91 Vert -- Painting in progress Crystal White -- Lots of pictures

#106

Rotary Enthusiast

Thread Starter

Join Date: Aug 2002

Location: Kansas

Posts: 1,273

Likes: 0

Received 0 Likes

on

0 Posts

Alright folks, I have a few more updates to make...

I recently purchased a generic 2.5" IC pipe kit off of Ebay -- didn't really take pics of it before I started installing it, but it's the basic generic kit that has 2 bends of 3 different angles and 2 straight pieces. It also had silicone connectors as well as 2 90 degree connectors. I was also surprised to find actual tbolt clamps included for the price, but honestly they are cheap clamps -- but for now they should do nicely. The funny thing is I actually ordered black pipe -- I thought the black would go nicely with the other black accents I have in my bay, but when it got here, everything was chrome. Seller stated "yeah, we've had other buyers say the same. We complained to the manufacturer, but not much we can do". Wow, way to make an effort there buddy -- ohwell, I had debated between the chrome and black anyway, so I wasn't heartbroken. Maybe sometime I'll powdercoat these or something -- then again, maybe not.

Anyway, on to the details & pics of the install...

Install was actually easier than I thought -- although it did take a little adjusting to get everything lined up the way I wanted. First pic is on the drivers side on the post-IC pipe.

I actually just used a pipe-expander on the existing hole on that side to simply make the hole big enough for a 2.5" pipe to fit through. I ended up cutting some of the lip off because it got to be fairly big and used fuel hose around the hole to protect the pipe and eliminate banging, etc. You'll probably notice in one of the pics I cut it too short -- I'll go back and fix that later.

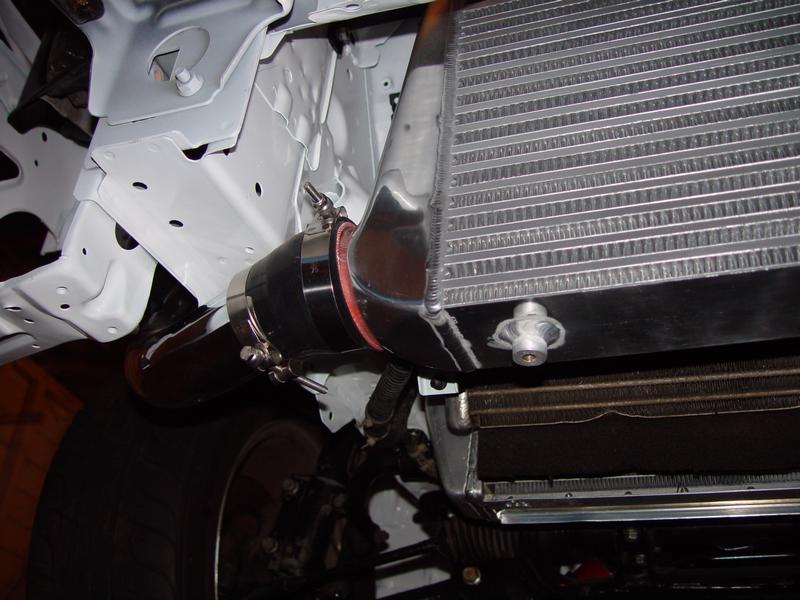

2nd pic shows the underside of that hole and the pipe from the IC to the hole. Should be fairly self explanatory, but note the very short bend coming off of the FMIC.

3rd pic is a top view of the pipe from the turbo down through the area behind the headlight.

A lot of the other installs that I looked at (particularly the Greddy kits) actually went through the vertical wall behind the headlight. In all my mock-ups and estimating and what-not, I couldn't figure out why it wouldn't work to go through a hole that was placed similarly to the hole on the drivers side on the horizontal metal, so that's what I did. I actually used a 2.5" hole-saw as a template and simply slipped the small pilot bit through an existing hole there and clamped the 2.5" hole-saw in place. I then used a plasma cutter (freaking handy!!) to cut around the hole-saw for a nice round hole in a matter of seconds. Then I used the pipe expander again to get it to the size I needed for the pipe to fit through (and the fuel line protection again). Turned out nicely and somehow I ended up not having to use an extra bend on that side like I did the drivers side. HOWEVER, the angle isn't real great and tends to put the couplers at a point where they may not hold under boost -- so I may actually go back and add that bend anyway for a smoother look and fit.

4th pic is the front view of the drivers underside pipe from IC to hole.

5th pic is the same pipe from a side view.

Overall I'm VERY pleased with the outcome of the pipes so far. I was honestly pretty intimidated by the effort and fabrication that might be needed to fully mount and pipe the FMIC, but honestly it turned out easier than I thought -- although a lot of careful and patient planning went into it and I studied pretty hard before I cut anything. Obviously as evidenced by the very first pic, I still need to put the intake together for final fitment, but that should be fairly painless to do later on...

continuing>>>

I recently purchased a generic 2.5" IC pipe kit off of Ebay -- didn't really take pics of it before I started installing it, but it's the basic generic kit that has 2 bends of 3 different angles and 2 straight pieces. It also had silicone connectors as well as 2 90 degree connectors. I was also surprised to find actual tbolt clamps included for the price, but honestly they are cheap clamps -- but for now they should do nicely. The funny thing is I actually ordered black pipe -- I thought the black would go nicely with the other black accents I have in my bay, but when it got here, everything was chrome. Seller stated "yeah, we've had other buyers say the same. We complained to the manufacturer, but not much we can do". Wow, way to make an effort there buddy -- ohwell, I had debated between the chrome and black anyway, so I wasn't heartbroken. Maybe sometime I'll powdercoat these or something -- then again, maybe not.

Anyway, on to the details & pics of the install...

Install was actually easier than I thought -- although it did take a little adjusting to get everything lined up the way I wanted. First pic is on the drivers side on the post-IC pipe.

I actually just used a pipe-expander on the existing hole on that side to simply make the hole big enough for a 2.5" pipe to fit through. I ended up cutting some of the lip off because it got to be fairly big and used fuel hose around the hole to protect the pipe and eliminate banging, etc. You'll probably notice in one of the pics I cut it too short -- I'll go back and fix that later.

2nd pic shows the underside of that hole and the pipe from the IC to the hole. Should be fairly self explanatory, but note the very short bend coming off of the FMIC.

3rd pic is a top view of the pipe from the turbo down through the area behind the headlight.

A lot of the other installs that I looked at (particularly the Greddy kits) actually went through the vertical wall behind the headlight. In all my mock-ups and estimating and what-not, I couldn't figure out why it wouldn't work to go through a hole that was placed similarly to the hole on the drivers side on the horizontal metal, so that's what I did. I actually used a 2.5" hole-saw as a template and simply slipped the small pilot bit through an existing hole there and clamped the 2.5" hole-saw in place. I then used a plasma cutter (freaking handy!!) to cut around the hole-saw for a nice round hole in a matter of seconds. Then I used the pipe expander again to get it to the size I needed for the pipe to fit through (and the fuel line protection again). Turned out nicely and somehow I ended up not having to use an extra bend on that side like I did the drivers side. HOWEVER, the angle isn't real great and tends to put the couplers at a point where they may not hold under boost -- so I may actually go back and add that bend anyway for a smoother look and fit.

4th pic is the front view of the drivers underside pipe from IC to hole.

5th pic is the same pipe from a side view.

Overall I'm VERY pleased with the outcome of the pipes so far. I was honestly pretty intimidated by the effort and fabrication that might be needed to fully mount and pipe the FMIC, but honestly it turned out easier than I thought -- although a lot of careful and patient planning went into it and I studied pretty hard before I cut anything. Obviously as evidenced by the very first pic, I still need to put the intake together for final fitment, but that should be fairly painless to do later on...

continuing>>>

#107

Rotary Enthusiast

Thread Starter

Join Date: Aug 2002

Location: Kansas

Posts: 1,273

Likes: 0

Received 0 Likes

on

0 Posts

Seats are also now installed -- honestly it was harder to install these than I thought it would be and actually required more time and work and blood and sweat and cursing and pain and grinding and cutting and cursing and fabrication and drilling and cursing than it did the FMIC and IC mounting...

Did I mention this was a pain in the rear??

Anyway, the DAD seats are in and I'm happy with the results, I'm just irritated that it took so long and was such a painful experience...

View from the front -- my son is VERY happy the seats are in now!

View from the passenger side.

View from the rear.

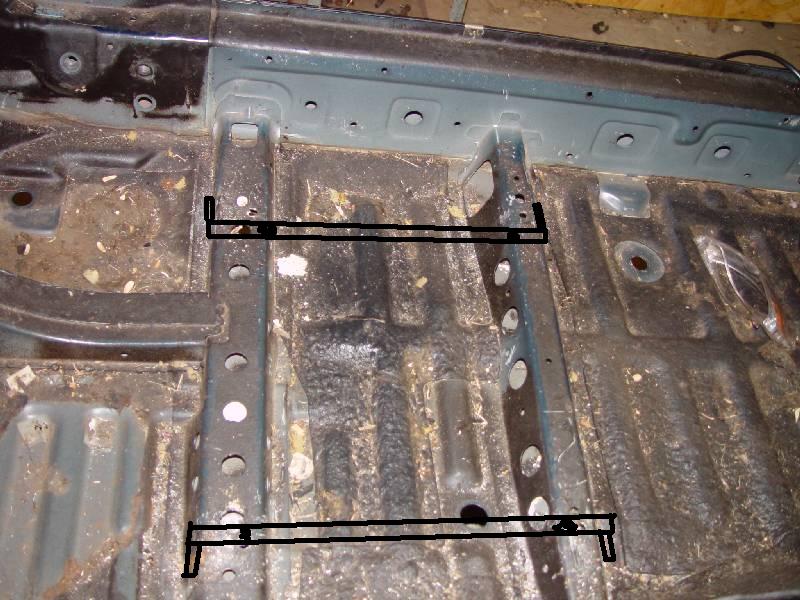

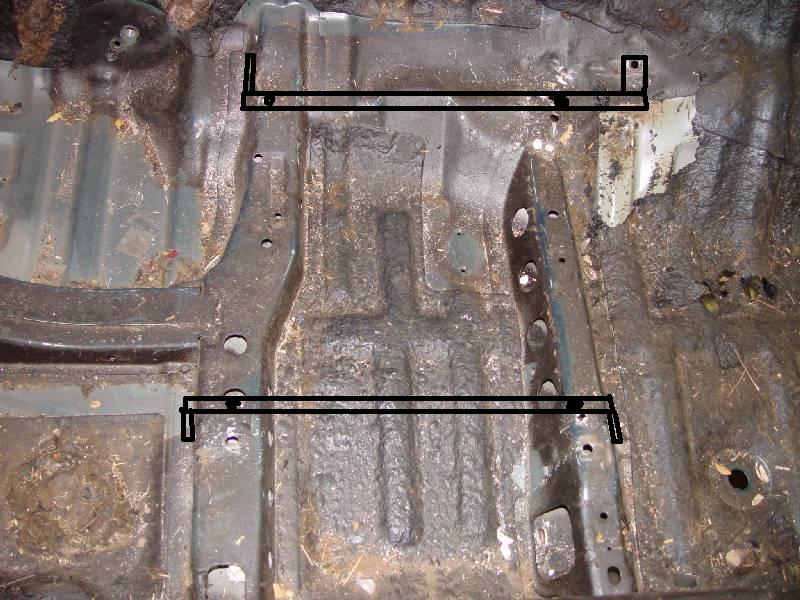

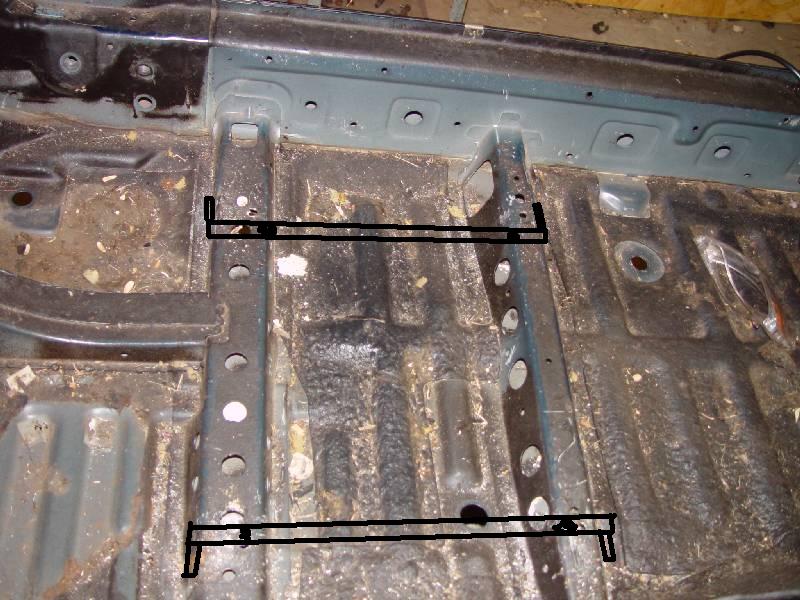

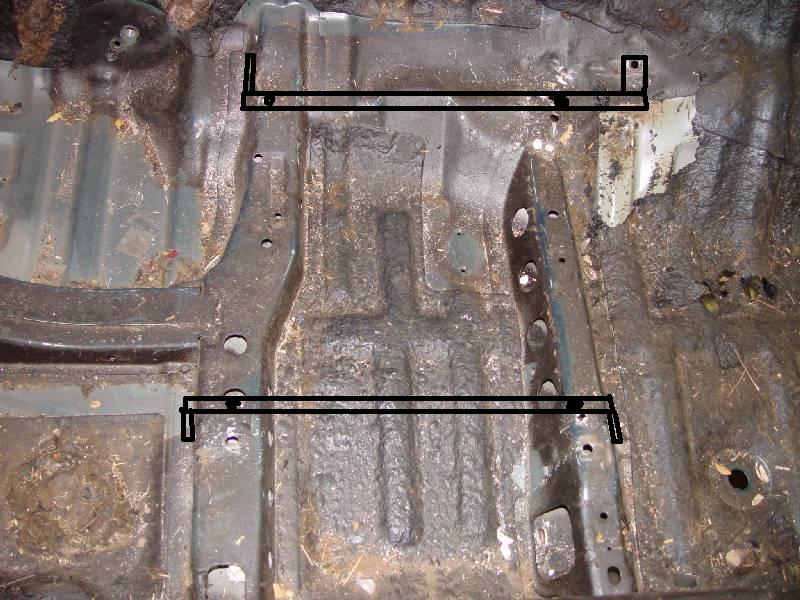

I know these last 2 pictures will not do my brackets any justice, but I did not take a picture of the brackets before installation -- mostly because I just wanted to get them in, but also because I didn't want you to laugh at my terrible welding. Honestly I could care less how they look since you can't see them.

Honestly I could care less how they look since you can't see them.

Anyway, the seats came with their own sliders, but they were positioned slightly narrower (closer together) than the factory sliders are. So basically my idea was that I could use pieces of angle iron to bolt the sliders to and then make "legs" on the angles to bolt to the existing mount locations on the floor.

The good news was that I could use my donor car as the guinea pig for fitment while I was welding and cutting and drilling the new rails...

Here are the pics of the drivers and passengers side floors -- they really don't do the actual design justice, but I think you'll get what I mean.

Driver's side:

Passenger's side:

Essentially my design worked, it just took awhile to get the fitment right since I had to grind away parts of the angle for it to fit against the floor. I also realized I had to cut the seat bolts short so they would allow the seat to fit down flush against the rails. Many hours later, the whole thing came together and I was happy with the results. The seats fit nice, but they may actually be a bit big for the FC's small interior. Won't really know for sure until everything is in place, but for now, I'm satisfied.

continuing>>>

Did I mention this was a pain in the rear??

Anyway, the DAD seats are in and I'm happy with the results, I'm just irritated that it took so long and was such a painful experience...

View from the front -- my son is VERY happy the seats are in now!

View from the passenger side.

View from the rear.

I know these last 2 pictures will not do my brackets any justice, but I did not take a picture of the brackets before installation -- mostly because I just wanted to get them in, but also because I didn't want you to laugh at my terrible welding.

Honestly I could care less how they look since you can't see them.

Honestly I could care less how they look since you can't see them.Anyway, the seats came with their own sliders, but they were positioned slightly narrower (closer together) than the factory sliders are. So basically my idea was that I could use pieces of angle iron to bolt the sliders to and then make "legs" on the angles to bolt to the existing mount locations on the floor.

The good news was that I could use my donor car as the guinea pig for fitment while I was welding and cutting and drilling the new rails...

Here are the pics of the drivers and passengers side floors -- they really don't do the actual design justice, but I think you'll get what I mean.

Driver's side:

Passenger's side:

Essentially my design worked, it just took awhile to get the fitment right since I had to grind away parts of the angle for it to fit against the floor. I also realized I had to cut the seat bolts short so they would allow the seat to fit down flush against the rails. Many hours later, the whole thing came together and I was happy with the results. The seats fit nice, but they may actually be a bit big for the FC's small interior. Won't really know for sure until everything is in place, but for now, I'm satisfied.

continuing>>>

#108

Rotary Enthusiast

Thread Starter

Join Date: Aug 2002

Location: Kansas

Posts: 1,273

Likes: 0

Received 0 Likes

on

0 Posts

Last update for now...

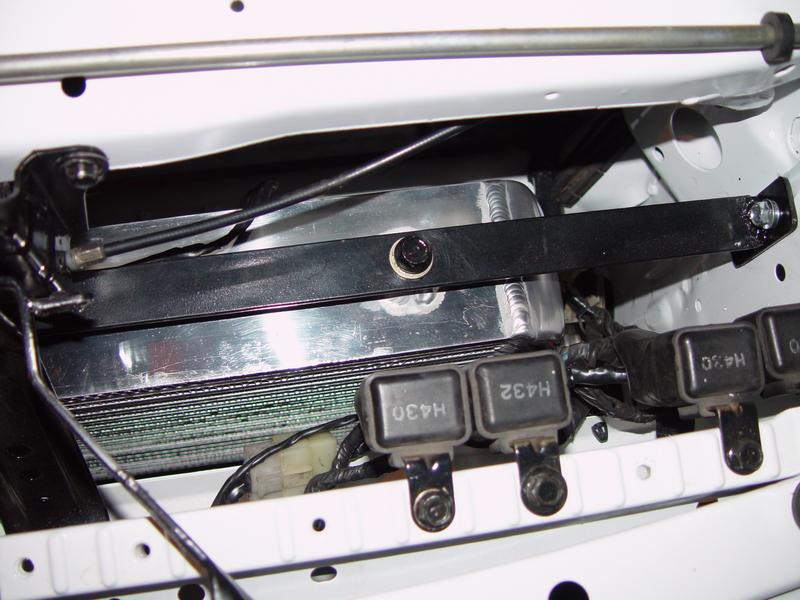

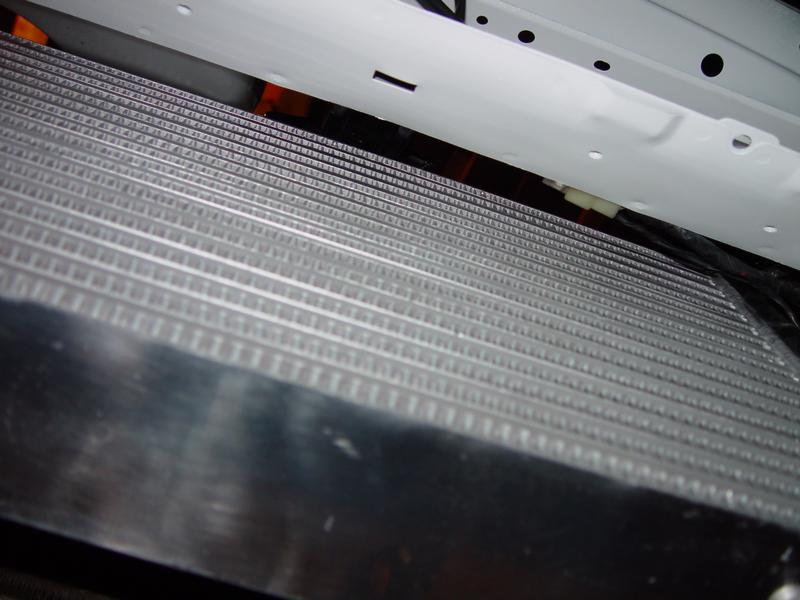

I have a Griffin radiator that I was trying to figure out how to mount and essentially designed a 'triangle' shaped mount for each side of the rad to bolt to and then bolt to the original rad mounts on the car. I'll have more pics of this when it's actually installed -- and it will probably make more sense at that point also. But anyway, I set the radiator in place where I thought it should be mounted -- more in a vertical fashion than the original which layed forward. Since that meant the top was farther away from the mount than the bottom, it needed that 'triangle' shape that I mentioned. So, I used cardboard to get the size right and then took sheet aluminum, cut to the right size, bent it into a 'box' and then took it to a professional welder here in town to weld the 'box' shut and weld it to the radiator. I think it turned out nicely and makes a nice shroud for the sides of the radiator. I do sort of wish he would have welded a longer seam on each side of the rad, but if it's going to work, it should work with what he did...

A couple of pics of the inside and outside of the mounts already welded to the rad.

Like I said, I'll get more pics once the radiator is actually bolted in so I think it will be more evident what I was doing. I do think the box will be strong enough to hold, however, I may go ahead and build a few reinforcments into the inside mounting points of the mounts and possibly some to go to the bottom of the radiator to support some weight. I actually had previously mounted this radiator in the other car by simply using aluminum straights and angles, so I may re-use the design I had for the bottom for that extra support. Hopefully this all works out -- we'll see if it holds up...

I'll probably bolt the radiator in this weekend and a few other little things and give you another short update after all that. Next tasks to do are the rad, intake, wiring, fuel & oil lines, coolant lines, a/c lines, etc.

On a final and sort of off-topic (and sad) note, I had a bit of a bad week last week. I was actually out of town (in Orlando for a conference) and because one side of my garage is being taken up by the RX7, my poor Dodge Ram became the sacrificial lamb.

We had golfball to baseball sized hail and unfortunately my truck took the brunt of that beating. Sucked because I wasn't even here and left my wife to deal with those problems while I was gone. I still have to call insurance about it (and the other car and the house). Just didn't have everything organized enough before I left, otherwise I could probably get all 3 vehicles under cover with a little creative planning -- maybe next time...

I'll leave you with that -- as always, I welcome comments, questions, suggestions, jokes, smart remarks, etc.

Thanks for looking!!

I have a Griffin radiator that I was trying to figure out how to mount and essentially designed a 'triangle' shaped mount for each side of the rad to bolt to and then bolt to the original rad mounts on the car. I'll have more pics of this when it's actually installed -- and it will probably make more sense at that point also. But anyway, I set the radiator in place where I thought it should be mounted -- more in a vertical fashion than the original which layed forward. Since that meant the top was farther away from the mount than the bottom, it needed that 'triangle' shape that I mentioned. So, I used cardboard to get the size right and then took sheet aluminum, cut to the right size, bent it into a 'box' and then took it to a professional welder here in town to weld the 'box' shut and weld it to the radiator. I think it turned out nicely and makes a nice shroud for the sides of the radiator. I do sort of wish he would have welded a longer seam on each side of the rad, but if it's going to work, it should work with what he did...

A couple of pics of the inside and outside of the mounts already welded to the rad.

Like I said, I'll get more pics once the radiator is actually bolted in so I think it will be more evident what I was doing. I do think the box will be strong enough to hold, however, I may go ahead and build a few reinforcments into the inside mounting points of the mounts and possibly some to go to the bottom of the radiator to support some weight. I actually had previously mounted this radiator in the other car by simply using aluminum straights and angles, so I may re-use the design I had for the bottom for that extra support. Hopefully this all works out -- we'll see if it holds up...

I'll probably bolt the radiator in this weekend and a few other little things and give you another short update after all that. Next tasks to do are the rad, intake, wiring, fuel & oil lines, coolant lines, a/c lines, etc.

On a final and sort of off-topic (and sad) note, I had a bit of a bad week last week. I was actually out of town (in Orlando for a conference) and because one side of my garage is being taken up by the RX7, my poor Dodge Ram became the sacrificial lamb.

We had golfball to baseball sized hail and unfortunately my truck took the brunt of that beating. Sucked because I wasn't even here and left my wife to deal with those problems while I was gone. I still have to call insurance about it (and the other car and the house). Just didn't have everything organized enough before I left, otherwise I could probably get all 3 vehicles under cover with a little creative planning -- maybe next time...

I'll leave you with that -- as always, I welcome comments, questions, suggestions, jokes, smart remarks, etc.

Thanks for looking!!

#109

Senior Member

Join Date: Sep 2005

Location: Cambridge, London

Posts: 283

Likes: 0

Received 0 Likes

on

0 Posts

man thats a great job, thats gunna be one purddy turbo vert!!! Props!! thats

shittty about the truck. hail sucks

shittty about the truck. hail sucks

Last edited by re.fc3s; 05-04-06 at 10:43 PM.

#111

Rotary Enthusiast

Thread Starter

Join Date: Aug 2002

Location: Kansas

Posts: 1,273

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by re.fc3s

man thats a great job, thats gunna be one purddy turbo vert!!! Props!! thats

shittty about the truck. hail sucks

shittty about the truck. hail sucks

Originally Posted by theagavejazz

wow, I love the seats.. and the rest of the car too. Superb work. You should be very proud.

Got them for a pretty good price and they definitely are snug on my body, so I hope that they'll hold me in good. I'd like to figure out something else to do w/ the seat belts, but at the moment I have the old blue vert belts to go with them. One of these days I'll find some black ones. I might go for the 4 points, but I think that looks a little "rice" if that's the only thing you have when you're running around in a daily driver (plus I'm not sure of the legality of it). When I fit the seats in the donor car long ago, the stock belt seemed to work great going through one of the holes in the seat back, so we'll see if everything still works that way or not...

Got them for a pretty good price and they definitely are snug on my body, so I hope that they'll hold me in good. I'd like to figure out something else to do w/ the seat belts, but at the moment I have the old blue vert belts to go with them. One of these days I'll find some black ones. I might go for the 4 points, but I think that looks a little "rice" if that's the only thing you have when you're running around in a daily driver (plus I'm not sure of the legality of it). When I fit the seats in the donor car long ago, the stock belt seemed to work great going through one of the holes in the seat back, so we'll see if everything still works that way or not...Thanks for the compliments!

#112

Rotary Enthusiast

Thread Starter

Join Date: Aug 2002

Location: Kansas

Posts: 1,273

Likes: 0

Received 0 Likes

on

0 Posts

more updates

Alright folks, time for a few more updates. Nothing really major to report, but I did make a little progress on a few things...

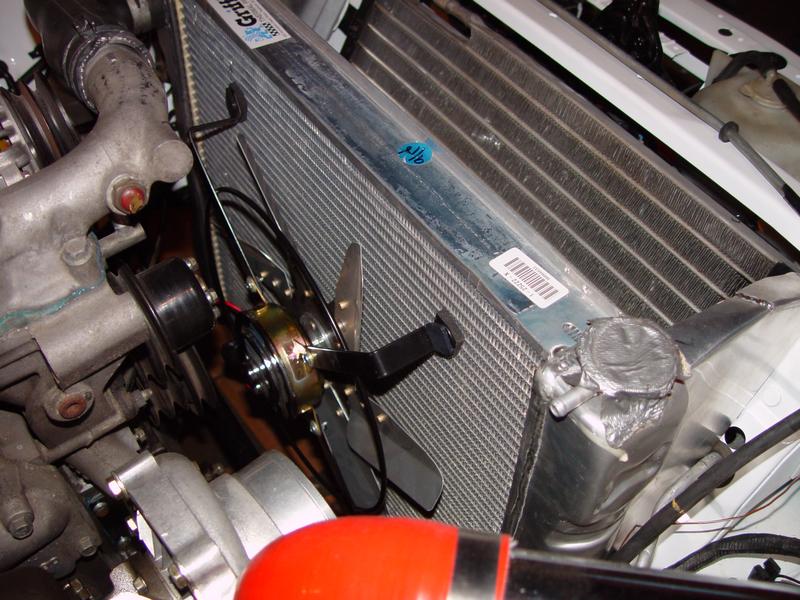

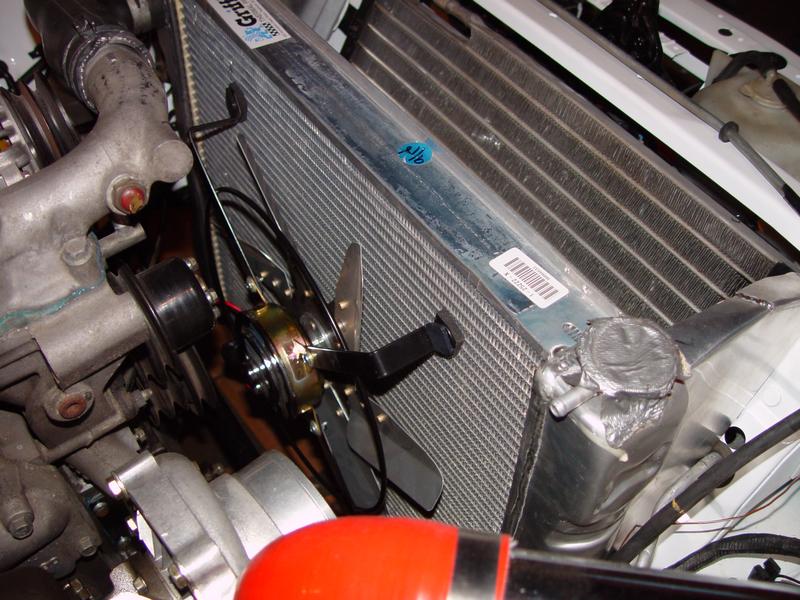

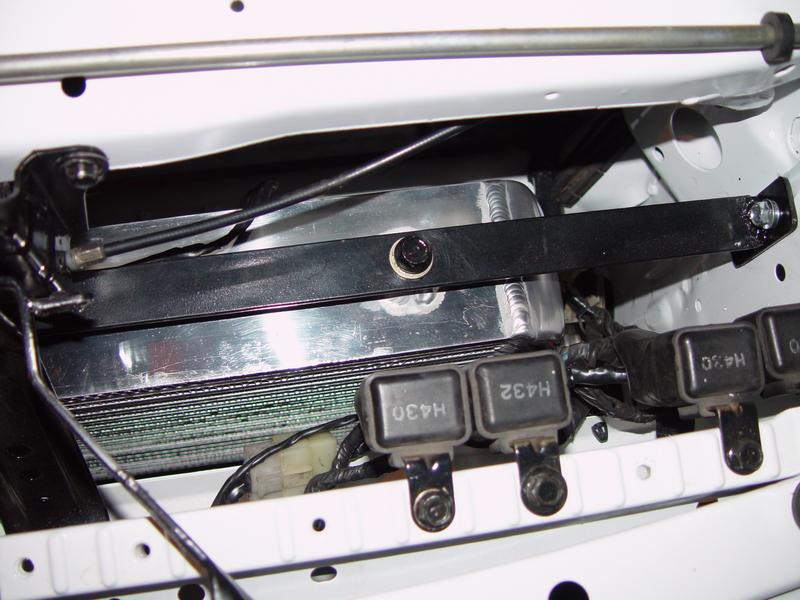

Radiator is mounted in the car now -- and it feels SOLID. I was a little concerned that the mounts might flex a bit, but it seems very stiff, so I'm happy with that. Hopefully I have no issues with the welds. A few pics of the mounted rad with the fan attached:

Back side of rad with finger chopper:

Between condenser and rad -- inside driver's rad mount visible:

Outside drivers rad mount:

Outside pass rad mount:

Overall I'm very pleased with the mounts and the fitment. Although I do have one concern now -- the mounts place the rad close to the intake of the turbo. I don't know for sure if I'm going to stick with that manifold, so it may or may not be a big deal -- but I'll probably consider getting a nice 90* bend to go on the turbo so I can place it out of the path of the hot air -- just not sure if there is enough room for all of that. It's my fault really -- I didn't have the turbo sitting there when I planned the rad mounts and didn't think about it's placement compared to the turbo. Anyway, we'll see how it turns out, it may be just fine...

<continued>

Radiator is mounted in the car now -- and it feels SOLID. I was a little concerned that the mounts might flex a bit, but it seems very stiff, so I'm happy with that. Hopefully I have no issues with the welds. A few pics of the mounted rad with the fan attached:

Back side of rad with finger chopper:

Between condenser and rad -- inside driver's rad mount visible:

Outside drivers rad mount:

Outside pass rad mount:

Overall I'm very pleased with the mounts and the fitment. Although I do have one concern now -- the mounts place the rad close to the intake of the turbo. I don't know for sure if I'm going to stick with that manifold, so it may or may not be a big deal -- but I'll probably consider getting a nice 90* bend to go on the turbo so I can place it out of the path of the hot air -- just not sure if there is enough room for all of that. It's my fault really -- I didn't have the turbo sitting there when I planned the rad mounts and didn't think about it's placement compared to the turbo. Anyway, we'll see how it turns out, it may be just fine...

<continued>

#113

Rotary Enthusiast

Thread Starter

Join Date: Aug 2002

Location: Kansas

Posts: 1,273

Likes: 0

Received 0 Likes

on

0 Posts

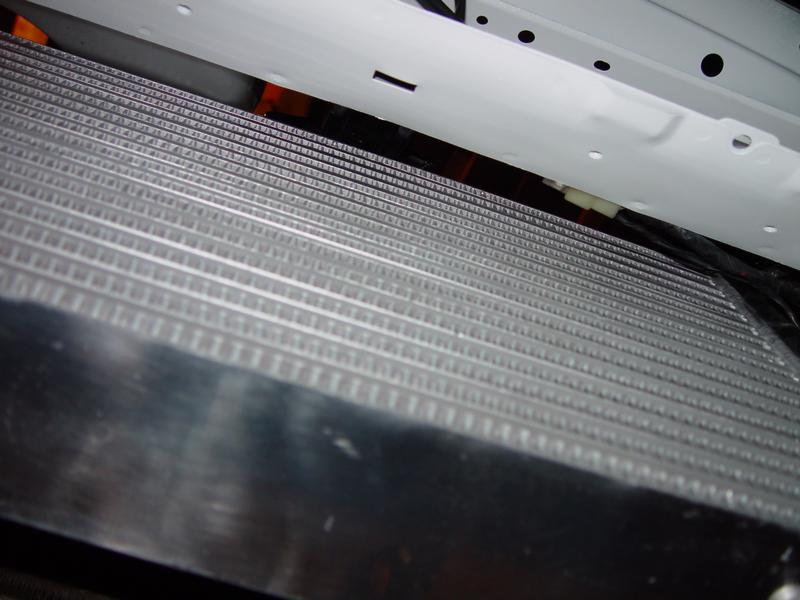

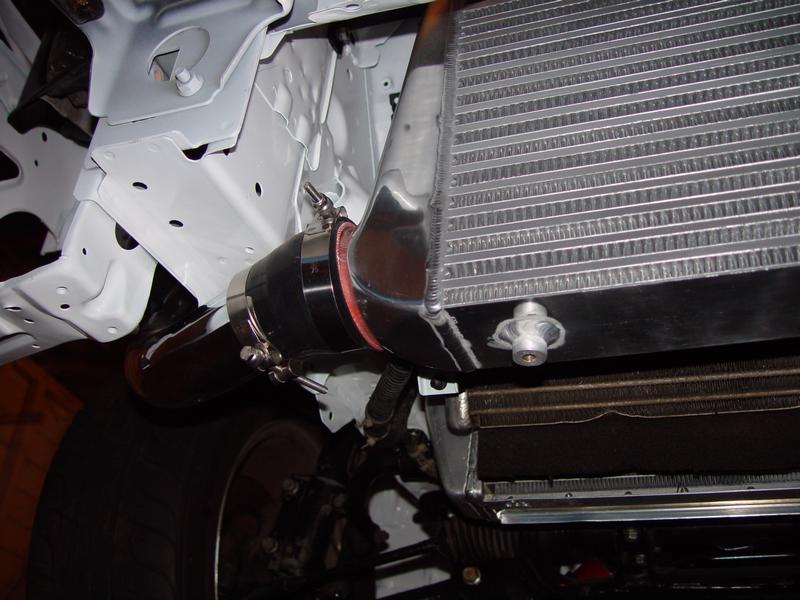

I promised some better pictures of the intercooler mounted in the car. These aren't great, but honestly there isn't much to see -- but it should give you a good idea where it fits and how it looks. I'm just happy I really didn't have to cut anything major. As I mentioned, I merely drilled 4 holes for my bracket across the top and cut the holes for the pipes to go through...

From front of car:

Top of IC showing driver's side end of mount:

Bottom right side of IC showing starting route of pipe:

Looking up from the bottom of the IC showing clearance and placement:

As I mentioned in previous posts, this size of IC fit very nicely and I hope since it's a good sized bar & plate that it will serve the purpose for anything I throw at it... I'm also happy to keep my bumper reinforcement in place.

<continued>

From front of car:

Top of IC showing driver's side end of mount:

Bottom right side of IC showing starting route of pipe:

Looking up from the bottom of the IC showing clearance and placement:

As I mentioned in previous posts, this size of IC fit very nicely and I hope since it's a good sized bar & plate that it will serve the purpose for anything I throw at it... I'm also happy to keep my bumper reinforcement in place.

<continued>

#115

Rotary Enthusiast

Thread Starter

Join Date: Aug 2002

Location: Kansas

Posts: 1,273

Likes: 0

Received 0 Likes

on

0 Posts

I also started working on some plumbing. I'm using an FD primary fuel rail machined to accept FD secondary injectors. That's mounted in place and I'm using the stock fitting on the front side of that rail -- I simply cut the banjo fitting off so I have a hose end to plumb to. I also tapped the back side of the rail to accept a barb fitting thanks to another thread I found with the details on that method. I've also got an Aeromotive FPR that I'll be mounting and plumbing in, but haven't figured out exactly where or how that will fit in the picture.

Don't have any pics of the fuel rail, but hopefully the description explains it -- I'll try to get out and take some pics when I have the complete fuel plumbing done.

Also today I went to several hydraulic shops trying to find someone who carried another banjo fitting I could use for my oil cooler lines. I had 2 banjo fittings already that I cut the old hose off of from the oil-cooler ends, but I was hoping to find a banjo fitting for the top of the block too. (FYI the back oil cooler line actually goes to the top of the block under the oil filter on an RE in case you're wondering).

Everywhere I went basically said they'd never seen a banjo that big so I felt like the scrap yard was my only hope. Finally I decided I would do a bit more research and found the thread size of the banjo bolts (18mm x 1.5 pitch). My hope restored, I figured I would be able to find a suitable fitting of that size instead of the banjo. I went back to one of the shops I visited and they had a nice swivel style fitting and a 90* barb. They then clamped on some high pressure high temp hose. He was feeling good and I got out of there for 12 BUCKS!!!!! Yep that's right, I replaced my oil cooler lines for 12 dollars, 12 bucks, 1200 pennies. Needless to say, I was ecstatic since the alternative is to go stainless and approach the $200 mark.

I then went and got raped by OReillys for the copper washers for 2 pairs it was $4.9x with tax. I was in too good of mood to complain much (although I did double check at the Ace close by to see if they were cheaper). But all told, I replaced the whole thing and got them installed tonight. Total price was just under $17 by reusing the 2 banjo fittings on the cooler, the short angle barb on the front of the block and the new swivel 90* fitting on the top (back) of the block.

Here's some pics...

Wide shot of both hoses:

Close up of the newly crimped hose on my reused banjo fittings

Close up of the newly crimped hose on my reused block fitting and the new swivel 90* fitting:

Hose is rated to 1000psi (that ought to do it) and over 300* (which may be a bit closer to concern, but still plenty of breathing room). They installed quite easily although I did have to turn one of the fittings on the short line a bit to make it line up. The short hose was 13 inches and the long hose was 33 inches. The short one could have stood to be about 1-2 inches longer for slack, although it still fit just right. The long one turned out to be about 2-3 inches on the long side, but as it turned out, the routing worked great so it was fine. I didn't take pictures of them mounted because I'm not sure there was really anything to see. If you're really interested, I'll get some good light in there and snap some pics later...

I think that's it for now -- I welcome questions, comments, etc!

Don't have any pics of the fuel rail, but hopefully the description explains it -- I'll try to get out and take some pics when I have the complete fuel plumbing done.

Also today I went to several hydraulic shops trying to find someone who carried another banjo fitting I could use for my oil cooler lines. I had 2 banjo fittings already that I cut the old hose off of from the oil-cooler ends, but I was hoping to find a banjo fitting for the top of the block too. (FYI the back oil cooler line actually goes to the top of the block under the oil filter on an RE in case you're wondering).

Everywhere I went basically said they'd never seen a banjo that big so I felt like the scrap yard was my only hope. Finally I decided I would do a bit more research and found the thread size of the banjo bolts (18mm x 1.5 pitch). My hope restored, I figured I would be able to find a suitable fitting of that size instead of the banjo. I went back to one of the shops I visited and they had a nice swivel style fitting and a 90* barb. They then clamped on some high pressure high temp hose. He was feeling good and I got out of there for 12 BUCKS!!!!! Yep that's right, I replaced my oil cooler lines for 12 dollars, 12 bucks, 1200 pennies. Needless to say, I was ecstatic since the alternative is to go stainless and approach the $200 mark.

I then went and got raped by OReillys for the copper washers for 2 pairs it was $4.9x with tax. I was in too good of mood to complain much (although I did double check at the Ace close by to see if they were cheaper). But all told, I replaced the whole thing and got them installed tonight. Total price was just under $17 by reusing the 2 banjo fittings on the cooler, the short angle barb on the front of the block and the new swivel 90* fitting on the top (back) of the block.

Here's some pics...

Wide shot of both hoses:

Close up of the newly crimped hose on my reused banjo fittings

Close up of the newly crimped hose on my reused block fitting and the new swivel 90* fitting:

Hose is rated to 1000psi (that ought to do it) and over 300* (which may be a bit closer to concern, but still plenty of breathing room). They installed quite easily although I did have to turn one of the fittings on the short line a bit to make it line up. The short hose was 13 inches and the long hose was 33 inches. The short one could have stood to be about 1-2 inches longer for slack, although it still fit just right. The long one turned out to be about 2-3 inches on the long side, but as it turned out, the routing worked great so it was fine. I didn't take pictures of them mounted because I'm not sure there was really anything to see. If you're really interested, I'll get some good light in there and snap some pics later...

I think that's it for now -- I welcome questions, comments, etc!

#116

Eats, Sleeps, Dreams Rotary

OMG what can i say. Words cant describe the beauty that i am seeing. This is the most amazing thing i have ever seen. I would love to do this someday. But i would buy all new OEM stuff from mazda and pretty much build a stock rx7 like if it came out the factory.

But man i give ya mad proops this **** is so friggin hot.

Mad love from New york city

Jason NYC

But man i give ya mad proops this **** is so friggin hot.

Mad love from New york city

Jason NYC