New clutch. now slipping.

#1

Junior Member

Thread Starter

Join Date: Oct 2007

Location: Mo

Posts: 18

Likes: 0

Received 0 Likes

on

0 Posts

New clutch. now slipping.

Hey guys

I just got an EXEDY clutch kit put into my 87 RX-7 and its been about 2 weeks and is now slipping. I've heard that if the resurficing isn't done exactly right that it will be about two weeks and it will start slipping. Do you think the guy that put it in did it wrong? or is it my clutch kit I bought cause i've had people recommend the EXEDY, I don't race or anything just stock engine.

I just got an EXEDY clutch kit put into my 87 RX-7 and its been about 2 weeks and is now slipping. I've heard that if the resurficing isn't done exactly right that it will be about two weeks and it will start slipping. Do you think the guy that put it in did it wrong? or is it my clutch kit I bought cause i've had people recommend the EXEDY, I don't race or anything just stock engine.

#2

Did you replace the rear main seal? Did you pack too much grease into the pilot bearing (assuming you replaced it)?

There are a number of things, but I'd suggest pulling it apart YOURSELF and taking a gander at it.

It's not hard to pull the transmission if you've got a few very very basic tools.

There are a number of things, but I'd suggest pulling it apart YOURSELF and taking a gander at it.

It's not hard to pull the transmission if you've got a few very very basic tools.

#3

Junior Member

Thread Starter

Join Date: Oct 2007

Location: Mo

Posts: 18

Likes: 0

Received 0 Likes

on

0 Posts

Ya I didn't do it but Im not sure the guy said somthing about the rear main seal then said I didn't need one on the RX-7 or maybe it was the rear crankshaft seal.

#4

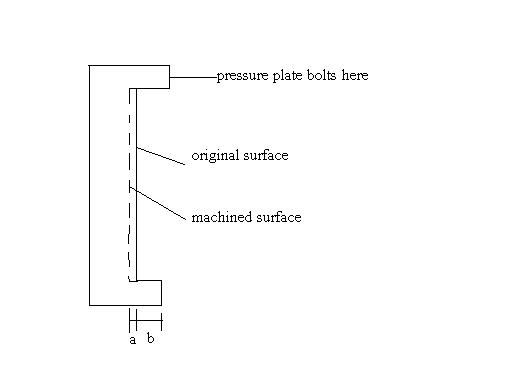

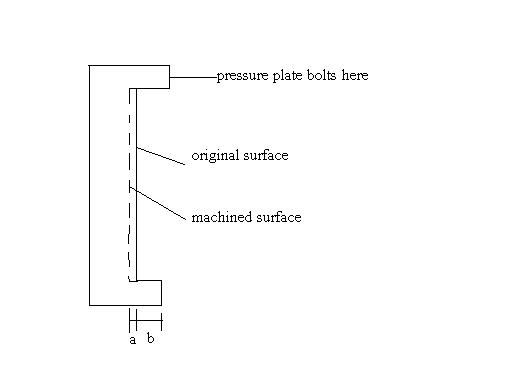

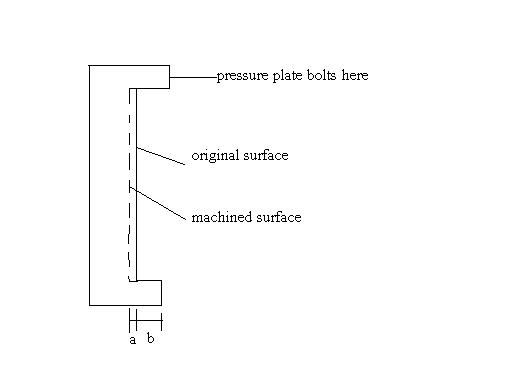

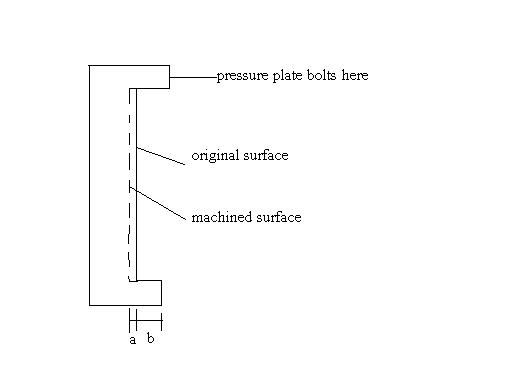

Check this out. I don't know about TII's, but if it's an N/A, and it was resurfaced, it could be F'd up real bad. The friction surface is set in to the flywheel, and the pressure plate bolts to these little raised studs on the flywheel. If only the friction surface is machined, it is now farther away from the mounting studs for the PP, and thus physically farther from the PP. What should have happened during the machining process (which almost never does) is that the machinist should have machined the mounting surfaces as much as he machined the flywheel friction surface. See diagram below for more info.

b represents the distance the flywheel once was from the studs. Now, a represents how far extra it is, making it that much farther from the PP, reducing the clamping force. Go back to the machine shop who f'd you, and see if they can either fix it, or pay for you to get a non-screwed one. I'm sure he can't recall the exact amount he machined from YOUR flywheel, because that's exactly how much he needs to machine from the mounting studs.

b represents the distance the flywheel once was from the studs. Now, a represents how far extra it is, making it that much farther from the PP, reducing the clamping force. Go back to the machine shop who f'd you, and see if they can either fix it, or pay for you to get a non-screwed one. I'm sure he can't recall the exact amount he machined from YOUR flywheel, because that's exactly how much he needs to machine from the mounting studs.

#5

Check this out. I don't know about TII's, but if it's an N/A, and it was resurfaced, it could be F'd up real bad. The friction surface is set in to the flywheel, and the pressure plate bolts to these little raised studs on the flywheel. If only the friction surface is machined, it is now farther away from the mounting studs for the PP, and thus physically farther from the PP. What should have happened during the machining process (which almost never does) is that the machinist should have machined the mounting surfaces as much as he machined the flywheel friction surface. See diagram below for more info.

b represents the distance the flywheel once was from the studs. Now, a represents how far extra it is, making it that much farther from the PP, reducing the clamping force. Go back to the machine shop who f'd you, and see if they can either fix it, or pay for you to get a non-screwed one. I'm sure he can't recall the exact amount he machined from YOUR flywheel, because that's exactly how much he needs to machine from the mounting studs.

b represents the distance the flywheel once was from the studs. Now, a represents how far extra it is, making it that much farther from the PP, reducing the clamping force. Go back to the machine shop who f'd you, and see if they can either fix it, or pay for you to get a non-screwed one. I'm sure he can't recall the exact amount he machined from YOUR flywheel, because that's exactly how much he needs to machine from the mounting studs.

Exactly right. This is what I have been warning people for many years to have done when doing clutches on their vehicles. As was said, most machine shops don't take the time to machine both surfaces, and the result is almost always a high pedal engagement and/or early slipping. If the guy at the machine shop has no clue how much he machined off, i'd start with having him remove around 4 thousandths inch from the upper surface.

Thread

Thread Starter

Forum

Replies

Last Post

Skeese

Rotary Car Performance

4

10-28-20 11:01 AM