Ignition advance table input

#4

Racing Rotary Since 1983

iTrader: (6)

one response and 318 reads to someone looking for help?

while many would conclude everyone likes to keep their cards close to their vest the more accurate reason is that many who have worked their timing realize that there are so many variables and such a error high cost that it might be best to stand down on the keyboard.

and they would be right because:

an excellent timing map in the boost area will be a bit different for each FD.

get it wrong and you will be calling an engine builder

in the NA world aggressive timing was the path to more power. Not so with the turbo rotary. stay rich, stay conservative on the timing and raise the boost.

on any single turbo rotary in the 21st century knock logs are the basis for proper timing.

why so?

because we all have different IATs and base fuel quality.

Turblown is is pretty close as to the 4.5 degree removal in boost as well as smoothing the transitions. rotaries don't like big jumps up or down.

timing is all about avoiding knock.

it used to be that knock was especially expensive. the older apex seals were too brittle for single turbo dynamics. they broke on detonation, rattled around inside the motor causing rotor, rotor housing damage and as a final insult damaged the turbine wheel on their exit.

nowadays the more malleable apex seals generally stay in one piece and the corner seal springs are the weak link in the chain. they wilt under the 3500 F heat of detonation and with that you generally lose 20-30% of your compression. the engine does have to come apart but at least you aren't faced with internal carnage. just be sure to replace the springs with FD, not RX8 springs. FD inconel. RX8 junkonel. you generally need to specify or you will get the cheap springs. spend the extra $10.

so knock is bad whether you break your apex seals or not.

the difference between knock and no knock can easily be 3 degrees of timing.

a timing map that works perfectly on Wisconsin Mobil 93 octane summer blend gas may knock on Mobil 93 winter gas. it may knock on 93 octane Mobil gas bought from a lower volume gas station as gas loses just over one octane per month after being refined.

a timing map that works perfectly on a car that has a really good intercooler may knock on a car with a so so intercooler.

the only way you will know is by monitoring knock carefully and having an active knock system. a proper active knock system can save your motor. i often see the word "safeguards" on the forum. there are no safeguards other than ignition. when the motor knocks at a certain magnitude a response must occur on the next rotor face. generally the greatest knock risk is at peak torque. my motors make peak torque at 6450. at 6450 their are 107 rotor faces passing by the sparkplug per second. you need a fix in .009 of one second. cutting boost or fuel is of course a sad joke. since electricity travels at the speed of light... ignition is the single "safeguard."

i had a boost spike once and before i knew it, it seemed like the whole engine compartment detonated... violent. and then all was fine. a look at the logs after the adrenaline stopped flowing showed the spike but also showed timing at zero. score one for a proper knock system properly set up and on duty.

you were helpful as to posting where your peak torque is on the motor.

peak torque is the rpm where maximum engine charge air fill is and often the point of max knock occurrence. peak torque is mainly determined by port configuration.

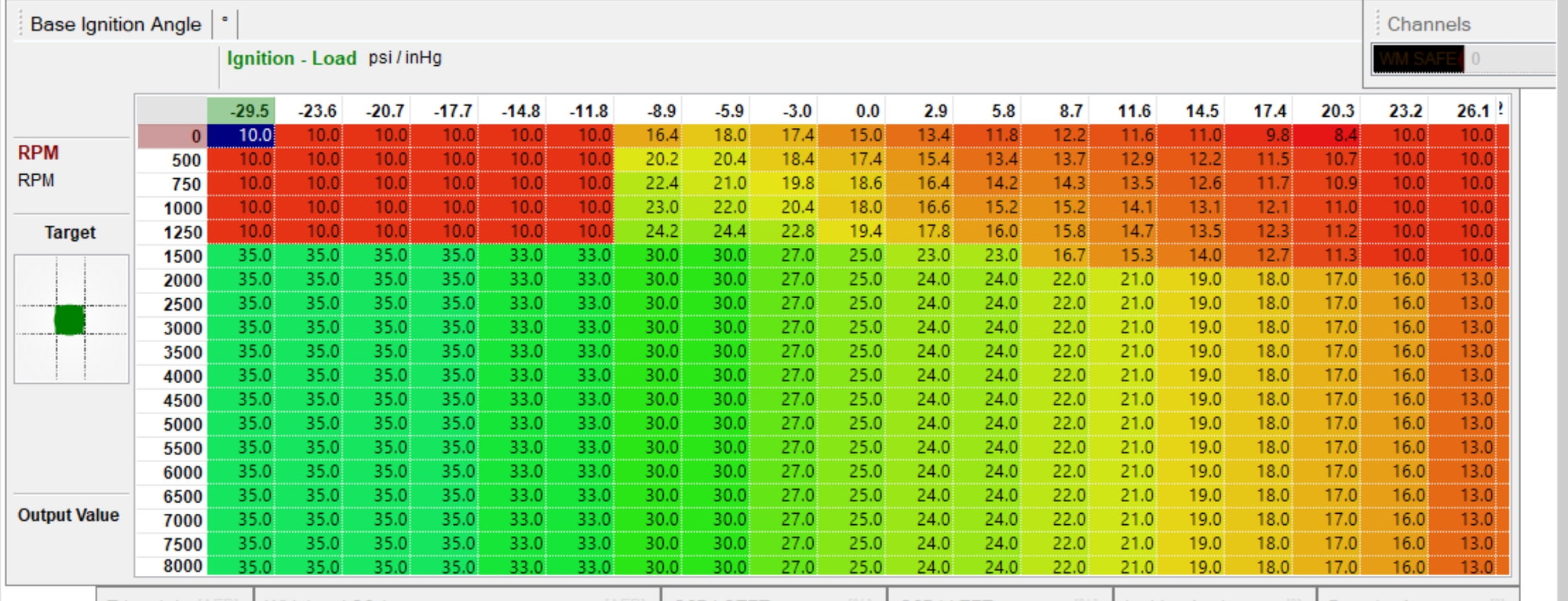

peak torque is the point of Maximum combustion chamber pressure (CCP) and as such should be the lowest point of ignition timing. after peak torque as the rpm rises fill time decreases, CCP is less and timing can be advanced approx 1 to 3 degrees towards redline. ( you will note the engines uses less fuel after peak torque)

split timing and the two plugs exist because the combustion chamber is loooong. the trail plug cleans up the one end of the chamber. i have heard the trail plug makes around 20% of the power but have no idea if this is correct. what i do know about the split is that the actual setpoint contributes to the overall (both plugs) timing. for instance if you are running 14 degrees advance on the leading and your split is 11 degrees your overall timing is less advanced than if you were running 14 L and 5 degrees split. i also know from experience the engine will studder if the trail transition from zero to 11 is too abrupt.

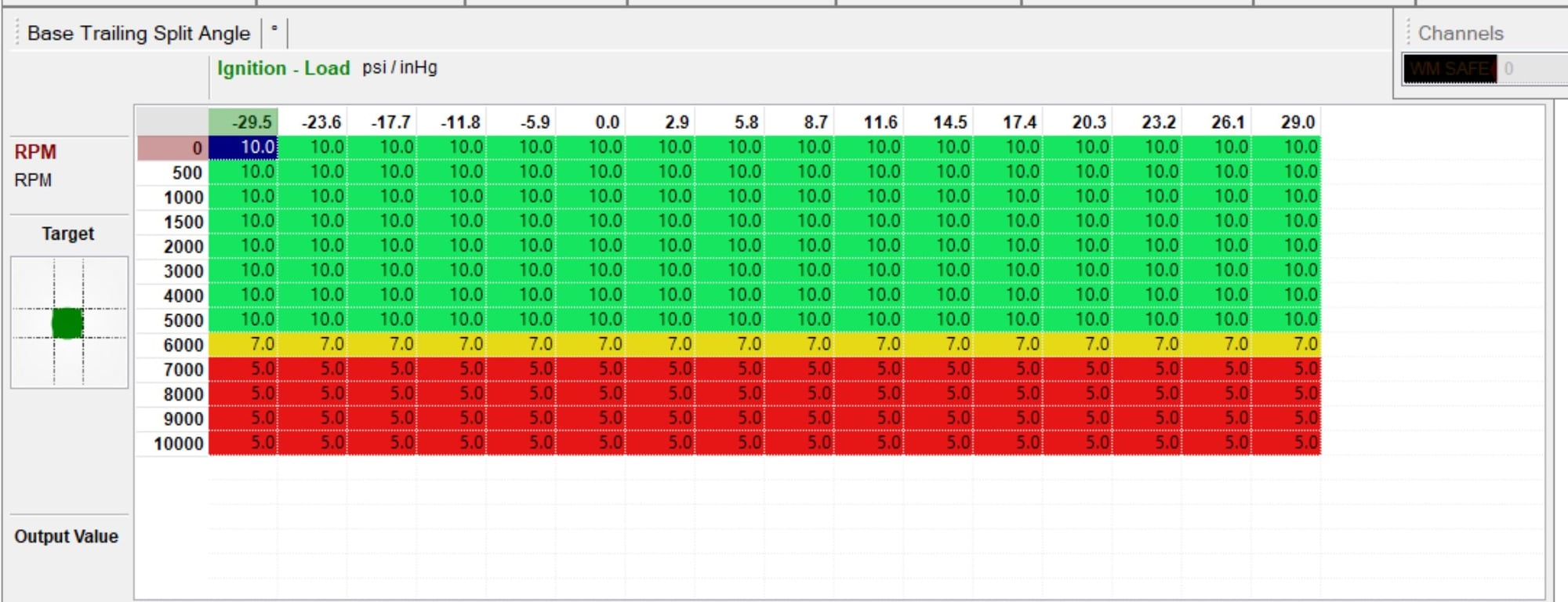

i run, like many, zero split in vacuum and 11 in boost but i transition smoothly between the two numbers. your split timing map needs to be completely re-oriented as it has split changing with rpm when it should change with load.

my primary point here is that everyone running a single turbo setup should have a proper active windowed knock system. it should be set up and active. in order not to go into ignition retard from a false knock event the system should have qualifiers, primarily a minimum TPS position.

without such a system you are virtually blind. sort of like setting your camber without a pyrometer.

if you go about the timing map construction process using knock as a guide and stay a bit conservative you will be fine.

while many would conclude everyone likes to keep their cards close to their vest the more accurate reason is that many who have worked their timing realize that there are so many variables and such a error high cost that it might be best to stand down on the keyboard.

and they would be right because:

an excellent timing map in the boost area will be a bit different for each FD.

get it wrong and you will be calling an engine builder

in the NA world aggressive timing was the path to more power. Not so with the turbo rotary. stay rich, stay conservative on the timing and raise the boost.

on any single turbo rotary in the 21st century knock logs are the basis for proper timing.

why so?

because we all have different IATs and base fuel quality.

Turblown is is pretty close as to the 4.5 degree removal in boost as well as smoothing the transitions. rotaries don't like big jumps up or down.

timing is all about avoiding knock.

it used to be that knock was especially expensive. the older apex seals were too brittle for single turbo dynamics. they broke on detonation, rattled around inside the motor causing rotor, rotor housing damage and as a final insult damaged the turbine wheel on their exit.

nowadays the more malleable apex seals generally stay in one piece and the corner seal springs are the weak link in the chain. they wilt under the 3500 F heat of detonation and with that you generally lose 20-30% of your compression. the engine does have to come apart but at least you aren't faced with internal carnage. just be sure to replace the springs with FD, not RX8 springs. FD inconel. RX8 junkonel. you generally need to specify or you will get the cheap springs. spend the extra $10.

so knock is bad whether you break your apex seals or not.

the difference between knock and no knock can easily be 3 degrees of timing.

a timing map that works perfectly on Wisconsin Mobil 93 octane summer blend gas may knock on Mobil 93 winter gas. it may knock on 93 octane Mobil gas bought from a lower volume gas station as gas loses just over one octane per month after being refined.

a timing map that works perfectly on a car that has a really good intercooler may knock on a car with a so so intercooler.

the only way you will know is by monitoring knock carefully and having an active knock system. a proper active knock system can save your motor. i often see the word "safeguards" on the forum. there are no safeguards other than ignition. when the motor knocks at a certain magnitude a response must occur on the next rotor face. generally the greatest knock risk is at peak torque. my motors make peak torque at 6450. at 6450 their are 107 rotor faces passing by the sparkplug per second. you need a fix in .009 of one second. cutting boost or fuel is of course a sad joke. since electricity travels at the speed of light... ignition is the single "safeguard."

i had a boost spike once and before i knew it, it seemed like the whole engine compartment detonated... violent. and then all was fine. a look at the logs after the adrenaline stopped flowing showed the spike but also showed timing at zero. score one for a proper knock system properly set up and on duty.

you were helpful as to posting where your peak torque is on the motor.

peak torque is the rpm where maximum engine charge air fill is and often the point of max knock occurrence. peak torque is mainly determined by port configuration.

peak torque is the point of Maximum combustion chamber pressure (CCP) and as such should be the lowest point of ignition timing. after peak torque as the rpm rises fill time decreases, CCP is less and timing can be advanced approx 1 to 3 degrees towards redline. ( you will note the engines uses less fuel after peak torque)

split timing and the two plugs exist because the combustion chamber is loooong. the trail plug cleans up the one end of the chamber. i have heard the trail plug makes around 20% of the power but have no idea if this is correct. what i do know about the split is that the actual setpoint contributes to the overall (both plugs) timing. for instance if you are running 14 degrees advance on the leading and your split is 11 degrees your overall timing is less advanced than if you were running 14 L and 5 degrees split. i also know from experience the engine will studder if the trail transition from zero to 11 is too abrupt.

i run, like many, zero split in vacuum and 11 in boost but i transition smoothly between the two numbers. your split timing map needs to be completely re-oriented as it has split changing with rpm when it should change with load.

my primary point here is that everyone running a single turbo setup should have a proper active windowed knock system. it should be set up and active. in order not to go into ignition retard from a false knock event the system should have qualifiers, primarily a minimum TPS position.

without such a system you are virtually blind. sort of like setting your camber without a pyrometer.

if you go about the timing map construction process using knock as a guide and stay a bit conservative you will be fine.

Last edited by Howard Coleman; 05-01-19 at 08:44 PM.

The following users liked this post:

Akaviri (04-20-22)

#5

my primary point here is that everyone running a single turbo setup should have a proper active windowed knock system. it should be set up and active. in order not to go into ignition retard from a false knock event the system should have qualifiers, primarily a minimum TPS position.

without such a system you are virtually blind. sort of like setting your camber without a pyrometer.

if you go about the timing map construction process using knock as a guide and stay a bit conservative you will be fine.

without such a system you are virtually blind. sort of like setting your camber without a pyrometer.

if you go about the timing map construction process using knock as a guide and stay a bit conservative you will be fine.

i do have a bosch knock sensor set up w/ my Haltech. my question is though, how do you properly set up and calibrate this without "inducing" knock?

second question, typically when you increase the timing advance beyond peak torque, should this happen across all the load cells beyond that peak RPM? do you have an example table?

thanks for the help, iím getting the hang of this slowly

#7

Haltech does have a basemap that is super conservative. right now im just gathering info on what is a good benchmark or what other people are having success with. i guess you can say i'm bored. lol

Thread

Thread Starter

Forum

Replies

Last Post

wpgrexx

2nd Generation Specific (1986-1992)

1

08-20-02 09:20 PM