need help wiring horn button

#1

need help wiring horn button

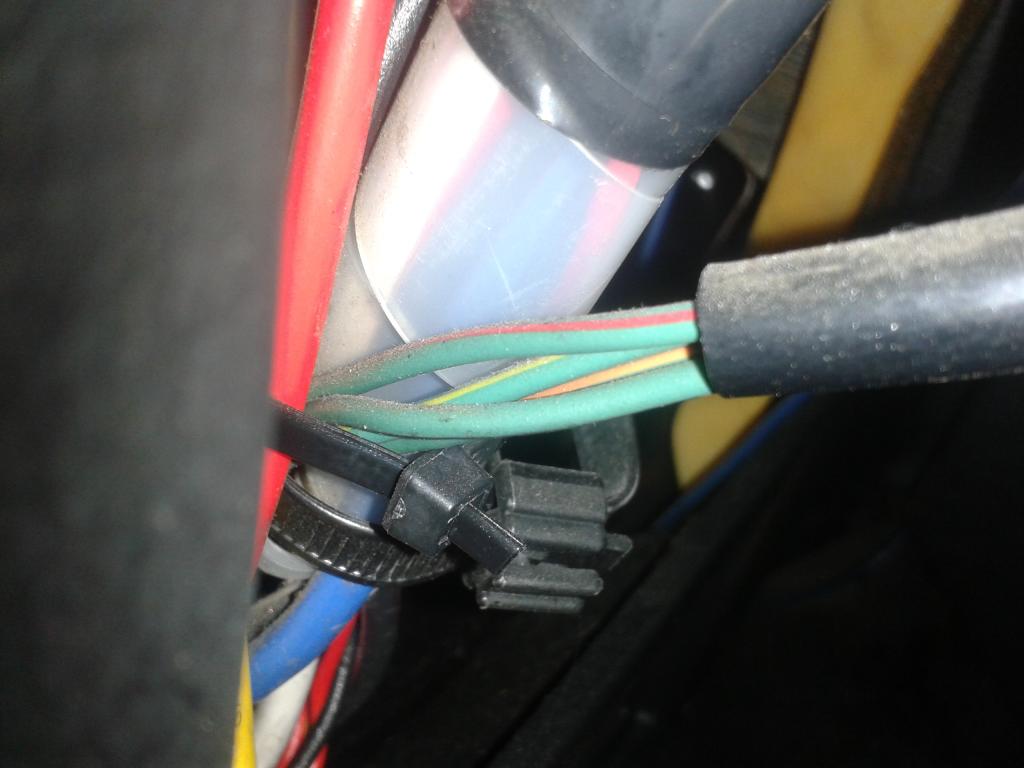

i have a nardi competition wheel and a works bell rapfix II QR and i can't seem to figure out how to wire the horn button. i don't see any connector to plug in the wire coming from the works bell. if anyone can tell me how i can get this thing going that'd be great. i've searched and all the threads talking about how to install the whole thing are basically useless or don't say how to actually do it. i have a 91 NA FC

#3

Senior Member

iTrader: (1)

Join Date: Oct 2012

Location: Ontario

Posts: 386

Likes: 0

Received 0 Likes

on

0 Posts

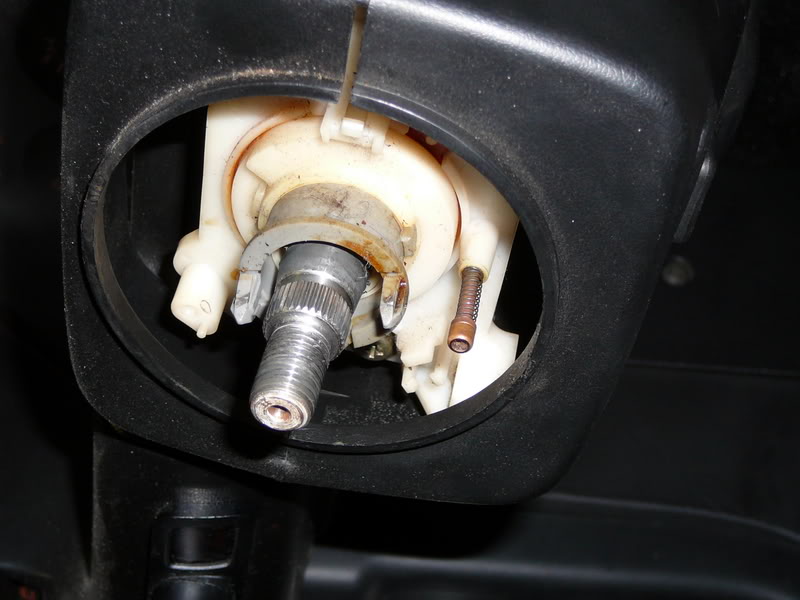

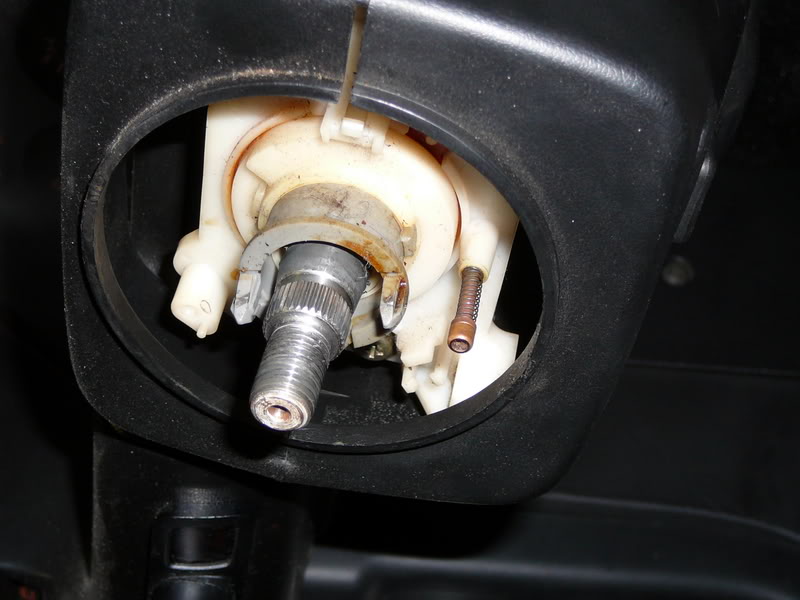

the way the button works is it essentially grounds itself to the steering column, if you have the stock wheel you will see a circular piece on the back which rides on a spring loaded pin.

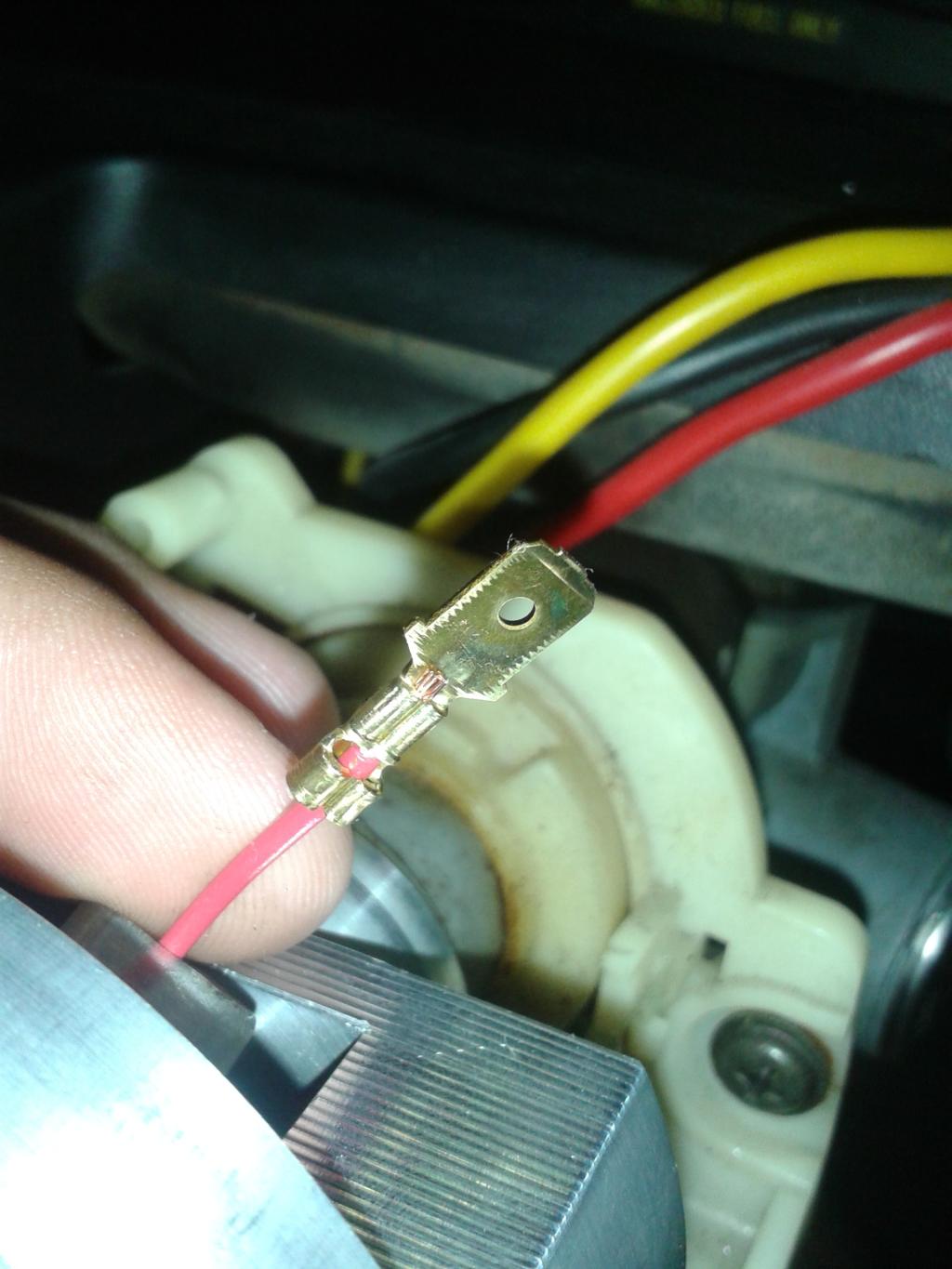

Here is the pin im talking about

I used an ebay boss kit so the install was a little different, post some pictures of what the QR looks like.

Here is the pin im talking about

I used an ebay boss kit so the install was a little different, post some pictures of what the QR looks like.

#6

Retired Moderator, RIP

iTrader: (142)

Join Date: Sep 2005

Location: Smiths Falls.(near Ottawa!.Mapquest IT!)

Posts: 25,581

Likes: 0

Received 131 Likes

on

114 Posts

The collared release part of the hub goes to the Horn button.Connect the 2 wires to the horn bottom from the collared hub (attach your 6 allen screws to steering wheel)

With the diveted part(that attaches to the steering shaft hub) you can put the black to Ground and run the red to the wire that will connect (through those little screws on the other side) to line up with the RED wire on the Collared hub.

Those little flush phillips screws are contacts for the collared hub to steering hub,SO IF you get them WRONG your HORN WILL BEEP when you put the steering wheel ON!

That sort of lets you know that you didn't follow instructions..lol!

With the diveted part(that attaches to the steering shaft hub) you can put the black to Ground and run the red to the wire that will connect (through those little screws on the other side) to line up with the RED wire on the Collared hub.

Those little flush phillips screws are contacts for the collared hub to steering hub,SO IF you get them WRONG your HORN WILL BEEP when you put the steering wheel ON!

That sort of lets you know that you didn't follow instructions..lol!

Last edited by misterstyx69; 02-27-15 at 09:25 AM.

#7

The collared release part of the hub goes to the Horn button.Connect the 2 wires to the horn bottom from the collared hub (attach your 6 allen screws to steering wheel)

With the diveted part(that attaches to the steering shaft hub) you can put the black to Ground and run the red to the wire that will connect (through those little screws on the other side) to line up with the RED wire on the Collared hub.

Those little flush phillips screws are contacts for the collared hub to steering hub,SO IF you get them WRONG your HORN WILL BEEP when you put the steering wheel ON!

That sort of lets you know that you didn't follow instructions..lol!

With the diveted part(that attaches to the steering shaft hub) you can put the black to Ground and run the red to the wire that will connect (through those little screws on the other side) to line up with the RED wire on the Collared hub.

Those little flush phillips screws are contacts for the collared hub to steering hub,SO IF you get them WRONG your HORN WILL BEEP when you put the steering wheel ON!

That sort of lets you know that you didn't follow instructions..lol!

Trending Topics

#8

I have no idea what your parts actually look like physically but perhaps this will help.

The spring loaded plunger on the column switch is carrying the ground signal from the horn relay.

Connect it to ground and the horn honks.

Your new hub system has to transfer this signal through the hub(s) to the horn button, without touching a ground. The signal goes to the horn button, which connects to ground when pressed.

On the back of whatever the first part to go on is, there must be a copper/brass slipring that is isolated from metal. This ring transfers the signal from the spring loaded plunger to the hub assembly as it spins.

There must be an insulated path from the slipring all the way through to the horn button.

The horn button is usually grounded to the wheel/hub itself, which, being directly connected to the steering column, is grounded to the chassis.

As I said, I don't know the specifics of how your particular parts are made, but that basic circuit is what you need to have and it should be pretty easy to figure out.

The spring loaded plunger on the column switch is carrying the ground signal from the horn relay.

Connect it to ground and the horn honks.

Your new hub system has to transfer this signal through the hub(s) to the horn button, without touching a ground. The signal goes to the horn button, which connects to ground when pressed.

On the back of whatever the first part to go on is, there must be a copper/brass slipring that is isolated from metal. This ring transfers the signal from the spring loaded plunger to the hub assembly as it spins.

There must be an insulated path from the slipring all the way through to the horn button.

The horn button is usually grounded to the wheel/hub itself, which, being directly connected to the steering column, is grounded to the chassis.

As I said, I don't know the specifics of how your particular parts are made, but that basic circuit is what you need to have and it should be pretty easy to figure out.

#9

I understand how the horn works and how the oem wheel has the ring so its always in contact with the spring loaded pin when turning the wheel. What my problem is, is since its all aftermarket and there is no ring to make contact with the spring pin. Im wondering if there is something that single red wire connects to or do i have to fab something up to make it work.

#15

MECP Certified Installer

Loosen the hub nut but DO NOT take the nut all the way off.

Attach steering wheel to hub.

Jerk the steering wheel toward you HARD like you hate the bitch until it loosens up.

(if you take the hub nut all the way off, you'll hit yourself in the face when it comes off.)

Attach steering wheel to hub.

Jerk the steering wheel toward you HARD like you hate the bitch until it loosens up.

(if you take the hub nut all the way off, you'll hit yourself in the face when it comes off.)

#17

MECP Certified Installer

I learned the hard way at work once. I had to take the steering wheel wheel of an older ford f150 and I took the nut all the way off and was using all the strength I had to get that **** off. I ended up with a bloody nose and a busted lip.

Thread

Thread Starter

Forum

Replies

Last Post

Jeff20B

1st Generation Specific (1979-1985)

73

09-16-18 07:16 PM

The1Sun

1st Generation Specific (1979-1985)

7

09-18-15 07:13 PM