Tall or short (ports)

#1

Tall or short (ports)

I'm running out of time and the other thread is getting too big.

Dealing with three engines here. The baja engine is mainly figured out. All that's left is the REPU engine and to a lesser extent, the MG engine.

Focusing on the REPU engine:

Tall or short port intermediate plate?

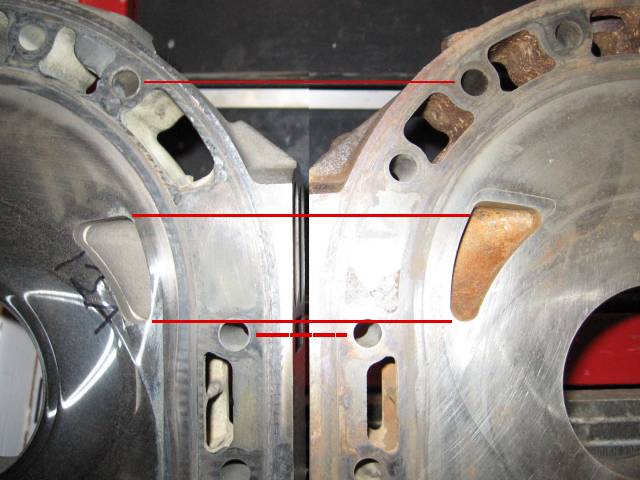

Port opening timing is similar. Maybe it's the camera angle, but does it look like the 12A port is a little lower?

If I use the Y plate, it will get ported out to '74 spec.

Channels or no channels in manifold?

Which rotor housings? Note the D ports will be corrected and reshaped to T2 spec because that's pretty much it for these things. Can't really go in there and add metal.

You know the smaller ports will flow less but have better torque. That's the theory anyway. I'm not against porting the stock exhaust a little larger. Just not out to T2 spec.

Dealing with three engines here. The baja engine is mainly figured out. All that's left is the REPU engine and to a lesser extent, the MG engine.

Focusing on the REPU engine:

Tall or short port intermediate plate?

Port opening timing is similar. Maybe it's the camera angle, but does it look like the 12A port is a little lower?

If I use the Y plate, it will get ported out to '74 spec.

Channels or no channels in manifold?

Which rotor housings? Note the D ports will be corrected and reshaped to T2 spec because that's pretty much it for these things. Can't really go in there and add metal.

You know the smaller ports will flow less but have better torque. That's the theory anyway. I'm not against porting the stock exhaust a little larger. Just not out to T2 spec.

#2

Jeff, what's your goal for the REPU engine?

doesn't seem like you want to port too much, so if it were mine, i would probably go with the 12A side housings - stock primaries, mild street secondaries. use the butchered rotor housings and reshape them to T2 timing spec as you said, but wider. use the manifold with the channels.

that way, the other housings can go in the lighter MG if you're not going to port those either.

what do you think?

doesn't seem like you want to port too much, so if it were mine, i would probably go with the 12A side housings - stock primaries, mild street secondaries. use the butchered rotor housings and reshape them to T2 timing spec as you said, but wider. use the manifold with the channels.

that way, the other housings can go in the lighter MG if you're not going to port those either.

what do you think?

#3

Focusing on the MG:

The REPU engine had phenominal power in the MG. Here it is right after I pulled it (you can see the MG in the background).

Notice the missing exhaust sleeve? lol That rotor housing turned out to be missing tons of chrome so I junked it. You can see its replacement to the left of the stupid D ported housing above.

I'm almost affraid to go with the bigger exhaust ports because it'll lose some low end and add more up high where it's scary. On primaries alone, this thing felt like it had a 20B in it. Seriously. Then you'd think once the secondaries opened it would start to travel through time, but sadly that was not the case with the crappy NO intermediate plate.

The port mismatch facing the wrong direction can still be seen just above and below the outer edges of the ports.

And the Cosmo's reversed runner manifold produced a horrible port mismatch. It's the only one that fits the car so I had to use it.

That will be remedied with a 12A Y plate for the tall ports, and the exhaust ACV port below the primary ports will get blocked with Devcon or Quicksteel. (as you can see, the Cosmo manifold lacks the material there to cover the port)

Since the REPU's engine's atock '74 spec ports performed so well, all three 12A Y plates of the new engine have been ported to '74 spec for the MG. Of course they are compatible with the REPU as well.

I've also already added channels to the Cosmo manifold because they've improved the running and driveability of every engine I've tried them on so far.

They should improve the MG as well. Can you imagine even more power in this thing? And actual flowing secondaries? Gulp

That covers the side plates. All that's left to figure out are the rotor housings.

Which set should I use? The stock ported set, as originally in the REPU engine, or the ported set (ported out to T2 spec or there abouts)?

Can exhaust port timing affect torque and power that much? More so than intake port timing?

Ok I know the high end of this engine will be much better with real flowing secondaries with the addition of a Y intermediate plate, so the high end is covered. Could I get away with larger exhaust ports?

Or would they benefit the REPU more? I can't see how large ports in the REPU would be a good thing, considering it's a truck and will be used for towing. Then again US spec exhaust ports are known to be small and restricitive. How much could I cut out of the stock ports and still retain my low end? Has it already been compromised thanks to the '74 spec intake ports? Will the ultra low REPU rear end gearing of 4.625 make up for it?

The MG rear is 3.7 and felt ok with the old style ribcase 4 speed and light steel flywheel. Felt like it had plenty of torque just off idle. This is what I don't want to ruin by going to larger exhaust ports.

The REPU engine had phenominal power in the MG. Here it is right after I pulled it (you can see the MG in the background).

Notice the missing exhaust sleeve? lol That rotor housing turned out to be missing tons of chrome so I junked it. You can see its replacement to the left of the stupid D ported housing above.

I'm almost affraid to go with the bigger exhaust ports because it'll lose some low end and add more up high where it's scary. On primaries alone, this thing felt like it had a 20B in it. Seriously. Then you'd think once the secondaries opened it would start to travel through time, but sadly that was not the case with the crappy NO intermediate plate.

The port mismatch facing the wrong direction can still be seen just above and below the outer edges of the ports.

And the Cosmo's reversed runner manifold produced a horrible port mismatch. It's the only one that fits the car so I had to use it.

That will be remedied with a 12A Y plate for the tall ports, and the exhaust ACV port below the primary ports will get blocked with Devcon or Quicksteel. (as you can see, the Cosmo manifold lacks the material there to cover the port)

Since the REPU's engine's atock '74 spec ports performed so well, all three 12A Y plates of the new engine have been ported to '74 spec for the MG. Of course they are compatible with the REPU as well.

I've also already added channels to the Cosmo manifold because they've improved the running and driveability of every engine I've tried them on so far.

They should improve the MG as well. Can you imagine even more power in this thing? And actual flowing secondaries? Gulp

That covers the side plates. All that's left to figure out are the rotor housings.

Which set should I use? The stock ported set, as originally in the REPU engine, or the ported set (ported out to T2 spec or there abouts)?

Can exhaust port timing affect torque and power that much? More so than intake port timing?

Ok I know the high end of this engine will be much better with real flowing secondaries with the addition of a Y intermediate plate, so the high end is covered. Could I get away with larger exhaust ports?

Or would they benefit the REPU more? I can't see how large ports in the REPU would be a good thing, considering it's a truck and will be used for towing. Then again US spec exhaust ports are known to be small and restricitive. How much could I cut out of the stock ports and still retain my low end? Has it already been compromised thanks to the '74 spec intake ports? Will the ultra low REPU rear end gearing of 4.625 make up for it?

The MG rear is 3.7 and felt ok with the old style ribcase 4 speed and light steel flywheel. Felt like it had plenty of torque just off idle. This is what I don't want to ruin by going to larger exhaust ports.

Last edited by Jeff20B; 11-24-06 at 03:50 PM.

#4

Originally Posted by diabolical1

Jeff, what's your goal for the REPU engine?

doesn't seem like you want to port too much, so if it were mine, i would probably go with the 12A side housings - stock primaries, mild street secondaries. use the butchered rotor housings and reshape them to T2 timing spec as you said, but wider. use the manifold with the channels.

that way, the other housings can go in the lighter MG if you're not going to port those either.

what do you think?

doesn't seem like you want to port too much, so if it were mine, i would probably go with the 12A side housings - stock primaries, mild street secondaries. use the butchered rotor housings and reshape them to T2 timing spec as you said, but wider. use the manifold with the channels.

that way, the other housings can go in the lighter MG if you're not going to port those either.

what do you think?

I suspect I could open the exhaust ports a little and it shouldn't hurt ultra low RPM that much as long as I don't open them any sooner. I just don't know how much later to close them.

Both sets of side plates are at '74 spec. Only the side plate for the baja will be unported. The MG is small and light. The REPU is fairly heavy but has a low geared rearend. Both are candidates for this port timing, I think.

If I did get a supercharger, the intake ports are probably fine but I know the exhaust ports could be opened up, if the using stock ones. Maybe I could save myself the trouble and use the ported ones in the REPU and the stock ones in the MG?

If I did that, the MG would retain its extraordinary 20B-ish torque curve down low and pass the sound barrier when the secondaries open.

The truck would get the T2 ported rotor housings for a future supercharger upgrade. For now it would retain its stock heavy 30 pound flywheel which should smooth out any irregularities at low RPM and make towing easier.

SoI 'll go with that idea for a while. Stock ported (or maybe very slightly opened) rotor housings in MG and T2 ports in the REPU.

Thoughts?

#5

well, now i'm definitely suggesting use of the 12A housings on the truck with the butchered rotor housings and channeled manifold (left untouched). the T2 exhaust shape and timing that you'll be porting on the rotor housings will be an asset for the supercharger, at least that's what i think. another plus to using those rotor housings is you'll be re-doing the portwork on those awful exhausts, so you can get the finish smooth. i believe three important keys to this engine will be leaving the primaries stock (casting flash and all), that channeled manifold and that ship-anchor-of-a-flywheel you mentioned. the secondaries can be done mild for times when the truck is not "working"  .

.

the stock 3B plates, stock rotor housings would be more than enough to provide low end grunt and top end kick in the MG, even if left unported. since you said you're stuck with the Cosmo manifold for space issues, i think you could probably recoup something by putting more of a venturi-type shape on the primary runners (engine, not manifold). just focus on runner work and leave the actual port alone. that way you can maybe get closer to them being matched and not hurt velocity as much. does that make sense?

.

. the stock 3B plates, stock rotor housings would be more than enough to provide low end grunt and top end kick in the MG, even if left unported. since you said you're stuck with the Cosmo manifold for space issues, i think you could probably recoup something by putting more of a venturi-type shape on the primary runners (engine, not manifold). just focus on runner work and leave the actual port alone. that way you can maybe get closer to them being matched and not hurt velocity as much. does that make sense?

#7

Thanks guys.

So Carl, you suggest that I keep the short port intermediate plate with this manifold

and cut channels in it? And put it in the REPU? That can certainly be done.

Edit:

Incidentally, this will be the first time that I know of where '74 spec timing with short ports will be used in conjunction with a '74 manifold with cut channels in the top connecting primaries to secondaries. I'm very curious to find out how it will run. I bet the low end torque will be nice, even with the larger ported exhaust.

Unfortunately the supercharger manifold will have a slight mismatch at the intermediate plate. Its ports are about half way between short and tall ports. Maybe I can do a quickie rebuild and throw in a Y plate or special request a shorter ported manifold? Ugh, when it's boosted, port velocity is less of an issue, and staying with the short port plate may not be a good idea.

There's also no telling how long I'll keep it NA so maybe I shouldn't worry about this right now? Nah, I want to try to make it future-proof. Besides, when it's boosted, port velocity is less of an issue. In other words, maybe I can get away with a slight port mismatch?

So Carl, you suggest that I keep the short port intermediate plate with this manifold

and cut channels in it? And put it in the REPU? That can certainly be done.

Edit:

Incidentally, this will be the first time that I know of where '74 spec timing with short ports will be used in conjunction with a '74 manifold with cut channels in the top connecting primaries to secondaries. I'm very curious to find out how it will run. I bet the low end torque will be nice, even with the larger ported exhaust.

Unfortunately the supercharger manifold will have a slight mismatch at the intermediate plate. Its ports are about half way between short and tall ports. Maybe I can do a quickie rebuild and throw in a Y plate or special request a shorter ported manifold? Ugh, when it's boosted, port velocity is less of an issue, and staying with the short port plate may not be a good idea.

There's also no telling how long I'll keep it NA so maybe I shouldn't worry about this right now? Nah, I want to try to make it future-proof. Besides, when it's boosted, port velocity is less of an issue. In other words, maybe I can get away with a slight port mismatch?

Last edited by Jeff20B; 11-24-06 at 06:04 PM.

Trending Topics

#8

Airflow is my life

If your going to use that manifold yes. If your gonna use the cosmo manifold I'd use the 12A plate since the runners match up better. Of course make paper templates and check them against each other for any mismatch no matter which combo you end up choosing. I've seen alot of core shift in Mazdas castings. And this is one interface thats really importrant to get right. I wish I could be more definitive but I've never flowed a Cosmo intake or the REPU intermediate plate.

#9

Jeff this may not pertain directly to your setup but the info is neat anyways. Several years ago I had a friend who drag raced a tube frame VW with a nonturbo 13B in it. He ran a very large bridgeport. He noticed a couple of things about that motor's powerband when it came to intake and exhaust setups. The first is that a true dual system isn't a good match for a high overlap engine like a brigdeport. That's no big secreat and hardly pertains to your situation. The intake on the other hand would have a similar effect. He had a Holley intake manifold and carb. While not the same manifold as the stock ones, they each do have 4 spearate runners. He noticed that his powerband fell off on the top end with it stock. He modified it so that the primaries were bridged with each other and the secondaries were bridged with each other. I know you want to bridge the primaries and secondaries from each rotor to each other to keep them separate as far as rotors are concerned. He noticed that power picked up quite a bit on the top end. Unfortunately I don't know what low end did because he never drove down there. It just goes to show what simple things can do to power. In his case 2 simple mods, changing from a true dual exhaust and a separate runner manifold to a long primary exhaust and a modified intake manifold took off a second and a half in the quarter mile. He ran 10's at the end btw.

It would be nice to know what effect modifying the manifold has in relation to powerband with each style of bridge (groove) in the manifold. It would be neat to compare a stock completely separate one to one that has the primaries joined together and the secondaires joined together, as well as one that has the primary and secondary from one rotor together and the primary and secondary from the other rotor together. I can tell you that the larger the open area between these runners, the higher the torque peak moves up. It becomes in essence a small plenum. Just something to think about.

It would be nice to know what effect modifying the manifold has in relation to powerband with each style of bridge (groove) in the manifold. It would be neat to compare a stock completely separate one to one that has the primaries joined together and the secondaires joined together, as well as one that has the primary and secondary from one rotor together and the primary and secondary from the other rotor together. I can tell you that the larger the open area between these runners, the higher the torque peak moves up. It becomes in essence a small plenum. Just something to think about.

#10

Carl, should I use the ported rotor housings in the REPU?

Truth be told, I have two unported Y intermediate plates. On one, the casting slug was a little off and the resulting ports are off to the side a little. It passed quality control and ran in a 12A for probably 20 years with no appearant problems. I picked it up at a local rotary shop for free so I shouldn't complain. The other (normal) unported plate will go into my baja.

I also have a third Y intermediate plate with finished '74 spec ports. Lastly, I have a stock 3B '74 plate pictured above with the 'normal' Y plate. So that's four plates for three engines. I was planning on leaving the off-center plate for emergency use.

So learning of my plan to future supercharge my REPU, you suggest that I use an unported Y plate, complete with casting flash, and mildly port the end plates? That could certainly work. However learning about port flow etc, it's always a good idea to remove the harsh 90° milled edge at the opening of the port and smooth it down all the way around, leaving a smooth rough textured surface with a wobbly dremel stone at slow speed. It leaves a fantastic finish which is almost as rough as the original sand casting surface, but removes all obstacles from the path of the incoming air. In my humble opinion, it is worth the time and effort. The results I've gotten so far prove it (to me anyway).

The MG already has a set of finished '74 ported Y plates waiting for it. Therefore no need to use the 3B plates in the MG, leaving them available for the REPU. They are heavier than Y plates so I'd like to not use them here if possible.

It makes the most sense to use a Y intermediate plate in the MG with the Cosmo manifold. They're lightest and will work well together. I've got some Quicksteel sitting here to smoosh into the ACV port. Just gotta clean the carbon and oil residue first.

Here is the current list of parts I think I'd like to use in both engines.

REPU:

3B plates unported, only smoothed and textured

ported rotor housings to T2 spec

'74 manifold with channels

heavy flywheel

MG:

'74 ported Y plates

unported rotor housings

Cosmo manifold with channels

light steel flywheel

And I'll throw this in just for S&G

Baja:

stock ported Y plates, smoothed and textured

J-spec ported rotor housings (better low end torque but peak sooner = win)

J-spec manifold with stock channels or maybe '78 manifold because it's the same style but with fully cast runners and a little lighter too

modded VW flywheel and adaptor plate

Originally Posted by diabolical1

well, now i'm definitely suggesting use of the 12A housings on the truck with the butchered rotor housings and channeled manifold (left untouched). the T2 exhaust shape and timing that you'll be porting on the rotor housings will be an asset for the supercharger, at least that's what i think. another plus to using those rotor housings is you'll be re-doing the portwork on those awful exhausts, so you can get the finish smooth. i believe three important keys to this engine will be leaving the primaries stock (casting flash and all), that channeled manifold and that ship-anchor-of-a-flywheel you mentioned. the secondaries can be done mild for times when the truck is not "working"  .

.

.

.I also have a third Y intermediate plate with finished '74 spec ports. Lastly, I have a stock 3B '74 plate pictured above with the 'normal' Y plate. So that's four plates for three engines. I was planning on leaving the off-center plate for emergency use.

So learning of my plan to future supercharge my REPU, you suggest that I use an unported Y plate, complete with casting flash, and mildly port the end plates? That could certainly work. However learning about port flow etc, it's always a good idea to remove the harsh 90° milled edge at the opening of the port and smooth it down all the way around, leaving a smooth rough textured surface with a wobbly dremel stone at slow speed. It leaves a fantastic finish which is almost as rough as the original sand casting surface, but removes all obstacles from the path of the incoming air. In my humble opinion, it is worth the time and effort. The results I've gotten so far prove it (to me anyway).

the stock 3B plates, stock rotor housings would be more than enough to provide low end grunt and top end kick in the MG, even if left unported. since you said you're stuck with the Cosmo manifold for space issues, i think you could probably recoup something by putting more of a venturi-type shape on the primary runners (engine, not manifold). just focus on runner work and leave the actual port alone. that way you can maybe get closer to them being matched and not hurt velocity as much. does that make sense?

It makes the most sense to use a Y intermediate plate in the MG with the Cosmo manifold. They're lightest and will work well together. I've got some Quicksteel sitting here to smoosh into the ACV port. Just gotta clean the carbon and oil residue first.

Here is the current list of parts I think I'd like to use in both engines.

REPU:

3B plates unported, only smoothed and textured

ported rotor housings to T2 spec

'74 manifold with channels

heavy flywheel

MG:

'74 ported Y plates

unported rotor housings

Cosmo manifold with channels

light steel flywheel

And I'll throw this in just for S&G

Baja:

stock ported Y plates, smoothed and textured

J-spec ported rotor housings (better low end torque but peak sooner = win)

J-spec manifold with stock channels or maybe '78 manifold because it's the same style but with fully cast runners and a little lighter too

modded VW flywheel and adaptor plate

Last edited by Jeff20B; 11-24-06 at 06:41 PM.

#11

Jeff this is a mold I made of a tall runner port. I made this so I could copy the actual port and runner out of plaster and then port and flowtest it without actually modifying a housing. There's a bit more to it than that but it's a trick I do for flowtesting when I don't want to damage a housing. It easier to make multiple models than it is to find mulitple housings sometimes and I'd much rather mess up on the cheap models.

You can clearly see the flare at the port runner inlet. The size of the runner appears much larger than it actually is. The total height is around 2" but the runner height is about 1.75". This is why it is a very bad idea to gasket match manifolds. I would never recommend it. The port runner tapers down to the port opening. You actually have a whole lot more area in the runner than in the port or at the radius into the port. At the opening edge of the port the intake runner is about 1.5" in height. You can clearly see that runner matching an intake manifold would only create an expansion and then contraction in the intake runner system. This uses energy and hurts power. The current setup also helps to fight reversion. Definitely don't choose one over the other based purely on looks. You could actually make this runner smaller and gain flow! It's not to say it does anything for reversion though but that's another story.

I thought you just might like to see these pictures. It's amazing how much more detail you notice by playing with them in person rather than staring at their pictures.

You can clearly see the flare at the port runner inlet. The size of the runner appears much larger than it actually is. The total height is around 2" but the runner height is about 1.75". This is why it is a very bad idea to gasket match manifolds. I would never recommend it. The port runner tapers down to the port opening. You actually have a whole lot more area in the runner than in the port or at the radius into the port. At the opening edge of the port the intake runner is about 1.5" in height. You can clearly see that runner matching an intake manifold would only create an expansion and then contraction in the intake runner system. This uses energy and hurts power. The current setup also helps to fight reversion. Definitely don't choose one over the other based purely on looks. You could actually make this runner smaller and gain flow! It's not to say it does anything for reversion though but that's another story.

I thought you just might like to see these pictures. It's amazing how much more detail you notice by playing with them in person rather than staring at their pictures.

#12

Thanks for the responses. Lots of good info here.

The Cosmo manifold fits best on the MG. I don't even have to pull the engine to install/remove it.

I'm glad I won't be forced to use my core-shifted intermediate plate. By the way, could some careful port work make one of these viable for use in anything you care about? I suspect it depends upon how shifted it is. Well, the 90° edge at the opening of the port is very thick on one side and very thin on the other. This plate would suck for making a bridgeport. Even on a regular side port I bet one port would always outflow the other.

rg, the carb spacer that came with my J-spec 13B had a channel connecting both primaries. The manifold had channels connecting primaries to secondaries. I believe this was done to smooth out the low RPM reversion waves as much as possible as this engine was designed for low RPM use only.

I've described its strange quirks before, but it deserve a brief mention here.

B6ET (hot) spark plugs, meant for points

190°F thermostat with a full-time bypass valve mounted in the bypass hole (very hot)

short primary ports (like NO/S4 NA spec)

12A spec secondary ports

exhaust ports with late opening and late closing (according to Paul Yaw, these should peak at around 4k RPM)

Auto rear counterweight.

Kenn Chan suggests these engines were in Luces where a different torque curve was required compared to its corporate cousin the CD Cosmo, which had more traditional or 'normal' features ie 180° themrostat, tall ports, cooler plugs etc.

If your going to use that manifold yes. If your gonna use the cosmo manifold I'd use the 12A plate since the runners match up better. Of course make paper templates and check them against each other for any mismatch no matter which combo you end up choosing. I've seen alot of core shift in Mazdas castings. And this is one interface thats really importrant to get right. I wish I could be more definitive but I've never flowed a Cosmo intake or the REPU intermediate plate.

I'm glad I won't be forced to use my core-shifted intermediate plate. By the way, could some careful port work make one of these viable for use in anything you care about? I suspect it depends upon how shifted it is. Well, the 90° edge at the opening of the port is very thick on one side and very thin on the other. This plate would suck for making a bridgeport. Even on a regular side port I bet one port would always outflow the other.

rg, the carb spacer that came with my J-spec 13B had a channel connecting both primaries. The manifold had channels connecting primaries to secondaries. I believe this was done to smooth out the low RPM reversion waves as much as possible as this engine was designed for low RPM use only.

I've described its strange quirks before, but it deserve a brief mention here.

B6ET (hot) spark plugs, meant for points

190°F thermostat with a full-time bypass valve mounted in the bypass hole (very hot)

short primary ports (like NO/S4 NA spec)

12A spec secondary ports

exhaust ports with late opening and late closing (according to Paul Yaw, these should peak at around 4k RPM)

Auto rear counterweight.

Kenn Chan suggests these engines were in Luces where a different torque curve was required compared to its corporate cousin the CD Cosmo, which had more traditional or 'normal' features ie 180° themrostat, tall ports, cooler plugs etc.

#13

The waterpump at the top is the J-spec. That strange object inside is a spring loaded valve which is opened when pulled downward by coolant flow. It has some thickness to it which acts to prevent the thermostat from fully opening (I believe). As the thermostat rod moves down, it encounters this bypass valve which then opens to effectively reduce the engine's cooling capacity by allowing a certain amount of coolant to bypass the radiator.

I'm sure this engine ran very hot under normal conditions. Interestingly, the thermostat was broken when I pulled it. It was a genuine Mazda thermostat with 190° stamped on it. The frame which holds the upper portion and valve to the lower half was broken in two pieces.

#14

Thanks for posting pictures of the inside of a tall port runner.

Yes! I hope everyone reads this thread for your post, if for no other reason.

The Cosmo manifold works only because its secondary runners don't start to flow until high RPM (I hope the channels I cut won't cause problems at low RPM). That is how Mazda could get away with port matched runners here. Then for whatever reason after '76, Mazda continued with the tall port intermediates but with short port manifolds and channels. They seem to work. This is the very reason I started this thread.

I was just hoping that maybe Mazda did what they did for increased gas mileage at the expense of power or torque or something. I'm shooting for maximum torque in my REPU.

Since Mazda seemed to have less restrictions in '74-'75, along with less knowldege about the 13B, I figured the progression from short to tall port intermediates was the next step up in power and reliability. Well, maybe not power, but the greatest majority of 4 port 13Bs around the world have tall ports. Those nitrided R5 13Bs are real workhorses and last as long as a 1st gen 12A. They have tall ports, nitriding and a high volume 17.5 oil pump.

This is why it is a very bad idea to gasket match manifolds.

The Cosmo manifold works only because its secondary runners don't start to flow until high RPM (I hope the channels I cut won't cause problems at low RPM). That is how Mazda could get away with port matched runners here. Then for whatever reason after '76, Mazda continued with the tall port intermediates but with short port manifolds and channels. They seem to work. This is the very reason I started this thread.

I was just hoping that maybe Mazda did what they did for increased gas mileage at the expense of power or torque or something. I'm shooting for maximum torque in my REPU.

Since Mazda seemed to have less restrictions in '74-'75, along with less knowldege about the 13B, I figured the progression from short to tall port intermediates was the next step up in power and reliability. Well, maybe not power, but the greatest majority of 4 port 13Bs around the world have tall ports. Those nitrided R5 13Bs are real workhorses and last as long as a 1st gen 12A. They have tall ports, nitriding and a high volume 17.5 oil pump.

#15

Airflow is my life

Jeff I would use a ported exhaust yes. Which one to start with? I dunno, someone with more experience should answer that.

RG- All I can say is wow. I wonder how many other guys are working secretly on parallel projects. Mines made from RTV and took a bit of work to create, and I used mold release spray on the runner so it comes out nice. What did you make your plug from? Theres a product I saw on a real crime show a while back that really caught my attention. It's called Mikrosil. They used it to take molds of pistol barrels to examine the lands for ballistic matching. Very detailed and impressive.

Mines made from RTV and took a bit of work to create, and I used mold release spray on the runner so it comes out nice. What did you make your plug from? Theres a product I saw on a real crime show a while back that really caught my attention. It's called Mikrosil. They used it to take molds of pistol barrels to examine the lands for ballistic matching. Very detailed and impressive.

Agreed, I made a special fixture/jig so when I port a manifold it's ported to be the exact same size as the runner, not the flare, actually slightly smaller to compensate for variations in housing castings/core shift, thicknesses etc.

You guys can clearly see what I was talking about in the other thread. The runner is so narrow and the turn so sharp abrupt that its no wonder that it flows like crap on the flowbench.

Originally Posted by rotarygod

Jeff this is a mold I made of a tall runner port. I made this so I could copy the actual port and runner out of plaster and then port and flowtest it without actually modifying a housing. There's a bit more to it than that but it's a trick I do for flowtesting when I don't want to damage a housing. It easier to make multiple models than it is to find mulitple housings sometimes and I'd much rather mess up on the cheap models.

You can clearly see the flare at the port runner inlet. The size of the runner appears much larger than it actually is. The total height is around 2" but the runner height is about 1.75". This is why it is a very bad idea to gasket match manifolds. I would never recommend it. The port runner tapers down to the port opening. You actually have a whole lot more area in the runner than in the port or at the radius into the port. At the opening edge of the port the intake runner is about 1.5" in height. You can clearly see that runner matching an intake manifold would only create an expansion and then contraction in the intake runner system. This uses energy and hurts power. The current setup also helps to fight reversion. Definitely don't choose one over the other based purely on looks. You could actually make this runner smaller and gain flow! It's not to say it does anything for reversion though but that's another story.

I thought you just might like to see these pictures. It's amazing how much more detail you notice by playing with them in person rather than staring at their pictures.

You can clearly see the flare at the port runner inlet. The size of the runner appears much larger than it actually is. The total height is around 2" but the runner height is about 1.75". This is why it is a very bad idea to gasket match manifolds. I would never recommend it. The port runner tapers down to the port opening. You actually have a whole lot more area in the runner than in the port or at the radius into the port. At the opening edge of the port the intake runner is about 1.5" in height. You can clearly see that runner matching an intake manifold would only create an expansion and then contraction in the intake runner system. This uses energy and hurts power. The current setup also helps to fight reversion. Definitely don't choose one over the other based purely on looks. You could actually make this runner smaller and gain flow! It's not to say it does anything for reversion though but that's another story.

I thought you just might like to see these pictures. It's amazing how much more detail you notice by playing with them in person rather than staring at their pictures.

RG- All I can say is wow. I wonder how many other guys are working secretly on parallel projects.

Mines made from RTV and took a bit of work to create, and I used mold release spray on the runner so it comes out nice. What did you make your plug from? Theres a product I saw on a real crime show a while back that really caught my attention. It's called Mikrosil. They used it to take molds of pistol barrels to examine the lands for ballistic matching. Very detailed and impressive.

Mines made from RTV and took a bit of work to create, and I used mold release spray on the runner so it comes out nice. What did you make your plug from? Theres a product I saw on a real crime show a while back that really caught my attention. It's called Mikrosil. They used it to take molds of pistol barrels to examine the lands for ballistic matching. Very detailed and impressive. Agreed, I made a special fixture/jig so when I port a manifold it's ported to be the exact same size as the runner, not the flare, actually slightly smaller to compensate for variations in housing castings/core shift, thicknesses etc.

You guys can clearly see what I was talking about in the other thread. The runner is so narrow and the turn so sharp abrupt that its no wonder that it flows like crap on the flowbench.

#16

Carl, here's a link to a site that shows exactly how I make the molds. I take it a step farther though. Since the plugs are hollow, I fill them with clay. I have a small wooden box that I insert the plug into. I fill up the box with a plaster called Ultracal 30. It costs about $20 for a 50 lb bag so one bag goes a long way. It's easy to port with even the most mundane of tools which is nice. The rtv plugs are reusable time and time again.

http://www.diyporting.com/molds.html

There are lots of little things that I try/test/do that I never post on this site. Too many people with zero experience always seem to argue how you're wrong. Oh well.

http://www.diyporting.com/molds.html

There are lots of little things that I try/test/do that I never post on this site. Too many people with zero experience always seem to argue how you're wrong. Oh well.

#18

Airflow is my life

RG- I've seen Mouses site, but that page wasnt up at the time thanks. I build mine till they're thick enough to hold shape but still removable. I made my first one in one pour, solid. And the center never cured LOL. What a frickin mess when it popped on removal.

Yea I understand. I dont usually post about any of these black box projects I fiddle with.

Yea I understand. I dont usually post about any of these black box projects I fiddle with.

#19

The very first mold I ever made (tried to make!) came out the same way. I got impatient and slathered the rtv on way too thick. The middle was still soft and when it did harden, the whole thing had warped into a new shape. It takes me a good 2-3 days to make a mold now. I take my sweet time now. Better safe than sorry.

Most of my work has been on exhaust ports and sleeves. I've got the 13B down and am trying to work on Renesis sleeves. Those will take a while though. I thought about going back to do 12A sleeves but there just aren't that many around anymore and I don't have one anyways. At least I have the CAD drawings of the 13B sleeves done so I can make those any time I want. I have a couple of intake manifold ideas too but again I have no idea when I'll get around to them. I have access to a small local foundry through a local live steam club I'm a member of but I've never taken the time to learn how to make sand casts. I'll get around to it one day. The day that happens I'll have a lot of new things to play with! I'm pretty busy with other things so that could happen next year or never depending on when I have free time. I also have too many other hobbies so my time gets divided. It's mostly just for the fun of it anyways. I definitely don't do this stuff for the investment return.

Most of my work has been on exhaust ports and sleeves. I've got the 13B down and am trying to work on Renesis sleeves. Those will take a while though. I thought about going back to do 12A sleeves but there just aren't that many around anymore and I don't have one anyways. At least I have the CAD drawings of the 13B sleeves done so I can make those any time I want. I have a couple of intake manifold ideas too but again I have no idea when I'll get around to them. I have access to a small local foundry through a local live steam club I'm a member of but I've never taken the time to learn how to make sand casts. I'll get around to it one day. The day that happens I'll have a lot of new things to play with! I'm pretty busy with other things so that could happen next year or never depending on when I have free time. I also have too many other hobbies so my time gets divided. It's mostly just for the fun of it anyways. I definitely don't do this stuff for the investment return.

#20

Originally Posted by Rx7carl

Jeff I would use a ported exhaust yes. Which one to start with? I dunno, someone with more experience should answer that.

Hey RG, since I want to use my ported rotor housings in the REPU engine and the unported ones in the MG, is it wise to copy T2 port timing and transfer it to the D ported rotor housings like I'm planning? Also should I enlarge the unported ports at all for the MG? I only seek to maximize port efficiency without moving the torque peak higher in the RPM range.

#21

I'd go with the 12a tall port and port it and work on the bowl to increase the velocity. check out BDC's ports and threads over on www.nopistons.com

#22

Jeff if you can copy the TII exhaust ports, go for it. They'd work fine. Any time you alter port timing, you are also going to alter where the torque peak occurs. It doesn't mean it would be drastic though. It all depends on how much you change it. The stock TII port timing is fine and I'd be tempted to take the smaller ports for the MG engine and make them the same size as well.

If you really want to maximize port efficiency without changing the powerband, you really need to look into doing something along the lines of my exhaust sleeves. You'll end up having a smaller primary header tube but it will flow more due to less turbulence. Mine are designed to fit the 2nd and 3rd gen housings so I don't know if they will work in the older ones or not. There is another way to simulate these though. Remove the stock sleeve completely. Take an appropriately sized pipe and shape one end of it down to an oval. Then cut the ovaled end at a 20 degree angle. Now insert this into the rotor housing from the exhaust flange side. Play with it until you can get a good fit. Port the housing out to match. Then weld this pipe through the exhaust flange. It works. Just be careful of what type of material you use for the pipe due to expansion properties. You'll want to leave a small amount of room betweeh the pipe and the rotor housing itself to account for expansion but the exhaut gasket should take care of that. Play with it and you'll figure it out. Once you have a setup like this that works, you'll never go back to stock exhaust sleeves. I personally like using the new sleeves better but this way works when you can't get access to them. I'd have the header ceramic coated with this technique though. It gets VERY hot!

If you really want to maximize port efficiency without changing the powerband, you really need to look into doing something along the lines of my exhaust sleeves. You'll end up having a smaller primary header tube but it will flow more due to less turbulence. Mine are designed to fit the 2nd and 3rd gen housings so I don't know if they will work in the older ones or not. There is another way to simulate these though. Remove the stock sleeve completely. Take an appropriately sized pipe and shape one end of it down to an oval. Then cut the ovaled end at a 20 degree angle. Now insert this into the rotor housing from the exhaust flange side. Play with it until you can get a good fit. Port the housing out to match. Then weld this pipe through the exhaust flange. It works. Just be careful of what type of material you use for the pipe due to expansion properties. You'll want to leave a small amount of room betweeh the pipe and the rotor housing itself to account for expansion but the exhaut gasket should take care of that. Play with it and you'll figure it out. Once you have a setup like this that works, you'll never go back to stock exhaust sleeves. I personally like using the new sleeves better but this way works when you can't get access to them. I'd have the header ceramic coated with this technique though. It gets VERY hot!

#23

Originally Posted by rotarygod

The stock TII port timing is fine and I'd be tempted to take the smaller ports for the MG engine and make them the same size as well.

#24

Ah, excellent suggestion. One caveat of the '74 rotor housings are the smaller, more oval shaped sleeves than '76 and up. Plus the outside of the port is smaller. It's closer to 12A size (around 1.5" diameter). Heh RG, I'm already half way to those cool sleeves without even trying.

I have no problem considering making the MG ports the same size as the others. One question though. Should I make them as wide as T2 ports as well? It's 4mm wider than '85 and older. That's 2mm on each side. The 45° Ito bevel adds another 1mm to the total width, reducing over all apex seal support. I'd think a smooth transition, such as the T2 closing should be ok for the RPM I plan to run these at (less than 8400 with stock seals).

I bet the larger ports will increase noise levels. The MG is already loud enough with a short primary header and just one Rotary engineering 24" glasspack. I don't have room for anything more. This was another reason to keep the exhaust ports small in the MG.

I had the opportunity to compare D ports to T2 ports in my bro's RX-4. The D rotor housings pictured above were in his RX-4 with a Racing Beat single pipe system (header, presilencer, Primaflow muffler) and it had a quiet idle with throatiness when you;d get on it.

Then we installed the GSL-SE rotor housings ported out to T2 spec (same opening, closing, and width) and now the idle has a noticeable metalic hitting sound. It's like someone is tapping the header with a small ballpien or sheet metal hammer in unison with the exhaust pulses. It's also a little louder all through the RPM range. You'd only notice the difference if you were familier with it before the swap.

One other posibility is the O2 sensor bung which was added during the engine rebuild. We've never heard the exhaust system with the T2 ports without the O2 sensor. Maybe a less than perfect weld is passing some exhaust noise?

So should I just go for the gusto and port them both to T2 spec? And how about the width?

Thanks everyone.

I have no problem considering making the MG ports the same size as the others. One question though. Should I make them as wide as T2 ports as well? It's 4mm wider than '85 and older. That's 2mm on each side. The 45° Ito bevel adds another 1mm to the total width, reducing over all apex seal support. I'd think a smooth transition, such as the T2 closing should be ok for the RPM I plan to run these at (less than 8400 with stock seals).

I bet the larger ports will increase noise levels. The MG is already loud enough with a short primary header and just one Rotary engineering 24" glasspack. I don't have room for anything more. This was another reason to keep the exhaust ports small in the MG.

I had the opportunity to compare D ports to T2 ports in my bro's RX-4. The D rotor housings pictured above were in his RX-4 with a Racing Beat single pipe system (header, presilencer, Primaflow muffler) and it had a quiet idle with throatiness when you;d get on it.

Then we installed the GSL-SE rotor housings ported out to T2 spec (same opening, closing, and width) and now the idle has a noticeable metalic hitting sound. It's like someone is tapping the header with a small ballpien or sheet metal hammer in unison with the exhaust pulses. It's also a little louder all through the RPM range. You'd only notice the difference if you were familier with it before the swap.

One other posibility is the O2 sensor bung which was added during the engine rebuild. We've never heard the exhaust system with the T2 ports without the O2 sensor. Maybe a less than perfect weld is passing some exhaust noise?

So should I just go for the gusto and port them both to T2 spec? And how about the width?

Thanks everyone.

#25

Originally Posted by Jeff20B

Ah, excellent suggestion. One caveat of the '74 rotor housings are the smaller, more oval shaped sleeves than '76 and up. Plus the outside of the port is smaller. It's closer to 12A size (around 1.5" diameter). Heh RG, I'm already half way to those cool sleeves without even trying.

I have no problem considering making the MG ports the same size as the others. One question though. Should I make them as wide as T2 ports as well? It's 4mm wider than '85 and older. That's 2mm on each side. The 45° Ito bevel adds another 1mm to the total width, reducing over all apex seal support. I'd think a smooth transition, such as the T2 closing should be ok for the RPM I plan to run these at (less than 8400 with stock seals).

I bet the larger ports will increase noise levels. The MG is already loud enough with a short primary header and just one Rotary engineering 24" glasspack. I don't have room for anything more. This was another reason to keep the exhaust ports small in the MG.

I had the opportunity to compare D ports to T2 ports in my bro's RX-4. The D rotor housings pictured above were in his RX-4 with a Racing Beat single pipe system (header, presilencer, Primaflow muffler) and it had a quiet idle with throatiness when you;d get on it.

Then we installed the GSL-SE rotor housings ported out to T2 spec (same opening, closing, and width) and now the idle has a noticeable metalic hitting sound. It's like someone is tapping the header with a small ballpien or sheet metal hammer in unison with the exhaust pulses. It's also a little louder all through the RPM range. You'd only notice the difference if you were familier with it before the swap.

One other posibility is the O2 sensor bung which was added during the engine rebuild. We've never heard the exhaust system with the T2 ports without the O2 sensor. Maybe a less than perfect weld is passing some exhaust noise?

So should I just go for the gusto and port them both to T2 spec? And how about the width?

Thanks everyone.

I have no problem considering making the MG ports the same size as the others. One question though. Should I make them as wide as T2 ports as well? It's 4mm wider than '85 and older. That's 2mm on each side. The 45° Ito bevel adds another 1mm to the total width, reducing over all apex seal support. I'd think a smooth transition, such as the T2 closing should be ok for the RPM I plan to run these at (less than 8400 with stock seals).

I bet the larger ports will increase noise levels. The MG is already loud enough with a short primary header and just one Rotary engineering 24" glasspack. I don't have room for anything more. This was another reason to keep the exhaust ports small in the MG.

I had the opportunity to compare D ports to T2 ports in my bro's RX-4. The D rotor housings pictured above were in his RX-4 with a Racing Beat single pipe system (header, presilencer, Primaflow muffler) and it had a quiet idle with throatiness when you;d get on it.

Then we installed the GSL-SE rotor housings ported out to T2 spec (same opening, closing, and width) and now the idle has a noticeable metalic hitting sound. It's like someone is tapping the header with a small ballpien or sheet metal hammer in unison with the exhaust pulses. It's also a little louder all through the RPM range. You'd only notice the difference if you were familier with it before the swap.

One other posibility is the O2 sensor bung which was added during the engine rebuild. We've never heard the exhaust system with the T2 ports without the O2 sensor. Maybe a less than perfect weld is passing some exhaust noise?

So should I just go for the gusto and port them both to T2 spec? And how about the width?

Thanks everyone.