Goopy Apex Seals

#26

Senior Member

3000+ miles on mine. TII w/ ~350 bhp and I do visit them levels often. zero issues. OMP +1oz/gal premix since rebuild.

Last edited by Clubuser; 09-16-13 at 03:08 PM.

#27

i haven't had any issues whatsoever with any of the seal sets i have installed over the past 2+ years, which is probably about 40 sets now.

and they have handled problems that would have left most other seals crippled or worse.

i now run them in just about every turbo engine i build.

if you have a few dealers who might be interested i can see what i can do to get them imported for you guys. keep in mind most of the problem is probably going to lie in how many hands they have to pass through along with shipping costs to get to your customers. would have to be more than just a few sets to be worthwhile for all parties involved.

and they have handled problems that would have left most other seals crippled or worse.

i now run them in just about every turbo engine i build.

only downfall is that in oz.. the seem to insist on pushing through one dealer.. with huge markup // previously i bought them direct..and love them..

i have pushed several potential customers there for ALL of them to baulk at the local price mark up .. and refusal from the master company to now deal with australian purchases

very disappointed with this ..especially considering i helped in fitting the first examples here and did promote them a little ...

i am hoping jack or john will see this and realize they have lost trade in australia by dealing with VIS and are knocking back the enthusiast trying to bypass a rort and its doing them bad things here

i have pushed several potential customers there for ALL of them to baulk at the local price mark up .. and refusal from the master company to now deal with australian purchases

very disappointed with this ..especially considering i helped in fitting the first examples here and did promote them a little ...

i am hoping jack or john will see this and realize they have lost trade in australia by dealing with VIS and are knocking back the enthusiast trying to bypass a rort and its doing them bad things here

Last edited by RotaryEvolution; 09-16-13 at 03:20 PM.

#28

got about 15k miles on mine, made 420rwhp the other day, seems to be strong.

altough it had 90 psi compression (housings were resurfaced thru goopy) i think they had to remove a decent amount of material so i wouldnt say they were in the greatest shape to begin with. starts perfectly fine warm or cold, and pulls strong.

altough it had 90 psi compression (housings were resurfaced thru goopy) i think they had to remove a decent amount of material so i wouldnt say they were in the greatest shape to begin with. starts perfectly fine warm or cold, and pulls strong.

#29

got about 15k miles on mine, made 420rwhp the other day, seems to be strong.

altough it had 90 psi compression (housings were resurfaced thru goopy) i think they had to remove a decent amount of material so i wouldnt say they were in the greatest shape to begin with. starts perfectly fine warm or cold, and pulls strong.

altough it had 90 psi compression (housings were resurfaced thru goopy) i think they had to remove a decent amount of material so i wouldnt say they were in the greatest shape to begin with. starts perfectly fine warm or cold, and pulls strong.

i've also been cutting the housings for as long as i've been using the seals and it seems to be a good combo(some other seals don't take to resurfaced housings as well as these seem to be).

#31

does this count?

a secondary injector crossover pipe got pinched and ran lean up top, the engine still ran fine but it started drinking coolant internally and idled a little low. we didn't know of the damage until we tore the engine apart, he was still running the car hard intermittently after it happened.

the seals all came out fine, but 4 rotor faces on both rotors combined were collapsed. the only items damaged were the rotors(pinned series 5 thin cast engine)

the engine was normally running on low boost at about 450whp when he drove it, high boost it was at about 500whp but he didn't run it at 20psi all that much.

the picture doesn't even do this rotor justice, as you can see the seal slot is deformed also because of how much the face was pushed in..

and on a 20B customer that has been having issues with setup and tuning the detonation cycles have been breaking the irons(including the thick center iron which i'm repairing now, B code early block with weak cast), the seals have managed it just fine and will go back in.

i was not present for those failures but they are detonation related and would have killed some seals like OEM and Atkins and done much more damage than pictured. my ultimate goal was/is to minimize damage to preserve the most parts as possible and so far these seals haven't let me down.

a secondary injector crossover pipe got pinched and ran lean up top, the engine still ran fine but it started drinking coolant internally and idled a little low. we didn't know of the damage until we tore the engine apart, he was still running the car hard intermittently after it happened.

the seals all came out fine, but 4 rotor faces on both rotors combined were collapsed. the only items damaged were the rotors(pinned series 5 thin cast engine)

the engine was normally running on low boost at about 450whp when he drove it, high boost it was at about 500whp but he didn't run it at 20psi all that much.

the picture doesn't even do this rotor justice, as you can see the seal slot is deformed also because of how much the face was pushed in..

and on a 20B customer that has been having issues with setup and tuning the detonation cycles have been breaking the irons(including the thick center iron which i'm repairing now, B code early block with weak cast), the seals have managed it just fine and will go back in.

i was not present for those failures but they are detonation related and would have killed some seals like OEM and Atkins and done much more damage than pictured. my ultimate goal was/is to minimize damage to preserve the most parts as possible and so far these seals haven't let me down.

Last edited by RotaryEvolution; 09-16-13 at 05:53 PM.

#35

Racing Rotary Since 1983

iTrader: (6)

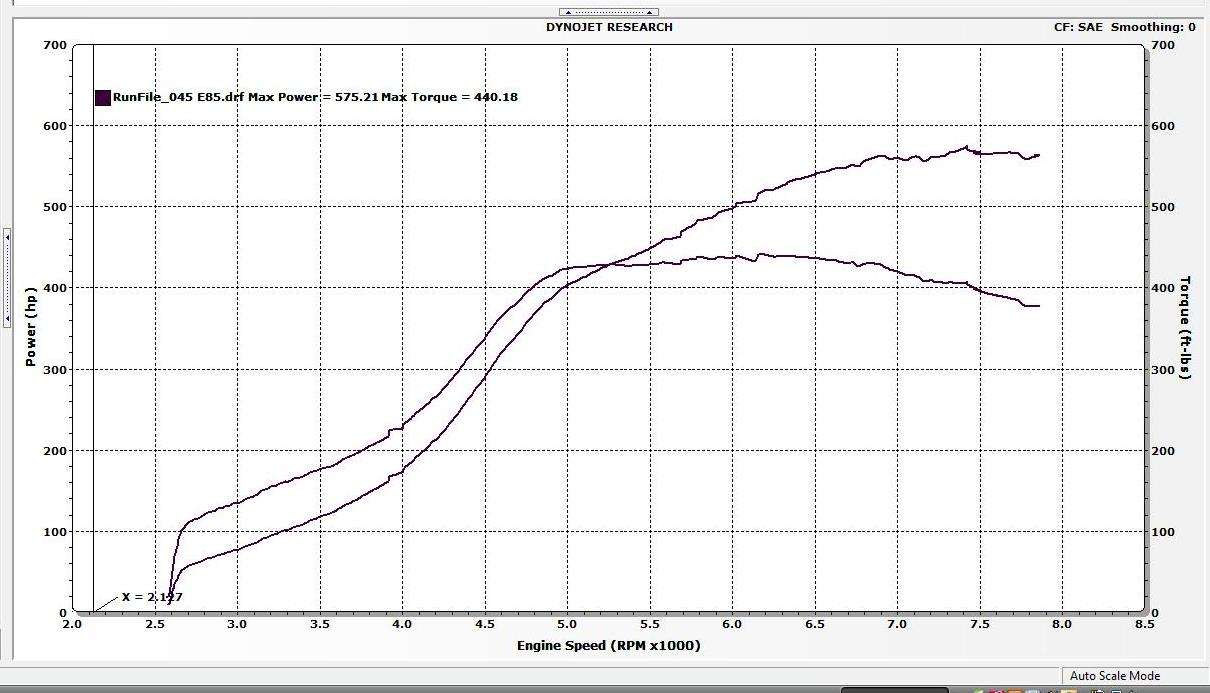

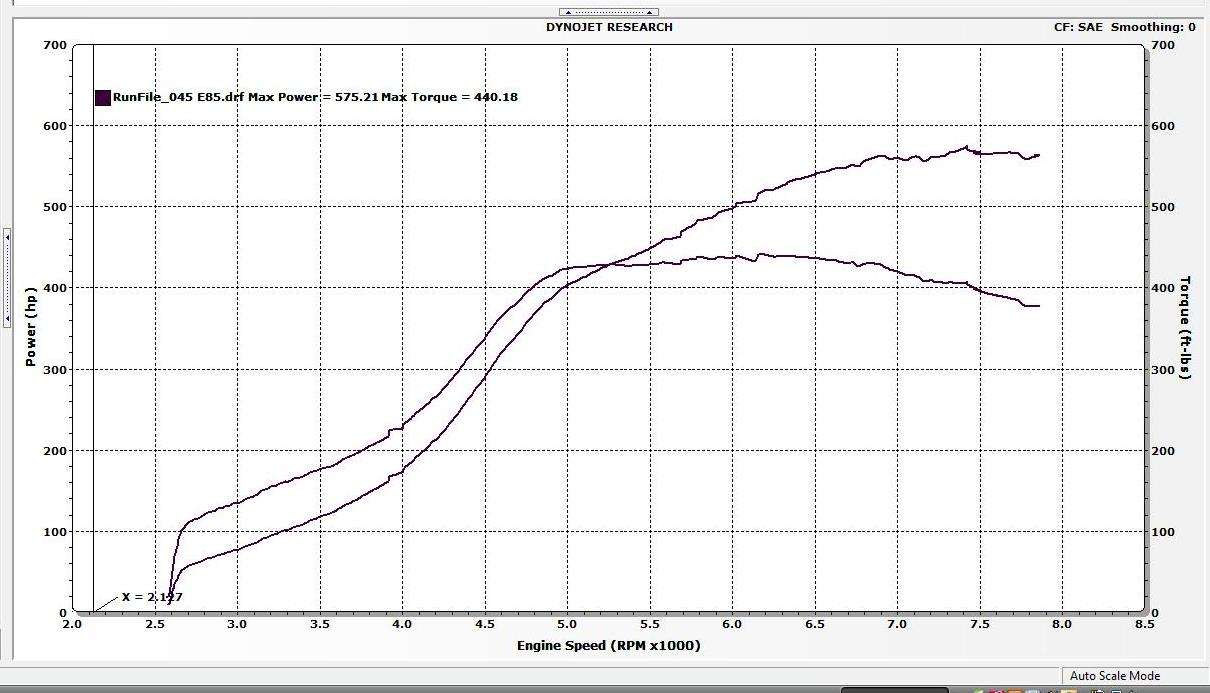

i have been running Goopy 2 mm (oversized) apex seals this year in my motor.

a few months ago i started running an AI system (25% water 75% meth) using Bosch EV14 injectors. one Pre turbo, one Post turbo. i had previously run such a system but was injecting 100% meth. it worked w no problems.

after a number of 3rd gear pulls off the WG spring (14 psi) i noticed high knock readings at the end of the pull. i richened it and backed off the already modest timing and the knock continued.

i removed the AI injectors, cycled them to find almost no flow. the water component of the AI injectant had rusted/clogged or otherwise screwed w the injectors.

i did a comp test and the motor seemed fine.

this is the motor i was expecting to run the Texas Mile with so i was prepared to yank it if necessary and replace the seals as it seemed to have endured a fair amount of knock. the BW S363 was making pretty good power at the time of the detonation even at 14 psi.

it seems like we put a period on the seals condition last saturday on the rollers.

i am liking Goopy.

howard

a few months ago i started running an AI system (25% water 75% meth) using Bosch EV14 injectors. one Pre turbo, one Post turbo. i had previously run such a system but was injecting 100% meth. it worked w no problems.

after a number of 3rd gear pulls off the WG spring (14 psi) i noticed high knock readings at the end of the pull. i richened it and backed off the already modest timing and the knock continued.

i removed the AI injectors, cycled them to find almost no flow. the water component of the AI injectant had rusted/clogged or otherwise screwed w the injectors.

i did a comp test and the motor seemed fine.

this is the motor i was expecting to run the Texas Mile with so i was prepared to yank it if necessary and replace the seals as it seemed to have endured a fair amount of knock. the BW S363 was making pretty good power at the time of the detonation even at 14 psi.

it seems like we put a period on the seals condition last saturday on the rollers.

i am liking Goopy.

howard

Last edited by Howard Coleman; 09-17-13 at 01:52 PM.

#37

water and metal don't mix. if you're going to run AI with an injection system, just use alcohol only. this is common sense, if you're insistent on attempting it premix your AI with klotz.

even some of the injector shops using a degreasing solution would rust the needles to the seat before they could be run and flushed out with fuel. why they were too cheap to use a parafin lubricant afterwards is beyond me..

i also ran into an issue with 2 different cars with brand new fuel pumps that kept running leaner and leaner on the dyno, at one point one engine was running 13.5:1AFR@20psi before i could back off and it didn't even fuss over it.

i keep giving the same stories but for some reason people tend to only believe what they see first hand. these seals work as well as any other i've tried and have so far exceeded my expectations(the seals are coated to aid in break in compression offset, they also come in oversize to save tired rotors instead of milling to 3mm which isn't ideal). i don't resell many things but i do support these.

i have also yet seen them gouge up housings, warp, break, or whatever else you could think of.

even some of the injector shops using a degreasing solution would rust the needles to the seat before they could be run and flushed out with fuel. why they were too cheap to use a parafin lubricant afterwards is beyond me..

i also ran into an issue with 2 different cars with brand new fuel pumps that kept running leaner and leaner on the dyno, at one point one engine was running 13.5:1AFR@20psi before i could back off and it didn't even fuss over it.

i keep giving the same stories but for some reason people tend to only believe what they see first hand. these seals work as well as any other i've tried and have so far exceeded my expectations(the seals are coated to aid in break in compression offset, they also come in oversize to save tired rotors instead of milling to 3mm which isn't ideal). i don't resell many things but i do support these.

i have also yet seen them gouge up housings, warp, break, or whatever else you could think of.

Last edited by RotaryEvolution; 09-17-13 at 05:28 PM.

#39

Senior Member

#40

the 3mm seals from the dented rotor measured out at 8.4mm height, i do not have a new set of 3mm seals to compare against. the engine had about 5k miles on it after it had to be torn apart again after the fuel system issue arose.

the 20B 2mm engine, the seals came out at 7.80mm, opened a new set of 2mm and they measure out at 7.78mm and the engine has less than a thousand miles on it. i'm going to say here there was almost no measurable wear and the difference is simply an allowable machining height discrepancy.

for measurable wear, less than 5% from my guesstimates, more like less than 1% but how does that span 100k miles with such a low initial mile reading? i can't really say. the 3mm seals did have some very minor scarring on the seal surface as did the housings but was easily correctable, the 2mm seals from the 20B still look virtually new. the 3mm seals did go through a period where the garrett turbo went south so it may have sucked in some small debris.

so in my experience i would shy away from the 3mm seals unless it is simply a drag engine and you need a little more seal girth. the 2mm seals hold up just fine, i have never tried to upsell 3mm seals but that FC engine was already milled for 3mm and i actually had him use 2mm seals after the rotors turned into paperweights.

no noticable leading edge wear. as far as common wear on these seals, so far i see nothing to lead me to believe they won't go upwards of 100k if the tune and everything else holds out that long.

Last edited by RotaryEvolution; 09-18-13 at 04:34 PM.

#42

Racing Rotary Since 1983

iTrader: (6)

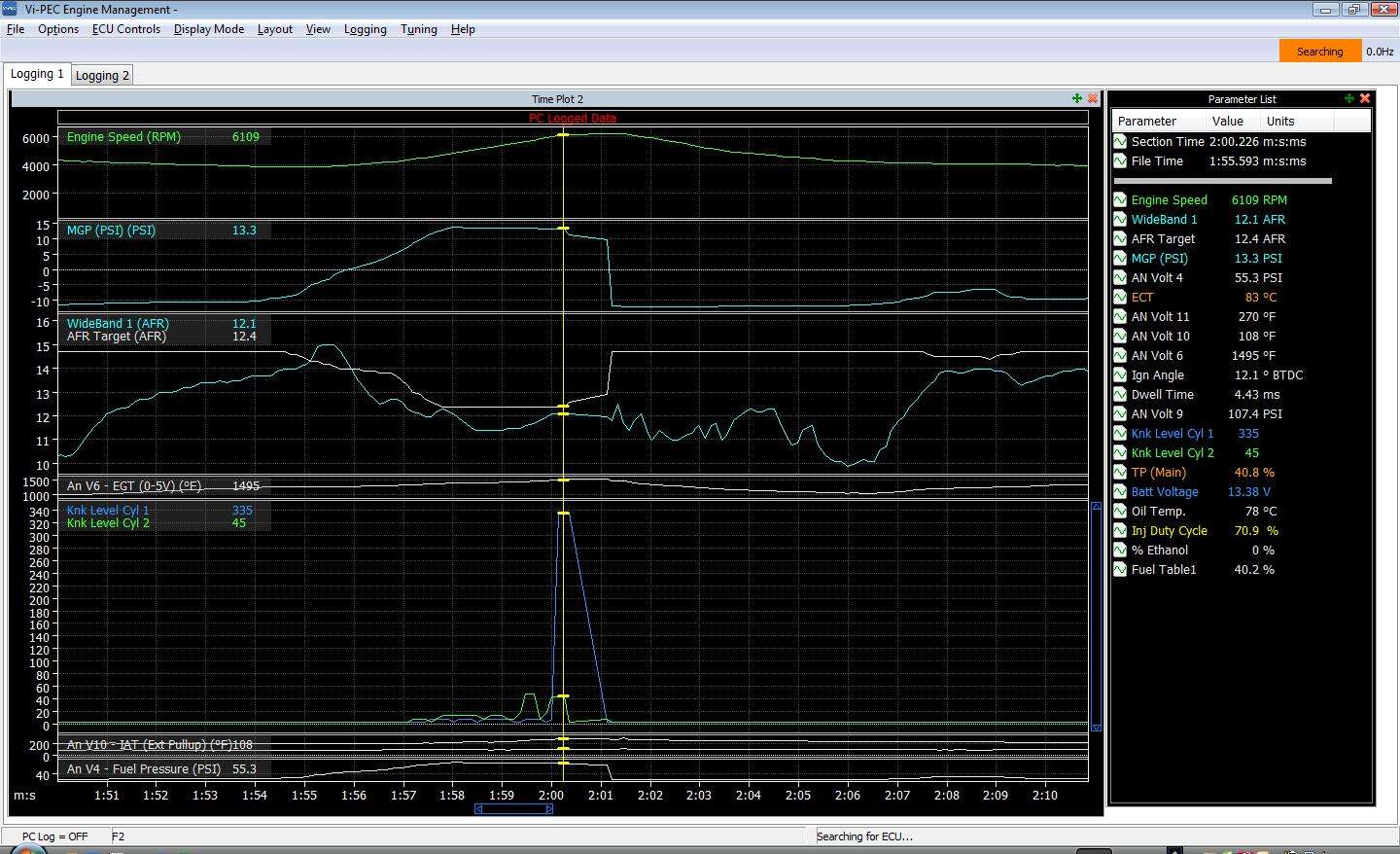

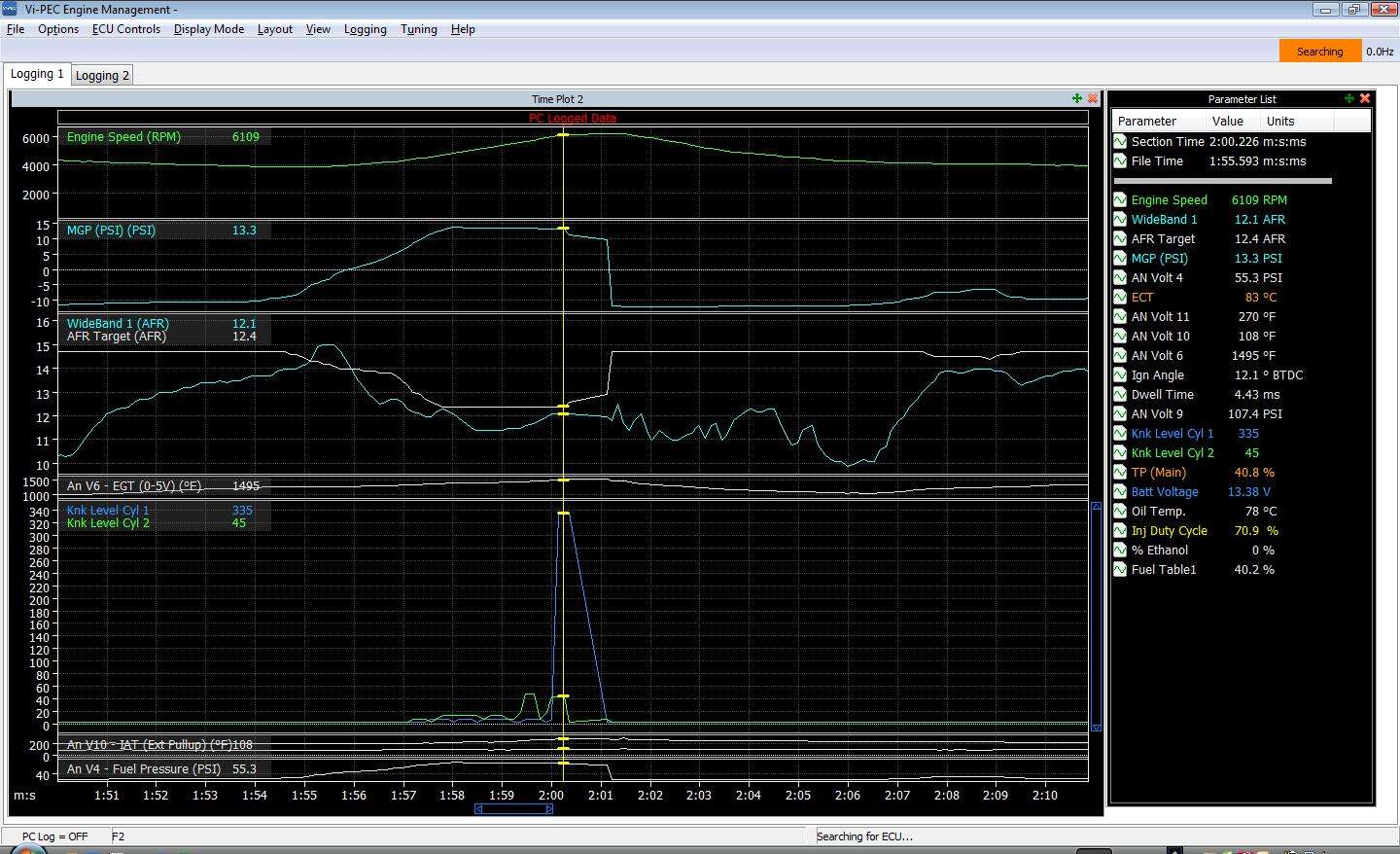

here's a log showing the knock that happened when my AI fuel injectors became plugged:

while i am relatively new to the knock readings on my ViPEC the 335 does get my attention. the same seals are currently in my motor which speaks well for them.

howard

while i am relatively new to the knock readings on my ViPEC the 335 does get my attention. the same seals are currently in my motor which speaks well for them.

howard

#43

Junior Member

Join Date: Apr 2007

Location: Australia

Posts: 15

Likes: 0

Received 0 Likes

on

0 Posts

only downfall is that in oz.. the seem to insist on pushing through one dealer.. with huge markup // previously i bought them direct..and love them..

i have pushed several potential customers there for ALL of them to baulk at the local price mark up .. and refusal from the master company to now deal with australian purchases

very disappointed with this ..especially considering i helped in fitting the first examples here and did promote them a little ...

i am hoping jack or john will see this and realize they have lost trade in australia by dealing with VIS and are knocking back the enthusiast trying to bypass a rort and its doing them bad things here

i have pushed several potential customers there for ALL of them to baulk at the local price mark up .. and refusal from the master company to now deal with australian purchases

very disappointed with this ..especially considering i helped in fitting the first examples here and did promote them a little ...

i am hoping jack or john will see this and realize they have lost trade in australia by dealing with VIS and are knocking back the enthusiast trying to bypass a rort and its doing them bad things here

I too am in Australia, and having grief even getting info for these products appart from Google searches!!

VIS wont return emails, Mazcare are too new and super honest not having done too many builds with them, it shouldnt be that hard if the products are as good as claimed.

Ive tried ringing Goopy direct, and they block numbers that are hidden, (Internet phone so will come up as hidden even locally).Emailed them on friday so Im hoping I get soem kind of reply soon.

All I want is some proper answers in regards to the oversize bolts and the oversize 12a seals and an avenue that will have them on my doorstep at a reasonable price.

Im willing to deal with any body in the US willing to send over the ditch and accept payapal.

email me on

Vesnajay@hotmail.com if your a re seller and have stock!!

#44

Psalms 37**25

Wow, just logged on here to see exactly who is willing to help me!!

I too am in Australia, and having grief even getting info for these products appart from Google searches!!

Im willing to deal with any body in the US willing to send over the ditch and accept payapal.

email me on

Vesnajay@hotmail.com if your a re seller and have stock!!

I too am in Australia, and having grief even getting info for these products appart from Google searches!!

Im willing to deal with any body in the US willing to send over the ditch and accept payapal.

email me on

Vesnajay@hotmail.com if your a re seller and have stock!!

Turblown Engineering

or

RotaryEvolution

Thread

Thread Starter

Forum

Replies

Last Post

als, apex, coolant, epex, goopy, goopyracingcom, goopyseals, goppy, performance, review, rx7, rx7club, seal, seals, tested