How to Rebuild a Stock HT-18 Turbo & Build a Hybrid

#101

I'm willing to bet its more than a little. My buddy just dyno'd his bnr stage one (vtrim comp wheel in a stock housing) and he made 290 whp @ 13 psi.

I'd like to go with an H-trim wheel myself, but 60-1 is so much easier to get a hold of, I may be doing that instead. Is your turbine wheel clipped?

I'd like to go with an H-trim wheel myself, but 60-1 is so much easier to get a hold of, I may be doing that instead. Is your turbine wheel clipped?

#102

I forgotten to give it an extra 1/4 turn and the nut came off (with locktite) and really fucked up my 60-1 wheel : /

I got a knightsport with a vtrim and a stock compressor housing with a to4e 54 trim wheel. both with stock unclipped hotside. I really want to see how much power these turbos make, but car is going to be down while I ready the new engine.

#103

When I torqued mine, I got it finger tight, then rotated the extra 90 degrees (+ red loctite). Getting all 3 pieces to line back up perfectly is a pain, and it took a few tries. And the only reason I had to take it all back apart (I had Gpopshop torque it the first time) was the incompatibility issue I ran into with S4/S5 heatshields and turbine housings. Apparently early-S4 turbos used 2 heatshields, which requires a deeper recess in the housing.

I added the heatshield info as well as more pictures and info on how I had to modify the wastegate actuator & oil drain line.

I added the heatshield info as well as more pictures and info on how I had to modify the wastegate actuator & oil drain line.

#105

give these guys a call, they are good source for individual turbo parts. not all 60-1 are the same, make sure you get the hifi version

http://turbocharged.com/main.htm

http://turbocharged.com/main.htm

#106

Hello, does this look like a good donor?

There's no specs listed and I'm not having any luck with google magic:

http://seattle.craigslist.org/tac/pts/3067618075.html

There's no specs listed and I'm not having any luck with google magic:

http://seattle.craigslist.org/tac/pts/3067618075.html

#113

Some info that may be useful with more searching:

T04B part numbers: TO4B - Garrett - Catalog - TurboMaster

T04S part numbers: TO4S - Garrett - Catalog - TurboMaster

You can see that many of the turbo models were used in OEM European applications. I attempted to find you a T04B 60-1 compressor part number/application, but couldn't find anywhere that gave the PN and wheel specs. I think the T04S turbos all had 60-1 compressors, but I'm not sure why there are so many PNs listed on that page.

T04B part numbers: TO4B - Garrett - Catalog - TurboMaster

T04S part numbers: TO4S - Garrett - Catalog - TurboMaster

You can see that many of the turbo models were used in OEM European applications. I attempted to find you a T04B 60-1 compressor part number/application, but couldn't find anywhere that gave the PN and wheel specs. I think the T04S turbos all had 60-1 compressors, but I'm not sure why there are so many PNs listed on that page.

#114

I finally found a 60-1 compressor side kit for a Cosworth RS, from a supplier in the UK. They're legit Garret parts, but unfortunately, because of the exchange rate, I'm gonna take it in the *** on price. All well, I'll just be glad to get the turbo built and get on my way to finishing my build.

#115

Bought this: Garrett T04 T04E Cosworth Compressor upgrade turbo RS Hybrid A/R 60 57 Trim kit | eBay

Not the cheapest, but is the most convenient for me, over here.

Not the cheapest, but is the most convenient for me, over here.

#116

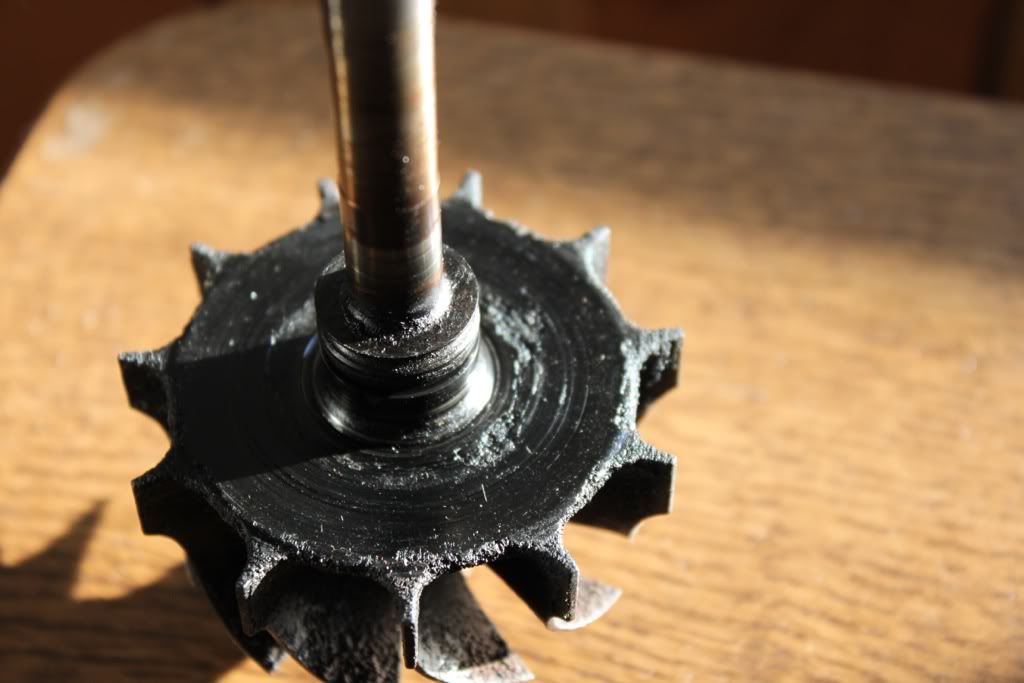

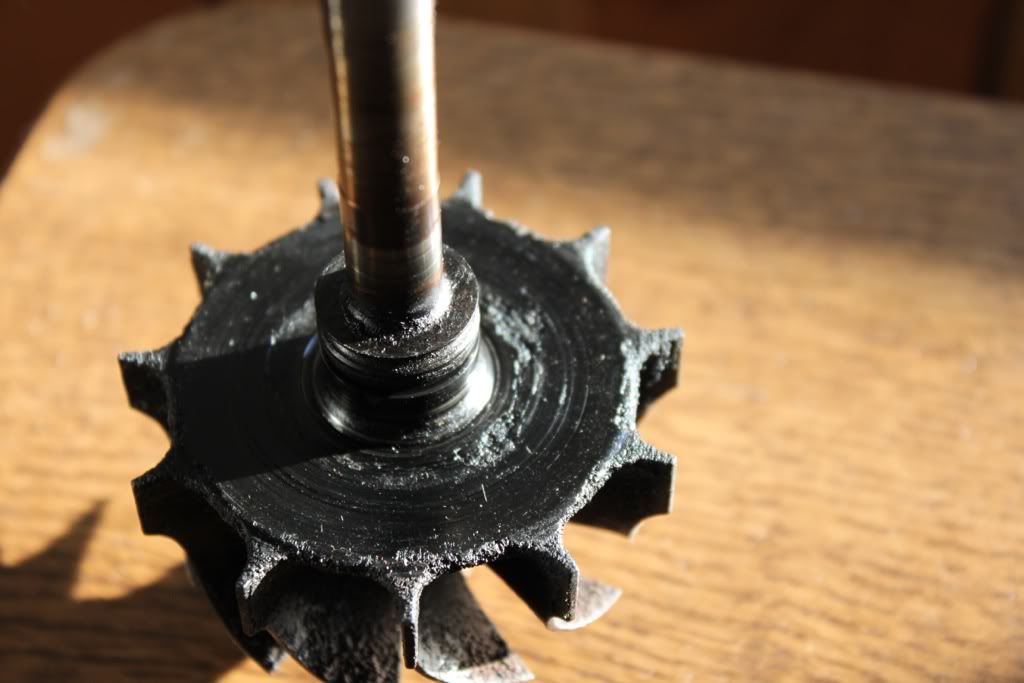

Ok, so I'm finally getting around to tearing down one of my donor turbos (I have 4) and I found this on one:

Should I be concerned? It appears to have occurred as a result of carbon building up between the heat shields and the "swelling" caused the shield to contact the turbine wheel. Everything is being balanced anyway, I just don't know if it's too much damage to be usable or not. Input?

Also, the 60-1 housing I got looks like it takes a different type of carbon seal...the factory one doesn't fit. If I just get the seal that fits (probably dynamic), is that the end of it or will it not seal to the factory CHRA?

Should I be concerned? It appears to have occurred as a result of carbon building up between the heat shields and the "swelling" caused the shield to contact the turbine wheel. Everything is being balanced anyway, I just don't know if it's too much damage to be usable or not. Input?

Also, the 60-1 housing I got looks like it takes a different type of carbon seal...the factory one doesn't fit. If I just get the seal that fits (probably dynamic), is that the end of it or will it not seal to the factory CHRA?

#117

^More likely the bearing failed allowing the wheel to contact the heat shield. I'd throw away that heat shield as it's just a liability to put more metal shards into the exhaust turbine. As long as the fins on the wheel didn't get chewed up by debris, it should be alright. The bearing surfaces look unaffected. If you do have 4 cores to work with, you will probably find a better one to use, though.

#118

I'm nearly positive it wasn't a bearing failure as there was no thrust play at all. It was actually very resistant to turning because of all the carbon build up in the turbine heat shields. I'm going to pull apart some other donors and will just keep this one as a reason for why you should address a severely smoking turbo sooner rather than later. My thought is that it was blowing so much oil past the seals that the oil and carbon in the exhaust created a pretty solid buildup that was allowed to put the parts into each other because of thermal expansion. You should have seen the area between the two shields...it was solid crap.

#119

Should I be concerned? It appears to have occurred as a result of carbon building up between the heat shields and the "swelling" caused the shield to contact the turbine wheel. Everything is being balanced anyway, I just don't know if it's too much damage to be usable or not. Input?

You just need a rebuild kit with the dynamic seal (piston ring) and the matching thrust collar. You can verify from the pictures I have at the beginning of the thread. My turbo has a dynamic seal.

#120

I had actually managed to get 4 S4 turbos for $50/ea a while back and this was one of those. Today I took another one apart and it was in much better shape. It had more axial and thrust play, but with all new bearings I should be good. I'm also working with the balancing shop to supply just the dynamic seal and thrust collar for when they balance everything.

#123

I am considering a S5 turbo with a T04B cover and U trim wheel TA34 turbine whicj I have on hand and ported wastegate but the problem I am facing is that i want to use a set of 9.4:1 S4 NA rotrors, and the thing thats scaring me is the internal wastegate even tough ported will it cope with the higher compression rotors ? the TA34 does reduce back pressure and is a bit lighter, but the internal wastegate / actuator ?

What should I watch out for in order to use the 9.4 rotors and a High flow S5 turbo ?

What should I watch out for in order to use the 9.4 rotors and a High flow S5 turbo ?

#124

I am considering a S5 turbo with a T04B cover and U trim wheel TA34 turbine whicj I have on hand and ported wastegate but the problem I am facing is that i want to use a set of 9.4:1 S4 NA rotrors, and the thing thats scaring me is the internal wastegate even tough ported will it cope with the higher compression rotors ? the TA34 does reduce back pressure and is a bit lighter, but the internal wastegate / actuator ?

What should I watch out for in order to use the 9.4 rotors and a High flow S5 turbo ?

What should I watch out for in order to use the 9.4 rotors and a High flow S5 turbo ?

#125

FC Maniac

iTrader: (1)

I am considering a S5 turbo with a T04B cover and U trim wheel TA34 turbine whicj I have on hand and ported wastegate but the problem I am facing is that i want to use a set of 9.4:1 S4 NA rotrors, and the thing thats scaring me is the internal wastegate even tough ported will it cope with the higher compression rotors ? the TA34 does reduce back pressure and is a bit lighter, but the internal wastegate / actuator ?

What should I watch out for in order to use the 9.4 rotors and a High flow S5 turbo ?

What should I watch out for in order to use the 9.4 rotors and a High flow S5 turbo ?