AUTO to MANUAL to TURBO driveshaft length issue

#1

AUTO to MANUAL to TURBO driveshaft length issue

I have an automatic chassis RX-7 with a complete Turbo II drivetrain from Japan2LA. Last year I purchased a new driveshaft from Mazdatrix because the car was down anyway and a driveshaft shop told me the non-replaceable u-joints were bad.

My turbo II driveshaft from Mazdatrix doesn't sit flush with the tail end of the transmission. There is ~0.75 inches of visible yoke.

Here's a picture of the gap with the yoke fully inserted into the tail end of the transmission:

When the engine is running with the car engaged in 4th gear (on jackstands) I can see in-and-out movement in the yoke. The issue I'm having with the car is a HORRENDOUS driveline vibration at higher speeds (50mph+). It's worst when I'm accelerating. When I accelerate to a high engine speed and decelerate with the car, the vibration has a different tone but is still very loud.

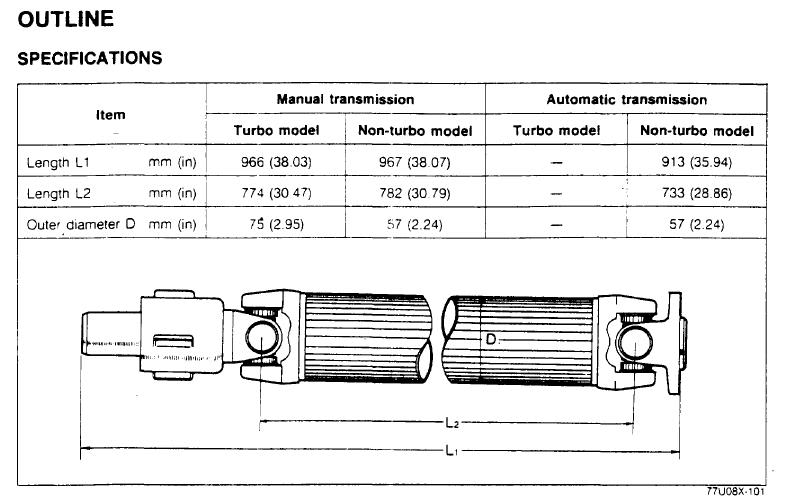

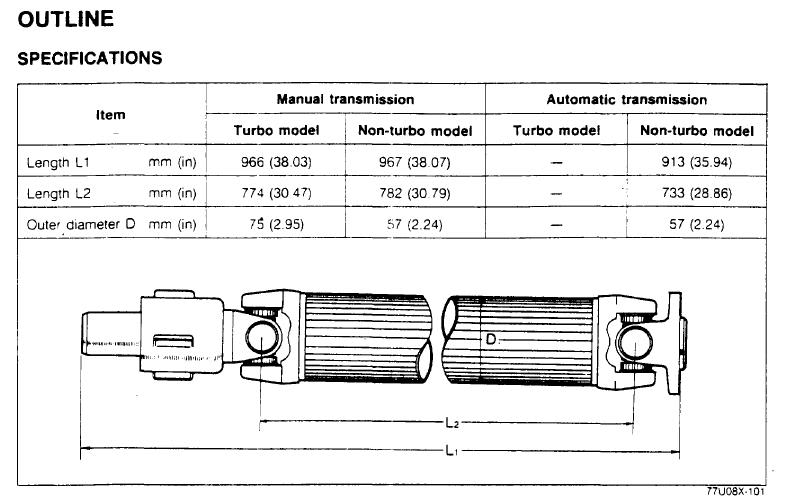

I've measured the driveshaft according to the specs in the following picture:

It is consistent with the turbo driveshaft dimensions.

I don't understand this crap. Yes, the transmission mounts differently because the car is an automatic chassis. But that difference is accounted for by the transmission adapter. The transmission still sits exactly where it should (right..?)

Rear end setup:

Polyurethane differential mounts

MMR front differential mounts

Polyurethane suspension bushings and DTSS eliminators.

I just installed new wheel bearings and studs.

I also threw away my old driveshaft like an idiot. I never had such an issue with the old setup.

There is some play in the yoke connection. I don't know if it's normal. Here is a video:

My turbo II driveshaft from Mazdatrix doesn't sit flush with the tail end of the transmission. There is ~0.75 inches of visible yoke.

Here's a picture of the gap with the yoke fully inserted into the tail end of the transmission:

When the engine is running with the car engaged in 4th gear (on jackstands) I can see in-and-out movement in the yoke. The issue I'm having with the car is a HORRENDOUS driveline vibration at higher speeds (50mph+). It's worst when I'm accelerating. When I accelerate to a high engine speed and decelerate with the car, the vibration has a different tone but is still very loud.

I've measured the driveshaft according to the specs in the following picture:

It is consistent with the turbo driveshaft dimensions.

I don't understand this crap. Yes, the transmission mounts differently because the car is an automatic chassis. But that difference is accounted for by the transmission adapter. The transmission still sits exactly where it should (right..?)

Rear end setup:

Polyurethane differential mounts

MMR front differential mounts

Polyurethane suspension bushings and DTSS eliminators.

I just installed new wheel bearings and studs.

I also threw away my old driveshaft like an idiot. I never had such an issue with the old setup.

There is some play in the yoke connection. I don't know if it's normal. Here is a video:

#2

I just ran into the following thread and I don't think that gap is any issue. Maybe it's just because the car is in the air. duh.

https://www.rx7club.com/2nd-generati...estion-996372/

If anyone has any advice on my vibration I'd still appreciate some help. The car has been down for a year for a full suspension overhaul. I installed:

MMR engine mounts

Full polyurethane suspension bushing kit

DTSS eliminators

rear wheel bearings

longer wheel studs

(it has an MMR front diff mount and poly rear mounts)

Like I said, when driving the car there is a horrendous vibration when applying throttle in 3rd gear and higher, above ~50mph. Feels like the rear end is coming apart.

When letting off the gas the rear end shakes like crazy (does not affect steering). I can put the car on jackstands and still feel the vibration and hear the noise.

The suspension has not been torqued at normal ride height yet. I'm trying to get everything sorted out before I do that with the alignment. I don't see how it could cause this issue but I may be wrong.

The driveshaft is the mazdatrix "aftermarket" replacement.

https://www.rx7club.com/2nd-generati...estion-996372/

If anyone has any advice on my vibration I'd still appreciate some help. The car has been down for a year for a full suspension overhaul. I installed:

MMR engine mounts

Full polyurethane suspension bushing kit

DTSS eliminators

rear wheel bearings

longer wheel studs

(it has an MMR front diff mount and poly rear mounts)

Like I said, when driving the car there is a horrendous vibration when applying throttle in 3rd gear and higher, above ~50mph. Feels like the rear end is coming apart.

When letting off the gas the rear end shakes like crazy (does not affect steering). I can put the car on jackstands and still feel the vibration and hear the noise.

The suspension has not been torqued at normal ride height yet. I'm trying to get everything sorted out before I do that with the alignment. I don't see how it could cause this issue but I may be wrong.

The driveshaft is the mazdatrix "aftermarket" replacement.

#4

I found the problem. The problem is this stupid $300 "aftermarket driveshaft" from Mazdatrix:

It doesn't sit flush with the flange on the differential because it doesn't have enough clearance in the center hole to accommodate the stud coming out of the differential.

I can test fit the driveshaft without the bolts, and the driveshaft flange 'dances' around the differential flange. If I torque the bolts, I can see that it isn't flush and can probably stick feeler guages inside and get a measurement.

So much for buying a brand new driveshaft. What a stupid idea. Will contact Mazdatrix Monday.

It doesn't sit flush with the flange on the differential because it doesn't have enough clearance in the center hole to accommodate the stud coming out of the differential.

I can test fit the driveshaft without the bolts, and the driveshaft flange 'dances' around the differential flange. If I torque the bolts, I can see that it isn't flush and can probably stick feeler guages inside and get a measurement.

So much for buying a brand new driveshaft. What a stupid idea. Will contact Mazdatrix Monday.

#5

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

I had the EXACT same issue with the aluminum driveshaft I bought from Mazdatrix. The differential flange would not sit flush because of interference with the nut.

I just ground down the diff threads until it fit. Still left a few threads in front of the nut in case the diff needs to be serviced.

As for the front yolk, it doesn't go 100% into the transmission. Some of the yolk is visible which allows slip to compensate for movement of the drivetrain.

I just ground down the diff threads until it fit. Still left a few threads in front of the nut in case the diff needs to be serviced.

As for the front yolk, it doesn't go 100% into the transmission. Some of the yolk is visible which allows slip to compensate for movement of the drivetrain.

#7

Retired Moderator, RIP

iTrader: (142)

Join Date: Sep 2005

Location: Smiths Falls.(near Ottawa!.Mapquest IT!)

Posts: 25,581

Likes: 0

Received 131 Likes

on

114 Posts

Dremel should work just fine.

That flange is going to attach to the Diff anyways,so a couple micrograms out( if the cut isn't " Spot on Exact") is not going to hurt anything.

That flange is going to attach to the Diff anyways,so a couple micrograms out( if the cut isn't " Spot on Exact") is not going to hurt anything.

Trending Topics

#8

Senior Member

Join Date: Aug 2005

Location: Onanole, Manitoba Canada

Posts: 250

Likes: 0

Received 0 Likes

on

0 Posts

I needed new bearings on the driveshaft UJs on my 88 vert. I bought a used driveshaft off a friend, and found out there is a machine shop in Winnipeg which will bore out the yokes and replace commonly available bearings, so I kept the old driveshaft, as it seems vert driveshafts are a rare item. So that is the fix, I was told.

Thread

Thread Starter

Forum

Replies

Last Post