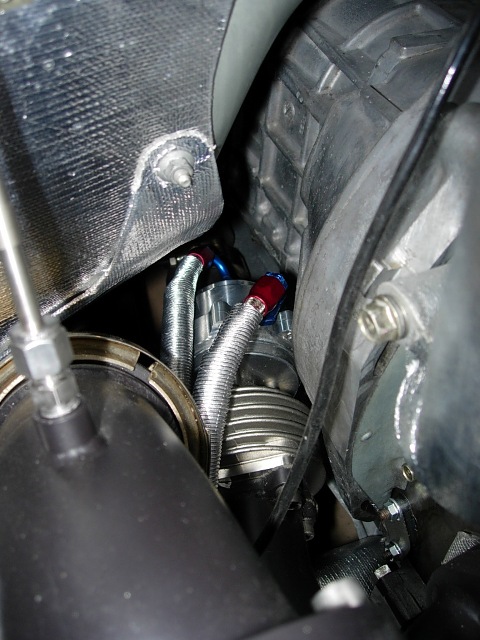

Stainles Braid Tial WG Lines

#26

Originally Posted by BLUE TII

I finally got that WG set-up to work for me without boost creep by porting the manifold and turbo exhaust housing very large up to the WG runners.

Fixed boost creep, but hurt boost response a bit since the stock velocity stacks in the manifold are ported to almost none. I still hits max boost at same rpms (15psi 3,300rpm in 5th), but boost below 3,000rpm boost is lower/slower than it was.

My next stock hybrid will circumvent this problem by putting the WG runners in the manifold right before the velocity stacks and angled so flow wants to exit the WG.

I think that if I put the WG runners in the right spot the turbulence at the far edge of the WG runners will just act as part of the velcocity stack and so not be detrimental to flow.

I am thinking two little Tial WGs to keep it divided instead of one large one with a divider. That WG divider pictured broke again even though it was 1/8" thick SS with a floating design for expansion.

I am thinking of using the BB T04B (T04S) center section and HiFi housing as well.

Anyways, the turbo/WG is working great now. Most of the time Auto-X ing I am having to short shift it keeping it out of the powerband to keep the RA-1s from spinning- but having the power to burn out there on the streets sure is nice. :P

Fixed boost creep, but hurt boost response a bit since the stock velocity stacks in the manifold are ported to almost none. I still hits max boost at same rpms (15psi 3,300rpm in 5th), but boost below 3,000rpm boost is lower/slower than it was.

My next stock hybrid will circumvent this problem by putting the WG runners in the manifold right before the velocity stacks and angled so flow wants to exit the WG.

I think that if I put the WG runners in the right spot the turbulence at the far edge of the WG runners will just act as part of the velcocity stack and so not be detrimental to flow.

I am thinking two little Tial WGs to keep it divided instead of one large one with a divider. That WG divider pictured broke again even though it was 1/8" thick SS with a floating design for expansion.

I am thinking of using the BB T04B (T04S) center section and HiFi housing as well.

Anyways, the turbo/WG is working great now. Most of the time Auto-X ing I am having to short shift it keeping it out of the powerband to keep the RA-1s from spinning- but having the power to burn out there on the streets sure is nice. :P

That is quite ported. I slapped a Tial 38MM on a stock S4 exhaust manifold for Node. Curious to see how well that will work. I'm also curious to see if there is a power increase..

#28

thats not paint....

Since on most external wastegate setups, the bottom side of the diaphragm is connected to manifold pressure, it is the main concern for protecting you motor against overboosting right?

This way if something happens to the other line, you might loose boost control, but your wastegate will open up at whatever your wastegate spring is. There is no way to overboost.

I only brought it up because some of the boost controllers with dual solenoids have nipples coming off the controller box. Which would bring the wastegate line back to silicone with clams or zip ties at some point.

This way if something happens to the other line, you might loose boost control, but your wastegate will open up at whatever your wastegate spring is. There is no way to overboost.

I only brought it up because some of the boost controllers with dual solenoids have nipples coming off the controller box. Which would bring the wastegate line back to silicone with clams or zip ties at some point.

#30

No heat issues to date, removing and uncluttering the space between the engine and the UIM really helped with the heat in that area and with my temp gun I periodically check the area and no temperatures of concern are ever noticed.

#31

I used SS lines on my HKS GT 60mm wastegate. Make sure you use swivel fittings so the hose can rotate even when tightened or it can loosen up easily from the weight of the hose/vibration.

I later added a Hallman Pro manual boost controller and fit it up for -AN lines as well. That was a bit of a pain as the lower nipple is also the valve seat for the ball and the side nipple has the bleed hole.- worked out very well in the end.

I later added a Hallman Pro manual boost controller and fit it up for -AN lines as well. That was a bit of a pain as the lower nipple is also the valve seat for the ball and the side nipple has the bleed hole.- worked out very well in the end.

Fellas, what fittings are you guys using on the turbo front cover? My turbo does not have a nipple\fitting on the front cover, so I'll have to drill and tap.

#41

It tends to spike less. I could be wrong, but I suspect it's because, after the pressure drop of the IC, you get less of a pressure signal to the top of the wastegate. Thus it's easier to tune the gain/duty cycle on the wastegate solenoid, which is hooked into the top port on a typical EBC setup. The more pressure the top of the wastegate receives, the more force is pushing down on it to keep it closed. It is the opposite on the lower port (it's like an internal WG) -- the more pressure it receives, the more it opens the wastegate to vent exhaust.

#43

Perpetual Rebuilder

it is a very good idea to do this for high boost applications. on my car awhile back i had regular rubber hose with a zip tie. one night on 100 octane i was really pushing the car hard (tuned for 27psi) and the line to the wastegate blew off. ended up at 38psi for a few seconds.

stainless lines w/ nice fittings ftw!

stainless lines w/ nice fittings ftw!

I lost my first engine from wastegate hose failure. Mine is now threaded connectors on both sides and I am using a stainless hose, wrapped in insulation, and covered with a silicon/teflon type material (hose i found at a local race shop).

If you havent done this do it now.

#45

It tends to spike less. I could be wrong, but I suspect it's because, after the pressure drop of the IC, you get less of a pressure signal to the top of the wastegate. Thus it's easier to tune the gain/duty cycle on the wastegate solenoid, which is hooked into the top port on a typical EBC setup. The more pressure the top of the wastegate receives, the more force is pushing down on it to keep it closed. It is the opposite on the lower port (it's like an internal WG) -- the more pressure it receives, the more it opens the wastegate to vent exhaust.

Didn't know that, but I'm a rookie at this aftermarket turbo\wg stuff.

Not sure if it would matter on my case, but I don't plan on running an IC.

#46

I am currently running my boost controller off of one of the nipples on the UIM. I know this probably isn't ideal but it was for convenience and initial setup of the EBC (to get a general idea). It seems to work ok, but I think the EBC functions better pulling pressure off of the compressor housing. Since there is almost 0 pressure drop in my intercoolerless setup...I am not sure that it matters a whole lot....

#47

Anyone know off hand what the thread pitch is for the Greddy solenoid? Looks to be similar to 1/8th NPT ... could be m10 like the wastegate too. I'm not sure. It isn't listed in the manual.

#48

I used hard lines and tube nuts. Much cheaper than SS and you don't have to insulate it. Where the lines connect to the solinoid i used short sections of rubber hose and AN fittings.

I was always told to get the boost signal (high boost setup) straight from the compressor housing because the signal is stronger. That way you have more pressure available to open the wastegate and hold it closed.

I was always told to get the boost signal (high boost setup) straight from the compressor housing because the signal is stronger. That way you have more pressure available to open the wastegate and hold it closed.

#49

Funny it happened this way, but the vacuum line came off the wastegate on my way home from the parts store today... 2nd gear I was full throttle from 3000-6000 rpm, I was watching the AFR gauge (around 10:1) and I saw out of the corner of my eye, the boost gauge warning light come on...too late... Lost the engine.

Open my hood to find the wastegate line dangling... I had just ordered the majority of the fittings from Summit.

Now going LS2. My rotary related parts will be parted out.

Open my hood to find the wastegate line dangling... I had just ordered the majority of the fittings from Summit.

Now going LS2. My rotary related parts will be parted out.

#50

Funny it happened this way, but the vacuum line came off the wastegate on my way home from the parts store today... 2nd gear I was full throttle from 3000-6000 rpm, I was watching the AFR gauge (around 10:1) and I saw out of the corner of my eye, the boost gauge warning light come on...too late... Lost the engine.

Open my hood to find the wastegate line dangling... I had just ordered the majority of the fittings from Summit.

Now going LS2. My rotary related parts will be parted out.

Open my hood to find the wastegate line dangling... I had just ordered the majority of the fittings from Summit.

Now going LS2. My rotary related parts will be parted out.

You are joking, right? (please, let this be a joke

)

)Water\Meth injection didn't save ur engine?