Refinish my side plates

#1

Junior Member

Thread Starter

Refinish my side plates

Hey guys,

I just pulled my motor apart and I need to refinish the side plates, does anyone know where I can get it refinish in Minnesota?

I just pulled my motor apart and I need to refinish the side plates, does anyone know where I can get it refinish in Minnesota?

#4

Not necessarily. The thread starter hasn't posted any pics, and if you remove the nitride from the entire surface, you've just ruined the irons. I seriously doubt he'll get them renitrided, due to cost. He is better off cleaning and then reusing as-is where a tiny bit of nitriding might be missing from the common step wear area, which is better than getting it removed from 100% of the surface and then having accelerated wear of all the seals on the sides of the rotors, leading to increased drag/friction, increased oil burning (smoke on startup) and other problems like surface rust if he ever lets it sit.

I refuse to use any resurfaced irons in any engine builds because I've seen the aftermath. No rotor seals are reusable. The irons are also ruined and get sent to the metal recycler. I've also tossed freshly resurfaced irons when I get them. Ever had a ball point pen leave a permanent mark on a freshly resurfaced iron? A mark that didn't go away with brake cleaner? Yeah, talk about an old softy.

As long as the step wear is within factory spec, you can reuse the original irons. Only an idiot gets his irons resurfaced these days.

Did you know resurfacing or "lapping" went obsolete back in 1979 when Mazda introduced nitriding? No one told you? Well I'm telling you.

How can I be certain? Let's look at the facts. The 74-78 irons were a harder material and could handle a couple of resurfacings before the engine got too short work anymore. The amount of wear seen on oil seals and other seals on the sides of rotors from this era was high at less than 100k miles, but not too high. Obviously smoke on startup and emissions were a major concern in a world where piston engines ruled as people thought the rotary needed oil rings. lol You can usually reuse the side seals and corner seals at least, but the oil seals are too far gone. There were other concerns too so Mazda went to a hard surface treatment and subsequently could get away with a softer iron underneath. But once you grind all that nice hard surface treatment off, you're left with an iron face that is softer than the factory intended and your engine will only last a short time before it smokes more than you're comfortable with.

Resurfacing is just a way for crooked shops to jack more money out of unsuspecting customers. Then when the engine needs a rebuild, and it will, they can squeeze even more money out of you. Best to avoid the whole crooked subject. Oh and if the intermediate plate is set in the resurfacing machine just a little off, it won't be resurfaced straight which can lead to a crooked engine and all kinds of problems. Do you really want to risk that possibility?

These aren't piston engines. They don't need a honed cylinder with a crosshatch pattern for a set of piston rings to bed into. The rotary side seals aren't exactly like piston compression rings, and shouldn't be treated as such. The factory nitrided surface has microchannels for oil retention. That's all that is needed. I don't even use fancy assembly lubes when I stack an engine because they are not needed. Regular engine oil (20w50 is thick and stays in place better than 10w30 but I've used both). Then a little wheel bearing grease to hold coolant seals and corner seals in place. A little RTV on the housing legs. Easy and not messy at all. Easy start ups where the spark plugs don't get fouled. But then I'm an engine builder primarily and I've looked at ways to improve the process.

I'm not a vendor here. I've got nothing to protect. I build a few engines a year and that's about it. I'm just tired of all the missinfo out there about lapping this, resurfacing that. I needed to speak up about it. If you feel like I offended you or you think I'm wrong, you're entitled to feel how ever you want. I'm just tired of all the BS and maybe I can save you a little cash so your engine will last longer.

Good luck on your engine build!

I refuse to use any resurfaced irons in any engine builds because I've seen the aftermath. No rotor seals are reusable. The irons are also ruined and get sent to the metal recycler. I've also tossed freshly resurfaced irons when I get them. Ever had a ball point pen leave a permanent mark on a freshly resurfaced iron? A mark that didn't go away with brake cleaner? Yeah, talk about an old softy.

As long as the step wear is within factory spec, you can reuse the original irons. Only an idiot gets his irons resurfaced these days.

Did you know resurfacing or "lapping" went obsolete back in 1979 when Mazda introduced nitriding? No one told you? Well I'm telling you.

How can I be certain? Let's look at the facts. The 74-78 irons were a harder material and could handle a couple of resurfacings before the engine got too short work anymore. The amount of wear seen on oil seals and other seals on the sides of rotors from this era was high at less than 100k miles, but not too high. Obviously smoke on startup and emissions were a major concern in a world where piston engines ruled as people thought the rotary needed oil rings. lol You can usually reuse the side seals and corner seals at least, but the oil seals are too far gone. There were other concerns too so Mazda went to a hard surface treatment and subsequently could get away with a softer iron underneath. But once you grind all that nice hard surface treatment off, you're left with an iron face that is softer than the factory intended and your engine will only last a short time before it smokes more than you're comfortable with.

Resurfacing is just a way for crooked shops to jack more money out of unsuspecting customers. Then when the engine needs a rebuild, and it will, they can squeeze even more money out of you. Best to avoid the whole crooked subject. Oh and if the intermediate plate is set in the resurfacing machine just a little off, it won't be resurfaced straight which can lead to a crooked engine and all kinds of problems. Do you really want to risk that possibility?

These aren't piston engines. They don't need a honed cylinder with a crosshatch pattern for a set of piston rings to bed into. The rotary side seals aren't exactly like piston compression rings, and shouldn't be treated as such. The factory nitrided surface has microchannels for oil retention. That's all that is needed. I don't even use fancy assembly lubes when I stack an engine because they are not needed. Regular engine oil (20w50 is thick and stays in place better than 10w30 but I've used both). Then a little wheel bearing grease to hold coolant seals and corner seals in place. A little RTV on the housing legs. Easy and not messy at all. Easy start ups where the spark plugs don't get fouled. But then I'm an engine builder primarily and I've looked at ways to improve the process.

I'm not a vendor here. I've got nothing to protect. I build a few engines a year and that's about it. I'm just tired of all the missinfo out there about lapping this, resurfacing that. I needed to speak up about it. If you feel like I offended you or you think I'm wrong, you're entitled to feel how ever you want. I'm just tired of all the BS and maybe I can save you a little cash so your engine will last longer.

Good luck on your engine build!

#6

It's the same mentality that insists every time you do brakes you MUST have the rotors turned, and every time you do a clutch job you MUST have the flywheel resurfaced. Otherwise the work and/or the new parts aren't warrantied. But all it does is make the rotors thinner so they can only be used for so many miles. Same for the flywheel. It's a way to guarantee you'll be back to spend more money.*

However if you're like me and have just done an occasional pad swap on your own car after a little scuffing to remove the glaze, or take a scuffing wheel to the flywheel and throw a new disc on it, what is the harm? No warranty on a new part? Do I really need to care? If I'm the one doing the work?

But those parts aren't the same as a nitrided side plate. They don't wear the same. Side seals are not a friction material. A simple resurfacing or lapping will actually destory the engine's longevity far worse than having rotors or flywheels resurfaced.

The problem with shops that do this is that the mentality is engrained and there's very little you or I can do about it. It's the same mentallity that will glass bead aluminum parts to clean them up even though it leaves glass particles embedded in the aluminum and fundamentally changes the surface characteristics so they no longer seal as they were intended. I've seen it several times on rotary parts I've gotten from shops who glass bead everything to clean it up. Rotor housings, oil filter pedestals, front covers etc. They all leak oil or coolant through capillary action and make for a very dirty engine.

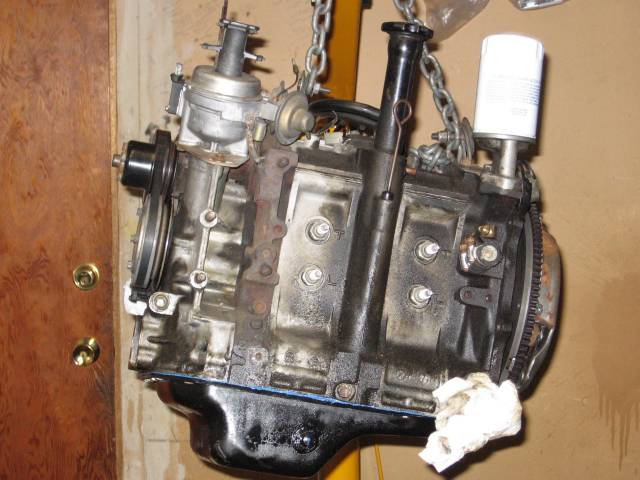

Proof: this engine was only 7 thousand miles old and it was this dirty:

A paid engine builder assembled this in 1995 and I got it in 1997. Then I test fitted it in my rotary MG Midget in 2001 when this photo was taken. Notice the little bit of gunk on the front cover as well? Not nearly as much as collected on the rotor housings from the glass beading he did. Oh he used RTV on the legs, but the oil still found a way up and out of the pan. This engine also had a failing thrust assembly because he apparently didn't understand how to set end play. I tore down at least two or three other engines built by him that all had failed or failing thrust assemblies and various other problems.

So that guy was a paid engine builder, and he built engines like this. You can see why I don't trust any of them.

I tore this engine down only to discover several problems. The intermediate plate was one of those crappy tiny ported NO irons that should be avoided at all cost. The rotors were A and C weight. The front rotor housing's exhaust sleeve had fallen out. The front rotor housing's chrome was missing far worse than I was expecting, and the thrust assembly needle bearings were disintegrating. Also the oil pump was scored up pretty badly and the stationary gear bearings were scratched a bit more than I was comfortable with.

*It happened with Stilletoman's rotary powered GLC where he had the RB aluminum flywheel resurfaced so many times over the course of 100 thousand miles, that it couldn't be resurfaced anymore and he just did one final disc swap because he didn't want to buy another flywheel right then and there. Seemed to work for him against his better judgement.

However if you're like me and have just done an occasional pad swap on your own car after a little scuffing to remove the glaze, or take a scuffing wheel to the flywheel and throw a new disc on it, what is the harm? No warranty on a new part? Do I really need to care? If I'm the one doing the work?

But those parts aren't the same as a nitrided side plate. They don't wear the same. Side seals are not a friction material. A simple resurfacing or lapping will actually destory the engine's longevity far worse than having rotors or flywheels resurfaced.

The problem with shops that do this is that the mentality is engrained and there's very little you or I can do about it. It's the same mentallity that will glass bead aluminum parts to clean them up even though it leaves glass particles embedded in the aluminum and fundamentally changes the surface characteristics so they no longer seal as they were intended. I've seen it several times on rotary parts I've gotten from shops who glass bead everything to clean it up. Rotor housings, oil filter pedestals, front covers etc. They all leak oil or coolant through capillary action and make for a very dirty engine.

Proof: this engine was only 7 thousand miles old and it was this dirty:

A paid engine builder assembled this in 1995 and I got it in 1997. Then I test fitted it in my rotary MG Midget in 2001 when this photo was taken. Notice the little bit of gunk on the front cover as well? Not nearly as much as collected on the rotor housings from the glass beading he did. Oh he used RTV on the legs, but the oil still found a way up and out of the pan. This engine also had a failing thrust assembly because he apparently didn't understand how to set end play. I tore down at least two or three other engines built by him that all had failed or failing thrust assemblies and various other problems.

So that guy was a paid engine builder, and he built engines like this. You can see why I don't trust any of them.

I tore this engine down only to discover several problems. The intermediate plate was one of those crappy tiny ported NO irons that should be avoided at all cost. The rotors were A and C weight. The front rotor housing's exhaust sleeve had fallen out. The front rotor housing's chrome was missing far worse than I was expecting, and the thrust assembly needle bearings were disintegrating. Also the oil pump was scored up pretty badly and the stationary gear bearings were scratched a bit more than I was comfortable with.

*It happened with Stilletoman's rotary powered GLC where he had the RB aluminum flywheel resurfaced so many times over the course of 100 thousand miles, that it couldn't be resurfaced anymore and he just did one final disc swap because he didn't want to buy another flywheel right then and there. Seemed to work for him against his better judgement.

#7

It's the same mentality that insists every time you do brakes you MUST have the rotors turned, and every time you do a clutch job you MUST have the flywheel resurfaced. Otherwise the work and/or the new parts aren't warrantied. But all it does is make the rotors thinner so they can only be used for so many miles. Same for the flywheel. It's a way to guarantee you'll be back to spend more money.*

i used beach sand to sand blast some irons, but i had a feeling it would be bad for the alum so i skipped it, i did sandblast my last set of rotors.. it always worries me to try a new way of doing it( i've build like 30 engines btw) but its got 1800 miles on it and gets ~19 mpg, right were it should be.

Trending Topics

#8

Information Regurgitator

I can only speak from my limited experience since I don't do rebuilds regularly but I'm not sure lapping is as bad as you say. Reason being my first rebuild I had my housings lapped by Mazdatrix. That engine made it 146,xxx miles. Longer than the original from Mazda actually but that was an apex seal failure as well. Engine locked up I think due to an apex seal trying to roll out of the rotor(stock 3-peice seals). I still think it would still be running with the 2-peice seals they use now. Engine did not smoke once warmed up. Did smoke a bit on start up. That said( and this does support what you say) there was a lot of stepped wear on those housings. They would have to be lapped again to be used which may make the water seal groove too shallow. That said I did not lap the ones I used on this build. I had some spare housings with approx. 104,xxxmi. and very little stepped wear. Plus I didn't want to pay the additional cost for the lapping plus all the shipping. I figured if these make it 150k to 200k miles then I've saved money. I also didn't reuse any internal parts from that motor except the rear rotor which was bought new at the first build( so the wearing out of corner seals, etc. didn't apply). I view it as almost a wash. If the rebuild goes 150k or more the housing are done for. It's just if you didn't lap the first time you might can lap them and use them again. If you did lap them they are probably trash. My final opinion is lapping has it's place but isn't needed on every set of housings like one might be led to believe.

So to the original poster. If the housings don't have a lot of stepped wear and are in spec you may think about not lapping them. If the step wear is out of spec you may have to lap them taking into consideration what has been said here. I'm in TN so don't know anyone local to you. You may have to ship them somewhere if that's the route you decide to go.

So to the original poster. If the housings don't have a lot of stepped wear and are in spec you may think about not lapping them. If the step wear is out of spec you may have to lap them taking into consideration what has been said here. I'm in TN so don't know anyone local to you. You may have to ship them somewhere if that's the route you decide to go.

#9

Junior Member

Thread Starter

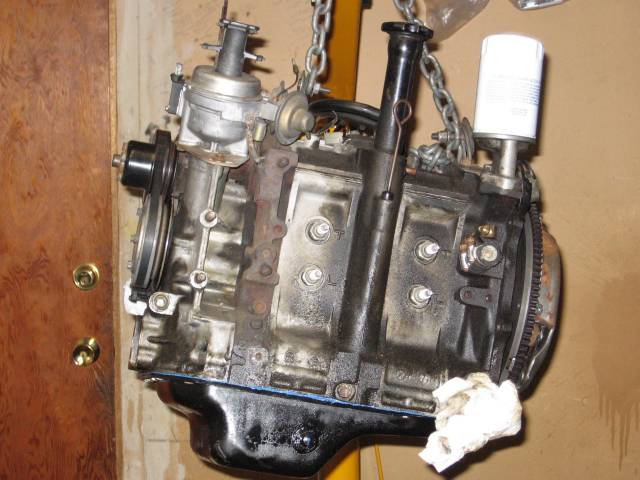

Thanks guys, so for some reason it's only letting me upload one pic, so here is the worst of them. Let me know what you all think.

What is the spec and how do you measure it?

What is the spec and how do you measure it?

#10

Do you have a copy of the FSM? See my sig. The engine section has all info you need in terms of specs. and how to check them. You'll need a dial indicator with an arm and base to check housing stepped wear.

As far as machining is concerned, I agree it should be only done to housings if really needed, because then you have to deal with nitriding and its additional cost. But brake rotors should be machined to remove shallow grooves so that new pads seat in nicely. Anything more than shallow grooves which require a small amount removed and you might as well put new ones in. If in doubt, just replace. Just the cost of machining can be similar to the price of rotors (depending). Flywheel machining also has its place. To remove high spots or heat spots, and to get even clutch grab (no chattering) and wear. There is no hard and fast rule on whether to machine or not. It has to be based on judgment after inspection and after seeing how much you'd have to machine to get the results you need.

As far as machining is concerned, I agree it should be only done to housings if really needed, because then you have to deal with nitriding and its additional cost. But brake rotors should be machined to remove shallow grooves so that new pads seat in nicely. Anything more than shallow grooves which require a small amount removed and you might as well put new ones in. If in doubt, just replace. Just the cost of machining can be similar to the price of rotors (depending). Flywheel machining also has its place. To remove high spots or heat spots, and to get even clutch grab (no chattering) and wear. There is no hard and fast rule on whether to machine or not. It has to be based on judgment after inspection and after seeing how much you'd have to machine to get the results you need.

Thread

Thread Starter

Forum

Replies

Last Post

CaptainKRM

2nd Generation Specific (1986-1992)

14

08-26-15 09:52 PM