wideband experience

#26

You're absolutely right. It's the AFX unit. Do you know of any other unit/box that uses the same sensor so I might be able to run up to 17 (that's enough for me)? I would prefer to have my range go from 9-17, any more is a bonus/waste to me IMO. Thanks again for your input.

#27

+1 for the NTK sensor. my wideband has tuned over 100 cars, i also used it in my personal car for about 30k miles and i purchased it second hand... the readings are still accurate and i still tune customer cars with it. the sensor is almost 15 years old now and has seen just about every type of fuel including leaded race gas and methanol/ethanol.

i have seen a handful of bosch units fail in a short period of time, they also have a tendency to read almost a point rich which in actuality means you are tuning your engine lean.

i have seen a handful of bosch units fail in a short period of time, they also have a tendency to read almost a point rich which in actuality means you are tuning your engine lean.

#28

Originally Posted by mono4lamar

Do you know of any other unit/box that uses the same sensor so I might be able to run up to 17 (that's enough for me)?

+1 for the NTK sensor. my wideband has tuned over 100 cars, i also used it in my personal car for about 30k miles and i purchased it second hand... the readings are still accurate and i still tune customer cars with it. the sensor is almost 15 years old now and has seen just about every type of fuel including leaded race gas and methanol/ethanol.

i have seen a handful of bosch units fail in a short period of time, they also have a tendency to read almost a point rich which in actuality means you are tuning your engine lean.

i have seen a handful of bosch units fail in a short period of time, they also have a tendency to read almost a point rich which in actuality means you are tuning your engine lean.

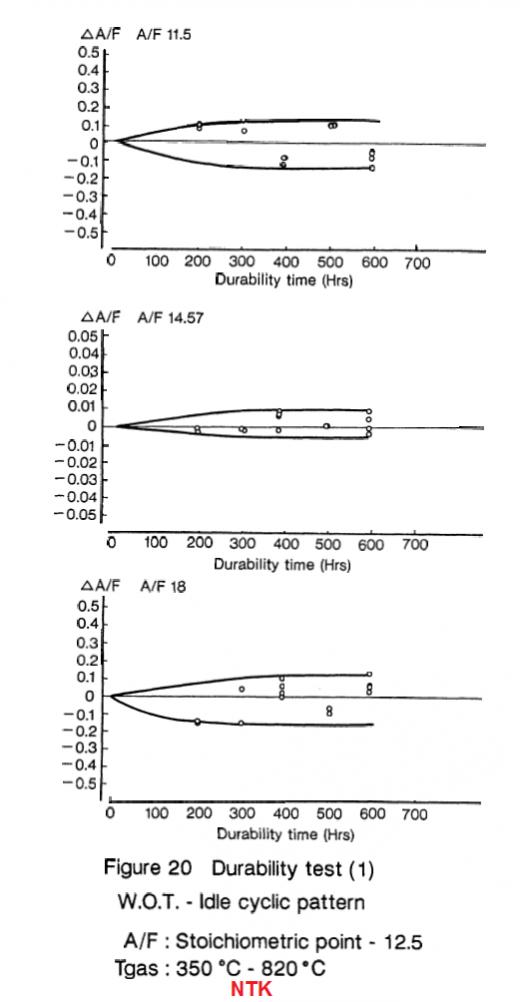

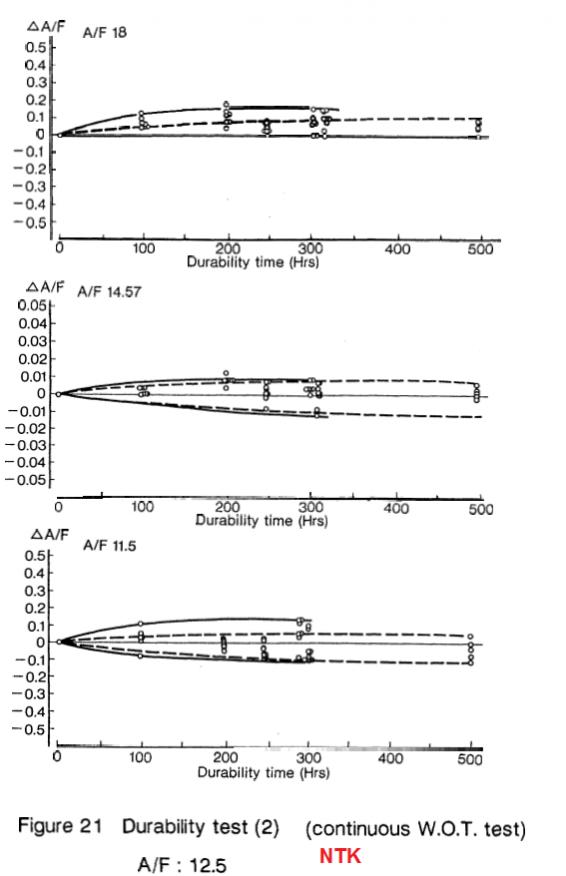

Here are engine dyno durability test results on the NTK sensor for a 4 cylinder n/a application:

I haven't seen that kind of chart for a Bosch LSU sensor. But that doesn't mean the LSU has or hasn't met similar durability targets. Remember that the LSU sensor is stock on expensive boosted German engines. They're also using OEM controllers that have to meet emission durability testing standards.

#32

using standard bosch 5 wire o2 sensor. Works good, and IMO 1k + widebands are necessary if you're tuning cars, not so necessary if you just want to keep an eye on your afr's.

#33

well, difference is the german makes have a basic map loaded which is close to where the fuelling needs to be and then in closed loop it is fine tuned by the wideband. similar to how old narrowbands worked but much more refined.

the bosch units aren't being subjected to sub 10AFR levels, burning oil and 2 stroke oils as well as being shocked by pure gasoline from overly rich rotary engines. i'm sure the bosch sensors survive much better in just about every other environment aside from these.

the bosch units aren't being subjected to sub 10AFR levels, burning oil and 2 stroke oils as well as being shocked by pure gasoline from overly rich rotary engines. i'm sure the bosch sensors survive much better in just about every other environment aside from these.

#34

Could you elaborate on that? Mine seems to read correctly but I certainly don't want to take any chances. Have you seen some that just read incorrectly right out of the box, is it a problem that develops over time or just hit and miss? And is it with all controllers using that sensor or just specific ones?

#36

T67, did I say 7?

Join Date: Jan 2008

Location: Raleigh

Posts: 171

Likes: 0

Received 0 Likes

on

0 Posts

#38

Much more likely the result of an inferior controller than the sensor itself. Again, the sensor's readings are influenced by heat and pressure. Most budget controllers do a poor job of controlling sensor temp and, as a result, you get skewed readings like this. The most heat is created at full load, and that's where you tend to see the readings skewed. A quality controller with a Bosch sensor, say a Motec LTC or the onboard controllers of any number of motorsport ECUs, will give measurements every bit as accurate as an ECM controller with an NTK sensor. Mostly the same reason you see so many Bosch sensors lasting such a short time. Poor controller function.

I'm still of the opinion the NTK sensor is better overall. It's just that the variety of cheap controllers, all using the less expensive Bosch sensor, tend to muddy the waters in terms of actual sensor capability.

#39

talking head

Wide Band O2 - LM1: result = volts / .5 + 10

Wide Band O2 - TE 2A0: result = volts / .5 + 9

Wide Band O2 - PLX: result = volts / .5 + 10

Wide Band O2 - Autronic MAFM1: result = volts / .25 + 10

Wide Band O2 - AEM: result = volts / .5 + 10

Wide Band O2 - AFM1000: result = volts / .5 + 8

Wide Band O2 - G100: result = volts / 0.71248 + 9

Wide Band O2 - DynoJet: result = volts / .625 + 10

Wide Band O2 - LC1: result = volts / 0.3324 + 7.35

Wide Band O2 - NGK: result = volts / 0.7142 + 9

Wide Band O2 - FJO: Internal non-linear map.

Wide Band O2 - TE 2A0: result = volts / .5 + 9

Wide Band O2 - PLX: result = volts / .5 + 10

Wide Band O2 - Autronic MAFM1: result = volts / .25 + 10

Wide Band O2 - AEM: result = volts / .5 + 10

Wide Band O2 - AFM1000: result = volts / .5 + 8

Wide Band O2 - G100: result = volts / 0.71248 + 9

Wide Band O2 - DynoJet: result = volts / .625 + 10

Wide Band O2 - LC1: result = volts / 0.3324 + 7.35

Wide Band O2 - NGK: result = volts / 0.7142 + 9

Wide Band O2 - FJO: Internal non-linear map.

which is handy if you have a non dedicated install and thus dont have a guage mounted in the car

,, you can use the DMM , and make up a quick chart to compare

( i have a double conversion to do,, i have to convert this to true lambda and then back to a LPG AFR )

may give a bit of a hint to the accuracy of some devices

and especially why some controllers seem to hit an accuracy limit beyond a certain AFR, when the math runs flat

#40

dyno queen potentials

Thread Starter

Join Date: Oct 2007

Location: ga

Posts: 445

Likes: 0

Received 0 Likes

on

0 Posts

do you guys think sensor location can have and effect on performance? i never install my sensors close to the turbo, it's alway under the passenger door area or at the tail pipe. the old techedge unit used to use the ntk sensor, it is now using the bosch sensor. most of the time i have to recalibrate it after a few uses, not sure why but it gets stuck at 14.7. i gave up on innovate long time ago, for some reason the cheap aem unit is the one that i trust the most. thinking about purchasing the fjo unit next.

#41

talking head

2ndly

can i run a LSU 4.9 or NTK sensor ?

if not ,, do you have issues with longevity with bosch 4.2 in the rotary turbo environment ?

Sorry only the 4.2 sensor works. I have never had any personal experience with rotary. So long as the sensor is not overheated or under heated (you can check the sensor temperature, using the PC software) and you do not run leaded fuel, the 4.2 is pretty durable. The primary killer of sensors is carbon build up inside the gas sampling chamber of the sensor, it is something that effects all wideband sensors equally, there are some differences between the 4.2/4.9/NTK that have an effect on longevity, but they are minor compared to carbon build up. There is no way to counteract carbon buildup, if there is carbon in the exhaust gas then it will build up inside the sensor, running the sensor at proper temperature (use the pc software to monitor) is the only thing you can do, when the sensor is at proper temperature it will burn off most of the carbon build up, but over time carbon will still build up.

Find a good spot for the sensor, monitor the temperature using the pc software, if the temp is less than 750C then move it closer to the exhaust port/turbo, if the temperature is greater than 750C then move it farther away from the exhaust port/turbo.

I do not know why other systems do not display sensor temperature, it is a very critical piece of information to prolong sensor life and ensuring accuracy.

can i run a LSU 4.9 or NTK sensor ?

if not ,, do you have issues with longevity with bosch 4.2 in the rotary turbo environment ?

Sorry only the 4.2 sensor works. I have never had any personal experience with rotary. So long as the sensor is not overheated or under heated (you can check the sensor temperature, using the PC software) and you do not run leaded fuel, the 4.2 is pretty durable. The primary killer of sensors is carbon build up inside the gas sampling chamber of the sensor, it is something that effects all wideband sensors equally, there are some differences between the 4.2/4.9/NTK that have an effect on longevity, but they are minor compared to carbon build up. There is no way to counteract carbon buildup, if there is carbon in the exhaust gas then it will build up inside the sensor, running the sensor at proper temperature (use the pc software to monitor) is the only thing you can do, when the sensor is at proper temperature it will burn off most of the carbon build up, but over time carbon will still build up.

Find a good spot for the sensor, monitor the temperature using the pc software, if the temp is less than 750C then move it closer to the exhaust port/turbo, if the temperature is greater than 750C then move it farther away from the exhaust port/turbo.

I do not know why other systems do not display sensor temperature, it is a very critical piece of information to prolong sensor life and ensuring accuracy.

but they do highlight the fact that they are recording sensor temps and that give you a means to 'tune' the position of your 4.2 for longevity

so answer to the post above mine is "most definately"

i dont think i have an issue with carbon,, my narrow band and my turbine housing are stark white ( LPG )

#42

Ok, I've been digging into this further, trying to get more manufacturer specs. I found the Bosch customer spec sheets for the LSU 4.2, 4.9, and ADV sensors.

Bosch Sensor Spec Comparison

max sensor temperature (at the actual hex)

4.2- 650C 1202F

4.9 - 680C 1256F

ADV - 700C 1292F

max exhaust temperature (short bursts): 1030C/1886F for all sensors

max exhaust temperature (sustained operating temperature): 930C/1706F for all sensors

These are pretty high exhaust temperatures, high enough to cook a cat. It's one of the main reasons why I tend to blame the controllers for overheated sensors more than I would blame the sensor itself.

Light off time:

4.2 - 20 sec

4.9 - 10 sec

ADV - 5 sec

rich limit:

4.2 - .70 lambda or ~ 10.3:1 AFR on pure gasoline

4.9 - .65 lambda or ~ 9.5:1 AFR on pure gasoline

ADV - .65 lambda or ~ 9.5:1 AFR on pure gasoline

The specs on the rich limit beg the question: what is the physical reason for those particular rich limit specs? A lot (ok, all) of the commonly available wideband systems will display a value richer than the spec provided by the manufacturer. This signal has to come from somewhere.

Is the rich limit related to physical properties of oxygen transfer in the sensor? Is it an accuracy limit according to their own specifications? The spec sheets have a nominal pumping current characteristic curve, with a max current at the rich limit. Does the current actually continue to change as the gas gets richer, and these controllers are just extrapolating beyond that point? Or is there some kind of guessing related to electrical resistance or something?

Bosch Sensor Spec Comparison

max sensor temperature (at the actual hex)

4.2- 650C 1202F

4.9 - 680C 1256F

ADV - 700C 1292F

max exhaust temperature (short bursts): 1030C/1886F for all sensors

max exhaust temperature (sustained operating temperature): 930C/1706F for all sensors

These are pretty high exhaust temperatures, high enough to cook a cat. It's one of the main reasons why I tend to blame the controllers for overheated sensors more than I would blame the sensor itself.

Light off time:

4.2 - 20 sec

4.9 - 10 sec

ADV - 5 sec

rich limit:

4.2 - .70 lambda or ~ 10.3:1 AFR on pure gasoline

4.9 - .65 lambda or ~ 9.5:1 AFR on pure gasoline

ADV - .65 lambda or ~ 9.5:1 AFR on pure gasoline

The specs on the rich limit beg the question: what is the physical reason for those particular rich limit specs? A lot (ok, all) of the commonly available wideband systems will display a value richer than the spec provided by the manufacturer. This signal has to come from somewhere.

Is the rich limit related to physical properties of oxygen transfer in the sensor? Is it an accuracy limit according to their own specifications? The spec sheets have a nominal pumping current characteristic curve, with a max current at the rich limit. Does the current actually continue to change as the gas gets richer, and these controllers are just extrapolating beyond that point? Or is there some kind of guessing related to electrical resistance or something?

#43

Source documents

https://docs.google.com/open?id=0B_j...mhBS3VhczFOMjg Bosch LSU 4.2

https://docs.google.com/open?id=0B_j...kVLc2Vhd0xDeFk Bosch LSU 4.9

https://docs.google.com/open?id=0B_j...UwzcTQweTdiMVk Bosch LSU ADV --> this sensor is not yet available for inexpensive home or shop use. It comes stock on high-end late model German cars and is used in big budget labs.

https://docs.google.com/open?id=0B_j...GdnTC1DTGpGNVU Ford document comparing Bosch LSU 4.9 to NGK/NTK ZFAS-U2 sensor (not too detailed).

The Ford document supports the claim that newer pump-cell type wideband sensors (newer than the LSU 4.2 style design) retain accuracy better over the life of the sensor and do not need a free-air calibration due to the design of the reference cell. I do not know how the NTK sensors compare to particular Bosch sensors, either the latest NTK sensors or whatever sensor is being used on the NGK wideband system people have been buying for a while.

I spoke directly to an NGK rep, who then talked to one of their engineers, and he told me the nominal rich limit of the NTK ZFAS-U2 sensor is 10:1 AFR. I'm still trying to dig up a spec sheet on a newer NTK sensor, instead of going off a paper published in 1993 that I alluded to in post #28.

https://docs.google.com/open?id=0B_j...mhBS3VhczFOMjg Bosch LSU 4.2

https://docs.google.com/open?id=0B_j...kVLc2Vhd0xDeFk Bosch LSU 4.9

https://docs.google.com/open?id=0B_j...UwzcTQweTdiMVk Bosch LSU ADV --> this sensor is not yet available for inexpensive home or shop use. It comes stock on high-end late model German cars and is used in big budget labs.

https://docs.google.com/open?id=0B_j...GdnTC1DTGpGNVU Ford document comparing Bosch LSU 4.9 to NGK/NTK ZFAS-U2 sensor (not too detailed).

The Ford document supports the claim that newer pump-cell type wideband sensors (newer than the LSU 4.2 style design) retain accuracy better over the life of the sensor and do not need a free-air calibration due to the design of the reference cell. I do not know how the NTK sensors compare to particular Bosch sensors, either the latest NTK sensors or whatever sensor is being used on the NGK wideband system people have been buying for a while.

I spoke directly to an NGK rep, who then talked to one of their engineers, and he told me the nominal rich limit of the NTK ZFAS-U2 sensor is 10:1 AFR. I'm still trying to dig up a spec sheet on a newer NTK sensor, instead of going off a paper published in 1993 that I alluded to in post #28.

#44

Racing Rotary Since 1983

iTrader: (6)

good info and tends to back up Accurate Lambda's claims re the 4.9 calibrating in an entirely different manner than the 4.2. calibration is a potential issue for the 4.2.

i bumped into another 4.9 WB vendor last night... Prosports.com. i don't know what chip they use but they have an interesting product line.

they have a pre and post intercooler charge air temp guage for instance. i am considering using EGT thermocouples for pre/post intercooler temps and logging them 0-5 V. EGT data response is in Ms.

hc

i bumped into another 4.9 WB vendor last night... Prosports.com. i don't know what chip they use but they have an interesting product line.

they have a pre and post intercooler charge air temp guage for instance. i am considering using EGT thermocouples for pre/post intercooler temps and logging them 0-5 V. EGT data response is in Ms.

hc

#45

the heaters just "warm" the sensors, they really hardly even get them hot so i don't really see how the controllers are cooking the sensors.. i accidentally left the cap on a sensor one time while i activated it(several times because i was cycling the ignition on checking the fuel system), it melted the plastic, just barely. hardly 1800F+ heat we are referring to with the internal heating elements. we're talking maybe 400F for the heating element internally to get the sensor warmed up enough to read something, anything.

if anything i would think killing the pre-heater would in fact help the service life of the sensor. the first firing sequence from the engine isn't going to be very hot and will be sopping wet with primer fuel, which is shocking the sensor from it's warm up cycle.

if anything i would think killing the pre-heater would in fact help the service life of the sensor. the first firing sequence from the engine isn't going to be very hot and will be sopping wet with primer fuel, which is shocking the sensor from it's warm up cycle.

Last edited by RotaryEvolution; 04-20-12 at 11:54 PM.

#46

Racing Rotary Since 1983

iTrader: (6)

i happened to receive an email from an OE engineer in Michigan and while it contains a mix of conjecture/opinion it also contains some very interesting commentary on how a WB sensor actually works... since it was an email to me i would prefer the author remain nameless. do forgive a modest amount of language misteps as English is not his home language. the content is valuable.

"To give some inputs from my understanding of the different widebands:

LSU 4.9 is definitely superior to 4.2. All OEMs who use Bosch O2 sensors are now using LSU 4.9. GM, Ford, Chrysler all use LSU 4.9 now. If you look at their recent car/SUV/Pickup models (since 2009 or even earlier), on the exhaust manifolds, they are exclusively LSU 4.9.

The major difference between 4.9 and 4.2 is the reference current-pumping cell vs. the reference air cell. The reference air cell is the major reason of high failure rate of LSU 4.2. Simply because it is not accurate, and easy to be contaminated.

There are a few companies in the aftermarket that are using LSU 4.9, but the controller makes the big difference here.

Even with LSU 4.2; controllers make big difference. Bosch sensors are not easy to fail overall, esp. LSU 4.9 are designed for more than 10 year life time of a vehicle. It should not fail in short time. Many aftermarket controllers don't have a right heating strategy which causes the damage to the sensor. One big reason for sensor failure is to heat it up too fast or too earlier. O2 sensors are made of ceramic materials, which are susceptible to crack by condensations or fast heat-up when it's cold. A very careful heating strategy to detect the dew point and a close-loop sensor temperature control are vital for the life of the sensors, and also the accuracy of the sensor.

Bosch CJ125 chip is designed for this task. The heating strategy is a close loop control based on the measured sensor temperature. LSU 4.9 has a much higher sensor temperature resolution and accuracy, so that the heater controls are much better than LSU 4.2. Therefore, 4.9 has longer life and better accuracy.

Accuracy of LSU sensors is highly dependent on the operating temperature of the sensing element. The sensor reading can be very different if the temperature is not accurately controlled.

In short, not only the sensor LSU 4.9 is superior to 4.2; but also the controller with a CJ125 chip makes the big difference.

I would suggest you to use an oscilloscope to actually measure the analog outputs of different widebands if you really want to see the difference. Data do not lie."

"To give some inputs from my understanding of the different widebands:

LSU 4.9 is definitely superior to 4.2. All OEMs who use Bosch O2 sensors are now using LSU 4.9. GM, Ford, Chrysler all use LSU 4.9 now. If you look at their recent car/SUV/Pickup models (since 2009 or even earlier), on the exhaust manifolds, they are exclusively LSU 4.9.

The major difference between 4.9 and 4.2 is the reference current-pumping cell vs. the reference air cell. The reference air cell is the major reason of high failure rate of LSU 4.2. Simply because it is not accurate, and easy to be contaminated.

There are a few companies in the aftermarket that are using LSU 4.9, but the controller makes the big difference here.

Even with LSU 4.2; controllers make big difference. Bosch sensors are not easy to fail overall, esp. LSU 4.9 are designed for more than 10 year life time of a vehicle. It should not fail in short time. Many aftermarket controllers don't have a right heating strategy which causes the damage to the sensor. One big reason for sensor failure is to heat it up too fast or too earlier. O2 sensors are made of ceramic materials, which are susceptible to crack by condensations or fast heat-up when it's cold. A very careful heating strategy to detect the dew point and a close-loop sensor temperature control are vital for the life of the sensors, and also the accuracy of the sensor.

Bosch CJ125 chip is designed for this task. The heating strategy is a close loop control based on the measured sensor temperature. LSU 4.9 has a much higher sensor temperature resolution and accuracy, so that the heater controls are much better than LSU 4.2. Therefore, 4.9 has longer life and better accuracy.

Accuracy of LSU sensors is highly dependent on the operating temperature of the sensing element. The sensor reading can be very different if the temperature is not accurately controlled.

In short, not only the sensor LSU 4.9 is superior to 4.2; but also the controller with a CJ125 chip makes the big difference.

I would suggest you to use an oscilloscope to actually measure the analog outputs of different widebands if you really want to see the difference. Data do not lie."

Last edited by Howard Coleman; 04-23-12 at 02:39 PM.

#47

I was skeptical of the claimed differences earlier in the thread because I thought the 4.9 was mostly just had a better light off time. Having read actual manufacturer data (under "sources" in my post above) I agree with that person's overall arguments. I have been saying for a long time that the controller does make a big difference for durability, because if it didn't then there would be a gazillion warranty claims on all these engines that came with the sensor from the factory.

So I'll refine my position on this matter--the 4.9 is clearly a big step up from the 4.2, but the ADV seems to be just a marginal improvement intended mostly for cold start emissions.

So I'll refine my position on this matter--the 4.9 is clearly a big step up from the 4.2, but the ADV seems to be just a marginal improvement intended mostly for cold start emissions.

#48

F-IT

iTrader: (5)

Join Date: Jun 2006

Location: ocala,fl

Posts: 995

Likes: 0

Received 0 Likes

on

0 Posts

I's still a ntk fan myself. Having used various controllers with the 4.2 they still don't last that long on a high powered turbo rotary.

I usually try to replace our sensors on the dyno every other month just because I've noticed a slight decline in repeatability and accuracy if they stay on any longer. The controller we use is a innovate lm-1. I would love to upgrade it to a afm or horriba unit.

I usually try to replace our sensors on the dyno every other month just because I've noticed a slight decline in repeatability and accuracy if they stay on any longer. The controller we use is a innovate lm-1. I would love to upgrade it to a afm or horriba unit.