-6 AN fuel line install?

#1

Senior Member

Thread Starter

iTrader: (3)

Join Date: Oct 2008

Location: Glenwood, Iowa

Posts: 447

Likes: 0

Received 0 Likes

on

0 Posts

-6 AN fuel line install?

I've been searching around the forum and I haven't quite been able to find a definitive guide on how to do a -6 or -8, or whatever size really, fuel line install. I was hoping somebody would be able to point me in the right direction or tell me how?

I'm finally getting around to fixing up my 7 that's been sitting for a while with a snapped line and would love to know. Eventually I do have big plans for it and I know I'm gonna need bigger lines down the road, so I figure be prepared and know what to do now, then start. Measure twice, cut once comes to mind.

I'm finally getting around to fixing up my 7 that's been sitting for a while with a snapped line and would love to know. Eventually I do have big plans for it and I know I'm gonna need bigger lines down the road, so I figure be prepared and know what to do now, then start. Measure twice, cut once comes to mind.

#2

Nothing RX-7 specific about your question.

http://www.inlinetube.com/

http://www.aircraftspruce.com/menus/to/tubing.html

http://www.summitracing.com/

http://www.amazon.com/Fasteners-Plum.../dp/0879384069

http://www.inlinetube.com/

http://www.aircraftspruce.com/menus/to/tubing.html

http://www.summitracing.com/

http://www.amazon.com/Fasteners-Plum.../dp/0879384069

#4

Rotorhead

Join Date: Feb 2001

Location: Charlottesville, Virginia, USA

Posts: 9,136

Likes: 0

Received 39 Likes

on

33 Posts

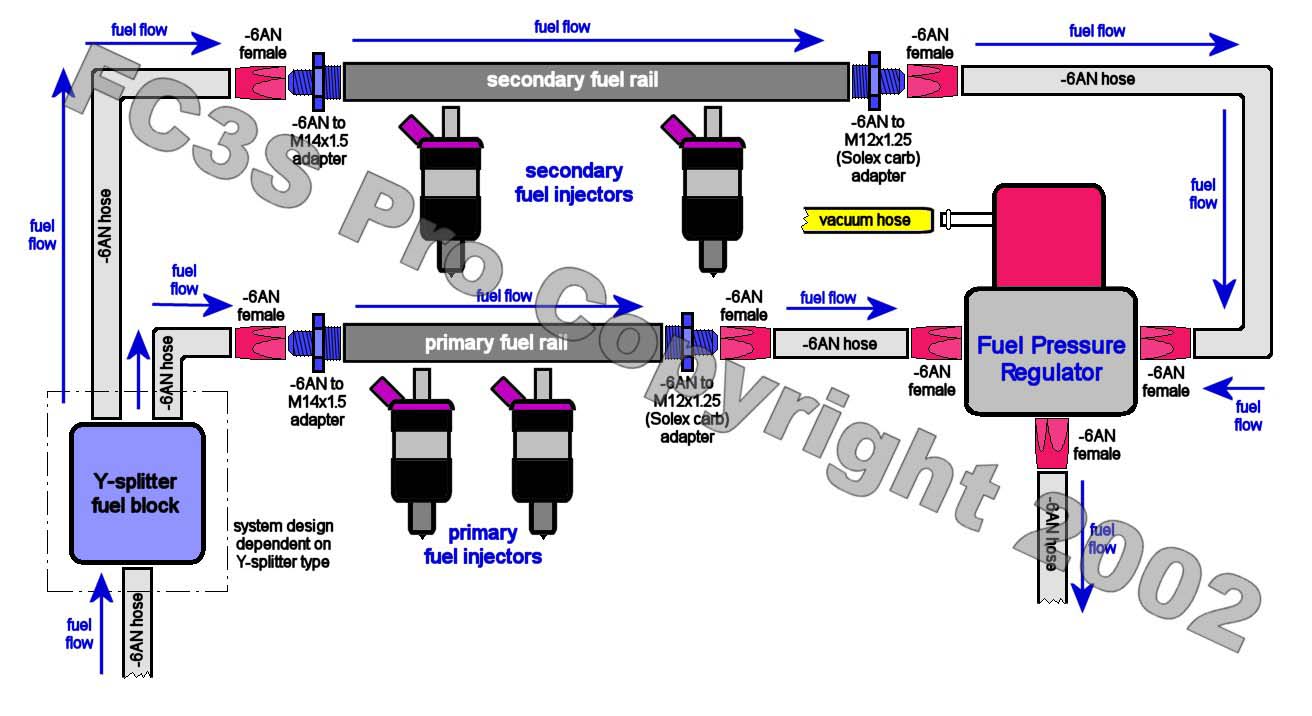

Actually, PvillKnight7 is right, there is not a specific method to do this. The diagram that you posted does not address the hard lines that go under the car, fuel filters, fuel pump(s), and fuel tank/cell, which are all going to be custom.

The OP needs to be more specific about the intent of his car if he wants more specific guidance. Since the OP did not specify the power level, fuel metering method, fuel delivery method, or racing class requirements, I will defer him to the Aeromotive Power Planning website for general guidance:

http://aeromotiveinc.com/power-planner/

A search of the internet will yield various techniques for installing AN fittings and how to bend and flair hard line. Also, you may want to replace the brake lines at the same time.

The OP needs to be more specific about the intent of his car if he wants more specific guidance. Since the OP did not specify the power level, fuel metering method, fuel delivery method, or racing class requirements, I will defer him to the Aeromotive Power Planning website for general guidance:

http://aeromotiveinc.com/power-planner/

A search of the internet will yield various techniques for installing AN fittings and how to bend and flair hard line. Also, you may want to replace the brake lines at the same time.

#5

I can tell you right now that the splitter method is perhaps helpful but certainly not necessary for sane power levels. I have been running my 6AN lines in series (like stock) for years.

My best advice would be not to overbuild your fuel system too much because it can be an expensive and time consuming headache. Dual fuel pumps, fuel cells, parallel rails, add up fast. If you plan on running a hybrid turbo then forget it, at most you can install an aftermarket FPR, fuel pump and injectors and you will be fine. That's unless you are really interested in the look of stainless steel lines for aesthetic purposes.

My best advice would be not to overbuild your fuel system too much because it can be an expensive and time consuming headache. Dual fuel pumps, fuel cells, parallel rails, add up fast. If you plan on running a hybrid turbo then forget it, at most you can install an aftermarket FPR, fuel pump and injectors and you will be fine. That's unless you are really interested in the look of stainless steel lines for aesthetic purposes.

#6

Plumbing a fuel system is a bit overwhelming if you've never done it. There are a lot of decisions that aren't outlined in any single post or write up I've seen. I have a folder on my computer that's full of pics of fuel systems and each fuel system is different. Everyone has their own method of developing and installing a fuel system...some are really bad. Some are good. Some are good and really expensive.

Aluminized steel lines will probably out last any project and they're easy to bend and flare. Much cheaper than SS or running braided lines from the tank to the engine. The Parker 37 degree flaring tool is expensive but it's a good investment if you like restoring cars.

One learning experience I had was discovering Earl's tube mate fittings, which are compression fittings used to go between hard-line and soft line, are not rated for fuel injection pressure.

There is also the potential issue of using the wrong fuel filter and burning out the fuel pump.

Aluminized steel lines will probably out last any project and they're easy to bend and flare. Much cheaper than SS or running braided lines from the tank to the engine. The Parker 37 degree flaring tool is expensive but it's a good investment if you like restoring cars.

One learning experience I had was discovering Earl's tube mate fittings, which are compression fittings used to go between hard-line and soft line, are not rated for fuel injection pressure.

There is also the potential issue of using the wrong fuel filter and burning out the fuel pump.

#7

Senior Member

Thread Starter

iTrader: (3)

Join Date: Oct 2008

Location: Glenwood, Iowa

Posts: 447

Likes: 0

Received 0 Likes

on

0 Posts

Specifically, I eventually want to go N/A 20b, for specific horsepower, I'll just throw a dart someday and build for that and run larger lines as I start doing that. I just figure 6AN for now as I hear that is close to stock.

More specifically even, it's just the connections between line and pump, and wherever up front it connects, I don't know how I would go about connecting. I do know how to flare and bend tubing that's not the problem. I guess I've just never had a chance to really sit down and study how the stock line connects to the pump as compared to how a 6AN line connects, mainly because I've never seen a 6AN line fuel system.

Would I need a different pump or could I connect a 6AN line to a stock pump for now? That I guess is the main question for now. I could also be rambling as I am sitting in class right now as I type this.

Edit: As I look at the parallel rail picture, does the underbody main line run straight up to the y-block in the picture? If so, I could do that, just the pump connection I'm still not sure on.

More specifically even, it's just the connections between line and pump, and wherever up front it connects, I don't know how I would go about connecting. I do know how to flare and bend tubing that's not the problem. I guess I've just never had a chance to really sit down and study how the stock line connects to the pump as compared to how a 6AN line connects, mainly because I've never seen a 6AN line fuel system.

Would I need a different pump or could I connect a 6AN line to a stock pump for now? That I guess is the main question for now. I could also be rambling as I am sitting in class right now as I type this.

Edit: As I look at the parallel rail picture, does the underbody main line run straight up to the y-block in the picture? If so, I could do that, just the pump connection I'm still not sure on.

Last edited by 88_N/A_GXL; 09-07-11 at 12:31 PM.

Trending Topics

#8

I'd budget $500 for an all new fuel system. If you know what parts you need, keep an eye on e-bay and the classifieds. This stuff is expensive.

-6 AN will be adequate. Run hard lines for the feed and return under the car. Flare the ends and use tube sleeves and tube nuts. Then you can use a -6AN male to whatever connector.

-6AN aluminized steel hardline

tubemate tube sleeve

tubemate tube nut

-6AN male to male connector

-6AN female to -6AN hose end

Russel braided -6AN fuel hose

On this project, I used weld on -6AN male fittings on the feed and return at the tank but there are better methods. MIG isn't the best method of welding on the fittings either. It's hard to weld on the small radius of the hard line going into the tank.

Another tip: don't mount the FPR on the firewall or at idle and low rpms you will hear the pulsing of the injectors through the firewall. It's a little annoying to me. I'd prefer to mount the FPR on the engine or at least use sound isolating rubber mounts like the kind on the AC line brackets.

-6 AN will be adequate. Run hard lines for the feed and return under the car. Flare the ends and use tube sleeves and tube nuts. Then you can use a -6AN male to whatever connector.

-6AN aluminized steel hardline

tubemate tube sleeve

tubemate tube nut

-6AN male to male connector

-6AN female to -6AN hose end

Russel braided -6AN fuel hose

On this project, I used weld on -6AN male fittings on the feed and return at the tank but there are better methods. MIG isn't the best method of welding on the fittings either. It's hard to weld on the small radius of the hard line going into the tank.

Another tip: don't mount the FPR on the firewall or at idle and low rpms you will hear the pulsing of the injectors through the firewall. It's a little annoying to me. I'd prefer to mount the FPR on the engine or at least use sound isolating rubber mounts like the kind on the AC line brackets.

#12

#13

Senior Member

Thread Starter

iTrader: (3)

Join Date: Oct 2008

Location: Glenwood, Iowa

Posts: 447

Likes: 0

Received 0 Likes

on

0 Posts

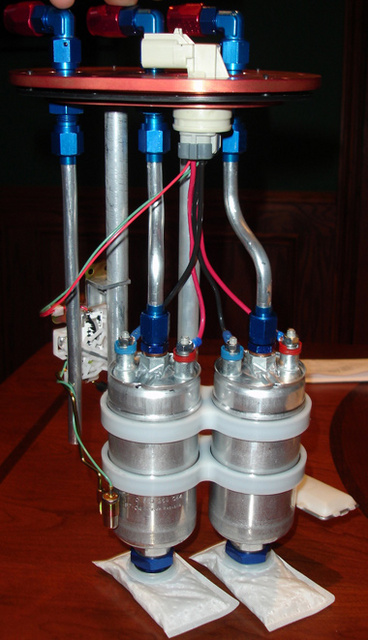

Hot damn, I think I'm all clear now with what to do. If only I knew which pumps those were, or is it kinda standard on some pumps to come with threaded fittings?

#15

In-line pumps like the Bosch 044 have threaded female fittings.

http://www.summitracing.com/parts/VPN-GSL392/

So you would need something like a 10mm x 1.0 male to -6AN male connector.

http://www.summitracing.com/parts/VPN-GSL392/

So you would need something like a 10mm x 1.0 male to -6AN male connector.

#16

those are bosch pumps, and good luck getting fittings for them to use with stock lines, bit of a pain in the *** that turned out to be

you cannot possibly get 2 of these pumps through the stock cover, you would need to fabricate a custom cover and backing plate, by the time you did that you would be better off just having the stock tank sumped

you cannot possibly get 2 of these pumps through the stock cover, you would need to fabricate a custom cover and backing plate, by the time you did that you would be better off just having the stock tank sumped

#18

Senior Member

Thread Starter

iTrader: (3)

Join Date: Oct 2008

Location: Glenwood, Iowa

Posts: 447

Likes: 0

Received 0 Likes

on

0 Posts

I guess I thought in-line pump meant external to the tank. Learn something everyday haha. And to think, I've been passing up looking at inline pumps.

Rob xx 7, I didn't plan on two pumps, at least for now, or running it to a stock line, I was planning on bulkhead connectors like PvillKnight7 showed in both his pictures, to 6AN lines all the way up to the rails, or at least until I can't run a metal line anymore.

Rob xx 7, I didn't plan on two pumps, at least for now, or running it to a stock line, I was planning on bulkhead connectors like PvillKnight7 showed in both his pictures, to 6AN lines all the way up to the rails, or at least until I can't run a metal line anymore.

#19

nope, I could either order a entire kit from some guy in Florida or New Jersey, which I didnt need, or order the single fitting from australia and wait 2-3 weeks for it to show up at about $38

I had mine welded up at the local hose shop for like $20

The pumps usually come with the AN fittings but if you want to adapt to the stock fuel system somewhere thats where the problem lies

you want my advice it would be to go with the bosch pump now, it offers the most room for upgrades especially if you ever want to go E85, calculating that E85 requires 30% more fuel remember any pump you read about, like my old pump that said good for 500hp, is now only good for 350. I seen this first hand on the dyno with my own car.

#20

Senior Member

Thread Starter

iTrader: (3)

Join Date: Oct 2008

Location: Glenwood, Iowa

Posts: 447

Likes: 0

Received 0 Likes

on

0 Posts

I do plan on E85, as I have about 6 stations within 10 miles that sell it and it's almost $1 cheaper, but that's injectors and such that I'm not worried about that right now, unless stock injectors would run it? I just want to get this car up and running. It had it's fuel line snapped like I said, so I figured while I'm at it just start on down the slippery slope.

Edit: Any pumps you guys would recommend over 80gph/300lph? Just for informational purpose, and just incase I happen to need more fuel than that. Don't get me wrong, I've heard a lot about the 044, but sometimes we get power hungry lol. And 350hp, for some like me, could potentially just be an appetizer. I'll just have to see after the 20b, if that's enough to satisfy.

Edit 2: Any recommendations on how long of a run I would need? It doesn't need to be specific, but I don't want to just buy 20' of line just to do that one for now. All I'm looking at for now is getting her running.

Edit: Any pumps you guys would recommend over 80gph/300lph? Just for informational purpose, and just incase I happen to need more fuel than that. Don't get me wrong, I've heard a lot about the 044, but sometimes we get power hungry lol. And 350hp, for some like me, could potentially just be an appetizer. I'll just have to see after the 20b, if that's enough to satisfy.

Edit 2: Any recommendations on how long of a run I would need? It doesn't need to be specific, but I don't want to just buy 20' of line just to do that one for now. All I'm looking at for now is getting her running.

Last edited by 88_N/A_GXL; 09-07-11 at 06:11 PM.

#21

I might have used the wrong term. I do know some tanks must be submerged for cooling and internal lubrication when they run or they can burn up. Others can survive in the air.

If you really think you'll need more than one 044 pump you might want to check into surge tanks and maybe even mechanical pumps:

http://www.fastecracing.com/fuel.html

http://www.watermanracing.com/

-6AN might be too small.

If you really think you'll need more than one 044 pump you might want to check into surge tanks and maybe even mechanical pumps:

http://www.fastecracing.com/fuel.html

http://www.watermanracing.com/

-6AN might be too small.

#22

I wouldnt do -6an lines, if you are going to the trouble and expense go larger and be set for the future.

The stock line from the tank to the filter is the last of my stock system

A walbro or a supra pump will be good, but remember what I said about E85- that pump will be no good once you take that step.

I bet for now to get the car running you could buy a used stock TII or even a NA pump, try to upgrade the fuel system once and be done with it when the time comes.

I built the system for 500hp on pump fuel and now with E85 in the tank I have had to change out my pump and my 1600's because they are maxed

The stock line from the tank to the filter is the last of my stock system

A walbro or a supra pump will be good, but remember what I said about E85- that pump will be no good once you take that step.

I bet for now to get the car running you could buy a used stock TII or even a NA pump, try to upgrade the fuel system once and be done with it when the time comes.

I built the system for 500hp on pump fuel and now with E85 in the tank I have had to change out my pump and my 1600's because they are maxed

#23

Senior Member

Thread Starter

iTrader: (3)

Join Date: Oct 2008

Location: Glenwood, Iowa

Posts: 447

Likes: 0

Received 0 Likes

on

0 Posts

So, -8 or -10? I'm just afraid of running too rich. I personally won't have a problem with using a new pump later down the road, this will probably be a LONG project, but e85 on a 13b n/a, possibly s5 rotors, and bigger injectors will probably be about as far as I'm gonna go right now.

#25

Rotorhead

Join Date: Feb 2001

Location: Charlottesville, Virginia, USA

Posts: 9,136

Likes: 0

Received 39 Likes

on

33 Posts

+1

If you install a fuel system that pumps too much fuel for the engine, then the FPR will bypass a lot of it, which heats up the gasoline, causing about a 10% decrease in power. To stop this from happening, you would need to install a fuel pump controller, which is currently priced at about $150-350.

A basic NA 20B or high-output street NA 13B is about 200-220bhp, which is supported by the stock lines just fine.

E85 is ****. It loses about 30% power and about 30% gas mileage vs. gasoline, plus it is more corrosive.

If you install a fuel system that pumps too much fuel for the engine, then the FPR will bypass a lot of it, which heats up the gasoline, causing about a 10% decrease in power. To stop this from happening, you would need to install a fuel pump controller, which is currently priced at about $150-350.

A basic NA 20B or high-output street NA 13B is about 200-220bhp, which is supported by the stock lines just fine.

E85 is ****. It loses about 30% power and about 30% gas mileage vs. gasoline, plus it is more corrosive.