Power potential of this setup?

#1

Eats, Sleeps, Dreams Rotary

Thread Starter

Power potential of this setup?

I'm curious to know how much power my car could potentially make.

It's a stock 13BREW with a TD06-25G (no air pump), V-mount (moderate size), resonated mid-pipe, and a fairly large exhaust (about 3.5 inches I think), stock injectors, Power FC, and fuel pressure regulator...

It makes about 350 HP at 0.8 bar (11.6 psi) boost, which is a conservative setting for durability. How much could I make with upgraded injectors and tuning?

400? 420?

How much would this setup make with a street port?

It's a stock 13BREW with a TD06-25G (no air pump), V-mount (moderate size), resonated mid-pipe, and a fairly large exhaust (about 3.5 inches I think), stock injectors, Power FC, and fuel pressure regulator...

It makes about 350 HP at 0.8 bar (11.6 psi) boost, which is a conservative setting for durability. How much could I make with upgraded injectors and tuning?

400? 420?

How much would this setup make with a street port?

#2

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,864

Received 2,621 Likes

on

1,858 Posts

the Greddy turbo handbook says a 25G turbo can flow 25 m^3 of air, and the rotary will make 468.75hp at the flywheel.

#3

How much would this setup make with a street port?

Porting cannot change how much the turbo can flow, so peak power is the same on a given turbo no matter what ports (or number of rotors).

But, you can max the turbo flow out much sooner in the engine RPMs and at lower boost by using ports that flow more for a broader power band and less exhaust manifold pressure. Both of which will improve reliability.

If you are not currently maxing a turbo out on flow, porting or more rotors can add more power at the same boost as you are currently running.

It is just like cams and displacement on a piston engine.

Porting cannot change how much the turbo can flow, so peak power is the same on a given turbo no matter what ports (or number of rotors).

But, you can max the turbo flow out much sooner in the engine RPMs and at lower boost by using ports that flow more for a broader power band and less exhaust manifold pressure. Both of which will improve reliability.

If you are not currently maxing a turbo out on flow, porting or more rotors can add more power at the same boost as you are currently running.

It is just like cams and displacement on a piston engine.

#4

How much would this setup make with a street port?

Porting cannot change how much the turbo can flow, so peak power is the same on a given turbo no matter what ports (or number of rotors).

But, you can max the turbo flow out much sooner in the engine RPMs and at lower boost by using ports that flow more for a broader power band and less exhaust manifold pressure. Both of which will improve reliability.

If you are not currently maxing a turbo out on flow, porting or more rotors can add more power at the same boost as you are currently running.

It is just like cams and displacement on a piston engine.

Porting cannot change how much the turbo can flow, so peak power is the same on a given turbo no matter what ports (or number of rotors).

But, you can max the turbo flow out much sooner in the engine RPMs and at lower boost by using ports that flow more for a broader power band and less exhaust manifold pressure. Both of which will improve reliability.

If you are not currently maxing a turbo out on flow, porting or more rotors can add more power at the same boost as you are currently running.

It is just like cams and displacement on a piston engine.

I guess this is why I don't agree/understand the "[engine] porting hurts [turbo] spool" line of thought. I am not saying that it is an incorrect statement, however, is the ported engine now producing same or more HP/TQ lower in the powerband, even though spoolup is "slower"?

#5

I guess this is why I don't agree/understand the "[engine] porting hurts [turbo] spool" line of thought. I am not saying that it is an incorrect statement, however, is the ported engine now producing same or more HP/TQ lower in the powerband, even though spoolup is "slower"?

Think your Ho/tq figures would be higher bottom end because may spool slower but you can move more air through that engine with a larger port

#6

KNONFS

I guess this is why I don't agree/understand the "[engine] porting hurts [turbo] spool" line of thought. I am not saying that it is an incorrect statement, however, is the ported engine now producing same or more HP/TQ lower in the powerband, even though spoolup is "slower"?

Well, the ported engine maxing out a turbo's compressor flow will move peak power down in rpms compared to a non-ported engine peak power,

but obviously you only max the turbo compressor flow out once it is spooled.

You can really see this on JDM semi-p-port and bridgeport T04Z circuit cars. They make great midrange, but max the T04Z turbo flow early and so have a low redline/shift point.

One Hot Version I was watching they taped a big red arrow on the tachometer at 7,000rpm to remind the drivers to shift up to the next gear to land back into peak torque instead of driving the rotary out to mechanical redline as they are used to.

-----

Really it depends on how the engine in ported on whether it hurts spool or helps spool and low rpm power.

Later intake closing increases intake reversion and larger runners on intake and exhaust slow velocity and increase reversion -so that does hurt spool and low end power.

Earlier opening intake and earlier opening exhaust by themselves will help spool.

It is possible to hurt spool with earlier opening intake and exhaust if you increase port volume and decrease velocity.

Early opening intake increases engine VE from idle up which increases the amount of engine power and therefore exhaust gas at any rpm.

You can clearly see this on dynocharts from the development of the rotary engine from various manufacturers in the '60s where they were choosing port configuration (side port versus peripheral port). They picked the rpm they wanted peak power and made side port engines and peripheral port engines with same peak power rpm. The peripheal port engines make more power/higher VE from idle to redline. I have posted these before.

Early opening exhaust dumps more high energy expanding exhaust into the exhaust manifold to spool the turbo. Early opening exhaust has a small detriment to engine low rpm power (and can have a big detriment on low rpm power if it enlarges the exhaust port volume excessively- that is why you port "down & round" not square for low rpm turbo torque), but on the turbo rotary it is more than offset by the increased boost pressure from spooling the turbo earlier.

Boost is how you get low rpm torque on the "undersquare" rotary.

Trending Topics

#8

KNONFS

I guess this is why I don't agree/understand the "[engine] porting hurts [turbo] spool" line of thought. I am not saying that it is an incorrect statement, however, is the ported engine now producing same or more HP/TQ lower in the powerband, even though spoolup is "slower"?

Well, the ported engine maxing out a turbo's compressor flow will move peak power down in rpms compared to a non-ported engine peak power,

but obviously you only max the turbo compressor flow out once it is spooled.

You can really see this on JDM semi-p-port and bridgeport T04Z circuit cars. They make great midrange, but max the T04Z turbo flow early and so have a low redline/shift point.

One Hot Version I was watching they taped a big red arrow on the tachometer at 7,000rpm to remind the drivers to shift up to the next gear to land back into peak torque instead of driving the rotary out to mechanical redline as they are used to.

-----

Really it depends on how the engine in ported on whether it hurts spool or helps spool and low rpm power.

Later intake closing increases intake reversion and larger runners on intake and exhaust slow velocity and increase reversion -so that does hurt spool and low end power.

Earlier opening intake and earlier opening exhaust by themselves will help spool.

It is possible to hurt spool with earlier opening intake and exhaust if you increase port volume and decrease velocity.

Early opening intake increases engine VE from idle up which increases the amount of engine power and therefore exhaust gas at any rpm.

You can clearly see this on dynocharts from the development of the rotary engine from various manufacturers in the '60s where they were choosing port configuration (side port versus peripheral port). They picked the rpm they wanted peak power and made side port engines and peripheral port engines with same peak power rpm. The peripheal port engines make more power/higher VE from idle to redline. I have posted these before.

Early opening exhaust dumps more high energy expanding exhaust into the exhaust manifold to spool the turbo. Early opening exhaust has a small detriment to engine low rpm power (and can have a big detriment on low rpm power if it enlarges the exhaust port volume excessively- that is why you port "down & round" not square for low rpm turbo torque), but on the turbo rotary it is more than offset by the increased boost pressure from spooling the turbo earlier.

Boost is how you get low rpm torque on the "undersquare" rotary.

Truth be told, my question was more of a "sarcastic" one (not really intended for you), as we have agreed on some of you other post that "overlap y escape" is the way to go for a street car . There are some of the "reputable" posters that constantly use the "porting" hurts spoolup blank statement; was trying to get them to chime in, but with your response, I doubt anybody will post any refutable information/idea/comments

#9

Yes, but I also tend to agree with the other "reputable" sources because all the available porting templates I have seen will hurt spool.

All the porting templates I have seen increase port closing timing.

I am saying it is possible to port for increased low rpm power (NA and turbo) and increased spool (turbo), but I haven't seen anyone else doing it.

---------

Rotaries are "different".

In the case of the early opening street port, it isn't even the case that you are adding overlap.

What?

The peripheral exhaust port is open to the expanding rotor intake stroke whether the intake port is open or not.

Yes, the intake port hasn't opened yet, but the engine is still in the intake stroke for 32 degrees (86-88) or 45 degrees (89-2002) after bottom dead center drawing only exhaust into the engine intake stroke before the intake port opens.

No doubt this internal EGR helps with emissions.

When you do an early opening street port you are not really adding overlap, you are just opening the intake port earlier so the engine intake stroke has a chance to draw in more air along with the exhaust. You are allowing the exhaust port overlap already designed into the engine to have the positive attributes of overlap instead of just the negative attributes of overlap.

Now, if you are porting the intake to open before top dead center you are adding overlap to the engine as well as enabling the exhaust port overlap already designed in to work correctly.

All the porting templates I have seen increase port closing timing.

I am saying it is possible to port for increased low rpm power (NA and turbo) and increased spool (turbo), but I haven't seen anyone else doing it.

---------

Rotaries are "different".

In the case of the early opening street port, it isn't even the case that you are adding overlap.

What?

The peripheral exhaust port is open to the expanding rotor intake stroke whether the intake port is open or not.

Yes, the intake port hasn't opened yet, but the engine is still in the intake stroke for 32 degrees (86-88) or 45 degrees (89-2002) after bottom dead center drawing only exhaust into the engine intake stroke before the intake port opens.

No doubt this internal EGR helps with emissions.

When you do an early opening street port you are not really adding overlap, you are just opening the intake port earlier so the engine intake stroke has a chance to draw in more air along with the exhaust. You are allowing the exhaust port overlap already designed into the engine to have the positive attributes of overlap instead of just the negative attributes of overlap.

Now, if you are porting the intake to open before top dead center you are adding overlap to the engine as well as enabling the exhaust port overlap already designed in to work correctly.

#10

Yes, but I also tend to agree with the other "reputable" sources because all the available porting templates I have seen will hurt spool.

All the porting templates I have seen increase port closing timing.

I am saying it is possible to port for increased low rpm power (NA and turbo) and increased spool (turbo), but I haven't seen anyone else doing it.

All the porting templates I have seen increase port closing timing.

I am saying it is possible to port for increased low rpm power (NA and turbo) and increased spool (turbo), but I haven't seen anyone else doing it.

Fair statement, was not thinking about that part, where most people just follow a port template to the T.

---------

Rotaries are "different".

In the case of the early opening street port, it isn't even the case that you are adding overlap.

What?

The peripheral exhaust port is open to the expanding rotor intake stroke whether the intake port is open or not.

Yes, the intake port hasn't opened yet, but the engine is still in the intake stroke for 32 degrees (86-88) or 45 degrees (89-2002) after bottom dead center drawing only exhaust into the engine intake stroke before the intake port opens.

No doubt this internal EGR helps with emissions.

When you do an early opening street port you are not really adding overlap, you are just opening the intake port earlier so the engine intake stroke has a chance to draw in more air along with the exhaust. You are allowing the exhaust port overlap already designed into the engine to have the positive attributes of overlap instead of just the negative attributes of overlap.

Now, if you are porting the intake to open before top dead center you are adding overlap to the engine as well as enabling the exhaust port overlap already designed in to work correctly.

Rotaries are "different".

In the case of the early opening street port, it isn't even the case that you are adding overlap.

What?

The peripheral exhaust port is open to the expanding rotor intake stroke whether the intake port is open or not.

Yes, the intake port hasn't opened yet, but the engine is still in the intake stroke for 32 degrees (86-88) or 45 degrees (89-2002) after bottom dead center drawing only exhaust into the engine intake stroke before the intake port opens.

No doubt this internal EGR helps with emissions.

When you do an early opening street port you are not really adding overlap, you are just opening the intake port earlier so the engine intake stroke has a chance to draw in more air along with the exhaust. You are allowing the exhaust port overlap already designed into the engine to have the positive attributes of overlap instead of just the negative attributes of overlap.

Now, if you are porting the intake to open before top dead center you are adding overlap to the engine as well as enabling the exhaust port overlap already designed in to work correctly.

Help me see your idea, how would you port in order to open the intake before TDC? Wouldn't that be porting down (towards the crank case?) Man, I am having a hard time picturing it

It is understood that there is an inherit overlap on engines with side intake ports + peripheral exhaust ports. If that's the case, wouldn't it be true that opening the intake earlier, increases overlap? Same with if you open the exhaust port earlier?

Not sure if I am utterly confused, or if we are stating the same thing

I guess this is the comment one that is really "blowing my mind":

When you do an early opening street port you are not really adding overlap, you are just opening the intake port earlier so the engine intake stroke has a chance to draw in more air along with the exhaust. You are allowing the exhaust port overlap already designed into the engine to have the positive attributes of overlap instead of just the negative attributes of overlap.

Last edited by KNONFS; 07-15-16 at 11:48 AM.

#11

Well, the stock Mazda '67-2002 rotaries are in a unique position of having overlap and an intake port that opens after top dead center.

It is a completely idiotic scheme, but it worked best for them based on the limitations of the combination of peripheral exhaust port and side intake port.

--------

If you look for a definition of overlap you will get definitions for "valve timing overlap" from piston engines. OK, we already know that definition won't work.

--------

What I am pointing out is-

the peripheral exhaust port overlap into the engine intake stroke phase is set.

If the intake isn't open yet (it isn't stock) the engine will pull exhaust into the engine intake stroke.

^^ we agree this is definitely overlap even though the intake port isn't open yet, right?. It is exhaust port overlap into the engine intake stroke timing.

Now, if we open the intake port earlier (but not before top dead center) the engine can pull intake or exhaust into the intake stroke and intake air can go out the exhaust port.

^^ is this really adding "more" overlap or is it just actually "correcting" the overlap that is already there.

Now we have exhaust port overlap into the engine intake stroke timing which also corresponds to overlap with the intake port timing.

It is a completely idiotic scheme, but it worked best for them based on the limitations of the combination of peripheral exhaust port and side intake port.

--------

If you look for a definition of overlap you will get definitions for "valve timing overlap" from piston engines. OK, we already know that definition won't work.

--------

What I am pointing out is-

the peripheral exhaust port overlap into the engine intake stroke phase is set.

If the intake isn't open yet (it isn't stock) the engine will pull exhaust into the engine intake stroke.

^^ we agree this is definitely overlap even though the intake port isn't open yet, right?. It is exhaust port overlap into the engine intake stroke timing.

Now, if we open the intake port earlier (but not before top dead center) the engine can pull intake or exhaust into the intake stroke and intake air can go out the exhaust port.

^^ is this really adding "more" overlap or is it just actually "correcting" the overlap that is already there.

Now we have exhaust port overlap into the engine intake stroke timing which also corresponds to overlap with the intake port timing.

Last edited by BLUE TII; 07-15-16 at 12:28 PM.

#12

I thought of an easy example to illustrate my point.

Single cam shaft piston engine.

You grind a cam with intake and exhaust overlap of 90 degrees of crankshaft rotation.

Now you put that cam in the engine timed 45 crankshaft degrees advanced*. The exhaust valve will still be open with the intake valve for 90 degrees crankshaft rotation, but for 0 degrees of engine exhaust stroke.

Exhaust and intake valves will only be open together during the engine intake stroke.

Do you still have 90 degrees of overlap since you haven't changed the cam shaft specifications or do you have 45 degrees of stupidity?

*originally typed retarded retardedly

Single cam shaft piston engine.

You grind a cam with intake and exhaust overlap of 90 degrees of crankshaft rotation.

Now you put that cam in the engine timed 45 crankshaft degrees advanced*. The exhaust valve will still be open with the intake valve for 90 degrees crankshaft rotation, but for 0 degrees of engine exhaust stroke.

Exhaust and intake valves will only be open together during the engine intake stroke.

Do you still have 90 degrees of overlap since you haven't changed the cam shaft specifications or do you have 45 degrees of stupidity?

*originally typed retarded retardedly

Last edited by BLUE TII; 07-15-16 at 03:23 PM.

#13

Well, the stock Mazda '67-2002 rotaries are in a unique position of having overlap and an intake port that opens after top dead center.

It is a completely idiotic scheme, but it worked best for them based on the limitations of the combination of peripheral exhaust port and side intake port.

--------

If you look for a definition of overlap you will get definitions for "valve timing overlap" from piston engines. OK, we already know that definition won't work.

--------

What I am pointing out is-

the peripheral exhaust port overlap into the engine intake stroke phase is set.

If the intake isn't open yet (it isn't stock) the engine will pull exhaust into the engine intake stroke.

^^ we agree this is definitely overlap even though the intake port isn't open yet, right?. It is exhaust port overlap into the engine intake stroke timing.

Now, if we open the intake port earlier (but not before top dead center) the engine can pull intake or exhaust into the intake stroke and intake air can go out the exhaust port.

^^ is this really adding "more" overlap or is it just actually "correcting" the overlap that is already there.

Now we have exhaust port overlap into the engine intake stroke timing which also corresponds to overlap with the intake port timing.

It is a completely idiotic scheme, but it worked best for them based on the limitations of the combination of peripheral exhaust port and side intake port.

--------

If you look for a definition of overlap you will get definitions for "valve timing overlap" from piston engines. OK, we already know that definition won't work.

--------

What I am pointing out is-

the peripheral exhaust port overlap into the engine intake stroke phase is set.

If the intake isn't open yet (it isn't stock) the engine will pull exhaust into the engine intake stroke.

^^ we agree this is definitely overlap even though the intake port isn't open yet, right?. It is exhaust port overlap into the engine intake stroke timing.

Now, if we open the intake port earlier (but not before top dead center) the engine can pull intake or exhaust into the intake stroke and intake air can go out the exhaust port.

^^ is this really adding "more" overlap or is it just actually "correcting" the overlap that is already there.

Now we have exhaust port overlap into the engine intake stroke timing which also corresponds to overlap with the intake port timing.

#14

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,864

Received 2,621 Likes

on

1,858 Posts

Yes, the intake port hasn't opened yet, but the engine is still in the intake stroke for 32 degrees (86-88) or 45 degrees (89-2002) after bottom dead center drawing only exhaust into the engine intake stroke before the intake port opens.

No doubt this internal EGR helps with emissions.

No doubt this internal EGR helps with emissions.

#15

Got you, now I need to go and play with one of the scrap rotor housing, intake housing, and rotor, to visually confirm it. I've always been under the impression that in stock form, there was a minimal {piston engine definition} of overlap, where the exhaust port and intake port were "open" at the same time. This "discussion" has been enlightening, thanks!

the amount of time the intake and exhaust are open is very minimal, because the intake port opens late.. the problem isn't the valves being open togather,,

but the chamber volume is growing larger(sucking air in) before the intake is open.. so it pulls on the {open during INTAKE STROKE}Exhaust port.. the stroke and the exhaust valve open are overlapped, but not the intake valve itself....

#16

Arrogant Wankeler

I'm going to go against exhaust port timing fixes overlap, that is like saying on a twin cam piston engine that exhaust cam timing relative only to crank timing controls overlap, which is incorrect, regardless of cam/port to crank/nominal stroke timing it is only overlap when both ports are open. The dynamic stroke phasing is different to crank phasing and the relative timing of both intake and exhaust effect it.

If you wanted to mess about with a piston motor you could easily have a zero overlap engine whose exhaust didn't close till after 0/720 TDC, intake only opening say after 45 degrees. Would still be zero overlap if the intake didn't coincide with it, regardless or whether the piston is moving down the bore with exhaust valve/port open or not.

If you wanted to mess about with a piston motor you could easily have a zero overlap engine whose exhaust didn't close till after 0/720 TDC, intake only opening say after 45 degrees. Would still be zero overlap if the intake didn't coincide with it, regardless or whether the piston is moving down the bore with exhaust valve/port open or not.

Last edited by Slides; 07-19-16 at 08:01 AM.

#17

I'm going to go against exhaust port timing fixes overlap, that is like saying on a twin cam piston engine that exhaust cam timing relative only to crank timing controls overlap, which is incorrect, regardless of cam/port to crank/nominal stroke timing it is only overlap when both ports are open. The dynamic stroke phasing is different to crank phasing and the relative timing of both intake and exhaust effect it.

If you wanted to mess about with a piston motor you could easily have a zero overlap engine whose exhaust didn't close till after 0/720 TDC, intake only opening say after 45 degrees. Would still be zero overlap if the intake didn't coincide with it, regardless or whether the piston is moving down the bore with exhaust valve/port open or not.

If you wanted to mess about with a piston motor you could easily have a zero overlap engine whose exhaust didn't close till after 0/720 TDC, intake only opening say after 45 degrees. Would still be zero overlap if the intake didn't coincide with it, regardless or whether the piston is moving down the bore with exhaust valve/port open or not.

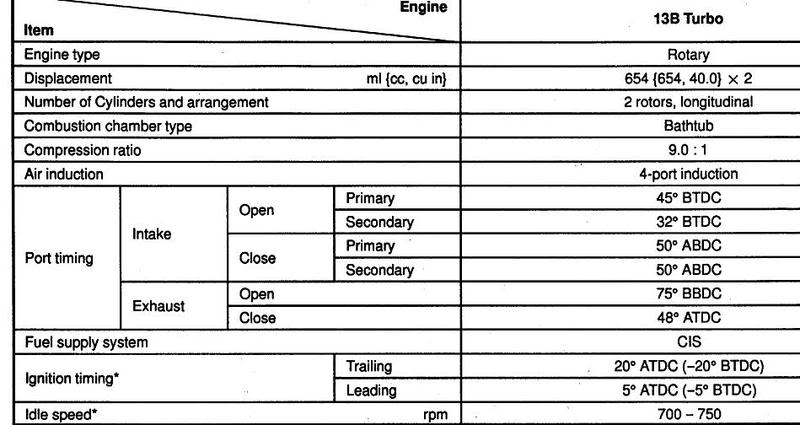

look at the timing between these tables...

compare exhaust closing, and intake opening, on the rx8 it clearly shows the exhuast closing 3 degrees before TDC, and intake opening 3 degrees after.

#18

What Slides is saying is the standard definition of overlap is-

"the duration in crank shaft degrees that both intake and exhaust valves are both open."

He is mutating that definition for the rotary so it reads-

"the duration in eccentric shaft degrees that both the intake and exhaust ports are both open."

I am saying you cannot neatly create the peripheral port rotary engine definition of overlap by changing a few words of the piston engine overlap without introducing misconceptions.

Because this definition simply doesn't cover that fact that from 1967 to 2002 Mazda had to have the intake port open After Top Dead Center for rotary specific reasons.

To say that opening the intake up at 0 degrees After Top Dead Center or later is "adding overlap" to the engine to suite your definition of overlap is only going to cause misconceptions.

"the duration in crank shaft degrees that both intake and exhaust valves are both open."

He is mutating that definition for the rotary so it reads-

"the duration in eccentric shaft degrees that both the intake and exhaust ports are both open."

I am saying you cannot neatly create the peripheral port rotary engine definition of overlap by changing a few words of the piston engine overlap without introducing misconceptions.

Because this definition simply doesn't cover that fact that from 1967 to 2002 Mazda had to have the intake port open After Top Dead Center for rotary specific reasons.

To say that opening the intake up at 0 degrees After Top Dead Center or later is "adding overlap" to the engine to suite your definition of overlap is only going to cause misconceptions.

#19

yeah i was getting lost in the words.

wait what.. the chart above say 45 B tdc.. which means it opens way sooner then the rx8.. i m trying to wrap my head around how mazda changed to port timing that much without moving the port very much, .. and the scalps just make the port timing even sooner on the rx8, yet the rx8 is 48 degrees later? (45-tdc+3)

or is that chart labeled wrong?

Because this definition simply doesn't cover that fact that from 1967 to 2002 Mazda had to have the intake port open After Top Dead Center for rotary specific reasons.

or is that chart labeled wrong?

Last edited by lastphaseofthis; 07-19-16 at 01:21 PM.

#20

wait what.. the chart above say 45 B tdc..

Yeah, someone who knows how a 4 stroke engine operates must have edited that chart before publication.

The real intake opening is 45 degrees After Top Dead Center for the primary and 32 degrees After Top Dead Center for the secondary ports from 1989 to 2002.

Yeah, someone who knows how a 4 stroke engine operates must have edited that chart before publication.

The real intake opening is 45 degrees After Top Dead Center for the primary and 32 degrees After Top Dead Center for the secondary ports from 1989 to 2002.

#21

I'm going to go against exhaust port timing fixes overlap, that is like saying on a twin cam piston engine that exhaust cam timing relative only to crank timing controls overlap, which is incorrect, regardless of cam/port to crank/nominal stroke timing it is only overlap when both ports are open. The dynamic stroke phasing is different to crank phasing and the relative timing of both intake and exhaust effect it.

So Slides, on a rotary you want to ignore what stroke the rotary engine is on when determining port timing for overlap.

OK... now when does the peripheral exhaust port open or close exactly. Never, it is always open.

It is always open to either exhaust or intake or both strokes.

So, is the rotary overlap then the full duration of the intake stroke?

You have created a definition of overlap for the rotary from the definition of overlap for a 4 stroke piston engine and the definition does not fit the rotary.

Your definition of peripheral exhaust port rotary overlap-

"The duration in eccentric shaft degrees that both the intake and exhaust ports are both open. The exhaust port is always open."

So Slides, on a rotary you want to ignore what stroke the rotary engine is on when determining port timing for overlap.

OK... now when does the peripheral exhaust port open or close exactly. Never, it is always open.

It is always open to either exhaust or intake or both strokes.

So, is the rotary overlap then the full duration of the intake stroke?

You have created a definition of overlap for the rotary from the definition of overlap for a 4 stroke piston engine and the definition does not fit the rotary.

Your definition of peripheral exhaust port rotary overlap-

"The duration in eccentric shaft degrees that both the intake and exhaust ports are both open. The exhaust port is always open."

#22

Arrogant Wankeler

You have to move with each chamber, not sit fixed on the housing. If the exhaust port was open to the chamber for the whole engine cycle you would have a pulse jet not a 4 stroke SI engine which it most certainly is. Each chamber has a definite period in terms of rotor degrees which it is open to exhaust or intake. I don't know if you are being intentionally facetious or can't get you head around the fact that due to the long (in crank degrees) rotary cycle that a particular engine angle(0-360) doesn't clearly define the position of a particular chamber in its 360 degree (1080 crank degree) cycle. Clearly the exhaust port is closed to any particular chamber you consider for the majority of the intake stroke.

All you have said is for practical application in a car at automotive rpm a peripheral exhaust port and side or pp intake must have overlap to produce reasonable performance in the field, it is by no means a physical limitation on port timing you could choose to run. I really don't get why you have your knickers in a twist about it, or are saying overlap is somehow different to a 4 stroke piston motor.

It really doesn't matter what the swept volume is doing, increasing or decreasing, you can't really call it start of intake until the intake is actually open. Do you lose your mind when you see the exhaust phase on a piston motor start while the piston is still heading down the bore on the "power stroke"? Rotaries do exactly the same thing as most "performance" 4 stroke piston engines in terms of port open timing relative to chamber volume movement on intake and exhaust, it is no different, the description in crank degrees is just a bit muddled as we go back to 0 from 360 instead of counting to full 1080 like most people do (720) on piston motors.

All you have said is for practical application in a car at automotive rpm a peripheral exhaust port and side or pp intake must have overlap to produce reasonable performance in the field, it is by no means a physical limitation on port timing you could choose to run. I really don't get why you have your knickers in a twist about it, or are saying overlap is somehow different to a 4 stroke piston motor.

It really doesn't matter what the swept volume is doing, increasing or decreasing, you can't really call it start of intake until the intake is actually open. Do you lose your mind when you see the exhaust phase on a piston motor start while the piston is still heading down the bore on the "power stroke"? Rotaries do exactly the same thing as most "performance" 4 stroke piston engines in terms of port open timing relative to chamber volume movement on intake and exhaust, it is no different, the description in crank degrees is just a bit muddled as we go back to 0 from 360 instead of counting to full 1080 like most people do (720) on piston motors.

Last edited by Slides; 07-20-16 at 12:08 AM.

#23

I was not being facetious.

I was pointing out you define rotary overlap by port timing without consideration to what stroke the engine is in, but following one rotor face through its strokes (how is that possible while not considering what stroke the engine in in).

This isn't a pedantic argument, the peripheral port exhaust rotary overlap is characterized by the constant flow open exhaust port, the shape of the rotor, shape and position of ports and the intake stroke above it more than by the degrees of overlap using your piston valve timing "equivalent" focusing on one rotor face.

If the exhaust port was open to the chamber for the whole engine cycle you would have a pulse jet not a 4 stroke SI engine which it most certainly is.

You will begin to understand rotary overlap when you realize that the peripheral exhaust port is a pulse jet with external combustion in addition to the rotary also operating as a 4 stroke internal combustion engine.

----------

So, if we keep your definition of rotary overlap as-

"The duration in eccentric shaft degrees that both the intake and exhaust ports are both open to one rotor face as it cycles through the exhaust and intake strokes."

we have to come up with a useful term that will sidestep your definition of rotary overlap so we can examine the effects of overlap in the rotary engine.

I will call this "rotary dynamic overlap"

Definition: Overlap as applied to the rotary engine factoring in actual operating principals.

Think of it much like the definition of Compression Ratio (Static) versus the definition of Dynamic Compression Ratio in a piston engine. They are both Compression Ratio, but one actually factors in operating principles.

I was pointing out you define rotary overlap by port timing without consideration to what stroke the engine is in, but following one rotor face through its strokes (how is that possible while not considering what stroke the engine in in).

This isn't a pedantic argument, the peripheral port exhaust rotary overlap is characterized by the constant flow open exhaust port, the shape of the rotor, shape and position of ports and the intake stroke above it more than by the degrees of overlap using your piston valve timing "equivalent" focusing on one rotor face.

If the exhaust port was open to the chamber for the whole engine cycle you would have a pulse jet not a 4 stroke SI engine which it most certainly is.

You will begin to understand rotary overlap when you realize that the peripheral exhaust port is a pulse jet with external combustion in addition to the rotary also operating as a 4 stroke internal combustion engine.

----------

So, if we keep your definition of rotary overlap as-

"The duration in eccentric shaft degrees that both the intake and exhaust ports are both open to one rotor face as it cycles through the exhaust and intake strokes."

we have to come up with a useful term that will sidestep your definition of rotary overlap so we can examine the effects of overlap in the rotary engine.

I will call this "rotary dynamic overlap"

Definition: Overlap as applied to the rotary engine factoring in actual operating principals.

Think of it much like the definition of Compression Ratio (Static) versus the definition of Dynamic Compression Ratio in a piston engine. They are both Compression Ratio, but one actually factors in operating principles.

#24

Arrogant Wankeler

You are describing the interference between the blowdown from the start of the following face with the one which is overlapping intake? Yes, that is an "overlap" you are unlikely to see on a modern piston engine, but there have been plenty of siamese port multi-cylinder engines in the past, same effects.

If you are still talking about intake to exhaust there is no difference to the 4 stroke piston, dynamic compression/mass inertia/ram effects whatever you want to call it.

If you are still talking about intake to exhaust there is no difference to the 4 stroke piston, dynamic compression/mass inertia/ram effects whatever you want to call it.

Last edited by Slides; 07-20-16 at 04:26 AM.

#25

You are describing the interference between the blowdown from the start of the following face with the one which is overlapping intake? Yes, that is an "overlap" you are unlikely to see on a modern piston engine, but there have been plenty of siamese port multi-cylinder engines in the past, same effects.

If you are still talking about intake to exhaust there is no difference to the 4 stroke piston, dynamic compression/mass inertia/ram effects whatever you want to call it.

If you actually look at the rotary pieces instead of thinking about the overlap timing of one rotor face you see the rotary overlap effect is very different than the piston engine overlap.

The tip of the rotor divides the working chambers (exhaust and intake during overlap phase). During the one rotor face overlap phase you are focused on you also have the rotor tip open the exhaust port and exhaust stroke blow-down begins with extremely high velocity exhaust gas exiting the exhaust port on the stroke below.

Exhaust port just opening below and intake port just opening above connected together by the always open exhaust port.

How is it possible that you have the very strong blow-down of the exhaust port opening affecting the intake port opening during overlap when you are focused on looking at one rotor face and its "overlap"?

Totally different than the piston engine overlap that just gets the tail end of exhaust velocity exiting the cylinder to elastically "pull" the intake in.

On the rotary you have exhaust stroke blow-down below the rotor apex creating a very effective high velocity siphon to the intake stroke above the rotor apex.

I understand you are trying to equate the 4 stroke piston engine exhaust blow-down at the header collector on one cylinder putting a negative pressure on another cylinder at the end of the exhaust stroke (in overlap) to help draw exhaust out of that cylinder (and intake in).

This is a powerful tool for 4 stroke piston engine performance, but it pales in order of magnitude to the direct in engine blow down siphon during overlap the 4 stroke rotary engine has that works at all rpms. Rotary also benefits from tuning the header collector on top of the in engine effects of overlap.

If you are still talking about intake to exhaust there is no difference to the 4 stroke piston, dynamic compression/mass inertia/ram effects whatever you want to call it.

If you actually look at the rotary pieces instead of thinking about the overlap timing of one rotor face you see the rotary overlap effect is very different than the piston engine overlap.

The tip of the rotor divides the working chambers (exhaust and intake during overlap phase). During the one rotor face overlap phase you are focused on you also have the rotor tip open the exhaust port and exhaust stroke blow-down begins with extremely high velocity exhaust gas exiting the exhaust port on the stroke below.

Exhaust port just opening below and intake port just opening above connected together by the always open exhaust port.

How is it possible that you have the very strong blow-down of the exhaust port opening affecting the intake port opening during overlap when you are focused on looking at one rotor face and its "overlap"?

Totally different than the piston engine overlap that just gets the tail end of exhaust velocity exiting the cylinder to elastically "pull" the intake in.

On the rotary you have exhaust stroke blow-down below the rotor apex creating a very effective high velocity siphon to the intake stroke above the rotor apex.

I understand you are trying to equate the 4 stroke piston engine exhaust blow-down at the header collector on one cylinder putting a negative pressure on another cylinder at the end of the exhaust stroke (in overlap) to help draw exhaust out of that cylinder (and intake in).

This is a powerful tool for 4 stroke piston engine performance, but it pales in order of magnitude to the direct in engine blow down siphon during overlap the 4 stroke rotary engine has that works at all rpms. Rotary also benefits from tuning the header collector on top of the in engine effects of overlap.

Last edited by BLUE TII; 07-20-16 at 01:06 PM.

Thread

Thread Starter

Forum

Replies

Last Post