twin sequential efr. 6258 or 7064.....?

#1

twin sequential efr. 6258 or 7064.....?

The idea will be to spool the EFR turbo and use its wastegate to control boost.. the 2nd turbo will likely be an sxe7670. the original plan was to use an efr 7670 with the sxe7670. but i want to go smaller, and lower the total hp output, i dont need 700. i dont have a set goal, but a set of them... i want to see 400ftlbs of tq at.. 3K RPM... i want to see 500fts from both turbos by 5k rpm... with no loss of boost during transition.

if there was no budget i would use two efrs..... but im working with about $7000. the ecu is taken care of, still need... injectors for ~700hp, and clutch. have wastegates and manifold fab up stuff... have a spare trans/diff/axles/rims

the the 6258 with twin scroll is $1500. and then 7064 $1735

the SXE ran me 664.. hope to hit the dyno with it by itself soon.

if there was no budget i would use two efrs..... but im working with about $7000. the ecu is taken care of, still need... injectors for ~700hp, and clutch. have wastegates and manifold fab up stuff... have a spare trans/diff/axles/rims

the the 6258 with twin scroll is $1500. and then 7064 $1735

the SXE ran me 664.. hope to hit the dyno with it by itself soon.

#2

Why not the obvious choice of the 0.85AR IWG EFR 7163 for the primary turbo?

THMotorsports has it for $1,675 so it sounds like it fits your budget?

I was hoping we would get another round of $350 EFR IRL car cast offs, but all the 7163s must be going back to BW for analysis. Must of just been because they would never use the 9180s and 6758s again (no need for analysis) that they went straight to ebay last season.

THMotorsports has it for $1,675 so it sounds like it fits your budget?

I was hoping we would get another round of $350 EFR IRL car cast offs, but all the 7163s must be going back to BW for analysis. Must of just been because they would never use the 9180s and 6758s again (no need for analysis) that they went straight to ebay last season.

#3

thm is where my price quotes are from, and where i got my sxe... i wasnt sure if the 7163 would be too big to hit 400ftlbs at 3k. imma need hella spool for that. at the same time will the size of the wastegates between the 6258 and the 7163 have an effect on the ability to control boost...

EDIT: looking at it again, now i remember why i stayed away from that one, aluminum only CHRA!. No thanks.

EDIT: looking at it again, now i remember why i stayed away from that one, aluminum only CHRA!. No thanks.

Last edited by lastphaseofthis; 07-15-16 at 08:58 PM.

#4

Arrogant Wankeler

If you want to avoid transition issues you probably want the primary turbo to be as big or bigger than secondary so they don't fall into surge on transition.

If you want a strong bottom end with more top end than a really responive turbo will give i would prefer buying a rebuilt m90 blower or similar geared for 5psi and run an efr 8374 or 9180 compounded with the blower.

If you want a strong bottom end with more top end than a really responive turbo will give i would prefer buying a rebuilt m90 blower or similar geared for 5psi and run an efr 8374 or 9180 compounded with the blower.

#5

If you want to avoid transition issues you probably want the primary turbo to be as big or bigger than secondary so they don't fall into surge on transition.

If you want a strong bottom end with more top end than a really responive turbo will give i would prefer buying a rebuilt m90 blower or similar geared for 5psi and run an efr 8374 or 9180 compounded with the blower.

If you want a strong bottom end with more top end than a really responive turbo will give i would prefer buying a rebuilt m90 blower or similar geared for 5psi and run an efr 8374 or 9180 compounded with the blower.

blowers dont take advantage of this, and on a rotary is why they typically dont preform well as turbos.

both turbos will have speed sensors. and i am thinking of running a MAF in front of the primary turbo, for starting/light load/ cruise fueling, but to also help to computer to know the primary turbo's run is up and its time to bring in it's big brother. then the ecu will switch to speed density..

Trending Topics

#8

not to mention i wouldn't need even more pressure ratio with the efr turbos.

the 2nd turbo will be completely blocked off, so that all of the exhaust hits the small 7064 turbo maxing it very quickly by 4500rpm.. then the 2nd comes on...

or would you have the supercharger on with the exhaust open, until it's time to spool the turbo? even then, i would want to dyno a peri port and super charger setup with a very open exhaust before hand just to see what kinda low down torque can be achieved,

because blue Tii did 300ft at 3k, and 400 at 4k..that was on an efr 7670... NEVER seen a supercharger do that on a rotary. prove me wrong..

show me the badass super charger build thread i havent seen where they made gobs of power... yeah.. i thought so.

Last edited by lastphaseofthis; 07-16-16 at 07:17 PM.

#9

Full Member

the 2nd turbo will be completely blocked off, so that all of the exhaust hits the small 6258 (or 7064)turbo maxing it very quickly by 4500rpm.. then the 2nd comes on...being only a smigde smaller, then the 7670 SXE, ther both will run parallel from 4.5k to run line.. the primary turbo will use its built in waste to control boost from both turbos, hopefully not creeping

Last edited by Brettus; 07-16-16 at 08:49 PM.

#10

so you would have the super charger and turbo run at the same time.

not to mention i wouldn't need even more pressure ratio with the efr turbos.

the 2nd turbo will be completely blocked off, so that all of the exhaust hits the small 7064 turbo maxing it very quickly by 4500rpm.. then the 2nd comes on...

or would you have the supercharger on with the exhaust open, until it's time to spool the turbo? even then, i would want to dyno a peri port and super charger setup with a very open exhaust before hand just to see what kinda low down torque can be achieved,

because blue Tii did 300ft at 3k, and 400 at 4k..that was on an efr 7670... NEVER seen a supercharger do that on a rotary. prove me wrong..

show me the badass super charger build thread i havent seen where they made gobs of power... yeah.. i thought so.

the 2nd turbo will be completely blocked off, so that all of the exhaust hits the small 6258 (or 7064)turbo maxing it very quickly by 4500rpm.. then the 2nd comes on...being only a smigde smaller, then the 7670 SXE, ther both will run parallel from 4.5k to run line.. the primary turbo will use its built in waste to control boost from both turbos, hopefully not creeping

not to mention i wouldn't need even more pressure ratio with the efr turbos.

the 2nd turbo will be completely blocked off, so that all of the exhaust hits the small 7064 turbo maxing it very quickly by 4500rpm.. then the 2nd comes on...

or would you have the supercharger on with the exhaust open, until it's time to spool the turbo? even then, i would want to dyno a peri port and super charger setup with a very open exhaust before hand just to see what kinda low down torque can be achieved,

because blue Tii did 300ft at 3k, and 400 at 4k..that was on an efr 7670... NEVER seen a supercharger do that on a rotary. prove me wrong..

show me the badass super charger build thread i havent seen where they made gobs of power... yeah.. i thought so.

the 2nd turbo will be completely blocked off, so that all of the exhaust hits the small 6258 (or 7064)turbo maxing it very quickly by 4500rpm.. then the 2nd comes on...being only a smigde smaller, then the 7670 SXE, ther both will run parallel from 4.5k to run line.. the primary turbo will use its built in waste to control boost from both turbos, hopefully not creeping

ive got a blower from a jap spec mr2 in the shed, was thinking of doing the same thing to my small japanese diesel, lol, which is why my eyes lit up when i saw his post.

I can see where you're coming from with the sequential thing though - it would be pretty bad **** - but it will be tricky getting it all to work smoothly!

#11

Yeah i know where your coming from how no ones ever made any real power with a supercharged rotary. I dont want to speak for him but i think Slides' idea with low boost supercharger fed by a bigger turbo would be a fair bit more efficient than what we've seen from previous SC efforts. Not much power would be leeched to make 1.3PR, but would make a world of difference to compressor efficiency and spoolup on the turbo.

ive got a blower from a jap spec mr2 in the shed, was thinking of doing the same thing to my small japanese diesel, lol, which is why my eyes lit up when i saw his post.

I can see where you're coming from with the sequential thing though - it would be pretty bad **** - but it will be tricky getting it all to work smoothly!

ive got a blower from a jap spec mr2 in the shed, was thinking of doing the same thing to my small japanese diesel, lol, which is why my eyes lit up when i saw his post.

I can see where you're coming from with the sequential thing though - it would be pretty bad **** - but it will be tricky getting it all to work smoothly!

#12

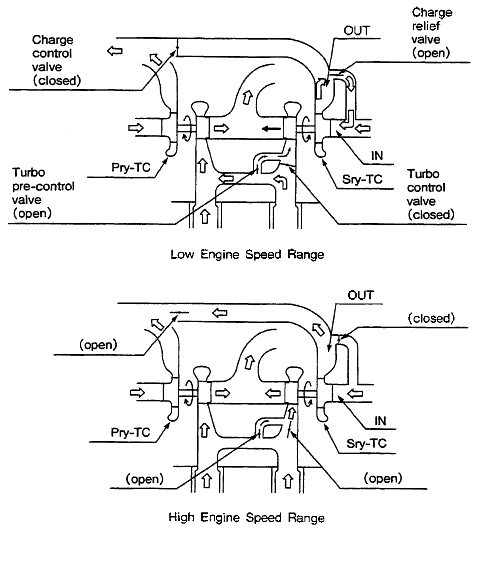

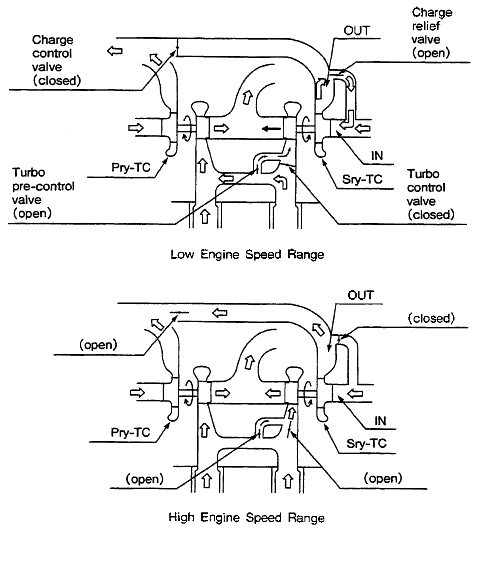

I'm still trying to understand how the sequential system is going to work. Is it patterned off the FD's system, or is it patterned off a compound turbo system you would find on a diesel? Is the first turbo's outlet connected to the second turbo's inlet?

stock FD system has:

charge control valve

charge relief valve

precontrol valve

wastegate valve

turbo control valve

Which of these actuators' functionality do you intend to keep? Sounds like charge relief and precontrol will be eliminated, and maybe charge control too. So now when the second turbo comes online you have to hope you sized everything correctly that you don't have a huge dip occurring.

Can someone point me to a dyno sheet down 400 lb/ft of torque at 3000rpm? Even if it's like 350. You're going to need a turbine housing that can build a lot of boost down low and a compressor wheel that can support a high pressure ratio.

The more aggressive your porting is in terms of intake closing timing and exhaust opening timing, the harder it is going to be to hit that goal.

stock FD system has:

charge control valve

charge relief valve

precontrol valve

wastegate valve

turbo control valve

Which of these actuators' functionality do you intend to keep? Sounds like charge relief and precontrol will be eliminated, and maybe charge control too. So now when the second turbo comes online you have to hope you sized everything correctly that you don't have a huge dip occurring.

Can someone point me to a dyno sheet down 400 lb/ft of torque at 3000rpm? Even if it's like 350. You're going to need a turbine housing that can build a lot of boost down low and a compressor wheel that can support a high pressure ratio.

The more aggressive your porting is in terms of intake closing timing and exhaust opening timing, the harder it is going to be to hit that goal.

#13

I'm still trying to understand how the sequential system is going to work. Is it patterned off the FD's system, or is it patterned off a compound turbo system you would find on a diesel? Is the first turbo's outlet connected to the second turbo's inlet?

stock FD system has:

charge control valve

charge relief valve

precontrol valve

wastegate valve

turbo control valve

Which of these actuators' functionality do you intend to keep? Sounds like charge relief and precontrol will be eliminated, and maybe charge control too. So now when the second turbo comes online you have to hope you sized everything correctly that you don't have a huge dip occurring.

Can someone point me to a dyno sheet down 400 lb/ft of torque at 3000rpm? Even if it's like 350. You're going to need a turbine housing that can build a lot of boost down low and a compressor wheel that can support a high pressure ratio.

The more aggressive your porting is in terms of intake closing timing and exhaust opening timing, the harder it is going to be to hit that goal.

stock FD system has:

charge control valve

charge relief valve

precontrol valve

wastegate valve

turbo control valve

Which of these actuators' functionality do you intend to keep? Sounds like charge relief and precontrol will be eliminated, and maybe charge control too. So now when the second turbo comes online you have to hope you sized everything correctly that you don't have a huge dip occurring.

Can someone point me to a dyno sheet down 400 lb/ft of torque at 3000rpm? Even if it's like 350. You're going to need a turbine housing that can build a lot of boost down low and a compressor wheel that can support a high pressure ratio.

The more aggressive your porting is in terms of intake closing timing and exhaust opening timing, the harder it is going to be to hit that goal.

its going to be controlled exactly like the FD twins..

both turbos will be divided.

two wastegates block flow to the 2nd turbo until the primary turbo reaches 20 ish psi, then they are cracked open just enough to keep the 1st turbo at 20psi ( this value may change during tuning.), while the rpm goes up, the wastegates slowly open more to feed more exhuast to the 2nd turbo... (pre spool right...) the 2nd turbo will be vented to atmosphere until change over, then it gets dumped into the intercooler parallel to the 1st turbo. this is when **** hits the fan and traction loss occurs.

at change over the wastegates are no longer progressively open but wide open and remain that way above 5.5k rpm.( this value may change during tuning.)

#14

Ok so you are going to use an external wastegate to control flow to the secondary turbo instead of a swing valve like the stock turbo control valve? That's interesting. That's the same way the Porsche 959 did it, as I mentioned in this post: https://www.rx7club.com/3rd-generati.../#post11180543

In that case, an external wastegate style valve was in-line with the downpipe for the secondary turbo.

Maybe I missed this but what ECU is it? Do you have enough outputs?

You will need two closed loop PWM control for boost, then some flexible rpm-based control for turbo control, charge control, and charge relief. It needs to have 3D speed and load mapping for control or at least some hysteresis capability, or at least something beyond "on above x rpm." Make sure you have flexible enough controls or you will be stuck later in a situation where you want x valve to change state under such and such condition and you can't because the ECU logic is too simple.

Enough outputs does NOT necessarily mean you have flexible enough controls.

In that case, an external wastegate style valve was in-line with the downpipe for the secondary turbo.

Maybe I missed this but what ECU is it? Do you have enough outputs?

You will need two closed loop PWM control for boost, then some flexible rpm-based control for turbo control, charge control, and charge relief. It needs to have 3D speed and load mapping for control or at least some hysteresis capability, or at least something beyond "on above x rpm." Make sure you have flexible enough controls or you will be stuck later in a situation where you want x valve to change state under such and such condition and you can't because the ECU logic is too simple.

Enough outputs does NOT necessarily mean you have flexible enough controls.

#15

i think two identical 6258's with the T25 0.65 IWG single-scroll housing would work very well.. it appears each compressor is capable of 250whp. With exhaust routed to just one, it should max out at 250whp at low RPM pretty easily with that tiny hot side, which is a little smaller than the oem FC turbo, with a little over half the A/R. then when both are operating, you should be around 500whp at 15-20psi, with an equivalent A/R of 1.3. The combined turbine wheel size would be a little bigger than a p-trim.. both have internal wastegates, so you shouldnt have any creep problems. If anything this turbo is probably too big, but idk it may work. and like arghx mentioned, operate it like factory twins..

you are going to need to make a crazy turbo manifold with a throttle in it lol, and a **** ton of ECU outputs

you are going to need to make a crazy turbo manifold with a throttle in it lol, and a **** ton of ECU outputs

Last edited by gxl90rx7; 07-18-16 at 09:02 PM.

#16

The secondary turbo's flow needs to be completely blocked on either the inlet side (like an Rx-7) or the outlet side (Supra, 959) for this to work. If you'll recall Mazda's SAE paper, the swing valve used for the turbo control actuator had a lot of trouble sealing against the backpressure in the early design phases.

If you can get a secondary turbo with a small vband outlet, you could connect it right to a vband inlet wastegate or with a short connecting pipe. So the turbo's speed is regulated on the outlet side, again like a Supra or a 959. Then when the secondary turbo is ready to come online, you open the wastegate with pwm control like any other boost control by connecting a solenoid to the side port of the gate. This would eliminate the precontrol valve from the system, like the 959 which had no precontrol valve.

If you want to control the inlet side of the secondary turbo you will need a swing valve or butterfly valve that won't leak. It's going to get really hot down there. Basically you have to decide if you want this to be like a Supra, Rx-7, or 959. I suggest you study those systems carefully. Fitment is going to be a big constraint.

If you use an electronic throttle type of device you won't be able to actually use a throttlebody because it won't handle the heat. You would need to source a valve from a sequential turbo diesel or a low pressure EGR valve. Then you will need to drive the motor with an H bridge if you want full electronic control (requiring an expensive ECU), or devise a pneumatic control system with solenoids.

If you can get a secondary turbo with a small vband outlet, you could connect it right to a vband inlet wastegate or with a short connecting pipe. So the turbo's speed is regulated on the outlet side, again like a Supra or a 959. Then when the secondary turbo is ready to come online, you open the wastegate with pwm control like any other boost control by connecting a solenoid to the side port of the gate. This would eliminate the precontrol valve from the system, like the 959 which had no precontrol valve.

If you want to control the inlet side of the secondary turbo you will need a swing valve or butterfly valve that won't leak. It's going to get really hot down there. Basically you have to decide if you want this to be like a Supra, Rx-7, or 959. I suggest you study those systems carefully. Fitment is going to be a big constraint.

If you use an electronic throttle type of device you won't be able to actually use a throttlebody because it won't handle the heat. You would need to source a valve from a sequential turbo diesel or a low pressure EGR valve. Then you will need to drive the motor with an H bridge if you want full electronic control (requiring an expensive ECU), or devise a pneumatic control system with solenoids.

Last edited by arghx; 07-18-16 at 09:19 PM.

#17

although now that I re-read your posts, you said you want a twin scroll secondary turbo with wastegates controlling each scroll. You do realize that you will have to completely block turbine inlet flow with the gates for this to work? Normally an external gate "branches off" to bleed away exhaust, but you need to fully block flow and have it inline with the turbine housing. In that case, when it's full open there will be no boost control possible on the secondary turbo, unless you plan an internally gated turbo.

#18

on the stock system the primary turbo's internal wastegate controls boost for both turbos, thats the reason for the EFR as the primary then the SXE as the 2ndary. i think if they setup was going on a 20b( !!!! idea !!!!).. the exhaust would be too much and creep would happen, on the 13bs and turbos of this size, i dont think it will as much, and i will deal with it later if i have too.

yesi will have two wastegates for each runner, inline with the 2nd turbo.. the primarys twin runner will be short( turblowns' cast would be a good start) and open to the primary turbo.

the ecu/// MS3-PRO... i do indeed have 3d mapping boost control, inputs for speed sensor on the turbos and two pwm generial funtion tables...

edit. holy FLUPP dude you are awesome with the Porsche 959 turbo diagrams, i havent seen those.. but i actually wondered if putting wastegates after the turbo, like where the cats would be, to keep the wastegates cooler.. and lasting longer. i"m glad to see the porchse engineers where thinking in the same box as me!

honestly i thouught the wastegate in the downpipe was better, but then i found these honkin wastegates to use instead... still no design elements are concrete at this point.

yesi will have two wastegates for each runner, inline with the 2nd turbo.. the primarys twin runner will be short( turblowns' cast would be a good start) and open to the primary turbo.

the ecu/// MS3-PRO... i do indeed have 3d mapping boost control, inputs for speed sensor on the turbos and two pwm generial funtion tables...

edit. holy FLUPP dude you are awesome with the Porsche 959 turbo diagrams, i havent seen those.. but i actually wondered if putting wastegates after the turbo, like where the cats would be, to keep the wastegates cooler.. and lasting longer. i"m glad to see the porchse engineers where thinking in the same box as me!

honestly i thouught the wastegate in the downpipe was better, but then i found these honkin wastegates to use instead... still no design elements are concrete at this point.

Last edited by lastphaseofthis; 07-19-16 at 06:46 AM.

#19

Arrogant Wankeler

Soo, soo much easier to compound with a low ratio blower with charge cooling or compounded turbos, you can then set it up with appropriate gate diaphragm pressure references such that the ecu drives a single solenoid like a single turbo setup.

I understand you urge for a wide torque band, to me there is nothing more frustrating than the transition lull when it should really be kicking hard.

People have some funny ideas about "turbo efficiency" too, remember that even down low the turbine and compressor on these are good relative to older designs and that total heat rejection is relative to mass flow and pressure ratio.

Think of it this way, with slightly less airflow than a 20b at the same rpm, you can spool the larger efr as well as a 20b due to the lesser volume and surface area of twin rather than triple manifold and the blower is multplying the boost, so a blower geared for 6psi base gives you a very flexible package. I would run it pre-throttle to make use of off the shelf throttle/manifold combos, easier to package charge cooler, obviously you need a bypass valve either blower integrated or exhaust style gate or plumb back bov style, to bypass the blower on cruise and maintain normal fuel consumption if post throttle.

So far as no big power supercharged rotaries getting around i haven't seen a single modern screw or internal compressor with chargecooling setup. Obviously a single turbo will have the highest outright power and efficiency as you are using wasted exhaust energy, but most of the blown rotaries are using 1930s technology.

Last edited by Slides; 07-19-16 at 07:38 AM.

#20

i would have to see a blower, capable of 400ftlbs at 3k on a rotary, and it's compressor map, do some calulations, and build the blower setup by itself and achieve those numbers, before i would go on building a compound blower setup. the fact is massive torque down low has been done on the 7670 efr, i havent seen it done on a blower on a rotary.. there are reasons for that. like most of the blowers energy goes right thru the motor and out the exhuast...

#21

Arrogant Wankeler

Even with the biggest efr by 3000rpm with a base of ~1.35 engine volume on the blower on a 13b you will be making more final boost than a lot of people are comfortable with on pump fuel. You don't want the blower to be doing all the work, that is the entire point of compounding. Not switching from one to the other, feeding the turbo (intercooled) into the blower.

With a turbo, low rpm charge loss from a blower/big overlap motor is anti-lag not waste in the top end it means emp:imp doesn't rise as quickly.

in the top end it means emp:imp doesn't rise as quickly.

With a turbo, low rpm charge loss from a blower/big overlap motor is anti-lag not waste

in the top end it means emp:imp doesn't rise as quickly.

in the top end it means emp:imp doesn't rise as quickly.

#22

Even with the biggest efr by 3000rpm with a base of ~1.35 engine volume on the blower on a 13b you will be making more final boost than a lot of people are comfortable with on pump fuel. You don't want the blower to be doing all the work, that is the entire point of compounding. Not switching from one to the other, feeding the turbo (intercooled) into the blower.

With a turbo, low rpm charge loss from a blower/big overlap motor is anti-lag not waste in the top end it means emp:imp doesn't rise as quickly.

in the top end it means emp:imp doesn't rise as quickly.

With a turbo, low rpm charge loss from a blower/big overlap motor is anti-lag not waste

in the top end it means emp:imp doesn't rise as quickly.

in the top end it means emp:imp doesn't rise as quickly.

the big giant ribbed wastegates are my 2nd turbo blocker/feeders

#24

Full Member

I know you have moved on from the blower discussion but here is a video with a Dyno screen shown at the end of a PP blowen motor but on a 20b. i know you were talking a 13b PP but for reference it was close to what what you were after earlier.

This is what they said on FB with the video.

Now with e85 in the tank Joshs nasty blowin 20b made a stonking 540whp with just 9.5lb of boost. We had to stop at just 8200 rpm as we ran out of fuel pump so there's still more left out of the ol girl. Just shows the blower can make turbo power on the little mazda motor. The sound has to be heard in person #castroledge

Now with e85 in the tank Joshs nasty blowin 20b made a stonking 540whp with just 9.5lb of boost. We had to stop at just 8200 rpm as we ran out of fuel pump so there's still more left out of the ol girl. Just shows the blower can make turbo power on the little mazda motor. The sound has to be heard in person #castroledge