Crankcase vent

#1

Pistons are gay

Thread Starter

iTrader: (11)

Join Date: Dec 2006

Location: Prince George, BC

Posts: 1,973

Likes: 0

Received 0 Likes

on

0 Posts

Crankcase vent

Well, i've been searching this for a while. There really is a alot of mixed up ideas of doing this, and I want to get it straight.

I have emissions removed. Currently oil tube nipple going to catch can, as well as the bigger nipple near the housing.

Blowby is blowing seals like crazy. Recently had a front cover gasket completely blowout on me. But when this happened I just had the lower nipple going to a pop bottle, and the top nipple capped.

I read about running the top nipple, into the catch can and tee'd to go to the tid. The lower nipple, with a check valve going to a nipple on the uim that sees vacuum.

I've also read up about gunking up pipes and intercoolers and such. Keep in mind i'm running a greddy fmic.

Proper way to do a vent?

Don't really want to run to the tid, but if that's what you guys recommend, that's what i'll do.

I have emissions removed. Currently oil tube nipple going to catch can, as well as the bigger nipple near the housing.

Blowby is blowing seals like crazy. Recently had a front cover gasket completely blowout on me. But when this happened I just had the lower nipple going to a pop bottle, and the top nipple capped.

I read about running the top nipple, into the catch can and tee'd to go to the tid. The lower nipple, with a check valve going to a nipple on the uim that sees vacuum.

I've also read up about gunking up pipes and intercoolers and such. Keep in mind i'm running a greddy fmic.

Proper way to do a vent?

Don't really want to run to the tid, but if that's what you guys recommend, that's what i'll do.

#2

MECP Certified Installer

I am going to go out on a limb here...

I don't own a turbo car, so when I see the acronym "TID" I think turbo to intercooler duct.

Now, based on that assumption, that area is going to see boost, and you don't want to pressurize your crankcase for obvious reasons.

I'd say go before the turbo where there is constant vacuum. Now assuming TID stands for Turbo intake Duct, then I would agree that is where the vent needs to go.

I don't own a turbo car, so when I see the acronym "TID" I think turbo to intercooler duct.

Now, based on that assumption, that area is going to see boost, and you don't want to pressurize your crankcase for obvious reasons.

I'd say go before the turbo where there is constant vacuum. Now assuming TID stands for Turbo intake Duct, then I would agree that is where the vent needs to go.

#4

running to the TID is for most stock systems that need to draw in filtered/metered air through the crank case.

you need to use manifold vacuum to pull on the crank case, with a check valve attached to prevent pressurization during boost. PULL from the nipple on the center iron, while drawing in air through a nipple on the oil filler neck. the catch tank needs to be between the fitting on the iron and the check valve leading to the plenum.

you need to use manifold vacuum to pull on the crank case, with a check valve attached to prevent pressurization during boost. PULL from the nipple on the center iron, while drawing in air through a nipple on the oil filler neck. the catch tank needs to be between the fitting on the iron and the check valve leading to the plenum.

#5

Pistons are gay

Thread Starter

iTrader: (11)

Join Date: Dec 2006

Location: Prince George, BC

Posts: 1,973

Likes: 0

Received 0 Likes

on

0 Posts

While drawing in air from the oil filler neck? So... Where should I get that from? My head is just dieing right now from this, hah. It's that time of the night.

Is the check valve absolutely necessary? Okay... What if I tee'd both nipples to the can. And the other nipple on my catch can going to the uim without a check valve? I'm really trying to avoid going to lordco/napa because asking them for something like this is like asking a baby to speak when they don't know how to.

Is the check valve absolutely necessary? Okay... What if I tee'd both nipples to the can. And the other nipple on my catch can going to the uim without a check valve? I'm really trying to avoid going to lordco/napa because asking them for something like this is like asking a baby to speak when they don't know how to.

#6

Alright man heres what i do. TAke your oil pan off, On the center iron a little ways down drill a big *** hole, like -10 fitting, run a 90 fittiing right from that to a catch can, then take the nipple from the oil filler and connect it to the catch can, then take the nipple on the center iron run it to the intake, before the turbo. a few inches away from the turbo like 4"...i had problems like you at one time

Trending Topics

#9

MECP Certified Installer

#10

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

Bottom nipple on center iron goes to your catch can through a nice thick hose.

Top nipple goes to an intake vacuum port through a PCV valve.

The catch can has a filter on top if you have a standalone, or a nice thick line to the TID if you have a stock ECU.

That's it.

Top nipple goes to an intake vacuum port through a PCV valve.

The catch can has a filter on top if you have a standalone, or a nice thick line to the TID if you have a stock ECU.

That's it.

#11

Pistons are gay

Thread Starter

iTrader: (11)

Join Date: Dec 2006

Location: Prince George, BC

Posts: 1,973

Likes: 0

Received 0 Likes

on

0 Posts

Bottom nipple on center iron goes to your catch can through a nice thick hose.

Top nipple goes to an intake vacuum port through a PCV valve.

The catch can has a filter on top if you have a standalone, or a nice thick line to the TID if you have a stock ECU.

That's it.

Top nipple goes to an intake vacuum port through a PCV valve.

The catch can has a filter on top if you have a standalone, or a nice thick line to the TID if you have a stock ECU.

That's it.

This method sounds alot simpler. Going to go along with this setup. Thanks aaron!

#12

Pistons are gay

Thread Starter

iTrader: (11)

Join Date: Dec 2006

Location: Prince George, BC

Posts: 1,973

Likes: 0

Received 0 Likes

on

0 Posts

Okay question...

How do you acquire a check valve/pcv? ... Went to lordco today, stood there for literally an hour in total. Explained my setup, and sketched it on a piece of paper. I stated that this was not an oem setup, and I just need a valve or something that diverts air only one way and has 5/32 hose connections on either end. Half an hour point he comes out with a pcv with 2 ports, and valve insertion whatever gay piston piece... At the hour point, he says yeah we can supply everything else you wanted but this check valve.

... Went to lordco today, stood there for literally an hour in total. Explained my setup, and sketched it on a piece of paper. I stated that this was not an oem setup, and I just need a valve or something that diverts air only one way and has 5/32 hose connections on either end. Half an hour point he comes out with a pcv with 2 ports, and valve insertion whatever gay piston piece... At the hour point, he says yeah we can supply everything else you wanted but this check valve.

Is this guy retarded, or does lordco actually have one? Could be the guy, because one time he did claim to have only one grade of fuel hose. He sold me a basic fuel injection hose. Later talked to another guy and found a higher pressure fuel hose. Absolute tool.

Edit:

Looks like this is all I need. http://catalog.industrialspec.com/vi...diaphragm/cv1?

I guess I can check napa and fortins tomorrow. Maybe there not retarded. Seems most parts guy's are.

How do you acquire a check valve/pcv?

... Went to lordco today, stood there for literally an hour in total. Explained my setup, and sketched it on a piece of paper. I stated that this was not an oem setup, and I just need a valve or something that diverts air only one way and has 5/32 hose connections on either end. Half an hour point he comes out with a pcv with 2 ports, and valve insertion whatever gay piston piece... At the hour point, he says yeah we can supply everything else you wanted but this check valve.

... Went to lordco today, stood there for literally an hour in total. Explained my setup, and sketched it on a piece of paper. I stated that this was not an oem setup, and I just need a valve or something that diverts air only one way and has 5/32 hose connections on either end. Half an hour point he comes out with a pcv with 2 ports, and valve insertion whatever gay piston piece... At the hour point, he says yeah we can supply everything else you wanted but this check valve. Is this guy retarded, or does lordco actually have one? Could be the guy, because one time he did claim to have only one grade of fuel hose. He sold me a basic fuel injection hose. Later talked to another guy and found a higher pressure fuel hose. Absolute tool.

Edit:

Looks like this is all I need. http://catalog.industrialspec.com/vi...diaphragm/cv1?

I guess I can check napa and fortins tomorrow. Maybe there not retarded. Seems most parts guy's are.

#13

Banned. I got OWNED!!!

Bottom nipple on center iron goes to your catch can through a nice thick hose.

Top nipple goes to an intake vacuum port through a PCV valve.

The catch can has a filter on top if you have a standalone, or a nice thick line to the TID if you have a stock ECU.

That's it.

Top nipple goes to an intake vacuum port through a PCV valve.

The catch can has a filter on top if you have a standalone, or a nice thick line to the TID if you have a stock ECU.

That's it.

The next question that should've been asked was, "Why?"

So I'll answer it -

It's to keep air circulating through the crankcase to keep moisture from building up that turns into that white milky nastiness in the oil fill tube. How do I know this? Becuase I had that same problem.

My solution is a variant of Aarons. Instead of the hose from the oil fill going to the TID duct, I am plumbing that into my catch can. My catch can is special though. It's got two chambers that are seperate. The first chamber is to catch any oil that creeps up the front iron and gets blown out. This chamber is also vents to atmosphere. The second chamber is sealed but filled with STAINLESS steel wool. This catchs the mist and contains most of it before heading out to the TID. Both have drains and sight tubes.

Results pending

#15

Currently oil tube nipple going to catch can, as well as the bigger nipple near the housing.

Also, a PCV valve isn't necessary if you don't care about emissions. Mazda eliminated the PCV valve altogether on the '95 and later FD. The confusing thing about the factory PCV routing on the turbo FC is that Mazda tied the PCV and the evaporative emissions line (charcoal canister) together for simplicity's sake. On the FD the evaporative emissions are completely separate from the PCV, plumbing wise.

#16

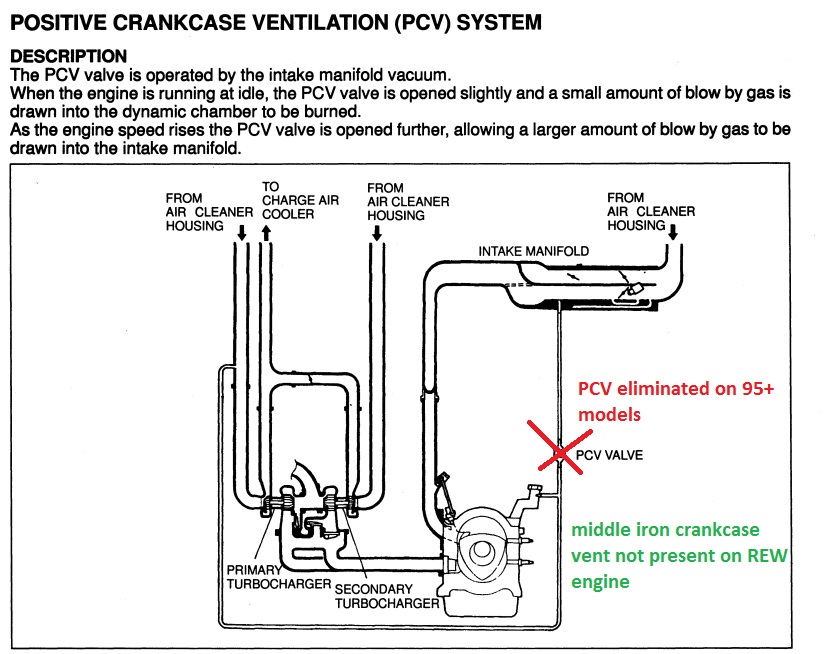

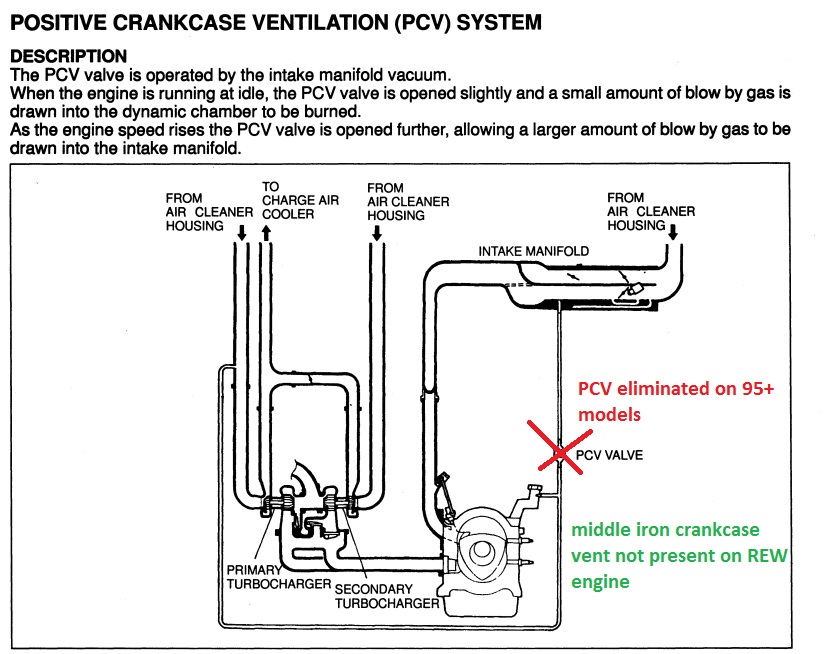

Alright so check this out. Here's the factory FC plumbing:

There are two ventilation ports. The one on the oil filler goes has a PCV valve and the PCV valve operates when the manifold has significant vacuum. From the factory the PCV valve closes under boost. So if you have a blowby problem under boost, installing a PCV valve in the stock manner isn't going to accomplish much, although it does improve ventilation during low load operation. The ventilation port on the iron mostly functions when the engine is under boost--the internal crankcase pressure forces the vapor and blowby out on its own. Now the confusing thing is that the charcoal canister happens to be Tee'd into the middle iron ventilation line.

Here's the Factory FD crankcase ventilation plumbing:

The ventilation port on the middle iron was eliminated for whatever reason. Only the oil filler is used for ventilation. On the 95+ model the PCV valve isn't even there. Blowby gases are not drawn out by manifold vacuum directly, but rather they force themselves out when there is sufficient crankcase pressure.

The charcoal canister and evaporative emissions system is completely separate from the crankcase ventilation system on the FD. This is because the charcoal canister vapers are delivered into the engine through a duty controlled solenoid.

There are two ventilation ports. The one on the oil filler goes has a PCV valve and the PCV valve operates when the manifold has significant vacuum. From the factory the PCV valve closes under boost. So if you have a blowby problem under boost, installing a PCV valve in the stock manner isn't going to accomplish much, although it does improve ventilation during low load operation. The ventilation port on the iron mostly functions when the engine is under boost--the internal crankcase pressure forces the vapor and blowby out on its own. Now the confusing thing is that the charcoal canister happens to be Tee'd into the middle iron ventilation line.

Here's the Factory FD crankcase ventilation plumbing:

The ventilation port on the middle iron was eliminated for whatever reason. Only the oil filler is used for ventilation. On the 95+ model the PCV valve isn't even there. Blowby gases are not drawn out by manifold vacuum directly, but rather they force themselves out when there is sufficient crankcase pressure.

The charcoal canister and evaporative emissions system is completely separate from the crankcase ventilation system on the FD. This is because the charcoal canister vapers are delivered into the engine through a duty controlled solenoid.

#17

Very Informative!

I currently have the following setup (as per some writeup I found while doing emissions removal )

)

Filler Nipple: Open

Middle Iron Nipple: connected to factory round check-valve w/ one large nipple. 2 smaller nipples run from the check-valve to nipples on the front side of the UIM.

Charcoal cannister small nipple: connected to vent tube from tank

Charcoal canister Large nipple: connected to hard line along firewall which is open to the engine bay

I haven't noticed any significant grime in the engine bay until I overfilled the oil a bit and there was some under the intercooler bracket. Seems like it might be a good idea to change this....

I currently have the following setup (as per some writeup I found while doing emissions removal

)

)Filler Nipple: Open

Middle Iron Nipple: connected to factory round check-valve w/ one large nipple. 2 smaller nipples run from the check-valve to nipples on the front side of the UIM.

Charcoal cannister small nipple: connected to vent tube from tank

Charcoal canister Large nipple: connected to hard line along firewall which is open to the engine bay

I haven't noticed any significant grime in the engine bay until I overfilled the oil a bit and there was some under the intercooler bracket. Seems like it might be a good idea to change this....

#18

Banned. I got OWNED!!!

You don't need anything more than this. I've been running this exact setup for years. I've run 21 lbs of boost with that setup--both nipples run to an open vented catch can, nothing to the TID and no PCV valve. It sounds like you have something else going on. How do you know this is a blowby or crankcase pressure issue? Are you blowing major oil smoke under boost? Is the dipstick blowing out? If it really is blowby and both your vent ports are being used you may have some sloppy tolerances in your motor causing blowby.

#19

Originally Posted by sharingan

Filler Nipple: Open

Middle Iron Nipple: connected to factory round check-valve w/ one large nipple. 2 smaller nipples run from the check-valve to nipples on the front side of the UIM.

Charcoal cannister small nipple: connected to vent tube from tank

Charcoal canister Large nipple: connected to hard line along firewall which is open to the engine bay

Charcoal canister Large nipple: connected to hard line along firewall which is open to the engine bay

A PCV valve isn't designed to relieve crankcase pressure under boost. If that's your problem, a PCV valve isn't going to solve it.

but there is a TON of moisture in the pan becuase the thing runs so damn cool. I need circulation to keep the oil clean.

#20

Banned. I got OWNED!!!

Again I don't have the car in front of me so I can't see it exactly. But IMO if you have that part of your evaporative emissions system vented you might as well toss the charcoal canister. The whole point of the charcoal canister is to keep fuel vapors from going into the atmosphere.

What I meant by that statement is that for 99% of setups [i]in order to prevent the serious negative effects of excessive crankcase pressure[/I you don't need more than having both ports hooked to vented catch can. If you do the opposite and cap off both your crankcase vents you will likely blow a ton of oil out the exhaust for example. On piston engines with ventilation problems I have seen dipsticks blow out.

The problem with hooking up the center iron nipple, at least on the Cosmo engine placed in a car that can actually handle, is that oil creeps up the iron, our the tube, into your catch can and then blown all over the engine bay, trust me on this one

Nope, not cold here by any stretch of the imagination. Factory T-stat, replaced with a factory T-stat because I thought it was defective, and I still stay at about 172*F on the highway and the highest I've seen is 185* on the dyno when the fan kicks on. I basically completely overbuilt the heat exchangers.

#21

Pistons are gay

Thread Starter

iTrader: (11)

Join Date: Dec 2006

Location: Prince George, BC

Posts: 1,973

Likes: 0

Received 0 Likes

on

0 Posts

This thread turned out to be very very informative. Thanks all that contributed!

Arghx... I'll be doing the aaron cake setup. Due to the fact that i've sourced everything I needed for this setup. Spent an hour at lordco, 15 seconds at fortins, and 5 minutes at napa. Napa wins victorious. The fortins location had a arrogant ***** that thinks he know's the entire book and computer. Walked in and he just says nope we don't.

Arghx... I'll be doing the aaron cake setup. Due to the fact that i've sourced everything I needed for this setup. Spent an hour at lordco, 15 seconds at fortins, and 5 minutes at napa. Napa wins victorious. The fortins location had a arrogant ***** that thinks he know's the entire book and computer. Walked in and he just says nope we don't.

#22

I see threads on this stuff all the time, but I still remain a little confused (dumb). Where is this middle iron nipple? It's hard to look close for me as some things are in the way (and I have poor vision). I can see a small hole in my middle iron where the filler neck inserts, is this that hole? Mine is only a hole, does something normally thread into that? Does anyone have a picture of the area?

#24

I see threads on this stuff all the time, but I still remain a little confused (dumb). Where is this middle iron nipple? It's hard to look close for me as some things are in the way (and I have poor vision). I can see a small hole in my middle iron where the filler neck inserts, is this that hole? Mine is only a hole, does something normally thread into that? Does anyone have a picture of the area?

but when you vent the middle iron ..your boost gauge stops reading...your loosing vac pressure for your boost gauge

Arghx... I'll be doing the aaron cake setup.

#25

I see threads on this stuff all the time, but I still remain a little confused (dumb). Where is this middle iron nipple? It's hard to look close for me as some things are in the way (and I have poor vision). I can see a small hole in my middle iron where the filler neck inserts, is this that hole? Mine is only a hole, does something normally thread into that? Does anyone have a picture of the area?