are we tuning too rich????????

#1

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

are we tuning too rich????????

a very interesting article from the Innovate Tech site...

what do you think????????????????????

"Application Note: You CAN be too Rich

By Klaus Allmendinger, VP of Engineering, Innovate Motorsports

Many people with turbochargers believe that they need to run at very rich mixtures. The theory is that the excess fuel cools the intake charge and therefore reduces the probability of knock. It does work in reducing knock, but not because of charge cooling. The following little article shows why.

First let’s look at the science. Specific heat is the amount of energy required to raise 1 kg of material by one degree K (Kelvin, same as Celsius but with 0 point at absolute zero). Different materials have different specific heats. The energy is measured in kJ or kilojoules:

Air ~ 1 kJ/( kg * deg K)

Gasoline 2.02 kJ/( kg * deg K)

Water 4.18 kJ/( kg * deg K)

Ethanol 2.43 kJ/( kg * deg K)

Methanol 2.51 kJ/( kg * deg K)

Fuel and other liquids also have what's called latent heat. This is the heat energy required to vaporize 1 kg of the liquid. The fuel in an internal combustion engine has to be vaporized and mixed thoroughly with the incoming air to produce power. Liquid gasoline does not burn. The energy to vaporize the fuel comes partially from the incoming air, cooling it. The latent heat energy required is actually much larger than the specific heat. That the energy comes from the incoming air can be easily seen on older carbureted cars, where frost can actually form on the intake manifold from the cooling of the charge.

The latent heat values of different liquids are shown here:

Gasoline 350 kJ/kg

Water 2256 kJ/kg

Ethanol 904 kJ/kg

Methanol 1109 kJ/kg

Most engines produce maximum power (with optimized ignition timing) at an air-fuel-ratio between 12 and 13. Let's assume the optimum is in the middle at 12.5. This means that for every kg of air, 0.08 kg of fuel is mixed in and vaporized. The vaporization of the fuel extracts 28 kJ of energy from the air charge. If the mixture has an air-fuel-ratio of 11 instead, the vaporization extracts 31.8 kJ instead. A difference of 3.8 kJ. Because air has a specific heat of about 1 kJ/kg*deg K, the air charge is only 3.8 C (or K) degrees cooler for the rich mixture compared to the optimum power mixture. This small difference has very little effect on knock or power output.

If instead of the richer mixture about 10% (by mass) of water would be injected in the intake charge (0.008 kg Water/kg air), the high latent heat of the water would cool the charge by 18 degrees, about 4 times the cooling effect of the richer mixture. The added fuel for the rich mixture can't burn because there is just not enough oxygen available. So it does not matter if fuel or water is added.

So where does the knock suppression of richer mixtures come from?

If the mixture gets ignited by the spark, a flame front spreads out from the spark plug. This burning mixture increases the pressure and temperature in the cylinder. At some time in the process the pressures and temperatures peak. The speed of the flame front is dependent on mixture density and AFR. A richer or leaner AFR than about 12-13 AFR burns slower. A denser mixture burns faster.

So with a turbo under boost the mixture density raises and results in a faster burning mixture. The closer the peak pressure is to TDC, the higher that peak pressure is, resulting in a high knock probability. Also there is less leverage on the crankshaft for the pressure to produce torque, and, therefore, less power.

Richening up the mixture results in a slower burn, moving the pressure peak later where there is more leverage, hence more torque. Also the pressure peak is lower at a later crank angle and the knock probability is reduced.

The same effect can be achieved with an optimum power mixture and more ignition retard. ////////bolded by howard//////

Optimum mix with “later” ignition can produce more power because more energy is released from the combustion of gasoline. Here’s why: When hydrocarbons like gasoline combust, the burn process actually happens in multiple stages. First the gasoline molecules are broken up into hydrogen and carbon. The hydrogen combines with oxygen from the air to form H2O (water) and the carbon molecules form CO. This process happens very fast at the front edge of the flame front. The second stage converts CO to CO2. This process is relatively slow and requires water molecules (from the first stage) for completion. If there is no more oxygen available (most of it consumed in the first stage), the second stage can't happen. But about 2/3 of the energy released from the burning of the carbon is released in the second stage. Therefore a richer mixture releases less energy, lowering peak pressures and temperatures, and produces less power. A secondary side effect is of course also a lowering of knock probability. It's like closing the throttle a little. A typical engine does not knock when running on part throttle because less energy and therefore lower pressures and temperatures are in the cylinder.

This is why running overly-rich mixtures can not only increase fuel consumption, but also cost power."

what do you think????????????????????

"Application Note: You CAN be too Rich

By Klaus Allmendinger, VP of Engineering, Innovate Motorsports

Many people with turbochargers believe that they need to run at very rich mixtures. The theory is that the excess fuel cools the intake charge and therefore reduces the probability of knock. It does work in reducing knock, but not because of charge cooling. The following little article shows why.

First let’s look at the science. Specific heat is the amount of energy required to raise 1 kg of material by one degree K (Kelvin, same as Celsius but with 0 point at absolute zero). Different materials have different specific heats. The energy is measured in kJ or kilojoules:

Air ~ 1 kJ/( kg * deg K)

Gasoline 2.02 kJ/( kg * deg K)

Water 4.18 kJ/( kg * deg K)

Ethanol 2.43 kJ/( kg * deg K)

Methanol 2.51 kJ/( kg * deg K)

Fuel and other liquids also have what's called latent heat. This is the heat energy required to vaporize 1 kg of the liquid. The fuel in an internal combustion engine has to be vaporized and mixed thoroughly with the incoming air to produce power. Liquid gasoline does not burn. The energy to vaporize the fuel comes partially from the incoming air, cooling it. The latent heat energy required is actually much larger than the specific heat. That the energy comes from the incoming air can be easily seen on older carbureted cars, where frost can actually form on the intake manifold from the cooling of the charge.

The latent heat values of different liquids are shown here:

Gasoline 350 kJ/kg

Water 2256 kJ/kg

Ethanol 904 kJ/kg

Methanol 1109 kJ/kg

Most engines produce maximum power (with optimized ignition timing) at an air-fuel-ratio between 12 and 13. Let's assume the optimum is in the middle at 12.5. This means that for every kg of air, 0.08 kg of fuel is mixed in and vaporized. The vaporization of the fuel extracts 28 kJ of energy from the air charge. If the mixture has an air-fuel-ratio of 11 instead, the vaporization extracts 31.8 kJ instead. A difference of 3.8 kJ. Because air has a specific heat of about 1 kJ/kg*deg K, the air charge is only 3.8 C (or K) degrees cooler for the rich mixture compared to the optimum power mixture. This small difference has very little effect on knock or power output.

If instead of the richer mixture about 10% (by mass) of water would be injected in the intake charge (0.008 kg Water/kg air), the high latent heat of the water would cool the charge by 18 degrees, about 4 times the cooling effect of the richer mixture. The added fuel for the rich mixture can't burn because there is just not enough oxygen available. So it does not matter if fuel or water is added.

So where does the knock suppression of richer mixtures come from?

If the mixture gets ignited by the spark, a flame front spreads out from the spark plug. This burning mixture increases the pressure and temperature in the cylinder. At some time in the process the pressures and temperatures peak. The speed of the flame front is dependent on mixture density and AFR. A richer or leaner AFR than about 12-13 AFR burns slower. A denser mixture burns faster.

So with a turbo under boost the mixture density raises and results in a faster burning mixture. The closer the peak pressure is to TDC, the higher that peak pressure is, resulting in a high knock probability. Also there is less leverage on the crankshaft for the pressure to produce torque, and, therefore, less power.

Richening up the mixture results in a slower burn, moving the pressure peak later where there is more leverage, hence more torque. Also the pressure peak is lower at a later crank angle and the knock probability is reduced.

The same effect can be achieved with an optimum power mixture and more ignition retard. ////////bolded by howard//////

Optimum mix with “later” ignition can produce more power because more energy is released from the combustion of gasoline. Here’s why: When hydrocarbons like gasoline combust, the burn process actually happens in multiple stages. First the gasoline molecules are broken up into hydrogen and carbon. The hydrogen combines with oxygen from the air to form H2O (water) and the carbon molecules form CO. This process happens very fast at the front edge of the flame front. The second stage converts CO to CO2. This process is relatively slow and requires water molecules (from the first stage) for completion. If there is no more oxygen available (most of it consumed in the first stage), the second stage can't happen. But about 2/3 of the energy released from the burning of the carbon is released in the second stage. Therefore a richer mixture releases less energy, lowering peak pressures and temperatures, and produces less power. A secondary side effect is of course also a lowering of knock probability. It's like closing the throttle a little. A typical engine does not knock when running on part throttle because less energy and therefore lower pressures and temperatures are in the cylinder.

This is why running overly-rich mixtures can not only increase fuel consumption, but also cost power."

Last edited by Howard Coleman; 03-17-12 at 10:01 PM.

#2

F-IT

iTrader: (5)

Join Date: Jun 2006

Location: ocala,fl

Posts: 995

Likes: 0

Received 0 Likes

on

0 Posts

....... Kinda known for a long time. Take a gander here for a mass load of info regarding that http://www.aquamist.co.uk/vbulletin/

#4

Banned. I got OWNED!!!

Join Date: Nov 2011

Location: scat ville

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

What exactly is good about it

Every decent turbo car I have ever seen looks like a Diesel out back, this directly contradicts what has been posted above does it not? Look up a video of IMSA 1992 Toyota Eagle running 3SGTE turbo 4 cyl @ 900bhp you will see it runs allot of fuel, massive amounts. I've never seen any racing turbo cars not run 50% or more over ideal ratio's. Another example is this motor fitted to Rod Millen Truck run at Goodwood Festival of Speed, you cant see the car for the excess fuel being dumped out the tail pipe! again totally against what is being posted here as good information, so this is why I am asking why this is classed as good information as always?

There is too much bum advice on the internet, from people who do not even have running cars it seems to me.

Every decent turbo car I have ever seen looks like a Diesel out back, this directly contradicts what has been posted above does it not? Look up a video of IMSA 1992 Toyota Eagle running 3SGTE turbo 4 cyl @ 900bhp you will see it runs allot of fuel, massive amounts. I've never seen any racing turbo cars not run 50% or more over ideal ratio's. Another example is this motor fitted to Rod Millen Truck run at Goodwood Festival of Speed, you cant see the car for the excess fuel being dumped out the tail pipe! again totally against what is being posted here as good information, so this is why I am asking why this is classed as good information as always?

There is too much bum advice on the internet, from people who do not even have running cars it seems to me.

Last edited by max keiser; 03-18-12 at 05:28 AM.

#5

Senior Member

iTrader: (7)

Join Date: Jun 2007

Location: aruba

Posts: 651

Likes: 0

Received 0 Likes

on

0 Posts

It's good to have as much information and as mane different opinion on the subject.

I do believe in theory it make sense and also probably more with piston engine, but i will probably never lean out my mixture to try it. even do i run a pre turbo water injection.

I feel my car runs good at the rich mixture it is now, why change it.

I do believe in theory it make sense and also probably more with piston engine, but i will probably never lean out my mixture to try it. even do i run a pre turbo water injection.

I feel my car runs good at the rich mixture it is now, why change it.

#6

Senior Member

iTrader: (7)

Join Date: Jun 2007

Location: aruba

Posts: 651

Likes: 0

Received 0 Likes

on

0 Posts

And the car did make more power at a leaner mixture, how i know? When the tuner was doing the runs on the dyno the afr was @ 12 something underboost and the car made almost 22hp more but he also doesn't like t that lean and kept adding more fuel, the car afr runs in the low low 11 now.

#7

Senior Member

Join Date: Nov 2008

Location: Czech republic

Posts: 357

Likes: 0

Received 0 Likes

on

0 Posts

What exactly is good about it

Every decent turbo car I have ever seen looks like a Diesel out back, this directly contradicts what has been posted above does it not? Look up a video of IMSA 1992 Toyota Eagle running 3SGTE turbo 4 cyl @ 900bhp you will see it runs allot of fuel, massive amounts. I've never seen any racing turbo cars not run 50% or more over ideal ratio's. Another example is this motor fitted to Rod Millen Truck run at Goodwood Festival of Speed, you cant see the car for the excess fuel being dumped out the tail pipe! again totally against what is being posted here as good information, so this is why I am asking why this is classed as good information as always?

There is too much bum advice on the internet, from people who do not even have running cars it seems to me.

Every decent turbo car I have ever seen looks like a Diesel out back, this directly contradicts what has been posted above does it not? Look up a video of IMSA 1992 Toyota Eagle running 3SGTE turbo 4 cyl @ 900bhp you will see it runs allot of fuel, massive amounts. I've never seen any racing turbo cars not run 50% or more over ideal ratio's. Another example is this motor fitted to Rod Millen Truck run at Goodwood Festival of Speed, you cant see the car for the excess fuel being dumped out the tail pipe! again totally against what is being posted here as good information, so this is why I am asking why this is classed as good information as always?

There is too much bum advice on the internet, from people who do not even have running cars it seems to me.

Whole article totally omitted facts about knock limited power. There is no point of tailoring air/fuel ratio for some "perfect" number, when engine can't live under high BMEP with such mixture. On the other hand, 10:1 AFR (gasoline scale) doesn't give most power for given airflow, but allows for much more power overall. And according to NACA papers, it works all the way to 70% excess fuel.

According to this article, everyone should be using optimum AFR and maximum brake torque timing and this really is how it should be, but when the load (boost) goes up, its not possible. At least without water injection and even in that case, even with high amount of water, highest knock limited power is again at very rich mixtures. And yes, this can be backed up by research papers.

Note: I'm not advocating use of very rich mixtures where it is not needed ie moderate power levels, low load, idle etc. but to produce really high power from any fuel, especially on delicate platform like wankel rotary, it is mandatory. Its not ideal, but it works.

Trending Topics

#8

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

as i said, the article, to me was interesting and i posted it for feedback.

there are a number of ways to make power and stay cool. excess gasoline, isn't the most efficient. it is often the only option due to rules.

other cooling options water, alcohol are superior to (excess) gasoline.

cooling per gallon (BTUs)

gasoline 952

ethanol alcohol 2398

methanol alcohol 3136

water 8087

i do agree there can be a positive offsets from running excess gasoline including keeping the motor together.

one of the reasons i am switching to a Link Xtreme is to upgrade knock monitoring v my Power FC. the knock program is totally user configurable, can sample @ 100Hz, samples both rotors and can generate ignition and fuel reactions. i expect to get a better picture of where the motor is happy. we will for sure very carefully look at AFRs and timing.

there are a number of ways to make power and stay cool. excess gasoline, isn't the most efficient. it is often the only option due to rules.

other cooling options water, alcohol are superior to (excess) gasoline.

cooling per gallon (BTUs)

gasoline 952

ethanol alcohol 2398

methanol alcohol 3136

water 8087

i do agree there can be a positive offsets from running excess gasoline including keeping the motor together.

one of the reasons i am switching to a Link Xtreme is to upgrade knock monitoring v my Power FC. the knock program is totally user configurable, can sample @ 100Hz, samples both rotors and can generate ignition and fuel reactions. i expect to get a better picture of where the motor is happy. we will for sure very carefully look at AFRs and timing.

#9

My 2cents......... I agree with the above, that running a leaner mixture with less IG advance is a good alternative to running richer mixtures to prevent knock. However, us rotary guys also have to contend with the possibility of warping apex seals if we run too lean for too long. And I think running 12+ afr on a 400+ HP rotary will definitely warp seals especially without AI. Richer mixtures are needed to prevent this.

So knock is not our only concern

So knock is not our only concern

#10

That's an old article (I remember seeing it a few years ago) and it drastically oversimplifies the issue. I'll address this from a theoretical perspective, throwing in some stuff about modern piston engines, I'll discuss calibration/tuning procedures used by OEM's on new boosted engines, and I will also discuss this from the practical standpoint of Rx-7 enthusiasts with modified engines.

The "ideal AFR" for engine output can really be understood as the mixture distribution within the combustion chamber. You don't really need to have an overall rich mixture as measured in the exhaust, you just have the right amount of fuel in the right places at the right time. The latest direct injected piston engines run at lambda=1 (14.7:1 on pure gasoline) under most full load conditions. Overall richer mixtures usually do hurt torque output. There are maps inside stock ECU's the compare engine torque output to AFR; the same can be said with ignition timing vs torque output. The Bosch Motronic system used by VW, Porsche, BMW, and GM has been doing this for years.

Here are two things to think about regarding durability and high exhaust temperatures:

1. Degrading engine components from the heat, such as seals, catalytic converters, and manifolds

2. Recirculating hot exhaust gases back into the intake stroke, increasing the tendency to knock. There is a BIG link between residual mass fraction (leftover hot gases in the chamber) and knock. That's a really complicated thing to study.

Besides major engine geometry changes, there are a number of ways to reduce exhaust temperatures:

1. Richening up the mixture does work. We can quibble about how it works, but it works. Here is a chart from a study of ethanol fuel blends, Air Fuel Ratio (in Lambda), and brake-specific heat consumption. A higher number is directly related to cooler temperatures in the combustion chamber and in the exhaust.

OEM's use it all the time to keep catalytic converters from aging prematurely. Generally speaking, if exhaust temps get over about 800C or ~1500F the catalytic converter will degrade faster. The same could be said for turbos, manifolds, and valves (on piston engines) if they can't handle the heat.

Richening a mixture does hurt engine output and increase CO emissions, so now the trend is toward other methods of charge cooling as costs and customer acceptance allow.

2. Some kind of AI --Ford has prototypes of E85 injected twin turbo V8 engines, but I'm not sure if this will ever see production.

3. EGR: we normally think of EGR as kind of useless emissions crap, but it's likely that newer boost gas engines will be using cooled EGR systems (like diesels) to reduce knock tendency and exhaust temps. Variable valve timing can have this effect too.

4. Water cooled exhaust manifolds--the newest VW turbo engines are already using them. A lot of new engines actually have the exhaust manifold and cylinder head integrated, so running coolant passages in there makes sense.

Collecting data on engine torque output vs ignition timing and AFR would help to understand the relationships. There are a gazillion combinations of conditions to try, so normally in development statistical methods are used to reduce the number of measurements needed and generate trend lines.

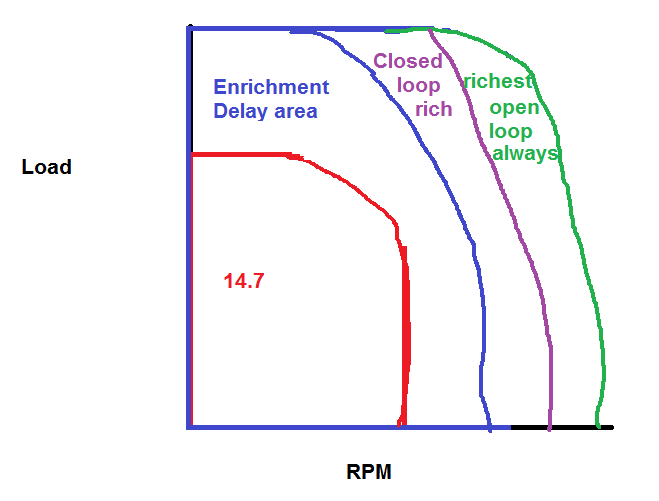

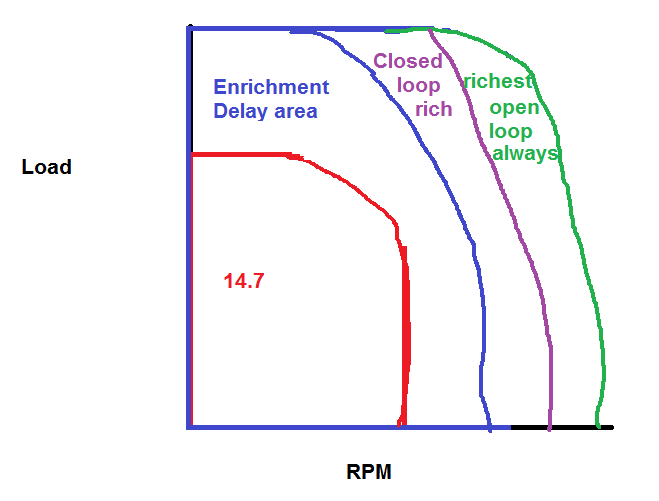

The newest stock ECU's can calculate the MBT (minimum spark advance for best torque) and required fuel mass with some accuracy, and then modifications can be made from there based on models and lookup tables. Here are examples of control strategies for AFR control:

That's basically how an FD and other engines from that era operate. They have narrowband O2 sensors and open/close loop zones.

On engines from say 10 years ago, you start to see delay timers introduced during certain operating zones. Under certain conditions the AFR will richen up after the timer increments. Subarus for example have a closed/open loop delay. Engines with an accurate enough O2 sensor can be closed loop and rich of stoichiometry to an extent:

The most expensive engines will run closed loop all the time and enrich only at the highest loads. This requires design elements to mitigate knock , accurate wideband sensors, complicated control strategies, and components that can handle the high temperatures. The R35 Nissan GT-R does this:

and so do all the new boosted BMW engines.

Most engines produce maximum power (with optimized ignition timing) at an air-fuel-ratio between 12 and 13. Let's assume the optimum is in the middle at 12.5.

Here are two things to think about regarding durability and high exhaust temperatures:

1. Degrading engine components from the heat, such as seals, catalytic converters, and manifolds

2. Recirculating hot exhaust gases back into the intake stroke, increasing the tendency to knock. There is a BIG link between residual mass fraction (leftover hot gases in the chamber) and knock. That's a really complicated thing to study.

Besides major engine geometry changes, there are a number of ways to reduce exhaust temperatures:

1. Richening up the mixture does work. We can quibble about how it works, but it works. Here is a chart from a study of ethanol fuel blends, Air Fuel Ratio (in Lambda), and brake-specific heat consumption. A higher number is directly related to cooler temperatures in the combustion chamber and in the exhaust.

OEM's use it all the time to keep catalytic converters from aging prematurely. Generally speaking, if exhaust temps get over about 800C or ~1500F the catalytic converter will degrade faster. The same could be said for turbos, manifolds, and valves (on piston engines) if they can't handle the heat.

Richening a mixture does hurt engine output and increase CO emissions, so now the trend is toward other methods of charge cooling as costs and customer acceptance allow.

2. Some kind of AI --Ford has prototypes of E85 injected twin turbo V8 engines, but I'm not sure if this will ever see production.

3. EGR: we normally think of EGR as kind of useless emissions crap, but it's likely that newer boost gas engines will be using cooled EGR systems (like diesels) to reduce knock tendency and exhaust temps. Variable valve timing can have this effect too.

4. Water cooled exhaust manifolds--the newest VW turbo engines are already using them. A lot of new engines actually have the exhaust manifold and cylinder head integrated, so running coolant passages in there makes sense.

My 2cents......... I agree with the above, that running a leaner mixture with less IG advance is a good alternative to running richer mixtures to prevent knock. However, us rotary guys also have to contend with the possibility of warping apex seals if we run too lean for too long. And I think running 12+ afr on a 400+ HP rotary will definitely warp seals especially without AI. Richer mixtures are needed to prevent this.

So knock is not our only concern

So knock is not our only concern

Collecting data on engine torque output vs ignition timing and AFR would help to understand the relationships. There are a gazillion combinations of conditions to try, so normally in development statistical methods are used to reduce the number of measurements needed and generate trend lines.

The newest stock ECU's can calculate the MBT (minimum spark advance for best torque) and required fuel mass with some accuracy, and then modifications can be made from there based on models and lookup tables. Here are examples of control strategies for AFR control:

That's basically how an FD and other engines from that era operate. They have narrowband O2 sensors and open/close loop zones.

On engines from say 10 years ago, you start to see delay timers introduced during certain operating zones. Under certain conditions the AFR will richen up after the timer increments. Subarus for example have a closed/open loop delay. Engines with an accurate enough O2 sensor can be closed loop and rich of stoichiometry to an extent:

The most expensive engines will run closed loop all the time and enrich only at the highest loads. This requires design elements to mitigate knock , accurate wideband sensors, complicated control strategies, and components that can handle the high temperatures. The R35 Nissan GT-R does this:

and so do all the new boosted BMW engines.

#12

arghx, do you know why or of what benefit is the enrichment delays? ive read a lot of the subaru guys ditch it when running more boost.

im sure closed loop knock control and direct injection helps allow modern engines to run so lean. DI not really available to 13B engines at this point. I would like to mess around with closed loop knock control though. Seems like the OP article is not applicable to us, in that we cannot run max power AFRs and just retard timing and not need a rebuild every week. Only if you were running water injection

im sure closed loop knock control and direct injection helps allow modern engines to run so lean. DI not really available to 13B engines at this point. I would like to mess around with closed loop knock control though. Seems like the OP article is not applicable to us, in that we cannot run max power AFRs and just retard timing and not need a rebuild every week. Only if you were running water injection

#13

tard of teh century

A lot of the subaru guys will get rid of the delay because it's eaiser to tune without it and they also run into issues with getting some knock in those areas as they get more power out of the car. There's a lot of variables that go into calculating how long the delay will last and it's not the easiest to follow or keep tabs of. Instead it's a lot easier to just set the delay to 0 so that you know you'll be inside your open loop map for the conditions you set. The delay would be nice to keep if you had the time to really dial it in but most people just aren't willing to run lean during spool and I haven't seen anybody that's done both on the subaru forums for them to say if there is a big difference. Most of the really good tuners would probably keep it to themselves if they're are doing it, same with the cam advance settings.

Here's an example of the settings available for an 05 STi on the delay

Here's an example of the settings available for an 05 STi on the delay

#14

Some Subaru tuners/owners are kind of paranoid/hardcore. Totally eliminating the delay timer just hurts fuel economy on a typical moderately modded street car, but yes it is standard practice. The issues is that in 2008 Subaru doubled the delay timer, meaning the engine runs at 14.7:1 for a longer period of time before entering enrichment than earlier models. At the same time, manufacturing quality IMO decreased and those engines became more prone to losing piston ring lands. I usually cut the delay timer in half of what you'd find on an older model. The delay timer has different logic controlling it depending on the engine; some have an actual exhaust temperature sensor output that contributes to the logic.

I disagree with a lot of Subaru tuners. There's a lot of groupthink and paranoia among them, and I guess after messing with rotaries for so long I don't find myself too worried about blowing up piston engines. The stock ECU is about a gazillion times more powerful and safer (in terms of knock and boost control) than anything available for an Rx-7 so it's not a big deal.

im sure closed loop knock control and direct injection helps allow modern engines to run so lean. DI not really available to 13B engines at this point. I would like to mess around with closed loop knock control though. Seems like the OP article is not applicable to us, in that we cannot run max power AFRs and just retard timing and not need a rebuild every week. Only if you were running water injection

The new boosted engines are built around squeezing a lot of power out per liter displacement. It's one of the only cost effective ways to meet emissions standards for high volume vehicles. Look at what BMW, Porsche, Ford, VW, and Hyundai are doing now. You can't just crank up the boost and dump fuel in to meet power and emissions targets. That's why intake port and fuel injector designs have gotten so sophisticated... mixture distribution is so optimized that you can run full load without enrichment until the upper rpms.

#15

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,892

Received 2,640 Likes

on

1,870 Posts

so the takeaways?

1. give the engine what it wants. target AFR is for the CAT. the cat NEEDS 14.7:1. without the cat, we tune as lean as we can in cruise, and as rich as we need too under boost.

2. rich mixture = EGT control. i have had the wideband on several S4 and S5 NA's. the S4 runs mid 12's after 4000rpm, the S5 runs 12.2:1@4000rpm, and then gradually richens up until its in the high 10's. why did Mazda have a non knock limited engine running so rich? they suck at tuning right?

no they had to warranty the cat. peak EGT, after many back to back runs was only 820c (1500F).

3. "Internal EGR" this is a HUGE effect. its basically the whole reason for the redesign of the Rx8's ports, and its also in the skyactive engines as well. a little exhaust gas in intake stroke is EGR, too much however = detonation. on the Rx7 engines this means you NEED as much chamber sealing as you can get.

4. if you're just looking at cooling BTU's, water > everything else by a wide margin. water also isn't flammable, and in some mystery tank in the back of the car, so its an easy choice.

1. give the engine what it wants. target AFR is for the CAT. the cat NEEDS 14.7:1. without the cat, we tune as lean as we can in cruise, and as rich as we need too under boost.

2. rich mixture = EGT control. i have had the wideband on several S4 and S5 NA's. the S4 runs mid 12's after 4000rpm, the S5 runs 12.2:1@4000rpm, and then gradually richens up until its in the high 10's. why did Mazda have a non knock limited engine running so rich? they suck at tuning right?

no they had to warranty the cat. peak EGT, after many back to back runs was only 820c (1500F).

3. "Internal EGR" this is a HUGE effect. its basically the whole reason for the redesign of the Rx8's ports, and its also in the skyactive engines as well. a little exhaust gas in intake stroke is EGR, too much however = detonation. on the Rx7 engines this means you NEED as much chamber sealing as you can get.

4. if you're just looking at cooling BTU's, water > everything else by a wide margin. water also isn't flammable, and in some mystery tank in the back of the car, so its an easy choice.

#17

Old [Sch|F]ool

My 2cents......... I agree with the above, that running a leaner mixture with less IG advance is a good alternative to running richer mixtures to prevent knock. However, us rotary guys also have to contend with the possibility of warping apex seals if we run too lean for too long.

It's not terribly difficult to make a lot of power, the big problem is making a lot of power, over time.

Witness F1 from the infamous turbo era. Qualifying power would be 1.5-2x standard race power. Race power is how much power the engine can make and the cooling systems can reject in an equilibrium. For qualifying, they only needed to make that power for a couple glorious laps, so it didn't matter if they couldn't cool the engine down fast enough. At that point the block/cooling system is more of a heat sink than a heat exchanger.

Likewise, you can make 400-500hp from a mostly stock Honda D16... for a few seconds. I bet you couldn't even get a full lap out of that power level on a road course before you're pouring the pistons and parts of the cylinder head out of the oil pan.

At some point, the tradeoff has to be made to make the engine more thermally tolerant than out-and-out more powerful. And that's when you see gasoline engined turbocars smoking like a badly-modified Diesel under full power.

#18

^ I see what you're saying, but F1 turbo engines mostly ran on 102 RON Toluene blends so that's far from what most hobbyists and racers are doing.

Here's some interesting stuff about Honda F1 turbo engines to consider. As F1 started to phase out turbo engines, they tightened restrictions on boost and fuel capacity:

The RA168E was their most fuel efficient and least powerful engine, having been limited to 2.5bar absolute pressure or around 21psi. Now as I mentioned, that engine ran on a 102 Research Octane racing fuel using about 80% Toluene (rules limited the max toluene %).

The team found that a large percentage of toluene could suppress knock better than other blends despite a similar nominal octane number.

In the above image, you can see that running the max allowable blend of Toluene allowed the most timing advance and the best specific fuel consumption. It does require fuel heaters and other complications though. The Honda team played around with fueling and ended up running about the equivalent of maybe 14.5:1 AFR on pure gasoline, when you do all the conversions.

You can see that the equivalence ratio for the high fuel efficiency tune was 1.02. Here is a chart roughly showing conversion into pure gasoline AFR:

You can see that they picked up power as the AFR richened to the equivalent of say high 12's AFR on pure gasoline. On the fuel efficient tune though they had the following power and specific fuel consumption curves:

Now that was a race team, and they did their tuning with cylinder pressure sensors instead of vibration/piezoelectric knock sensors or the old "guess and check" methods used by us regular guys. You can see that, in the right applications there really can somewhat of a disconnect between AFR and knock suppression.

The established guidelines and rules of thumb for tuning a modified street rotary are there for a reason though. They come from a lot of hard lessons learned on the setups that are most commonly run.

Here's some interesting stuff about Honda F1 turbo engines to consider. As F1 started to phase out turbo engines, they tightened restrictions on boost and fuel capacity:

The RA168E was their most fuel efficient and least powerful engine, having been limited to 2.5bar absolute pressure or around 21psi. Now as I mentioned, that engine ran on a 102 Research Octane racing fuel using about 80% Toluene (rules limited the max toluene %).

The team found that a large percentage of toluene could suppress knock better than other blends despite a similar nominal octane number.

In the above image, you can see that running the max allowable blend of Toluene allowed the most timing advance and the best specific fuel consumption. It does require fuel heaters and other complications though. The Honda team played around with fueling and ended up running about the equivalent of maybe 14.5:1 AFR on pure gasoline, when you do all the conversions.

You can see that the equivalence ratio for the high fuel efficiency tune was 1.02. Here is a chart roughly showing conversion into pure gasoline AFR:

You can see that they picked up power as the AFR richened to the equivalent of say high 12's AFR on pure gasoline. On the fuel efficient tune though they had the following power and specific fuel consumption curves:

Now that was a race team, and they did their tuning with cylinder pressure sensors instead of vibration/piezoelectric knock sensors or the old "guess and check" methods used by us regular guys. You can see that, in the right applications there really can somewhat of a disconnect between AFR and knock suppression.

The established guidelines and rules of thumb for tuning a modified street rotary are there for a reason though. They come from a lot of hard lessons learned on the setups that are most commonly run.

#21

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,892

Received 2,640 Likes

on

1,870 Posts

^ I see what you're saying, but F1 turbo engines mostly ran on 102 RON Toluene blends so that's far from what most hobbyists and racers are doing.

Here's some interesting stuff about Honda F1 turbo engines to consider. As F1 started to phase out turbo engines, they tightened restrictions on boost and fuel capacity:

Here's some interesting stuff about Honda F1 turbo engines to consider. As F1 started to phase out turbo engines, they tightened restrictions on boost and fuel capacity:

this was done to limit the speeds of the cars, the 1937 cars were capable of 190mph on the straights, but even though they went to 3liters, they also went to compound supercharging (its WW1 technology), so power isn't down much.

http://www.youtube.com/watch?v=RT0mo...eature=related

at 1-2mpg you can bet they were running on the rich side.....

mercedes had an in house chassis dyno that let them simulate running the car on the different tracks, and auto union had some kind of analog datalogger, so even in the 30's the OEMs have some stuff that's hard to duplicate at the hobby level....

although we have things like seat belts, and hydraulic shocks....

#23

Senior Member

Join Date: Nov 2008

Location: Czech republic

Posts: 357

Likes: 0

Received 0 Likes

on

0 Posts

rich mixture = EGT control. i have had the wideband on several S4 and S5 NA's. the S4 runs mid 12's after 4000rpm, the S5 runs 12.2:1@4000rpm, and then gradually richens up until its in the high 10's. why did Mazda have a non knock limited engine running so rich? they suck at tuning right?

no they had to warranty the cat. peak EGT, after many back to back runs was only 820c (1500F).

no they had to warranty the cat. peak EGT, after many back to back runs was only 820c (1500F).

Someone please post video with Rod Millen's Toyota Tacoma, I had no luck with embedding videos

#24

Junior Member

Join Date: Dec 2008

Location: Auburn, Al

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

This is a very interesting thread, gonna love reading and re-reading all this info.

Mad - interesting how Subaru does it, VW runs a target lambda of around .9 untill calculated turbine temp goes too high and then it changes to .72-.8 (depends on which car, which trans, etc) They strickly use it to keep from melting the turbo. Funny thing is at that little boost, thus more timing advance they never get close to using it. Once the boost is turned up it does come into play. There is a calculated Cat temp but it seems that is only used for OBD stuff. So Mazda may be doing this same thing, running rich to save the turbo becuase they have to tune to for 100% load 100% of the time, anything less and they are just guessing at how we will drive our cars Remember replacing turbos under warranty are expensive but my gas is free to Mazda.

And looking at how far timing control and knock feedback have come (in the aftermarket world) why would we not try running alittle leaner and rely on knock control to save our a$$ when something goes wrong instead of compensating ahead of time in our tunes.

Mad - interesting how Subaru does it, VW runs a target lambda of around .9 untill calculated turbine temp goes too high and then it changes to .72-.8 (depends on which car, which trans, etc) They strickly use it to keep from melting the turbo. Funny thing is at that little boost, thus more timing advance they never get close to using it. Once the boost is turned up it does come into play. There is a calculated Cat temp but it seems that is only used for OBD stuff. So Mazda may be doing this same thing, running rich to save the turbo becuase they have to tune to for 100% load 100% of the time, anything less and they are just guessing at how we will drive our cars Remember replacing turbos under warranty are expensive but my gas is free to Mazda.

And looking at how far timing control and knock feedback have come (in the aftermarket world) why would we not try running alittle leaner and rely on knock control to save our a$$ when something goes wrong instead of compensating ahead of time in our tunes.

#25

yes, but it's misleading info. almost every rotary tuner has a specific tuning procedure and that generally isn't taking fuel to the bleeding edge and retarding timing to compensate for additional heat.

it would be a great way to set up a ticking grenade on someone you really didn't like though i suppose..

reason being, not every car will yield the same results. some cars tuned will give almost spot on AFRs with each pass in each corresponding cell, others can vary to dangerous levels. rule of thumb will always be= choose the safest path. those that are pushing the limits know the risks already and accept them.

it would be a great way to set up a ticking grenade on someone you really didn't like though i suppose..

reason being, not every car will yield the same results. some cars tuned will give almost spot on AFRs with each pass in each corresponding cell, others can vary to dangerous levels. rule of thumb will always be= choose the safest path. those that are pushing the limits know the risks already and accept them.

Last edited by RotaryEvolution; 03-21-12 at 07:08 PM.