Oiling system mods. (lots of pics!!!!)

#26

Allen

To plug the front oil galley(dowel) I normally open the hole to 7/16 and use a couple of freeze plugs of the same diameter. I don't like use anything threaded in that area so as to reduce stress crack failures.

To plug the front oil galley(dowel) I normally open the hole to 7/16 and use a couple of freeze plugs of the same diameter. I don't like use anything threaded in that area so as to reduce stress crack failures.

#28

The Firestarter

AGAIN!! Your such a bad influence on me..first fuel

NOW OIL! jesus christ! your gona make me into a very broke rotor junkie putting all these thoughts of mods in my head.

...yet i still have the need to worship you...

NOW OIL! jesus christ! your gona make me into a very broke rotor junkie putting all these thoughts of mods in my head.

...yet i still have the need to worship you...

#31

#35

Senior Member

Join Date: Mar 2002

Location: Logan Utah

Posts: 409

Likes: 0

Received 0 Likes

on

0 Posts

I actually have done a few of these mods on my recent streetport build. I get about 50psi idle and it will peg the stock oil pressure gauge anywhere above 3200rpm. (I have an fd regulator)

Its interesting how well you can make the stock oil pump work with just a few little tweaks. And as Mr. Hannover says, its a poorly designed unit

Its interesting how well you can make the stock oil pump work with just a few little tweaks. And as Mr. Hannover says, its a poorly designed unit

#36

"Elusive, not deceptive!”

Lee, a couple of ideas that I would add to this oil thread.

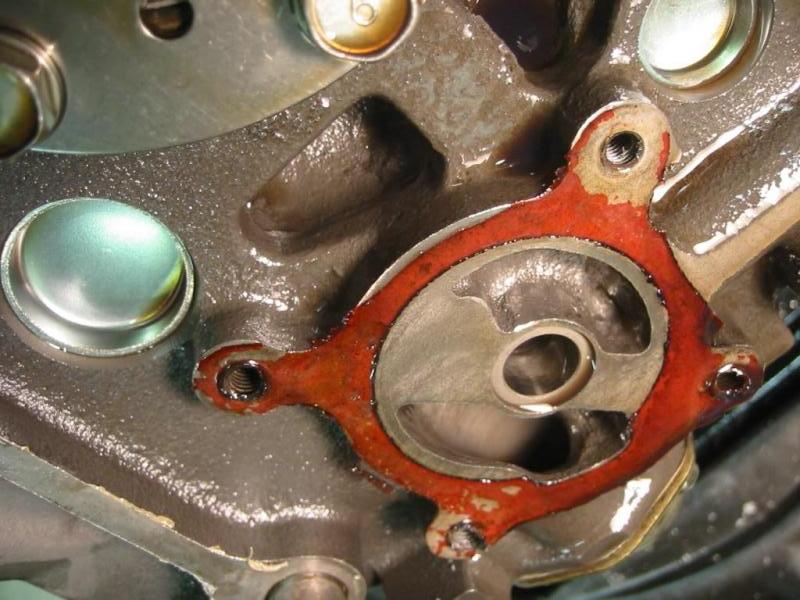

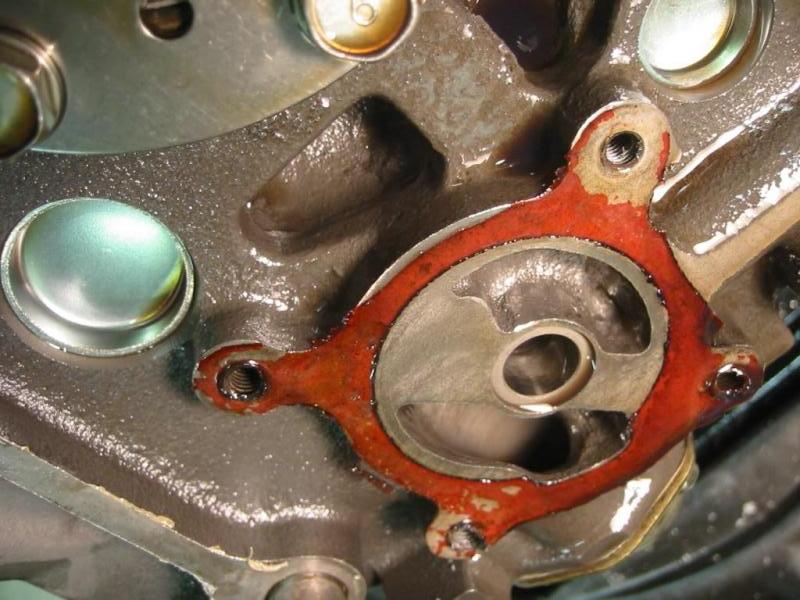

The pump itself leaks at its parting surface. One side can suck air the other side leaks pressure!

I do a Judge Ito mod by making the thinnest possible gasket saturated with Loctite 515. Incidentally this gives the pump an extra .0015” clearance so the next step is lap the housing back to the original dimension. I also lap all the gears and the separator plate.

The other idea is from Lynn Hannover. Remove the pickup tube screen, bell mouth the end and reinstall the screen.

It is a little hard to see in this picture.

The pump itself leaks at its parting surface. One side can suck air the other side leaks pressure!

I do a Judge Ito mod by making the thinnest possible gasket saturated with Loctite 515. Incidentally this gives the pump an extra .0015” clearance so the next step is lap the housing back to the original dimension. I also lap all the gears and the separator plate.

The other idea is from Lynn Hannover. Remove the pickup tube screen, bell mouth the end and reinstall the screen.

It is a little hard to see in this picture.

#37

I addressed both of those problems but didnt take any pictures.

On the pump, i didn't like the idea of a gasket so i used silk thread and gasket maker. Silk thread is what they use to seal the case halfs on aircraft piston engines, there is no possibility for oil to wick past the silk and the gasket maker is only to hold the thread during assembly.

As for the pickup, i used a piece of 3/4 id tubing and welded it to the factory flange. Then i heated it with a torch and used a 1/2" piece of steel rod to roll a radius into the inlet. It actually worked much better than i thought it would. I did leave the screen off though.

On the pump, i didn't like the idea of a gasket so i used silk thread and gasket maker. Silk thread is what they use to seal the case halfs on aircraft piston engines, there is no possibility for oil to wick past the silk and the gasket maker is only to hold the thread during assembly.

As for the pickup, i used a piece of 3/4 id tubing and welded it to the factory flange. Then i heated it with a torch and used a 1/2" piece of steel rod to roll a radius into the inlet. It actually worked much better than i thought it would. I did leave the screen off though.

#38

Senior Member

Join Date: Mar 2002

Location: Logan Utah

Posts: 409

Likes: 0

Received 0 Likes

on

0 Posts

Ha, I didn't reinstall a screen. As mr hannover has stated; It causes oil foaming. I also didn't worry about lapping the oil pump to regain clearance. It works pretty good. The main thing is to get the pump to stop pumping air and pump more oil. This works great

Easy in, Easy out

Easy in, Easy out

#39

On the pump, i didn't like the idea of a gasket so i used silk thread and gasket maker. Silk thread is what they use to seal the case halfs on aircraft piston engines, there is no possibility for oil to wick past the silk and the gasket maker is only to hold the thread during assembly...

Sounds pretty killer. Nice mods too - I'm taking notes

#40

"Elusive, not deceptive!”

I addressed both of those problems but didnt take any pictures.

On the pump, i didn't like the idea of a gasket so i used silk thread and gasket maker. Silk thread is what they use to seal the case halfs on aircraft piston engines, there is no possibility for oil to wick past the silk and the gasket maker is only to hold the thread during assembly.

On turbine engine gearboxes (which had vertical seams) we used unwaxed dental floss with 515 Loctite.

As for the pickup, i used a piece of 3/4 id tubing and welded it to the factory flange. Then i heated it with a torch and used a 1/2" piece of steel rod to roll a radius into the inlet. It actually worked much better than i thought it would. I did leave the screen off though.

On the pump, i didn't like the idea of a gasket so i used silk thread and gasket maker. Silk thread is what they use to seal the case halfs on aircraft piston engines, there is no possibility for oil to wick past the silk and the gasket maker is only to hold the thread during assembly.

On turbine engine gearboxes (which had vertical seams) we used unwaxed dental floss with 515 Loctite.

As for the pickup, i used a piece of 3/4 id tubing and welded it to the factory flange. Then i heated it with a torch and used a 1/2" piece of steel rod to roll a radius into the inlet. It actually worked much better than i thought it would. I did leave the screen off though.

I also use a rare-earth magnet pressed into the drain plug. We probably should be using chip-detectors to alert us to debris.

You have a nice oil system write-up,

Barry

#41

Thanks Barry. Like i said i can't take credit for all of it but i did put my own twist on things. I am using a magnetic drain plug  .

.

Classicauto, i don't have any info other than what i stated. They use it on the case halfs, and the oil pump cover. I don't know if just any old silk thread would work but i wouldnt see why not. I used it on many places in my motor and have not had any problems yet. It is a very new engine ( http://www.youtube.com/watch?v=_OqpVQN_eJo )so i may have problems down the road.

.

.Classicauto, i don't have any info other than what i stated. They use it on the case halfs, and the oil pump cover. I don't know if just any old silk thread would work but i wouldnt see why not. I used it on many places in my motor and have not had any problems yet. It is a very new engine ( http://www.youtube.com/watch?v=_OqpVQN_eJo )so i may have problems down the road.

#47

I did not clearance the rotors on this motor.

You could use silicone or hylomar but you would have to be very careful not to put too much on. Just remember, what you see squeeze out on the outside of the pump is probably the same amount as will be on the inside.

You could use silicone or hylomar but you would have to be very careful not to put too much on. Just remember, what you see squeeze out on the outside of the pump is probably the same amount as will be on the inside.