How to Rebuild a Stock HT-18 Turbo & Build a Hybrid

#27

Should I get the 270 Thrust Bearing/STD Piston Ring or should I get the "High-Performance option" with a 360 Thrust Bearing/Step Gap Piston Ring?

Found this as well "Most conventional journal bearing turbos use a 270-degree thrust-bearing washer, while many of the new breed of turbos employ 360-degree thrust bearings. The advantages of a 360-degree bearing include a full circle of lubrication, more orifices on the washer, and an updated pad strategy to better disperse oil where it's needed. "

Opinions?

Found this as well "Most conventional journal bearing turbos use a 270-degree thrust-bearing washer, while many of the new breed of turbos employ 360-degree thrust bearings. The advantages of a 360-degree bearing include a full circle of lubrication, more orifices on the washer, and an updated pad strategy to better disperse oil where it's needed. "

Opinions?

#29

all the style of bearings fail, the 360 just can take a little more abuse before the lubrication issue comes into effect.

keep in mind most stock turbos last well over 100k miles with the stock type thrust bearing and even up to 14psi.

so if you beat the snot out of the turbo then sure, update the thrust bearing. if you have a stock setup then the stock bearing is fine.

keep in mind most stock turbos last well over 100k miles with the stock type thrust bearing and even up to 14psi.

so if you beat the snot out of the turbo then sure, update the thrust bearing. if you have a stock setup then the stock bearing is fine.

#32

Great writeup rocket, archive material for sure.

I am curious if you are willing to share your sources (if any) for finding used, inexpensive T04 turbos? Last March when I was rebuilding the turbo in my S5 I had no luck finding parts T04s in my usual places (the forum, ebay, craigslist, etc). I wound up just reinstalling the stock stuff after porting the wastegate.

I am curious if you are willing to share your sources (if any) for finding used, inexpensive T04 turbos? Last March when I was rebuilding the turbo in my S5 I had no luck finding parts T04s in my usual places (the forum, ebay, craigslist, etc). I wound up just reinstalling the stock stuff after porting the wastegate.

#34

Great writeup rocket, archive material for sure.

I am curious if you are willing to share your sources (if any) for finding used, inexpensive T04 turbos? Last March when I was rebuilding the turbo in my S5 I had no luck finding parts T04s in my usual places (the forum, ebay, craigslist, etc). I wound up just reinstalling the stock stuff after porting the wastegate.

I am curious if you are willing to share your sources (if any) for finding used, inexpensive T04 turbos? Last March when I was rebuilding the turbo in my S5 I had no luck finding parts T04s in my usual places (the forum, ebay, craigslist, etc). I wound up just reinstalling the stock stuff after porting the wastegate.

Used turbos pop up on ebay all the time. You just have to be patient, and be able to sift through all the Chinese copies. If it looks brand new, has no markings or says something stupid like "turbocharger" on it, it's probably Chinese.

#35

my bnr is burning oil from the turbine side.

Took it apart and found the p-trim wheel chewed up, the piston ring seems fine.

The piston ring is what keeps the oil contained in the unit?

If so then the wobbling of the unbalance turbine wheel would make it leak oil past the ring?

i was going to swap in a stock S5 turbine wheel and change its piston ring which seems bad

Took it apart and found the p-trim wheel chewed up, the piston ring seems fine.

The piston ring is what keeps the oil contained in the unit?

If so then the wobbling of the unbalance turbine wheel would make it leak oil past the ring?

i was going to swap in a stock S5 turbine wheel and change its piston ring which seems bad

#37

my bnr is burning oil from the turbine side.

Took it apart and found the p-trim wheel chewed up, the piston ring seems fine.

The piston ring is what keeps the oil contained in the unit?

If so then the wobbling of the unbalance turbine wheel would make it leak oil past the ring?

i was going to swap in a stock S5 turbine wheel and change its piston ring which seems bad

Took it apart and found the p-trim wheel chewed up, the piston ring seems fine.

The piston ring is what keeps the oil contained in the unit?

If so then the wobbling of the unbalance turbine wheel would make it leak oil past the ring?

i was going to swap in a stock S5 turbine wheel and change its piston ring which seems bad

But more importantly, what the heck went through your turbine? Did you lose a seal?

#38

yep, lost a few seals and pieces of the rotor actually from detonation lol.

From what ive seen inside the chra where the piston ring meets with it, there is no visible wear. The wiggle of the shaft in the chra is very minimal that it is barely noticeable.

If I were to get a new chra, a regular garrett t3 is the correct one? Ive seen BB garrett to4e chra going for $1k+ Way too much, but its basically the entire turbo minus the housings

From what ive seen inside the chra where the piston ring meets with it, there is no visible wear. The wiggle of the shaft in the chra is very minimal that it is barely noticeable.

If I were to get a new chra, a regular garrett t3 is the correct one? Ive seen BB garrett to4e chra going for $1k+ Way too much, but its basically the entire turbo minus the housings

#39

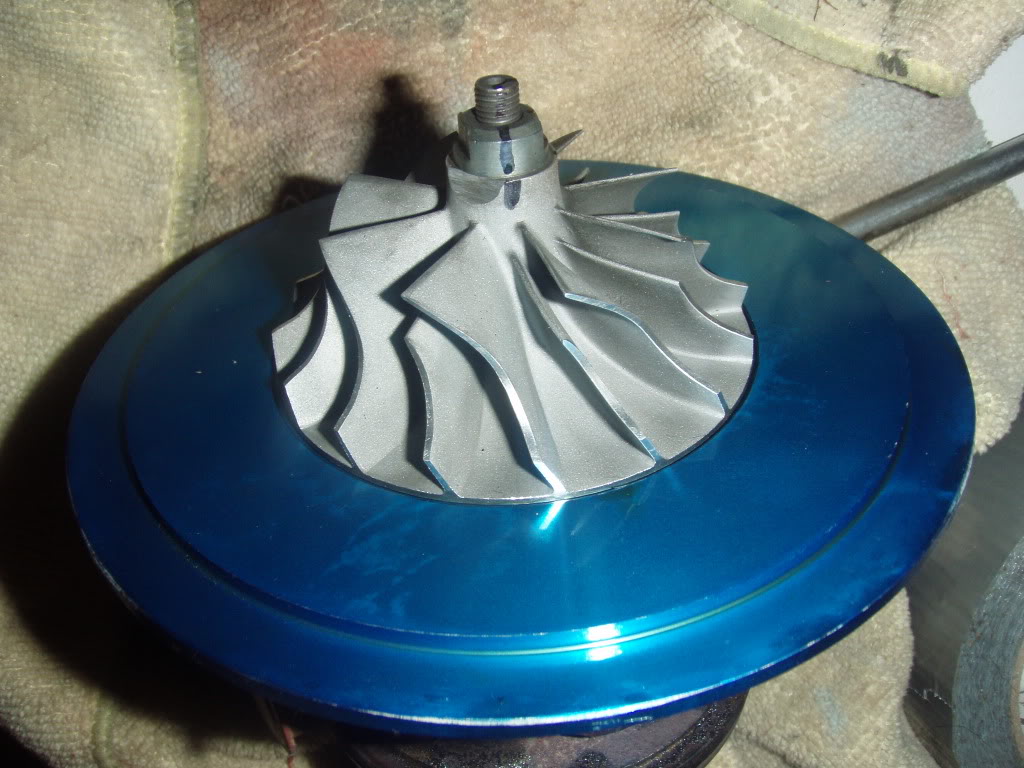

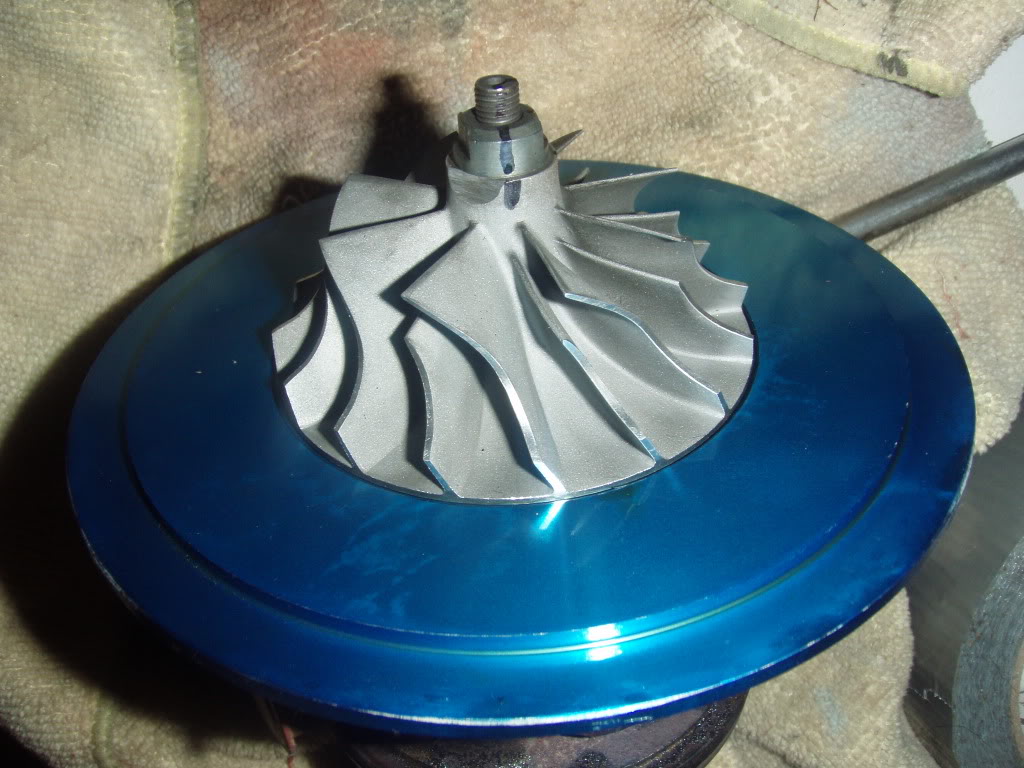

I tried to reassemble the turbo back and there is binding. When tightening the turbo nut I spun the turbine wheel and the shaft will not turn. I took it apart and everything is there. The thrust collar, thrust bearing, thrust spring, dynamic seal, to4b housing, 60-1 wheel, in that order.

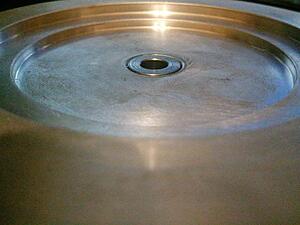

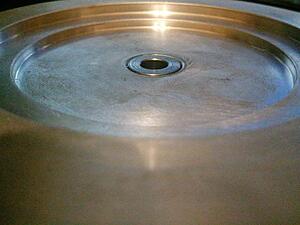

It seems the wheel is rubbing against the housing from this picture when I took the wheel back off

this is how it looks like before I installed the wheel

The back of the wheel

Definitely a notice in how much it protrudes out of the housing.

Anybody knows what causes this???

More pictures here

http://rotaryknight.imgur.com/turbo#k7A9w

It seems the wheel is rubbing against the housing from this picture when I took the wheel back off

this is how it looks like before I installed the wheel

The back of the wheel

Definitely a notice in how much it protrudes out of the housing.

Anybody knows what causes this???

More pictures here

http://rotaryknight.imgur.com/turbo#k7A9w

#40

Is the backplate seated correctly? If it isn't all the way tight or sitting at a slight angle, the nose of the thrust collar won't protrude far enough.

Did you change any of the thrust parts out? If new parts were used, are they identical to what you replaced? The height of the bearing stack must be the same.

Did you change any of the thrust parts out? If new parts were used, are they identical to what you replaced? The height of the bearing stack must be the same.

#43

Turbo Tear Down. I was going to upgrade, but decided to just rebuild because the turbo was blowing oil.

Marked for disassembly. (2 places)

Can anyone Identify that mark on the compressor wheel? It looks like a whale? I think...

54 Trim 2.032 inducer 2.750 Exducer

Oil all over the back of Compressor wheel.

Backing plate off, friggen bolt sheared off. 270 deg thrust washer?

Backing plate, thrust spring and Dynamic seal. I think.

Dynamic seal I presume.

Shaft and Turbine

Here it is broken down. Left to Right, Compressor housing, compressor wheel, compressor bearing? & c-clip, backing plate, thrust bearing & spacer?, dynamic seal, CHRA?, Turbine wheel and heat shields, and turbing housing. Ignore all the other junk.

Will the HT-18 Kit work from gpopshop? I just need to specify dynamic seal? Any and all information is appreciated.

Marked for disassembly. (2 places)

Can anyone Identify that mark on the compressor wheel? It looks like a whale? I think...

54 Trim 2.032 inducer 2.750 Exducer

Oil all over the back of Compressor wheel.

Backing plate off, friggen bolt sheared off. 270 deg thrust washer?

Backing plate, thrust spring and Dynamic seal. I think.

Dynamic seal I presume.

Shaft and Turbine

Here it is broken down. Left to Right, Compressor housing, compressor wheel, compressor bearing? & c-clip, backing plate, thrust bearing & spacer?, dynamic seal, CHRA?, Turbine wheel and heat shields, and turbing housing. Ignore all the other junk.

Will the HT-18 Kit work from gpopshop? I just need to specify dynamic seal? Any and all information is appreciated.

#44

After doing some research, I might have been missing that rubber seal on the CHRA. I will probably just take it to a turbo shop, let them rebuild/balance it. I'm not sure it was balanced correctly anyway.

I got it off of ebay for $500. Looked to be Practically brand new when I got it, and started blowing oil just about at 10k miles. Most I ever boosted it was about 12psi.

I got it off of ebay for $500. Looked to be Practically brand new when I got it, and started blowing oil just about at 10k miles. Most I ever boosted it was about 12psi.

#45

it's a dynamic seal and probably the better designed as most current turbos use them.

balancing it would be a good idea and have a professional measure all the tolerances to be sure the new compressor seal is working properly as that looks to be where it failed.

balancing it would be a good idea and have a professional measure all the tolerances to be sure the new compressor seal is working properly as that looks to be where it failed.

Last edited by RotaryEvolution; 10-17-11 at 01:45 PM.

#48

get a rebuild kit first, change out the bearings , oil them up and assemble the chra with the compressor housing plate bolted up.. The turbo shop only needs the turbine, compressor wheel and nut to balance. When I got mine done it was $20.. THen just bring the assembled chra with you and mention about assembling it.. Dude just popped it in for me and bolted down the compressor wheel and watched it spin perfectly. Put the turbine bolt end on a vise and spun the chra. Good to go.

Being broke sucks, I can't wait to put mine to good use

before all that

EDit - get the T3 basic rebuild kit with dynamic seal. Reuse all your hardware. http://gpopshop.com/garrett-t3-t4-t3t4-kits-2

Being broke sucks, I can't wait to put mine to good use

before all that

EDit - get the T3 basic rebuild kit with dynamic seal. Reuse all your hardware. http://gpopshop.com/garrett-t3-t4-t3t4-kits-2

#49

Backing plate off, friggen bolt sheared off. 270 deg thrust washer?

Backing plate, thrust spring and Dynamic seal. I think.

Dynamic seal I presume.

Shaft and Turbine

Will the HT-18 Kit work from gpopshop? I just need to specify dynamic seal? Any and all information is appreciated.

Backing plate, thrust spring and Dynamic seal. I think.

Dynamic seal I presume.

Shaft and Turbine

Will the HT-18 Kit work from gpopshop? I just need to specify dynamic seal? Any and all information is appreciated.

When you order a rebuild kit, you'll need to make sure it has these parts. The generic T3 rebuild kit with the 360 bearing option will work.

Also, gpopshop will let you ship them the whole CHRA so they can balance the rotating assembly, then torque/locktite the compressor nut. That's the route I went, so I basically shipped them the whole turbo minus the housings. I called to check that this was ok, since their website says to just send them the shaft, compressor and thrust parts.

Last edited by RotaryRocket88; 10-19-11 at 02:23 PM.