Suggestions for a modern FB AC condenser?

#1

Suggestions for a modern FB AC condenser?

I'm thinking about restoring the AC system in my LE, but things have changed in the AC world since 1983.

Anybody have any suggestions for an after market AC condenser, about 20 inches wide (51 cm) by 14 inches tall (36 cm)?

Maybe a little bigger?

One of those UAC aluminum units would be fantastic, I just got one for the MP5 and it's very nice.

Thanks

Ray

Anybody have any suggestions for an after market AC condenser, about 20 inches wide (51 cm) by 14 inches tall (36 cm)?

Maybe a little bigger?

One of those UAC aluminum units would be fantastic, I just got one for the MP5 and it's very nice.

Thanks

Ray

#2

Rotary Enthusiast

I kept my original one, really cleaned it and straightened all the fins and it works great.

I'm sure a new one is out there, but don't give up on the factory one if you have it. I've been running new refrigerant in mine for almost 4 years.

I'm sure a new one is out there, but don't give up on the factory one if you have it. I've been running new refrigerant in mine for almost 4 years.

#4

www.AusRotary.com

A few people in Australia have upgraded to a newer style universal parallel flow condenser. The main benefits would be increasing airflow to the radiator and perhaps better performance from the newer type gasses (depending on what you are using in your system). See here for more info:

1st gen rx7 AC condenser alternatives - AusRotary

and

S2 RX-7 - Upgraded the Air Con condenser - AusRotary

The part numbers are likely to be Australian specific, but hopefully the dimension information and pictures give you an idea of what is involved.

1st gen rx7 AC condenser alternatives - AusRotary

and

S2 RX-7 - Upgraded the Air Con condenser - AusRotary

The part numbers are likely to be Australian specific, but hopefully the dimension information and pictures give you an idea of what is involved.

#5

Good to hear CK, I do have the original and it's in great shape.

Only problem is the 1983 unit was designed for R12, which is unobtanium for all practical purposes.

The newer units are super exchangers, tiny little ports and tons of surface area.

What you need to make R-134A work, I've read, it doesn't make cold like the old R12 used to do.

But if R-134A is working for you with the original condenser it should work for me.

Thanks

Edit:

Dang Kypreo, you are a gold mine. Thank you very much!

Only problem is the 1983 unit was designed for R12, which is unobtanium for all practical purposes.

The newer units are super exchangers, tiny little ports and tons of surface area.

What you need to make R-134A work, I've read, it doesn't make cold like the old R12 used to do.

But if R-134A is working for you with the original condenser it should work for me.

Thanks

Edit:

Dang Kypreo, you are a gold mine. Thank you very much!

The following users liked this post:

KYPREO (07-10-19)

The following users liked this post:

t_g_farrell (07-11-19)

#7

84SE-EGI helpy-helperton

I've been running R134a for over 10yrs now, Sonoran Desert...

No problems cooling as long as the pressures are where they need to be. I just recharged it last weekend and drove the car today, in 112F Arizona heat - and though it's running full blast on the interior fan, it cools quickly and is a comfortable ride home on my afternoon commute of 25mi. In the mornings, when the temps are 90F, sometimes I have to turn the interior fan speed to 2 instead of 4 because it freezes me out!

Will look into R152 if you say it's better. Is it compatible with orifice sizing and lubricants used with R134a? It would have to be substantially better cooling over ambient for me to change, though...

Will look into R152 if you say it's better. Is it compatible with orifice sizing and lubricants used with R134a? It would have to be substantially better cooling over ambient for me to change, though...

Trending Topics

#8

Waffles - hmmm good

iTrader: (1)

The duster stuff is at staples: https://www.staples.com/Staples-Elec...fromSearchPage

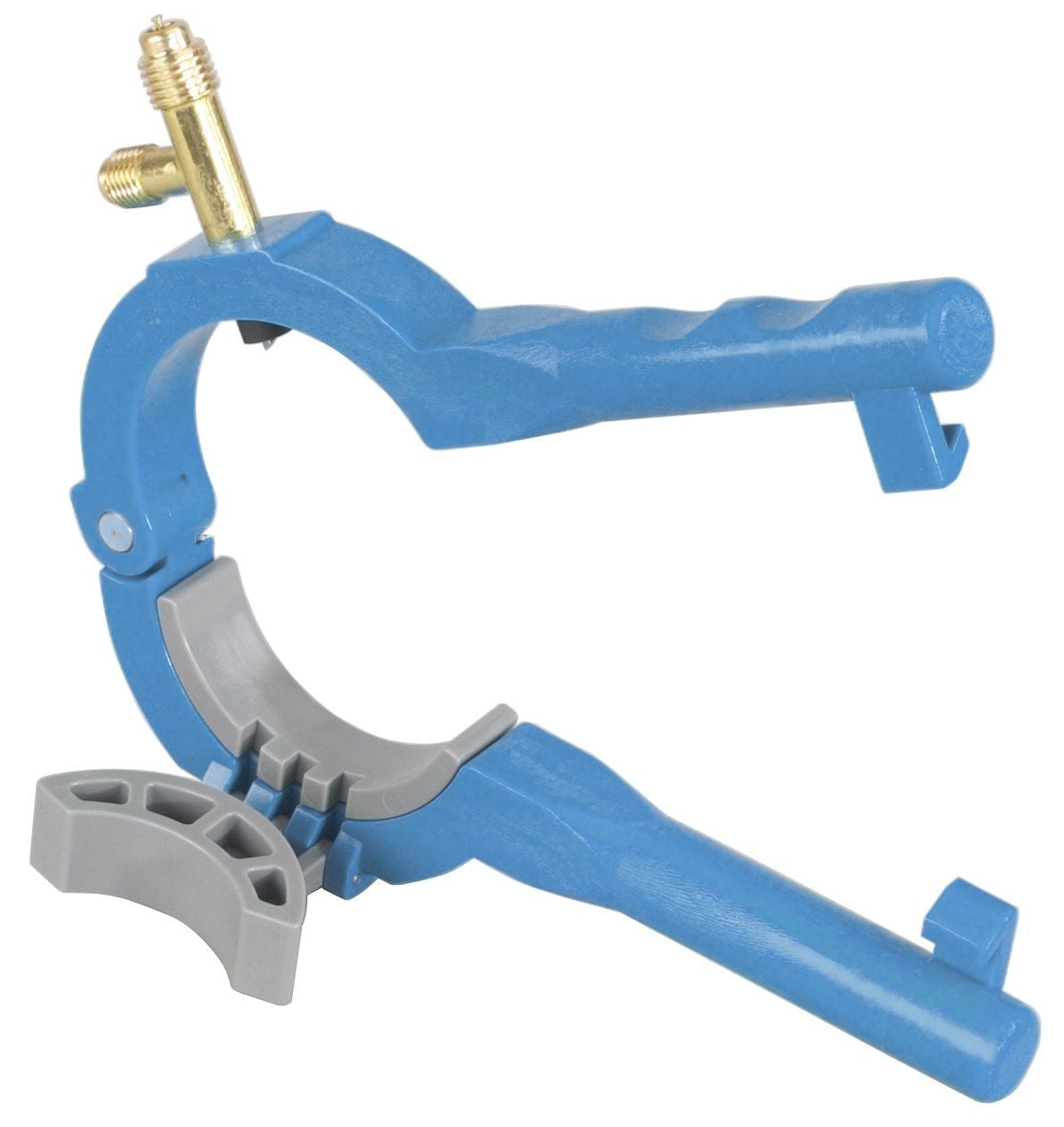

If you have the AC guages already the only other tool you need is a vampire tap to use the duster cans. Like one of these:

#9

ancient wizard...

Ray,i can give you the rundown on nuts and bolts on what's needed to make AC most efficient and last longer. I assume since system is apart and out of car? it'll be easier than if you had to break down components to do what's needed.

Refrigerant hoses if in good physical condition could be reinstalled with rest of parts and a vacuum pulled on system 1st to determine if any leaks present before charging. If it's determined you have a leaky hose,take that hose to local truck shop. They can remove old hose and replace with new reusing fittings on ends of hoses. Some auto parts houses like Napa can do this.

All o rings in system should be renewed before assembly with green nitrile type. A good sized kit can be found online for@ $10

R152 is close to chemical makeup of R12 and leakage thru oe hoses is nothing like what's seen with R134 conversions..Likely if system was functional previously,it'll be again with minimal effort. Nowhere near as much crying if you have to replace a component and recharge.

I have found computer duster spray at Walmart cheapest,on sale $8 for 3 10 oz cans.

I've done a handful of R152 conversions on cars from sixties up thru early 2000 and they work as they did with R12. My 84 Ramcharger was a good candidate,it had that freeze you out type ac til a rock kicked up by another vehicle punctured condenser.

Went @year with no ac,replaced condenser and drier,this truck holds 4lbs of R12,if a leak present,there goes @$200 of refrigerant...considered R134 changeover but had done a few Dodge pickups late 80s vintage that worked but not as cold as oe R12 charge. My Ramcharger interior volume is @ 4 x volume of pickup cab. This was my 1st R152 retrofit,the guinea pig,turned out good,temp output air at dash outlets same as R12 charge before. 11 years since done,still works well.

Refrigerant hoses if in good physical condition could be reinstalled with rest of parts and a vacuum pulled on system 1st to determine if any leaks present before charging. If it's determined you have a leaky hose,take that hose to local truck shop. They can remove old hose and replace with new reusing fittings on ends of hoses. Some auto parts houses like Napa can do this.

All o rings in system should be renewed before assembly with green nitrile type. A good sized kit can be found online for@ $10

R152 is close to chemical makeup of R12 and leakage thru oe hoses is nothing like what's seen with R134 conversions..Likely if system was functional previously,it'll be again with minimal effort. Nowhere near as much crying if you have to replace a component and recharge.

I have found computer duster spray at Walmart cheapest,on sale $8 for 3 10 oz cans.

I've done a handful of R152 conversions on cars from sixties up thru early 2000 and they work as they did with R12. My 84 Ramcharger was a good candidate,it had that freeze you out type ac til a rock kicked up by another vehicle punctured condenser.

Went @year with no ac,replaced condenser and drier,this truck holds 4lbs of R12,if a leak present,there goes @$200 of refrigerant...considered R134 changeover but had done a few Dodge pickups late 80s vintage that worked but not as cold as oe R12 charge. My Ramcharger interior volume is @ 4 x volume of pickup cab. This was my 1st R152 retrofit,the guinea pig,turned out good,temp output air at dash outlets same as R12 charge before. 11 years since done,still works well.

Last edited by GSLSEforme; 07-11-19 at 10:21 AM.

#10

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,796

Received 2,574 Likes

on

1,830 Posts

oh another thing to add to update the car is a condenser fan, it helps a lot to get airflow over the condenser.

you can use the a/c compressor wire as a trigger for a relay, and then the fan can just run when the compressor is running

you can use the a/c compressor wire as a trigger for a relay, and then the fan can just run when the compressor is running

#11

Check, check and check.

I'm gonna do all those things guys, thanks. Mike is Right, I'll follow his directions.

Where can I get lots of that computer duster stuff for cheap?

Cheaper than Staples of course, they're Capitalist Pigs. Walmart is a little better, thanks Mike.

But anybody got any Chinese stuff?

Ebay? Amazon? Give me a link if you find something cheaper than Walmart.

And J9, have you got a link to that condenser fan?

Sounds pretty cool.

I figure if I install a whole new system according to kypreo, add a condenser fan and charge it with computer dust I'll be good to go..

I'm gonna do all those things guys, thanks. Mike is Right, I'll follow his directions.

Where can I get lots of that computer duster stuff for cheap?

Cheaper than Staples of course, they're Capitalist Pigs. Walmart is a little better, thanks Mike.

But anybody got any Chinese stuff?

Ebay? Amazon? Give me a link if you find something cheaper than Walmart.

And J9, have you got a link to that condenser fan?

Sounds pretty cool.

I figure if I install a whole new system according to kypreo, add a condenser fan and charge it with computer dust I'll be good to go..

#12

www.AusRotary.com

If you already have a radiator thermo fan, you can trigger iy to turn on whenever the A/C compressor clutch switch is enabled. This saves installing a separate condensor fan. Run a trigger wire from the A/C clutch relay output to the relay coil of the thermo fan relay. This trigger wire will need to wire in a diode to prevent the thermofan from turning on the A/C. This is how I had it set up on my car before I began EFI conversion and it worked great (ECU now controls fan to turn on with A/C when required).

#13

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,796

Received 2,574 Likes

on

1,830 Posts

#14

OK, now my ignorance it catching up with me. What exactly is this "condenser fan" you guys speak of?

The only fan under the hood I know of is the radiator fan.

Which is also a condenser fan, I guess, since the radiator and the condenser are sandwiched together.

And when the AC comes on and heats up the condenser, the radiator fan turns on and cools both the radiator and condenser, right?

But it sounds like you guys are talking about separate electronic circuits and e-fans activated by the AC itself.

My newer Mazdas, a 2002 MP5 and a 2012 M3, have the electronic fans, so I can imagine activating these with the AC like kipreo says.

But my 1983 LE (and our 1993 Jeep Wrangler, which I'm also updating the AC on) both have fan clutches - no electronics.

I like keeping classics like the LE and Jeep original, allowing performance upgrades only when they don't change the character of the car.

And putting an e-fan in an FB is anything but original, sure to anger the Rotary Gods, in my opinion.

Not to mention that e-fans, with their *****-nilly temp sensors and random air flow, don't work nearly as well as a properly ducted fan clutch.

So who needs an accessory condenser fan when you've got the best of the best already cooling the engine bay - a fan clutch?

Now back to the R152a, this sounds like the way to go, especially when totally replacing the system like I'm doing in the LE, Jeep and MP5.

Three questions:

1) I've read R152a needs either ester oil or PAG for a lubricant, just like R134a. Is one better than the other? When you buy a complete system PAG is usually included and that's what I have for the MP5 and Jeep.

2) There seems to be hundreds of brands of computer duster. Are they all R152a and are some brands better or less expensive than others?

3) Do I use my gauge set to measure the pressures of the high and low side the same way as for R134a to verify proper charging?

Thanks guys and sorry for all the questions, AC systems are simple in concept and complex with details.

The only fan under the hood I know of is the radiator fan.

Which is also a condenser fan, I guess, since the radiator and the condenser are sandwiched together.

And when the AC comes on and heats up the condenser, the radiator fan turns on and cools both the radiator and condenser, right?

But it sounds like you guys are talking about separate electronic circuits and e-fans activated by the AC itself.

My newer Mazdas, a 2002 MP5 and a 2012 M3, have the electronic fans, so I can imagine activating these with the AC like kipreo says.

But my 1983 LE (and our 1993 Jeep Wrangler, which I'm also updating the AC on) both have fan clutches - no electronics.

I like keeping classics like the LE and Jeep original, allowing performance upgrades only when they don't change the character of the car.

And putting an e-fan in an FB is anything but original, sure to anger the Rotary Gods, in my opinion.

Not to mention that e-fans, with their *****-nilly temp sensors and random air flow, don't work nearly as well as a properly ducted fan clutch.

So who needs an accessory condenser fan when you've got the best of the best already cooling the engine bay - a fan clutch?

Now back to the R152a, this sounds like the way to go, especially when totally replacing the system like I'm doing in the LE, Jeep and MP5.

Three questions:

1) I've read R152a needs either ester oil or PAG for a lubricant, just like R134a. Is one better than the other? When you buy a complete system PAG is usually included and that's what I have for the MP5 and Jeep.

2) There seems to be hundreds of brands of computer duster. Are they all R152a and are some brands better or less expensive than others?

3) Do I use my gauge set to measure the pressures of the high and low side the same way as for R134a to verify proper charging?

Thanks guys and sorry for all the questions, AC systems are simple in concept and complex with details.

#17

OK, now my ignorance it catching up with me. What exactly is this "condenser fan" you guys speak of?

The only fan under the hood I know of is the radiator fan.

Which is also a condenser fan, I guess, since the radiator and the condenser are sandwiched together.

And when the AC comes on and heats up the condenser, the radiator fan turns on and cools both the radiator and condenser, right?

But it sounds like you guys are talking about separate electronic circuits and e-fans activated by the AC itself.

My newer Mazdas, a 2002 MP5 and a 2012 M3, have the electronic fans, so I can imagine activating these with the AC like kipreo says.

But my 1983 LE (and our 1993 Jeep Wrangler, which I'm also updating the AC on) both have fan clutches - no electronics.

I like keeping classics like the LE and Jeep original, allowing performance upgrades only when they don't change the character of the car.

And putting an e-fan in an FB is anything but original, sure to anger the Rotary Gods, in my opinion.

Not to mention that e-fans, with their *****-nilly temp sensors and random air flow, don't work nearly as well as a properly ducted fan clutch.

So who needs an accessory condenser fan when you've got the best of the best already cooling the engine bay - a fan clutch?

Now back to the R152a, this sounds like the way to go, especially when totally replacing the system like I'm doing in the LE, Jeep and MP5.

Three questions:

1) I've read R152a needs either ester oil or PAG for a lubricant, just like R134a. Is one better than the other? When you buy a complete system PAG is usually included and that's what I have for the MP5 and Jeep.

2) There seems to be hundreds of brands of computer duster. Are they all R152a and are some brands better or less expensive than others?

3) Do I use my gauge set to measure the pressures of the high and low side the same way as for R134a to verify proper charging?

Thanks guys and sorry for all the questions, AC systems are simple in concept and complex with details.

The only fan under the hood I know of is the radiator fan.

Which is also a condenser fan, I guess, since the radiator and the condenser are sandwiched together.

And when the AC comes on and heats up the condenser, the radiator fan turns on and cools both the radiator and condenser, right?

But it sounds like you guys are talking about separate electronic circuits and e-fans activated by the AC itself.

My newer Mazdas, a 2002 MP5 and a 2012 M3, have the electronic fans, so I can imagine activating these with the AC like kipreo says.

But my 1983 LE (and our 1993 Jeep Wrangler, which I'm also updating the AC on) both have fan clutches - no electronics.

I like keeping classics like the LE and Jeep original, allowing performance upgrades only when they don't change the character of the car.

And putting an e-fan in an FB is anything but original, sure to anger the Rotary Gods, in my opinion.

Not to mention that e-fans, with their *****-nilly temp sensors and random air flow, don't work nearly as well as a properly ducted fan clutch.

So who needs an accessory condenser fan when you've got the best of the best already cooling the engine bay - a fan clutch?

Now back to the R152a, this sounds like the way to go, especially when totally replacing the system like I'm doing in the LE, Jeep and MP5.

Three questions:

1) I've read R152a needs either ester oil or PAG for a lubricant, just like R134a. Is one better than the other? When you buy a complete system PAG is usually included and that's what I have for the MP5 and Jeep.

2) There seems to be hundreds of brands of computer duster. Are they all R152a and are some brands better or less expensive than others?

3) Do I use my gauge set to measure the pressures of the high and low side the same way as for R134a to verify proper charging?

Thanks guys and sorry for all the questions, AC systems are simple in concept and complex with details.

The condenser fan is just an add on. It'll increase the performance of the ac at idle. When you are driving there is plenty of air moving along. I use just the clutch fan that the engine turns. At idle the ac does suffer a bit, but not too much of a problem for me cause I get in my car to MOVE. lol

1)Ester oil. Use Ester oil. I heard pag doesn't react well with old r12 and duster refrigerants. They cost the same so why even risk it.

2)makes almost no difference. its so cheap who cares. I used the $4/can for 385gram cans from Walmart. Pair of cans filled me up a few years ago.

3)Yes and no. Use the gauges to make sure your pressures are good, but honestly I just pumped in about 600grams and called it good.

Ray, you will need an R12 to 134 adaptor on your system to hook up modern ac manifold gauge set. If you have a sanden unit you probably won't be able to get the high side to connect. That's no big deal. As you normally charge from the low side anyways.

Here are some links....

Line lock tool. (I own one if you want to borrow it)

https://www.ebay.com/itm/A-C-Hydraul...EAAOSwJcxc1eik

A/C hose kit. Even comes with a dryer which is a new part you WILL need to replace in your old r12 system.

https://www.ebay.com/itm/134a-Air-Co...wAAOSwHgdaxPRK

Last edited by Qingdao; 07-12-19 at 09:30 PM.

#18

ancient wizard...

Ray,if you open the hood on your modern cars you see a pair of electric fans.Some cars use one to cool the radiator and other to cool the ac condenser=condenser fan.

Question:

1) With R152 refrigerant use only ester oil. Use of PAG oil will cause leftover mineral oil to combine with it and react to R152=difloroethane and gum up,plugging everything that has small orifices. In your ac system it is these small orifices(expansion valve) that separate low/high side of refrigerant system and control change of gas to liquid that allows system to function and exactly control in car temp output. Once these components,lines,drier,condenser begin to get plugged up-they have to be replaced-there's no cleaning them. Again Ester oil ONLY w R152

2) There are many brands of duster spray. Some manufacturers include some other extra chemicals,one is a Bitterment to keep druggies from huffing duster spray. Another is a chemical that makes it smell nice...R152=Difloroethane. It must state that on the can,it will also state if it has a Bitterment added-most do. It may or may not list any other components. Stick with the brands that state it is Difloroethane. If it doesn't say that on the can,put it back on the shelf. If it does and also lists some other chemicals,put it back on the shelf.

I've used essentially one brand of duster spray on all my conversions with no adverse effects. I have read articles about several duster sprays causing ac system not to work right after a time,problems traced back to unnamed chemicals in duster spray breaking down lubricating oil in system causing compressor failures and system wide contamination. Aware you're frugal,this stuff doesn't cost that much-especially in comparison to R12...think hard about what you're introducing into your ac system,kinda like letting the genie out of the bottle. The great price you got on duster spray doesn't look so cheap now...nuff said.

3) I could try to find a temp/pressure differential chart i have on my computer that compares R12-R134-R152 air outlet temps,lo/hi side compressor head operating temps at various ambient temps. In short just know That R152 has lowest operating pressure,followed by R12,with R134 having the highest operating pressures. Use of R134 as a retrofit for R12 raises system operating temps/tempsenough to cause the oe condenser to be unable to transfer the extra heat load. A lot of vehicles,like ours,have these systems packaged in very small environments and sometimes impossible to retrofit larger condenser. A dual pass unit would be the answer for better heat transfer if R134 was chosen refrigerant retrofit for an original fill of R12. Dual pass units are neither bolt in or cheap.

Use of R152 will actually give the oe condenser some reserve as it won't be maxed out by higher pressuures/temps of R134. It will have more reserve than even the original R12 fill operating pressures/temps.This is the reason why if you have an oe condenser in good condition with straight fins and a fan clutch that works properly,no more cooling assist is needed. The factory fan/clutch/shroud combo is very well designed and can move some air.

Don't overlook foam seal on bottom of radiator to bellypan. If you don't have the bellypan installed-do it. With the foam seal in place,all air is forced thru condenser/radiator making them 100% efficient. No bellypan,all air doesn't travel thru condenser/radiator,makes a noticeable difference in cooling system/ac performance and on FMOC cars pulls air thru them too instead of around.

This means that it is possible to have cooler air outlet temps with R152 than with oe fill of R12 using @1/3 less charge weight by volume. Also means it takes less hp for ac compressor to compress refrigerant that has lower operating pressures compared to oe refrigerant. This will translate into smaller loss of fuel economy as less drag on engine as ac compressor not working as hard.

For a long time i ran a large assist fan on my ac condenser in my SE,16". The fan was activated by relay,a binary switch installed in receiver drier that used ac compressor clutch feed to activate it. A lot of folks run condenser fan(s) that operate when ac compressor is engaged,whether you're stopped or driving 100+mph. Having that fan run when car is moving more than 20 mph is a waste/unneeded wear on fan motor and unnecessary draw on electrical system as it's not needed,nor is the fan clutch on radiator fan at that speed and above.

A binary/trinary switch senses hi side ac system pressure and temperature and when those two exceed its set point,it turns the condenser fan on to keep head pressures on ac compressor steady,system operating pressures lower and air outlet temp in car more constant. Once moving again,air forced thru condenser/radiator lower operating pressure/temps and binary switch shuts condenser fan off til next time car is stopped. For those that have limited reserve in alternator size or are trying to wring out every last bit of fuel economy or power from engine maybe should look into one of these.

Over the 20+years i had condenser assist fan on my car,even though the fan was balanced,the minor vibration it had transferred to tubes on condenser over that time eventually rubbed thru causing a small leak. I did not know this at 1st,i thought the leak may have been somewhere else. A rock chucked up off the road into condenser put an end to it. Another thing i eventually noticed was oe fan clutch was wearing out and letting coolant temp rise a bit much before it engaged and cooled car down at stoplights and this was the real reason i felt i had to have an assist fan to keep ac cool at stoplights-which it did. The reality was the assist fan was actually compensating for the aging fan clutch...for those that have SEs,oe fan clutch is NLA,switch to a 12A unit. The calibration is different and very slightly more aggressive than 13B part and steps up fan speed at idle when fan clutch engaged. Lower steady readings on temp gauge are noticed.

Ray,this condenser was replaced by the one you sent me,i was back and forth over mounting the assist fan on "new"condenser but didn't want the fan to eventually ruin it. I considered fabbing some brackets across condenser opening and mounting fan to that,but a couple things changed my mind. 1st don't want to be drilling extra holes in car. 2nd,i had never run anything but R12 in this car,i had enough R12 but was considering switching to R152. After doing the math with comparing head pressures,outlet temps in car to R12 and R134 i decided to go with the R152 and abandon the assist fan on condenser. With the fan clutch being replaced and R152 conversion i had 36 degree air at dash vents where previous best was around 40 degrees.

Ray,take your ac compressor and turn it upside down over a measuring cup to catch oil from compressor. Turn compressor shaft back and forth to get all mineral oil out of it. Measure total volume collected.Sit compressor upright and pour in @3 oz of ester oil and turn shaft back and forth several times,then turn over and drain out,turning shaft back and forth to remove as much as possible. Pour 3 oz of ester oil into compressor and turn shaft to distribute and set compressor aside.

Buy a new receiver drier. Take all lines and ac hoses and spray brakleen thru them a couple times each followed up with a strong blast of compressed air to clear out any contaminants,same for ac condenser.

All the male/female fittings on lines and hoses should be lightly lubricated with a light oil like CRC powerlube to prevent galling. Renew all o rings with green HNBR ones and lubricate with ester oil to help seat the o rings and minimize rolling/pinching.

When assembling connections,do so by hand before putting wrenches on fittings. Much easier to feel crossthreading by hand than at the end of a wrench.When you're about to install new drier first pour 3 oz of ester oil in,mount in place and until ready to connect hoses on each side of it,put caps back on it came with. Keeps excessive moisture out of drier especially if humid outside.Connect hoses with new o rings and tighten fittings snug.

Once the system is assembled and airtight,hook up your gauges and rent a vacuum pump from a parts store(autozone doesn't charge anything for this other than a fee that protects them if you don't bring the tool back-that fee is refunded in entirety when you return pump).

Some people skip this step as they feel it's not that important. Consider the fact that if all air/moisture is still in system,you cannot get a proper charge of refrigerant in system,if you try and succeed in getting all the correct amount of refrigerant in,you are now overcharged and air/moisture in system do nothing to enhance performance,in reality keep system from performing to potential. Proper use of pump and manifold gauges can give a very good indication of any leaks in system-before you start charging. Lastly,that full vacuum in system will suck in 1st can of refrigerant very quickly.

Open both lo/hi side valves on manifold set,connect fill hose from gauge set to pump and turn on. Let it run for 15 minutes,you want to see 30" of vacuum on both gauges. Close valves on manifold set and turn pump off. If system is "tight",the needles on gauges should stay where they are and not creep. If system holds that vacuum for 30+ minutes,about 98%sure system is tight. Open valves and turn pump on for at least 45 minutes. The purpose is to get vacuum to 30" for long enough to boil all moisture(from system being open for how long?) and remove it thru pump. Close valves and turn off and disconnect pump.

Time for some math,i'll give you the values to do math...

Molecular weight of R12=120-multiply original fill volume by .56 to get weight by volume for correct fill of R152

Molecular weight of R134=102-multiply original fill volume by .64 to get weight by volume for correct fill of R152

Molecular weight ofR152=68

Fill a bucket with hot water. Use your side can tap and tap can near the top or bottom as less likely to dent and collapse and leak. Hook can tap to fill hose on manifold set,loosen fill hose at manifold just long enough to purge air from hose so you don't push that into system with refrigerant. You will know when all air is out when fitting gets cold from refrigerant,tighten up fitting.

Open lo and hi side valves and let refrigerant flow into system. Pay attention to any sounds of leaks in system and stop charging if you hear anything. When the duster can gets cold to the touch,it is nearing empty,drop it in bucket of hot water to get rest of refrigerant out.

When it floats on top it's empty. Pick it up and shake it,if it doesn't feel cold its empty. Close lo side and hi side valves on manifold set. Take note of system pressure. Start car and turn on ac to lowest fan speed,close recirculate door,lever? Close windows.

Observe gauge readings,particularly lo side. Open lo side valve to let compressor pull in remains of refrigerant from can. Compressor may be cycling on/off somewhat quickly. Once lo side pressure drops as low as it can-while compressor is on-close lo side valve on manifold.

Open latch on can tap and quickly switch new can and tap it. Purge air from fill hose at manifold and slowly open lo side valve and let refrigerant flow in. Keep lo side pressure about 40 psi,compressor should settle down in steady run.

Once duster can gets cold,drop in bucket to get all refrigerant out of can. You will know it's empty as lo side pressure drops to 25-30 psi depending on ambient temps. When lo side pressure stabilizes,pull can from bucket and shake,if warm it's empty,close lo side valve. While car is running with ac on and compressor engaged,disconnect lo side manifold hose from compressor and put cap on port.

Doing this is to minimize loss of refrigerant at gauge fitting/hose when removing. The lower the pressure the less refrigerant will be lost. Shut car down and let sit for @20 minutes. The hi side pressure will slowly drop from @130-150 psi to @60-80 psi as lo/hi sides of system equalize. Remove hi side gauge fitting and cap port.

Fill volume for your car @16-18oz of R152. disconnecting gauges,tapping cans and purging air will vent off @ 1.5-2 oz of refrigerant. Using 2-10 oz cans of duster spray=20 oz. Should be very close to optimal charge by weight. Post manifold gauge readings and current ambient temp/humidity with lo fan speed,on recirculate and windows closed. Put a thermometer in center dash vent and see what air output temp is,should be @38-42 degrees.

Last edited by GSLSEforme; 07-12-19 at 11:43 PM. Reason: add pics

The following 5 users liked this post by GSLSEforme:

#19

Fantastic details Mike, thanks for putting this together! I'm printing it out and adding it to my FSM for those dark days ahead when a cyber attack shuts down the internet. Thanks especially for all the little tips, like dropping the can in hot water to get out all the refrigerant.

I get the problem of using PAG in a system that's previously seen R12, it's risky due to residual mineral oil.

But what if you are charging an all new system with R-152a? Would PAG be better in this case? As I understand it the PAG40 has very low viscosity which means the compressor doesn't have to work as hard moving it around, saving gas and wear and tear on the system. That's why it's now being used over PAG100 in new car applications, which will happen with the Jeep and MP5 and also the LE if I can find a new condenser or clean the old condenser and evaporator very thoroughly to remove all mineral oil.

PAG is also hydroscopic, so to a certain extent it will dissolve residue water in the system. I don't think ester oil can do this. So in the absence of residual R12 and mineral oil, which is better, PAG or ester oil?

Thanks for the tips on the Utra Duster and the refrigeration system insulation. Since I plan on either replacing or at least removing the evaporators in my projects I'll need to replace the line and evaporator insulation.

I got the new evaporator for the Jeep in the mail today, brand new AOC unit, $50 shipped, no tax, on ebay. That's cheaper than the labor needed to clean out the old one! So I'm still looking for a compatible condenser and maybe even an evaporator for the LE, I'll bet there's something out there someplace.

I think I'm all set with my gauges, they cover R134a and have the quick fit adapters. So I think I just need to add the R134a adapter kit to the compressor fittings. Here's a cheap set on Amazon, but there's lots of other ones out there, anybody have one they especially like?

I get the problem of using PAG in a system that's previously seen R12, it's risky due to residual mineral oil.

But what if you are charging an all new system with R-152a? Would PAG be better in this case? As I understand it the PAG40 has very low viscosity which means the compressor doesn't have to work as hard moving it around, saving gas and wear and tear on the system. That's why it's now being used over PAG100 in new car applications, which will happen with the Jeep and MP5 and also the LE if I can find a new condenser or clean the old condenser and evaporator very thoroughly to remove all mineral oil.

PAG is also hydroscopic, so to a certain extent it will dissolve residue water in the system. I don't think ester oil can do this. So in the absence of residual R12 and mineral oil, which is better, PAG or ester oil?

Thanks for the tips on the Utra Duster and the refrigeration system insulation. Since I plan on either replacing or at least removing the evaporators in my projects I'll need to replace the line and evaporator insulation.

I got the new evaporator for the Jeep in the mail today, brand new AOC unit, $50 shipped, no tax, on ebay. That's cheaper than the labor needed to clean out the old one! So I'm still looking for a compatible condenser and maybe even an evaporator for the LE, I'll bet there's something out there someplace.

I think I'm all set with my gauges, they cover R134a and have the quick fit adapters. So I think I just need to add the R134a adapter kit to the compressor fittings. Here's a cheap set on Amazon, but there's lots of other ones out there, anybody have one they especially like?

#20

ancient wizard...

I don't know about you Ray,i'm not ready for that just yet....

Pag oil is ok to leave in a system in which it was originally installed when switching to R152 refrigerant.They are compatible.

Might want to reread my above "book"...if you have an intact oe condenser,use it. Is your evaporator box assembly still in your LE,if so leave it in the car. The majority of mineral oil in an R12 system will be in the compressor and receiver drier. Like i wrote in previous post,drain,fill,drain,fill ac compressor. Replace drier. Use brakleen to clean hoses-or get new hoses made as i recommended above. REPLACE receiver drier!!! Do not use Pag oil in your Le! Ester oil only.

I seriously doubt you will find level of quality of parts presently in your car in aftermarket unless you buy NOS parts from somewhere$$$. If your stuff is functional-use it. I would buy carefully looked over used parts before i'd consider any of the crap available aftermarket today.

Condenser ,brakleen it couple times,blast it with compressed air,it will be fine. What do you think i did with the condenser i received from you?

It got actual AC flush solvent treatment,a coat of paint and went in the car. I flushed all the lines/hoses on car-with the exception of evaporator core/expansion valve. I didn't do this purposely,there is next to no oil in there and there's a lot of small orifices that i wouldn't want to compromise by putting ac flush or brakleen through it. I knew my evap/expansion valve was operational. If you do as i outlined,you will have removed 95% of mineral oil from your system. The compressor and the drier hold the majority of oil contained in system. The other 5%? that may be left in the system will basically be inert as that small amount will blend with ester oil with no negative consequences.

Your statement about Pag oil being hygroscopic...ANY moisture in any ac system,not just automotive,is the enemy of the system. For a proper 100% proper functioning system,it can have 0% moisture in it. In any other application water mixing with oil is undesired,ac systems are no different and even more important to have no presence of moisture as any in the system WILL mix with both the refrigerant and oil in system and the result is a mild acid that is formed that loves to work on all the aluminum(majority) components.

Your intent to change the Pag oil weight in your other two vehicles is ill advised. I get why you want to do it but the components in new vehicles are designed around the fact that they will be used with that lighter oil configuration. I personally for a customer's vehicle or my own would never substitute a different weight lubricant in the system in the intent of increased fuel economy. You may be building in an unwanted advanced wear factor on all moving system components,a gamble i don't want to take.

You don't say why you're replacing evaporator in Jeep,pattern failure,whether system was inop,working poorly,regardless,with whatever repairs you are doing,replace the receiver drier.If you are looking to get 100% out of ac system and see a perceptible increase of cooling by using a new refrigerant,a new drier is a necessary component. You will need to replace oil in system to make up for what was in drier and condenser,@2.5 oz of correct weight oil can be poured into drier,recapping drier until lines are ready to be attached to keep excess moisture from fouling dessicant in drier. New o rings for any connections opened up for repairs.

Use of vacuum pump to pull deep vacuum to boil off any moisture in system should be sop anytime servicing an ac system.

A good idea whenever a system is apart is to use refrigerant oil with dye in it,makes subsequent searching for system leaks that much easier.

Maybe save up on patience before you begin this job,i know how you love working on this Jeep. Final tip...get the evaporator case assembled and back in Jeep,replace drier or whatever else you're doing,get system closed up and hook up gauges and pump and pull vacuum on system long enough to get to 30". Close valves on gauges,turn pump off,go get a snack,something to drink for @25 minutes and come back and look at the gauges to be sure system is holding vacuum and only then finish putting interior back together. REALLY sucks to do an evap job twice because it was leaking...i won't say how i learned that tip...but here's another that might prevent the prior scenario.

I ALWAYS leaktest evap and heater cores before installing to prevent doing job twice...and it's much easier to return a part as defective if it has not yet been installed. Photos of component leaking go a long way in proving your case.

Pics of bottom of radiator in my car was to illustrate what i used to replace the foam strip used to seal radiator bottom to bellypan. Double sided 3M tape for attaching side moldings and emblems is what i used to hold the strip onto radiator bottom.

The other insulation in pic is hot water pipe insulation i used to replace the foam on oil cooler lines that i made up converting oe oil lines and oil cooler to -10AN braided line. Thought about starting a thread,or posting in what did you do to your FB thread about fabricating AN lines to replace oe FMOC lines for less than you can buy them premade.

Pag oil is ok to leave in a system in which it was originally installed when switching to R152 refrigerant.They are compatible.

Might want to reread my above "book"...if you have an intact oe condenser,use it. Is your evaporator box assembly still in your LE,if so leave it in the car. The majority of mineral oil in an R12 system will be in the compressor and receiver drier. Like i wrote in previous post,drain,fill,drain,fill ac compressor. Replace drier. Use brakleen to clean hoses-or get new hoses made as i recommended above. REPLACE receiver drier!!! Do not use Pag oil in your Le! Ester oil only.

I seriously doubt you will find level of quality of parts presently in your car in aftermarket unless you buy NOS parts from somewhere$$$. If your stuff is functional-use it. I would buy carefully looked over used parts before i'd consider any of the crap available aftermarket today.

Condenser ,brakleen it couple times,blast it with compressed air,it will be fine. What do you think i did with the condenser i received from you?

It got actual AC flush solvent treatment,a coat of paint and went in the car. I flushed all the lines/hoses on car-with the exception of evaporator core/expansion valve. I didn't do this purposely,there is next to no oil in there and there's a lot of small orifices that i wouldn't want to compromise by putting ac flush or brakleen through it. I knew my evap/expansion valve was operational. If you do as i outlined,you will have removed 95% of mineral oil from your system. The compressor and the drier hold the majority of oil contained in system. The other 5%? that may be left in the system will basically be inert as that small amount will blend with ester oil with no negative consequences.

Your statement about Pag oil being hygroscopic...ANY moisture in any ac system,not just automotive,is the enemy of the system. For a proper 100% proper functioning system,it can have 0% moisture in it. In any other application water mixing with oil is undesired,ac systems are no different and even more important to have no presence of moisture as any in the system WILL mix with both the refrigerant and oil in system and the result is a mild acid that is formed that loves to work on all the aluminum(majority) components.

Your intent to change the Pag oil weight in your other two vehicles is ill advised. I get why you want to do it but the components in new vehicles are designed around the fact that they will be used with that lighter oil configuration. I personally for a customer's vehicle or my own would never substitute a different weight lubricant in the system in the intent of increased fuel economy. You may be building in an unwanted advanced wear factor on all moving system components,a gamble i don't want to take.

You don't say why you're replacing evaporator in Jeep,pattern failure,whether system was inop,working poorly,regardless,with whatever repairs you are doing,replace the receiver drier.If you are looking to get 100% out of ac system and see a perceptible increase of cooling by using a new refrigerant,a new drier is a necessary component. You will need to replace oil in system to make up for what was in drier and condenser,@2.5 oz of correct weight oil can be poured into drier,recapping drier until lines are ready to be attached to keep excess moisture from fouling dessicant in drier. New o rings for any connections opened up for repairs.

Use of vacuum pump to pull deep vacuum to boil off any moisture in system should be sop anytime servicing an ac system.

A good idea whenever a system is apart is to use refrigerant oil with dye in it,makes subsequent searching for system leaks that much easier.

Maybe save up on patience before you begin this job,i know how you love working on this Jeep. Final tip...get the evaporator case assembled and back in Jeep,replace drier or whatever else you're doing,get system closed up and hook up gauges and pump and pull vacuum on system long enough to get to 30". Close valves on gauges,turn pump off,go get a snack,something to drink for @25 minutes and come back and look at the gauges to be sure system is holding vacuum and only then finish putting interior back together. REALLY sucks to do an evap job twice because it was leaking...i won't say how i learned that tip...but here's another that might prevent the prior scenario.

I ALWAYS leaktest evap and heater cores before installing to prevent doing job twice...and it's much easier to return a part as defective if it has not yet been installed. Photos of component leaking go a long way in proving your case.

Pics of bottom of radiator in my car was to illustrate what i used to replace the foam strip used to seal radiator bottom to bellypan. Double sided 3M tape for attaching side moldings and emblems is what i used to hold the strip onto radiator bottom.

The other insulation in pic is hot water pipe insulation i used to replace the foam on oil cooler lines that i made up converting oe oil lines and oil cooler to -10AN braided line. Thought about starting a thread,or posting in what did you do to your FB thread about fabricating AN lines to replace oe FMOC lines for less than you can buy them premade.

Last edited by GSLSEforme; 07-14-19 at 12:32 AM. Reason: spelling

#21

OK, thanks Mike, you've convinced me.

I'll keep the original condenser, evaporator and lines in the LE and clean them out really well with the brake cleaner assisted with a little compressed air.

Then I'll add a new compressor and drier and pull a good vacuum to get rid of water and test for leaks.

Then charge with ester oil and R152a. I'll report back here on how that goes.

For the jeep and MP5, I'm going total new systems except the lines, so PAG40 and R152a go in these.

We'll see which system works better.

Thanks for all the helpful details!

I'll keep the original condenser, evaporator and lines in the LE and clean them out really well with the brake cleaner assisted with a little compressed air.

Then I'll add a new compressor and drier and pull a good vacuum to get rid of water and test for leaks.

Then charge with ester oil and R152a. I'll report back here on how that goes.

For the jeep and MP5, I'm going total new systems except the lines, so PAG40 and R152a go in these.

We'll see which system works better.

Thanks for all the helpful details!

#23

ancient wizard...

No problems cooling as long as the pressures are where they need to be. I just recharged it last weekend and drove the car today, in 112F Arizona heat - and though it's running full blast on the interior fan, it cools quickly and is a comfortable ride home on my afternoon commute of 25mi. In the mornings, when the temps are 90F, sometimes I have to turn the interior fan speed to 2 instead of 4 because it freezes me out!

Will look into R152 if you say it's better. Is it compatible with orifice sizing and lubricants used with R134a? It would have to be substantially better cooling over ambient for me to change, though...

Will look into R152 if you say it's better. Is it compatible with orifice sizing and lubricants used with R134a? It would have to be substantially better cooling over ambient for me to change, though...

In answer to your other question,R152 is much closer in refrigerant characteristics to R12 than R134 is. Don't know how much you tried to remove mineral oil from system prior to switching to R134. Maybe replace the drier while switching refrigerants if it's original or has been a while since changed. Pag oil is compatible with R152.

#24

ancient wizard...

OK, thanks Mike, you've convinced me.

I'll keep the original condenser, evaporator and lines in the LE and clean them out really well with the brake cleaner assisted with a little compressed air.

Then I'll add a new compressor and drier and pull a good vacuum to get rid of water and test for leaks.

Then charge with ester oil and R152a. I'll report back here on how that goes.

For the jeep and MP5, I'm going total new systems except the lines, so PAG40 and R152a go in these.

We'll see which system works better.

Thanks for all the helpful details!

I'll keep the original condenser, evaporator and lines in the LE and clean them out really well with the brake cleaner assisted with a little compressed air.

Then I'll add a new compressor and drier and pull a good vacuum to get rid of water and test for leaks.

Then charge with ester oil and R152a. I'll report back here on how that goes.

For the jeep and MP5, I'm going total new systems except the lines, so PAG40 and R152a go in these.

We'll see which system works better.

Thanks for all the helpful details!

May also encounter a surge at idle speed in gear when ac compressor cycles on again after cycling off, the long term software memory in ecu knows how many steps to open the idle air control(IAC)with its stepper motor to compensate for given ac compressor load. It will take a couple hundred miles for ecu to relearn the lesser hp drag of compressor with different refrigerant and adjust IAC steps accordingly.

#25

Thanks Mike, I just reread part of your post on PAG, on your recommendation I'l be using the ester oil on all three systems, including the MP5 and Jeep.

And yes, the MP5 does have the duel electric fans. I'm curious now, is one a "radiator" fan controlled by the water temp and the second an "AC" fan controlled by the AC compressor temp?

So all I need to add to the replacement R-12 compatible compressors in the LE and the 93 Jeep Wrangler are a pair of R134a fitting adapters, right?

And yes, the MP5 does have the duel electric fans. I'm curious now, is one a "radiator" fan controlled by the water temp and the second an "AC" fan controlled by the AC compressor temp?

So all I need to add to the replacement R-12 compatible compressors in the LE and the 93 Jeep Wrangler are a pair of R134a fitting adapters, right?