taurus 2spd fan wiring and Wideband placment

#1

Don't hate my V8

Thread Starter

iTrader: (4)

Join Date: Mar 2006

Location: Cornfield, Indiana

Posts: 1,129

Likes: 0

Received 0 Likes

on

0 Posts

taurus 2spd fan wiring and Wideband placment

Hey,

I'm going to try and install my taurus 2spd fan today and i was wondering how i could wire the circuit so that it kicks on high speed when the factory aux fan turns on. (and what temp aprox. does the aux fan turn on at?) if i think its too hot, i'm just going to run two switches into the cabin rather then just the one i was going to run for the low speed.

second is that next week i'm swaping the engine in my car (87 tII) and putting my hybrid turbo on (t04e compressor). so i'm trying to find a good spot to put my wide band sensor. i would obviously like it in a place where it can return optimal data. I have the xspower/ssac exhaust (for down pipe reference)

Thanks!

I'm going to try and install my taurus 2spd fan today and i was wondering how i could wire the circuit so that it kicks on high speed when the factory aux fan turns on. (and what temp aprox. does the aux fan turn on at?) if i think its too hot, i'm just going to run two switches into the cabin rather then just the one i was going to run for the low speed.

second is that next week i'm swaping the engine in my car (87 tII) and putting my hybrid turbo on (t04e compressor). so i'm trying to find a good spot to put my wide band sensor. i would obviously like it in a place where it can return optimal data. I have the xspower/ssac exhaust (for down pipe reference)

Thanks!

#2

The O2 sensor should go ~36" from the turbo in the 2 or 10 o'clock position. Basically, the end of most downpipes will be about this distance.

A stock TII aux. fan switch triggers at 207F. I hope you have a strong alternator, as those fans will pull a lot of amps on the high setting. There's also a wiring writeup for taurus fans: https://www.rx7club.com/showthread.p...ghlight=taurus

A stock TII aux. fan switch triggers at 207F. I hope you have a strong alternator, as those fans will pull a lot of amps on the high setting. There's also a wiring writeup for taurus fans: https://www.rx7club.com/showthread.p...ghlight=taurus

#3

Don't hate my V8

Thread Starter

iTrader: (4)

Join Date: Mar 2006

Location: Cornfield, Indiana

Posts: 1,129

Likes: 0

Received 0 Likes

on

0 Posts

the stock alt is kinda **** right now, but i've gotta s5 to swap on next week

i was also wondering how the aux fan circuit worked. as the temp goes up the resistance (ohms) goes up as well untill it must be high enough to an open circuit the fan starts. same goes if you unplug the fan, it motors up. so i'm trying to figure out how this circuit is operated. so i can wire my high speed on the same signal.

i was also wondering how the aux fan circuit worked. as the temp goes up the resistance (ohms) goes up as well untill it must be high enough to an open circuit the fan starts. same goes if you unplug the fan, it motors up. so i'm trying to figure out how this circuit is operated. so i can wire my high speed on the same signal.

#4

From a little googling, it looks like 30-33 AMPs continuous draw for that fan on the high setting. I don't think a 80A S5 alternator is going to cut it; the Taurus alternator was a 130A unit.

There's a diagram of the aux. fan circuit in the FSM wiring section, page 50-38. The temp switch energizes the electrical fan relay (which grounds the fan to turn it on), but only if the electrical sub-relay is also energized. The ECU apparently controls the sub-relay. Under what conditions it allows it may be listed elsewhere in the FSM.

Also, it looks like the Fan Control Unit is a glorified title for something that just turns a light on in the cluster when the fan is running. I don't see any relay control, so it's not doing much.

There's a diagram of the aux. fan circuit in the FSM wiring section, page 50-38. The temp switch energizes the electrical fan relay (which grounds the fan to turn it on), but only if the electrical sub-relay is also energized. The ECU apparently controls the sub-relay. Under what conditions it allows it may be listed elsewhere in the FSM.

Also, it looks like the Fan Control Unit is a glorified title for something that just turns a light on in the cluster when the fan is running. I don't see any relay control, so it's not doing much.

#5

36" is a bit far IMO. Most wideband installation instructions say 24" from the turbo. Now, I understand rotary exhaust is quite a bit hotter than piston motor exhaust, but an extra 12" seems a bit much and would probably put it pretty close to the cat/test pipe/presilencer.

I'm curious as to why you would specifically mention the 2 or 10 o'clock positions? I would think anything between 9 and 3 o'clock (on the top side) would be fine. As long as the sensor isn't in a position that would allow condensation to collect in/around it.

Not trying to be a snot, just curious about where your info comes from. Thanks.

I'm curious as to why you would specifically mention the 2 or 10 o'clock positions? I would think anything between 9 and 3 o'clock (on the top side) would be fine. As long as the sensor isn't in a position that would allow condensation to collect in/around it.

Not trying to be a snot, just curious about where your info comes from. Thanks.

#6

Innovate instructions: http://www.innovatemotorsports.com/s...C-1_Manual.pdf

10 or 2 o'clock position preferred. No mention of how far from the turbo, but I can tell you that the end of my down pipe (~30") is still not enough on really hot days. It can and will overheat, even with a nice heatsink.

NGK instructions: http://www.ngksparkplugs.com/pdf/AFX...ual_REV_06.pdf

10 or 2 o'clock preferred. Up to 48" from the engine suggested. It also mentions that the furthest downstream you can go is about 30" from the tail pipe with a 3" exhaust. If you look at some of the modern OEM wideband 02 sensors, they're typically stuck at the end of the exhaust before the mufflers.

10 or 2 o'clock position preferred. No mention of how far from the turbo, but I can tell you that the end of my down pipe (~30") is still not enough on really hot days. It can and will overheat, even with a nice heatsink.

NGK instructions: http://www.ngksparkplugs.com/pdf/AFX...ual_REV_06.pdf

10 or 2 o'clock preferred. Up to 48" from the engine suggested. It also mentions that the furthest downstream you can go is about 30" from the tail pipe with a 3" exhaust. If you look at some of the modern OEM wideband 02 sensors, they're typically stuck at the end of the exhaust before the mufflers.

Trending Topics

#8

I suppose it's just habit from reading military regulations, but both of the cited instructions say 'between' 10 and 2...so 11, 12, and 1 are also recommended/preferred.

Personally, I plan to mount mine in the presilencer pipe, either before or after the actual silencer and using this heat sink: http://www.innovatemotorsports.com/x...cat=250&page=2

Is that the heatsink you're using?

Personally, I plan to mount mine in the presilencer pipe, either before or after the actual silencer and using this heat sink: http://www.innovatemotorsports.com/x...cat=250&page=2

Is that the heatsink you're using?

#9

Don't hate my V8

Thread Starter

iTrader: (4)

Join Date: Mar 2006

Location: Cornfield, Indiana

Posts: 1,129

Likes: 0

Received 0 Likes

on

0 Posts

do you really need the heat sink if you're supposed to place it ~30 inches away from the turbocharger, do you really think its going to maintain a temp > 1300 degrees? i know the rotary egt is hot, but thats a fair amount of down pipe to travel through.

#10

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

Widebands are self heated.

Generally I place them 24" - 36" away from the turbo, the exact distance depending on where it will fit due to physical interference and the like.

I've had problems when they were closer to the turbo, especially with the AEM wideband. The sensor overheats and the gauge stops, or gives crazy readings.

Generally I place them 24" - 36" away from the turbo, the exact distance depending on where it will fit due to physical interference and the like.

I've had problems when they were closer to the turbo, especially with the AEM wideband. The sensor overheats and the gauge stops, or gives crazy readings.

#11

You know, I think I can help figure out this positioning issue. Why not take a bung plug, drill and tap it for a EGT sensor and log temps at a few different locations? I may do it with mine since welding in the bungs isn't a big deal. I think mine will need to be on the further end of the measurement because my exhaust is wrapped (both my tubular manifold and my downpipe). Probably won't help you out much cause it'll be almost a month before I can do it (vacation time), but it may be a good idea for another thread and for future reference.

#12

Don't hate my V8

Thread Starter

iTrader: (4)

Join Date: Mar 2006

Location: Cornfield, Indiana

Posts: 1,129

Likes: 0

Received 0 Likes

on

0 Posts

did you still use the N/A perf housings in your build Aaron? Do you would the fins cool the exhaust gas enough to make a noticeable difference in the EGT after the turbo?

#13

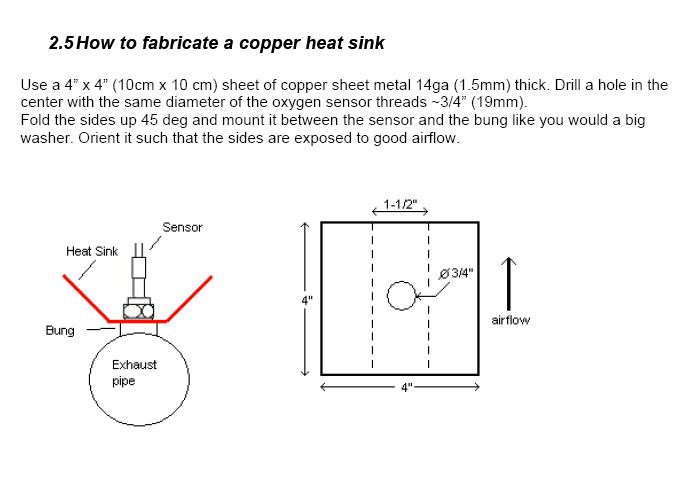

No, I have a large heatsink made from 1/8" copper plate. The innovate one should work fine, but it's expensive.

You know, I think I can help figure out this positioning issue. Why not take a bung plug, drill and tap it for a EGT sensor and log temps at a few different locations? I may do it with mine since welding in the bungs isn't a big deal. I think mine will need to be on the further end of the measurement because my exhaust is wrapped (both my tubular manifold and my downpipe). Probably won't help you out much cause it'll be almost a month before I can do it (vacation time), but it may be a good idea for another thread and for future reference.

Thread

Thread Starter

Forum

Replies

Last Post

Jeff20B

1st Generation Specific (1979-1985)

73

09-16-18 07:16 PM