tap water shouldn't exceed 120-125degF.

#4

Yo dawg, Im happy for you

Thread Starter

iTrader: (2)

Join Date: Jan 2006

Location: Corvallis, Oregon

Posts: 574

Likes: 0

Received 0 Likes

on

0 Posts

Excellent thanks, I will give that a shot.

What about where I am testing the tps, is the connector right at the harness the correct place? And if so I am to test the green and black wires yes?

What about where I am testing the tps, is the connector right at the harness the correct place? And if so I am to test the green and black wires yes?

#5

Yo dawg, Im happy for you

Thread Starter

iTrader: (2)

Join Date: Jan 2006

Location: Corvallis, Oregon

Posts: 574

Likes: 0

Received 0 Likes

on

0 Posts

How hot? Hailers thinks you used boiling water but you didn't actually say that. You do need to use boiling water because water from the hot tap is quite a bit cooling that the coolant in a warmed-up engine. I believe the cam and roller should separate at ~150degF, and tap water shouldn't exceed 120-125degF.

I'll add though that I'm a little confused, because in the pictures it shows that once the engine heats up the idle cam and the roller separate. But when I put the boiling water through it they moved closer together. Maybe the way i imagine it should work is wrong.

But I will try to keep turning counter-clockwise until they separate.

#6

I'm a boost creep...

Join Date: Jan 2002

Location: Auckland, New Zealand

Posts: 15,608

Likes: 0

Received 8 Likes

on

8 Posts

You can easily simulate the thermowax extending by lifting the adjustment screw (bottom left of your drawing) off the top of the thermowax. The roller will separate from the cam.

#7

I'm reading this and thinking to myself.....this all happened suddenly. Which means the adjustment screw didn't suddenly change itself, meaning that making changes to the adjustment screw settings is just a bandaid to his problem. You first need to verify hot coolant flow from the rear iron port all the way to the water pump return. If you still have your BAC valve, remove the coolant hose that goes from it to the water pump housing. Start the engine long enough to check coolant flow out of the hose. There should be good flow, not like a fire hydrant, but not a trickle either.It will be messy, but needs to be checked. It is common to have corrosion at the coolant hose nipples that either restricts or blocks coolant flow. If there is hot coolant to the t-wax and it still doesn't fully extend, then likely some wax has leaked out and replacement of the t-wax will be necessary.

Trending Topics

#8

Yo dawg, Im happy for you

Thread Starter

iTrader: (2)

Join Date: Jan 2006

Location: Corvallis, Oregon

Posts: 574

Likes: 0

Received 0 Likes

on

0 Posts

Well I messed up the fast idle cam myself, by trying to adjust it to what the book said. The tps and the idle screw on top of the uim was some elses doing, but them thinking they knew what they were doing. I still have not decided whether to physically explain to them what they messed up lol.

I do still have bac and will check that out too.

Also I wanted to confirmed that I am testing the tps at the right connector?

I do still have bac and will check that out too.

Also I wanted to confirmed that I am testing the tps at the right connector?

#9

HAILERS

Join Date: May 2001

Location: FORT WORTH, TEXAS,USA

Posts: 20,563

Likes: 0

Received 21 Likes

on

19 Posts

You may not set the TPS until the problem with the thermowax is settled. It is NOT allowed. Verboten.

But there is a way around this (meet Mr Jekel and Hyde). See your picture? See the screw on the far right of your picture? Who's end is resting on the piston of the thermowax? Yes, youi see it.

THAT is the screw NZCONVERTIBLE is suggesting you lift up with your finger to seperate the cam/roller. THEN the throttle plates will go full closed and NOW you MAY set your TPS.

If you DO NOT let the throttle plates return to full closed, then if you set the TPS, it will be all buggered up and wrong to boot. Becaue the plunger on the TPS will move anytime the thermowax piston moves. IF the piston moves, the setting of the TPS will be corrupted.

Something like that. Not that well explained. Maybe use water at 180 degrees. But boiling water should certainly move the cam off the roller if things are not to messed up. My tap water runs only at about 120 degrees.

There is a small screw called the fast idle screw, and it can also mess up the thermowax setting. See the FSM, FUEL SECTION for how to set the fast idle screw. You have to measure the opening of the throttle plates if memory serves and make screw adjustments if required.

The screws mentioned above are a lot harder to get at on a NON TURBO car vs a turbo. I'd recommend removing the throttle body to set them. I've tried it with the throttle body on the engine and it just does not work for me. Too hard to get at the screws and see things. ON a turbo it's childs play. Easy access.

But there is a way around this (meet Mr Jekel and Hyde). See your picture? See the screw on the far right of your picture? Who's end is resting on the piston of the thermowax? Yes, youi see it.

THAT is the screw NZCONVERTIBLE is suggesting you lift up with your finger to seperate the cam/roller. THEN the throttle plates will go full closed and NOW you MAY set your TPS.

If you DO NOT let the throttle plates return to full closed, then if you set the TPS, it will be all buggered up and wrong to boot. Becaue the plunger on the TPS will move anytime the thermowax piston moves. IF the piston moves, the setting of the TPS will be corrupted.

Something like that. Not that well explained. Maybe use water at 180 degrees. But boiling water should certainly move the cam off the roller if things are not to messed up. My tap water runs only at about 120 degrees.

There is a small screw called the fast idle screw, and it can also mess up the thermowax setting. See the FSM, FUEL SECTION for how to set the fast idle screw. You have to measure the opening of the throttle plates if memory serves and make screw adjustments if required.

The screws mentioned above are a lot harder to get at on a NON TURBO car vs a turbo. I'd recommend removing the throttle body to set them. I've tried it with the throttle body on the engine and it just does not work for me. Too hard to get at the screws and see things. ON a turbo it's childs play. Easy access.

#10

Yo dawg, Im happy for you

Thread Starter

iTrader: (2)

Join Date: Jan 2006

Location: Corvallis, Oregon

Posts: 574

Likes: 0

Received 0 Likes

on

0 Posts

Okay here is where I'm at.

I took the TB off again and did the Mr Jekel and Hyde tps setting and noticed when I lifted the cam it would get stuck on the roller. I put a little wd40 on that and got the roller to move more freely, I also adjusted the fast idle screw to see if it would take care of the cam sticking.

I then boiled some water to 200 degrees(I used a thermometer from deep frying this years turkey ) and ran it through the thermo wax and watched the piston come out, moving the cam and separating it from the roller. I noticed from adjusting the fast idle screw that there was now a gap between the cam and the roller, and adjusted again to compensate.

) and ran it through the thermo wax and watched the piston come out, moving the cam and separating it from the roller. I noticed from adjusting the fast idle screw that there was now a gap between the cam and the roller, and adjusted again to compensate.

I think my problem to begin with was I was working backwards and making the roller and cam move closer together, I think now I'm heading in the right direction.

I'm going to head back outside and measure the clearance between the throttle valve and bore and put everything back together and see where I'm at. I'll report back after I'm done.

Thanks for the help so far!

I took the TB off again and did the Mr Jekel and Hyde tps setting and noticed when I lifted the cam it would get stuck on the roller. I put a little wd40 on that and got the roller to move more freely, I also adjusted the fast idle screw to see if it would take care of the cam sticking.

I then boiled some water to 200 degrees(I used a thermometer from deep frying this years turkey

I think my problem to begin with was I was working backwards and making the roller and cam move closer together, I think now I'm heading in the right direction.

I'm going to head back outside and measure the clearance between the throttle valve and bore and put everything back together and see where I'm at. I'll report back after I'm done.

Thanks for the help so far!

#11

HAILERS

Join Date: May 2001

Location: FORT WORTH, TEXAS,USA

Posts: 20,563

Likes: 0

Received 21 Likes

on

19 Posts

Yeah. It's difficult to describe *how to* online. Actual hands on and reading the FSM, making mistakes, correcting the mistakes etc and seeing how things works while pouring real hot water thru the thermowax helps more than reading opinions.

The non turbo are difficult to work on in this area because the throttle body is *upside down* compared to a Turbo throttle body. They are literally 180* out b/t turob vs non turbo.

A good 180* thermostat helps out. If your is a 160* it takes longer for the thing to trip over the cam/roller on a cold day.

About that *roller*. In fact for ages I didn't know that there is a sleeve on that roller and that sleeve should roll/rotate/spin. I'm talking about the area where the roller touches the cam. Hmmm. That's about half *** explained. Look at it closely and you'll see what I mean.

The non turbo are difficult to work on in this area because the throttle body is *upside down* compared to a Turbo throttle body. They are literally 180* out b/t turob vs non turbo.

A good 180* thermostat helps out. If your is a 160* it takes longer for the thing to trip over the cam/roller on a cold day.

About that *roller*. In fact for ages I didn't know that there is a sleeve on that roller and that sleeve should roll/rotate/spin. I'm talking about the area where the roller touches the cam. Hmmm. That's about half *** explained. Look at it closely and you'll see what I mean.

#12

Yo dawg, Im happy for you

Thread Starter

iTrader: (2)

Join Date: Jan 2006

Location: Corvallis, Oregon

Posts: 574

Likes: 0

Received 0 Likes

on

0 Posts

Yeah it's hard to grasp how things work just from reading online, when I actually ran water through the thermo wax I started to get an idea of how to set things up, but was actually working backworks. With the help from you guys I realized that and started to work in the right direction.

The n/a throttle body is a pain, but I got it figured out now for the most part. Damn near took it off 30 times now lol.

So last night I adjusted the cam so that it would separate from the roller, and things got better, but it wouldn't hold an idle at all. I found out today that the throttle bore clearance was 0. I adjusted that today and It held an idle at about 750, but was still not very steady. Looks like i'm moving in the right direction now, just have to fine tune some things. It's at a point now where I can actually drive it, and will take it to a friends shop where I have access to better tools.

Thanks for the help so far guys! I let you know what I find as things progess.

I let you know what I find as things progess.

The n/a throttle body is a pain, but I got it figured out now for the most part. Damn near took it off 30 times now lol.

So last night I adjusted the cam so that it would separate from the roller, and things got better, but it wouldn't hold an idle at all. I found out today that the throttle bore clearance was 0. I adjusted that today and It held an idle at about 750, but was still not very steady. Looks like i'm moving in the right direction now, just have to fine tune some things. It's at a point now where I can actually drive it, and will take it to a friends shop where I have access to better tools.

Thanks for the help so far guys!

Thread

Thread Starter

Forum

Replies

Last Post

LunchboxSA22

2nd Generation Specific (1986-1992)

37

10-26-15 10:53 AM

Turblown

2nd Generation Specific (1986-1992)

2

05-20-02 09:31 PM

Turblown

2nd Generation Specific (1986-1992)

4

04-28-02 10:34 AM