Crankcase vent

#26

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

You don't need anything more than this. I've been running this exact setup for years. I've run 21 lbs of boost with that setup--both nipples run to an open vented catch can, nothing to the TID and no PCV valve. It sounds like you have something else going on. How do you know this is a blowby or crankcase pressure issue? Are you blowing major oil smoke under boost? Is the dipstick blowing out? If it really is blowby and both your vent ports are being used you may have some sloppy tolerances in your motor causing blowby.

Also, a PCV valve isn't necessary if you don't care about emissions. Mazda eliminated the PCV valve altogether on the '95 and later FD. The confusing thing about the factory PCV routing on the turbo FC is that Mazda tied the PCV and the evaporative emissions line (charcoal canister) together for simplicity's sake. On the FD the evaporative emissions are completely separate from the PCV, plumbing wise.

Also, a PCV valve isn't necessary if you don't care about emissions. Mazda eliminated the PCV valve altogether on the '95 and later FD. The confusing thing about the factory PCV routing on the turbo FC is that Mazda tied the PCV and the evaporative emissions line (charcoal canister) together for simplicity's sake. On the FD the evaporative emissions are completely separate from the PCV, plumbing wise.

On a street car, air needs to be sucked through the lower nipple to circulate to the center of the crankcase and then extracted via the top nipple and burned.

The FD also has a sort of built in catch can in the oil filler neck.

I see threads on this stuff all the time, but I still remain a little confused (dumb). Where is this middle iron nipple? It's hard to look close for me as some things are in the way (and I have poor vision). I can see a small hole in my middle iron where the filler neck inserts, is this that hole? Mine is only a hole, does something normally thread into that? Does anyone have a picture of the area?

In this picture, you can see the inner most nipple sticking out of the center iron, and then the filler neck nipple (with a 90 degree hose hanging off of it) on the filler neck:

#27

Thanks for the answers (and picture). I got a closer look at my center iron. All I have there is a hole. My engine is an S4 as far as I know, but then again when I had it apart I never thought to check the series of parts I had, I was more concerned with being able to re-use them...

Anyway, what should I do about this? I can't exactly tap the hole and put something in. Maybe I can find a metal tube though and gently hammer it in?

Anyway, what should I do about this? I can't exactly tap the hole and put something in. Maybe I can find a metal tube though and gently hammer it in?

#29

Thanks for the answers (and picture). I got a closer look at my center iron. All I have there is a hole. My engine is an S4 as far as I know, but then again when I had it apart I never thought to check the series of parts I had, I was more concerned with being able to re-use them...

Anyway, what should I do about this? I can't exactly tap the hole and put something in. Maybe I can find a metal tube though and gently hammer it in?

Anyway, what should I do about this? I can't exactly tap the hole and put something in. Maybe I can find a metal tube though and gently hammer it in?

Originally Posted by Aaron Cake

About the only time I'd say that some kind of PCV valve (whether it is an actual PCV or just a check valve) isn't necessary is on a track car. On a street car, maintaining the ventilation of the crankcase will prevent all the moisture and nasties from building up. If not vented, it's not unusual to have rust in the oil filler neck and water in the bottom of the oil pan. No on a track car of course, no one cares about those things, so just plumb both lines to a catch can.

On a street car, air needs to be sucked through the lower nipple to circulate to the center of the crankcase and then extracted via the top nipple and burned.

On a street car, air needs to be sucked through the lower nipple to circulate to the center of the crankcase and then extracted via the top nipple and burned.

#30

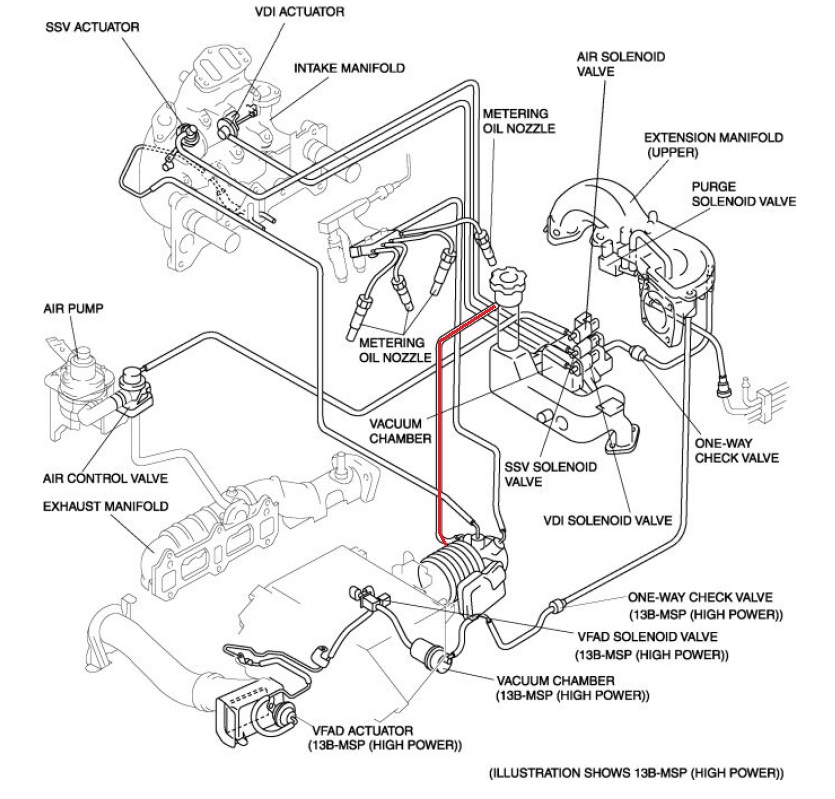

Look at all those switches, valves and lines.....

I opted to run non vented. N/a or turbo, the thought of spraying oil all over my engine bay did not seem too promising. The oil fill neck and the port on the middle iron are t'd together somewhere right behind the throttle body against the firewall, lines run against the firewall to my catch tank and from there run to the bung on the intake pipe. I'll see how it works out. I'm not fond of that location because it's so close to the exhaust manifold but it will have to do for now. I wont have dick for room until i go efan and electric ps pump. Yet another car of mine that wont have working ac....ho-hum.

I opted to run non vented. N/a or turbo, the thought of spraying oil all over my engine bay did not seem too promising. The oil fill neck and the port on the middle iron are t'd together somewhere right behind the throttle body against the firewall, lines run against the firewall to my catch tank and from there run to the bung on the intake pipe. I'll see how it works out. I'm not fond of that location because it's so close to the exhaust manifold but it will have to do for now. I wont have dick for room until i go efan and electric ps pump. Yet another car of mine that wont have working ac....ho-hum.

#33

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

Thanks for the answers (and picture). I got a closer look at my center iron. All I have there is a hole. My engine is an S4 as far as I know, but then again when I had it apart I never thought to check the series of parts I had, I was more concerned with being able to re-use them...

Anyway, what should I do about this? I can't exactly tap the hole and put something in. Maybe I can find a metal tube though and gently hammer it in?

Anyway, what should I do about this? I can't exactly tap the hole and put something in. Maybe I can find a metal tube though and gently hammer it in?

You do?

We'll agree to disagree on this one then. The 95+ REW engines don't have a PCV valve and they don't have a breather port on the middle iron. The Renesis doesn't have a PCV valve or a breather on the middle iron either. There's just one hose from the oil filler to the inlet duct:

I also don't believe it is relevant, because we don't have REWs in our 2nd gens (well, TTT does). What we do have are old, worn out 13Bs that are built to looser specs. With a street engine, I don't see why one would not keep the PCV function working. The valve comes with the car and the plumbing isn't really that hard. From looking in TIDs, intercoolers and 2nd gen intake manifolds, it's clear how much oil actually ends up being blown out of the engine.

I also don't believe it is relevant, because we don't have REWs in our 2nd gens (well, TTT does). What we do have are old, worn out 13Bs that are built to looser specs. With a street engine, I don't see why one would not keep the PCV function working. The valve comes with the car and the plumbing isn't really that hard. From looking in TIDs, intercoolers and 2nd gen intake manifolds, it's clear how much oil actually ends up being blown out of the engine. The Renesis probably doesn't have the same PCV system as the 2nd gen because the Renesis has keystone side seals and a cutoff oil seal. There is probably far less blowby due to these items and the fact that the Renesis runs leaner in general.

#34

^I notice a tiny bit of oil near the hole, but sometimes I don't see any. It's weird, because I put a small breather (just temporary) on the oil filler neck tube and I find it soaked in oil all the time. Maybe the oil by the hole is getting "washed" away and burned off by the heat. If I get a tube in place, should I put a vacuum line with a simple check valve in it?

My filter pedestal is leaking too, probably need a new o-ring.

My entire engine bay is an oily mess.

My filter pedestal is leaking too, probably need a new o-ring.

My entire engine bay is an oily mess.

#35

Pistons are gay

Thread Starter

iTrader: (11)

Join Date: Dec 2006

Location: Prince George, BC

Posts: 1,973

Likes: 0

Received 0 Likes

on

0 Posts

Well I checked my catch can today. I've been on 3, 1 hour cruises. Lots of boosting. And still nothing in the can.

Every once in a while, when the car is pushed hard, smoke blows down near the downpipe. Smell of burnt oil I guess. I've made sure oil pipes are good, and gaskets there all great. Possibly vented debris making it's way out somewhere in and around the turbo, due to improper venting? This can't be normal?

I've set this up as per aaron cake. Bottom nipple to can, oil fill nipple to a universal one way vacuum check valve and connected up to the intake manifold for vacuum. The other nipple on the can, is just open with no hose, intended for atmosphere.

Should it matter that my hose slightly curves up, and maybe the fluid is just staying in the engine and getting burned off?

You can see here that it's slightly kinked up. Sorry best pic i have.

Every once in a while, when the car is pushed hard, smoke blows down near the downpipe. Smell of burnt oil I guess. I've made sure oil pipes are good, and gaskets there all great. Possibly vented debris making it's way out somewhere in and around the turbo, due to improper venting? This can't be normal?

I've set this up as per aaron cake. Bottom nipple to can, oil fill nipple to a universal one way vacuum check valve and connected up to the intake manifold for vacuum. The other nipple on the can, is just open with no hose, intended for atmosphere.

Should it matter that my hose slightly curves up, and maybe the fluid is just staying in the engine and getting burned off?

You can see here that it's slightly kinked up. Sorry best pic i have.

#36

Banned. I got OWNED!!!

I can't speak as to why Mazda changed the PCV system on the REW, but they made a lot of weird decisions on that car.  I also don't believe it is relevant, because we don't have REWs in our 2nd gens (well, TTT does). What we do have are old, worn out 13Bs that are built to looser specs. With a street engine, I don't see why one would not keep the PCV function working. The valve comes with the car and the plumbing isn't really that hard. From looking in TIDs, intercoolers and 2nd gen intake manifolds, it's clear how much oil actually ends up being blown out of the engine.

I also don't believe it is relevant, because we don't have REWs in our 2nd gens (well, TTT does). What we do have are old, worn out 13Bs that are built to looser specs. With a street engine, I don't see why one would not keep the PCV function working. The valve comes with the car and the plumbing isn't really that hard. From looking in TIDs, intercoolers and 2nd gen intake manifolds, it's clear how much oil actually ends up being blown out of the engine.

I also don't believe it is relevant, because we don't have REWs in our 2nd gens (well, TTT does). What we do have are old, worn out 13Bs that are built to looser specs. With a street engine, I don't see why one would not keep the PCV function working. The valve comes with the car and the plumbing isn't really that hard. From looking in TIDs, intercoolers and 2nd gen intake manifolds, it's clear how much oil actually ends up being blown out of the engine.

I also don't believe it is relevant, because we don't have REWs in our 2nd gens (well, TTT does). What we do have are old, worn out 13Bs that are built to looser specs. With a street engine, I don't see why one would not keep the PCV function working. The valve comes with the car and the plumbing isn't really that hard. From looking in TIDs, intercoolers and 2nd gen intake manifolds, it's clear how much oil actually ends up being blown out of the engine.The passage in the center iron will let LOTS of oil up it during hard driving, trust me. I can make a 14 hr road trip with no oil collecting but after one or two trips around an auto-x track it can be half full.

#37

Pistons are gay

Thread Starter

iTrader: (11)

Join Date: Dec 2006

Location: Prince George, BC

Posts: 1,973

Likes: 0

Received 0 Likes

on

0 Posts

When I get a chance going to check the path of my check valve. Maybe it's not sucking under vacuum, and only pushing air in psi and just forcing the oil to stay in the engine...? Really thinking about all possibilities.

I had it setup like so, arrows pointing to the only way the air was allowed to flow.

Intake mani ------------- > Check valve -----------> Oil upper nipple.

I had it setup like so, arrows pointing to the only way the air was allowed to flow.

Intake mani ------------- > Check valve -----------> Oil upper nipple.

#39

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

Yep, backwards.

Another thing I'm going to change about mine is to move the charcoal canister line to the upper nipple, because I am getting oil forced into the canister.

Another thing I'm going to change about mine is to move the charcoal canister line to the upper nipple, because I am getting oil forced into the canister.

#40

My experiences diverge from most FC owners on this one.

In both my turbo and my non-turbo cars my evap emissions and PCV system have always been bone stock. And as long as i have run a fully baffled oil pan i have never had a problem with the entire system. My intakes have been fairly clean every time i have had them apart.

This is with full on track driving and racing...

In both my turbo and my non-turbo cars my evap emissions and PCV system have always been bone stock. And as long as i have run a fully baffled oil pan i have never had a problem with the entire system. My intakes have been fairly clean every time i have had them apart.

This is with full on track driving and racing...

#41

Pistons are gay

Thread Starter

iTrader: (11)

Join Date: Dec 2006

Location: Prince George, BC

Posts: 1,973

Likes: 0

Received 0 Likes

on

0 Posts

That's what I was thinking guys!

Good thing I didn't drive like this very long. I don't really want to think to hard on what that could have done to my engine having it reversed. With the pressure being at 12psi was probly just forcing that gunk into places it probly shouldn't be.

RockLobster. I wish I had kept my stock pcv. Unfortunately trashed everything so was forced to go with a check valve, being that I needed something really quick.

Good thing I didn't drive like this very long. I don't really want to think to hard on what that could have done to my engine having it reversed. With the pressure being at 12psi was probly just forcing that gunk into places it probly shouldn't be.

RockLobster. I wish I had kept my stock pcv. Unfortunately trashed everything so was forced to go with a check valve, being that I needed something really quick.

#42

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

You wouldn't have caused any real issues as long as there was a vent in the catch can. Most OEM PCV systems blow into the crankcase when the engine is under boost anyway. Very few PCV valves are actual check valves.

#44

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

There's not much to take a picture of. Bottom nipple Ts to the catch can and the charcoal canister. Top nipple goes through a one way check valve to the manifold. The catch can has a filter on the top so it can draw air.

I'm going to move the canister line to the top nipple.

I'm going to move the canister line to the top nipple.

#46

Would it be a problem to....

Delete the charcoal canister (put the catch can in its place) and run the top nipple (oil tube) to the Charcoal canister line, which runs to the catch can. Run the bottom nipple to one of the nipples on the front of the manifold with a check valve (opening toward the manifold) and have a nipple on the catch can run to the TID (or vent) ?

There would be 3 nipples (or 2 nipples and a vent ) on the catchcan

----> Fuel vapor line from tank

----> Upper nipple on oil filler neck via old charcoal canister hard line

<--- TID ......OR........ Vent

Delete the charcoal canister (put the catch can in its place) and run the top nipple (oil tube) to the Charcoal canister line, which runs to the catch can. Run the bottom nipple to one of the nipples on the front of the manifold with a check valve (opening toward the manifold) and have a nipple on the catch can run to the TID (or vent) ?

There would be 3 nipples (or 2 nipples and a vent ) on the catchcan

----> Fuel vapor line from tank

----> Upper nipple on oil filler neck via old charcoal canister hard line

<--- TID ......OR........ Vent