How to improve spool, scientifically speaking

#26

Consider the R35 GT-R. It is a regular port injected engine but it has been optimized for stoichiometric operation during normal daily driving. That's why it gets relatively good gas mileage for a big heavy powerful AWD car.

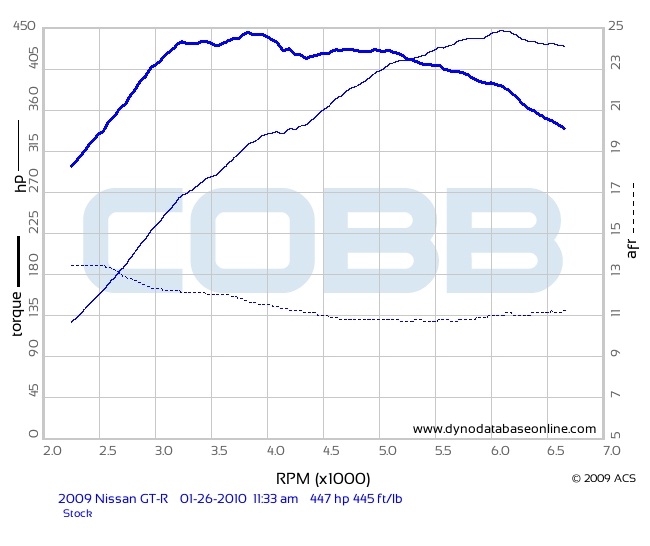

So under normal driving the AFR is scheduled based on the rpm and the torque request. We don't have to go into it but torque request calculations are part of modern ECU architecture in order to integrate all the different control systems. Here is a dyno of a stock R35 GT-R:

I don't know how accurate their dyno wideband is but you can see it's still relatively lean (compared to your typical modified turbo car) as the engine gets into the peak torque area around 3200rpm.

The ignition timing is usually handled by "high octane" ignition maps which are normally used in order to get the best torque and fuel economy. Then the ECU learns knock patterns and makes realtime adjustments. Knock control strategies seem to vary significantly across manufacturers.

#27

Doesn't suck

iTrader: (5)

Join Date: Dec 2004

Location: Pensacola FL

Posts: 701

Likes: 0

Received 0 Likes

on

0 Posts

I understand how general tuning works. I thought we were talking about anti-lag? specifically the lean-advance style. I understand how retarding and enriching builds boost. Perhaps I misunderstood your post:

^I took that to mean that OEM's achieve anti-lag type results (increased turbo response) by leaning and advancing. My question was, how does leaning and advancing timing help spool the turbo between shifts, when conventionally the opposite is required?

The OEM's actually do the opposite of a racing anti lag system. They lean out the mixture and advance the timing. Some Evos and Ralliarts have a "lean spool" system which consists of a transfer function designed to run a leaner target AFR.

#28

Fuel

AFR FAR Equivalence

Ratio Lambda

Gas stoich 14.68 0.068 1.000 1.000

Gas max power rich ~12.5 0.080 1.176 0.8503

Gas max power lean ~13.2 0.0755 1.111 0.900

E85 stoich 9.87 0.101 1.000 1.000

E85 max power rich ~6.98 0.1434 1.40 0.7143

E85 max power lean ~8.47 0.118 1.153 0.8673

E100 stoich 9.00 0.111 1.000 1.000

E100 max power rich ~6.43 0.155 1.40 0.714

E100 max power lean ~7.80 0.128 1.150 0.870

AFR FAR Equivalence

Ratio Lambda

Gas stoich 14.68 0.068 1.000 1.000

Gas max power rich ~12.5 0.080 1.176 0.8503

Gas max power lean ~13.2 0.0755 1.111 0.900

E85 stoich 9.87 0.101 1.000 1.000

E85 max power rich ~6.98 0.1434 1.40 0.7143

E85 max power lean ~8.47 0.118 1.153 0.8673

E100 stoich 9.00 0.111 1.000 1.000

E100 max power rich ~6.43 0.155 1.40 0.714

E100 max power lean ~7.80 0.128 1.150 0.870

Look up ^ .85 lambda is gas max power rich. Maybe OK as a mixture for a petrol 1JZ. Not usually OK on a turbo rotary using pump 93 octane.

Look up E85 max power rich, 7:1 / .71 lambda.

That is honest science about why E85 makes more power on cars that can't usually handle MBT at 12.5:1 Gas / 0.85.

Real racecars doing pitstops carrying fuel around a circuit for 2 hours try to use MBTtiming, max power lean mixtures.

Drag racers and raw power applications where fuel stopping is no problem or say tmeattack/ 5 lap events will be tuning to max power rich or richer.

PS That is some bloody awesome info you have there on the R35 GTR. I would love to go over that.

#29

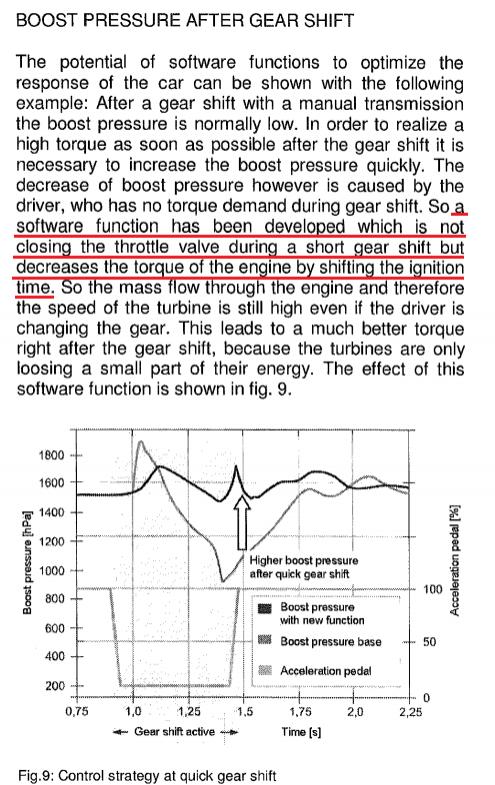

The best way to spool the turbo between shifts is to not let it lose much boost in the first place. That's what throttle and (if applicable) shift tuning can do. You can use an electronically controlled transmission (like the GT-R has). I don't have direct access to an R35 but I have acquired some logs. Here is a WOT pull:

On BMW's with N54 engines and manual transmissions the throttle does not close between shifts:

You don't have that option with these old cable-driven throttles--another reason why I've grown to hate to them.

#30

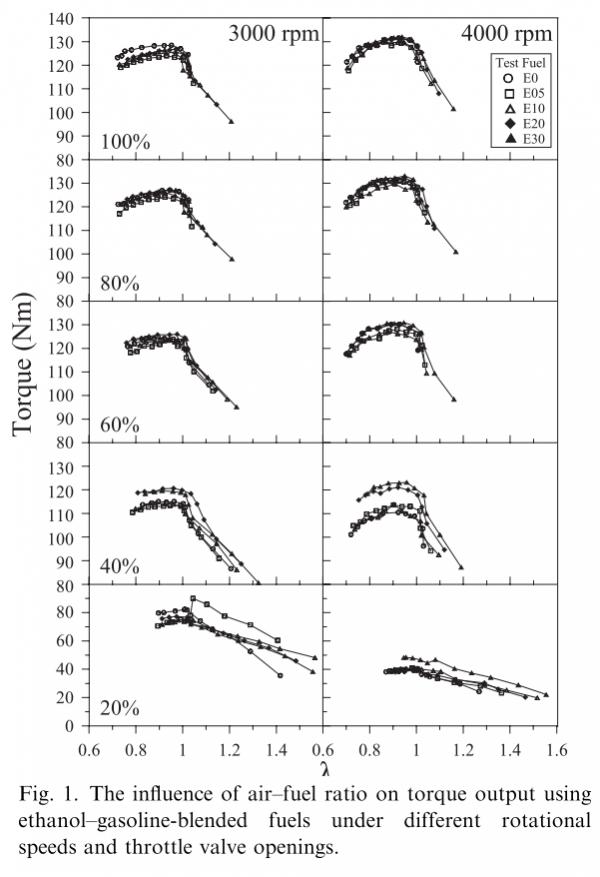

Wu, "The influence of air–fuel ratio on engine performance and pollutant emission of an SI engine using ethanol–gasoline-blended fuels" 2004

Look up E85 max power rich, 7:1 / .71 lambda. That is honest science about why E85 makes more power on cars that can't usually handle MBT at 12.5:1 Gas / 0.85.

PS That is some bloody awesome info you have there on the R35 GTR. I would love to go over that.

#31

Arrogant Wankeler

I understand how general tuning works. I thought we were talking about anti-lag? specifically the lean-advance style. I understand how retarding and enriching builds boost. Perhaps I misunderstood your post:

^I took that to mean that OEM's achieve anti-lag type results (increased turbo response) by leaning and advancing. My question was, how does leaning and advancing timing help spool the turbo between shifts, when conventionally the opposite is required?

^I took that to mean that OEM's achieve anti-lag type results (increased turbo response) by leaning and advancing. My question was, how does leaning and advancing timing help spool the turbo between shifts, when conventionally the opposite is required?

What the evos run is not about off throttle, just getting the very best from the engine when you first punch it before all the internals get hot and you can't run steady state under those conditions.

#32

I have never put a wideband on a completely stock FD, but running in closed loop at low rpm/high oad is more like the rule rather than the exception when you consider completely stock calibrations. There are different control strategies used across manufacturers. I already mentioned the lean spool system for Mitsu. GM uses the "power enrichment" mode which has a set of conditions to enable it. Subaru uses an open loop/closed loop transition with a delay timer. Nissan has a max torque limitation for stoichiometric operation and then a separate torque curve when enrichment is allowed.

i usually have a tendency to want to richen up that early area to make sure that the AFRs are safe until they eventually take that dip in the later RPMs/boost range. the base maps just simply stay around stoich(14.7:1) until they are basically almost fully spooled. which is all fine at least until the engine approaches the peak torque curve where it is a necessity to drop everything down.

for everyone who complains about the stock twins they were actually a marvel when working properly, there is so much going on with the car in the 3500-4500 RPM range that has be sorted out that it isn't even funny.

Last edited by RotaryEvolution; 02-14-11 at 02:38 PM.

#33

Doesn't suck

iTrader: (5)

Join Date: Dec 2004

Location: Pensacola FL

Posts: 701

Likes: 0

Received 0 Likes

on

0 Posts

There is basically 2 effects, the best power/torque effect as described above, which means the car accelerates faster anyway which is what you are really aiming at, and when running closer to stoic, the exhaust is hotter & thus has more energy & takes up more volume & thus imparts more energy to the turbine rather than loosing that energy as partially burned hydrocarbons which impart less energy to the turbine.

What the evos run is not about off throttle, just getting the very best from the engine when you first punch it before all the internals get hot and you can't run steady state under those conditions.

What the evos run is not about off throttle, just getting the very best from the engine when you first punch it before all the internals get hot and you can't run steady state under those conditions.

#34

here is an interesting article on WRC car tuning. their intakes have 34mm restricter, so they have to maximize power throughout the band, anti-lag, water injection, up to 45 psi boost, making 300hp from 3k - redline

http://www.i-club.com/forums/subaru-...popcorn-69783/

http://www.i-club.com/forums/subaru-...popcorn-69783/

#35

The Dirty Mexican

iTrader: (1)

Join Date: Mar 2005

Location: Californian refugee taking shelter in Texas

Posts: 231

Likes: 0

Received 0 Likes

on

0 Posts

Something like this, but with a bit more travel:

http://www.youtube.com/watch?v=zJuzhLorW1A

#36

yessir

iTrader: (24)

Join Date: May 2005

Location: Sebring FL

Posts: 722

Likes: 0

Received 0 Likes

on

0 Posts

[QUOTE=cesarx7;10997854]Isn't that somewhat mimicking a carburetor dashpot? Of course, they have the option to use software on a drive-by-wire system and I'm sure it works a lot better too, but couldn't you add a carburetor dashpot to a throttle body to achieve the same effect? If you're shifting quickly, the throttle would not fully close between shifts.

Something like this, but with a bit more travel:

video is up there^^^^^

I was digging the idea of the push button ignition cut. You just leave your foot to the floor and hit a button to kill ignition during gear change. The bmw article says they "shift timing" to cause the power loss. Not sure what they mean but I'm sure a full cut would work.

If you used a dashpot the engine would continue you to rev upwards. You could just attempt no lift ***** lol.. I find that my rpms have GOT to be below 5 to 6 thousandish before these rx7 trannys LET me go into gear.

Something like this, but with a bit more travel:

video is up there^^^^^

I was digging the idea of the push button ignition cut. You just leave your foot to the floor and hit a button to kill ignition during gear change. The bmw article says they "shift timing" to cause the power loss. Not sure what they mean but I'm sure a full cut would work.

If you used a dashpot the engine would continue you to rev upwards. You could just attempt no lift ***** lol.. I find that my rpms have GOT to be below 5 to 6 thousandish before these rx7 trannys LET me go into gear.

Last edited by First gen man; 02-29-12 at 05:28 PM. Reason: removed video part of quote

#37

The Dirty Mexican

iTrader: (1)

Join Date: Mar 2005

Location: Californian refugee taking shelter in Texas

Posts: 231

Likes: 0

Received 0 Likes

on

0 Posts

Upward revving? Likened to no-lift shifts? What? Dashpots, in stock form, only come into play at very low RPMs. The shaft on the dashpot only sticks out so far, so the throttle lever doesn't even touch the dashpot until the lever closes most of the way. I guess the video I used wasn't ideal as they really weren't smashing on the throttle to show this. It was used on carbureted engines for decades without this upward-revving effect you speak of.

#39

Rising of the Phoenix

iTrader: (19)

Join Date: Jan 2010

Location: Wisconsin

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

[quote=First gen man;10999372

I was digging the idea of the push button ignition cut. You just leave your foot to the floor and hit a button to kill ignition during gear change. The bmw article says they "shift timing" to cause the power loss. Not sure what they mean but I'm sure a full cut would work. [/quote]

The Link G4 Extreme and the Pro EFI both have a feature called, Flat Shift. Basically itís an ignition cut to permit full throttle shifts.

For Sale: New FJO water/meth kit

https://www.rx7club.com/3rd-generation-rx-7-1993-2002-parts-99/new-box-fjo-2nd-gen-water-meth-kit-1000cc-nozzles-988251/

I was digging the idea of the push button ignition cut. You just leave your foot to the floor and hit a button to kill ignition during gear change. The bmw article says they "shift timing" to cause the power loss. Not sure what they mean but I'm sure a full cut would work. [/quote]

The Link G4 Extreme and the Pro EFI both have a feature called, Flat Shift. Basically itís an ignition cut to permit full throttle shifts.

For Sale: New FJO water/meth kit

https://www.rx7club.com/3rd-generation-rx-7-1993-2002-parts-99/new-box-fjo-2nd-gen-water-meth-kit-1000cc-nozzles-988251/

Last edited by R_1; 03-02-12 at 10:45 PM.

#40

For years I've been full-throttle flat shifting against the standard rev limiter that cuts fuel, i.e., the injectors, and it works fine; no loss of boost during shifts, no ill effects.

The idea of cutting ignition timing seems to be intended for part-throttle shifts and daily driving--as in the BMW application. If you hard cut the ignition, you'll accumulate a bunch of raw fuel in the exhaust--which tends to go bang.

Moreover, I'm wondering why few have spoke to the OP's point of improving the turbo itself to improve its response. Better materials, and lighter, smaller, more efficient wheels, etc.. Is it just me or am I the only one to think this is relevant? Seems like many, if not most enthusiasts are hellbent on putting a Ferris wheel in their compressor. And perhaps resigned to using a two-step to get it spinning....

There is much to be gained by properly matching the turbo to the real load requirements and optimizing its response. Not only for racing, but especially for those who actually drive their cars--normally, often, and want to enjoy the experience--while still be being fast/quick.

The idea of cutting ignition timing seems to be intended for part-throttle shifts and daily driving--as in the BMW application. If you hard cut the ignition, you'll accumulate a bunch of raw fuel in the exhaust--which tends to go bang.

Moreover, I'm wondering why few have spoke to the OP's point of improving the turbo itself to improve its response. Better materials, and lighter, smaller, more efficient wheels, etc.. Is it just me or am I the only one to think this is relevant? Seems like many, if not most enthusiasts are hellbent on putting a Ferris wheel in their compressor. And perhaps resigned to using a two-step to get it spinning....

There is much to be gained by properly matching the turbo to the real load requirements and optimizing its response. Not only for racing, but especially for those who actually drive their cars--normally, often, and want to enjoy the experience--while still be being fast/quick.

#41

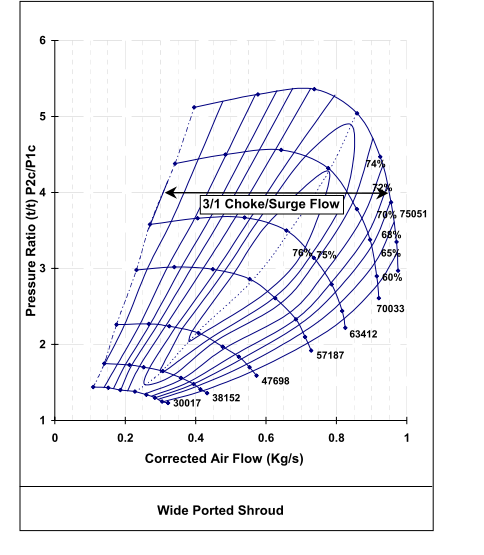

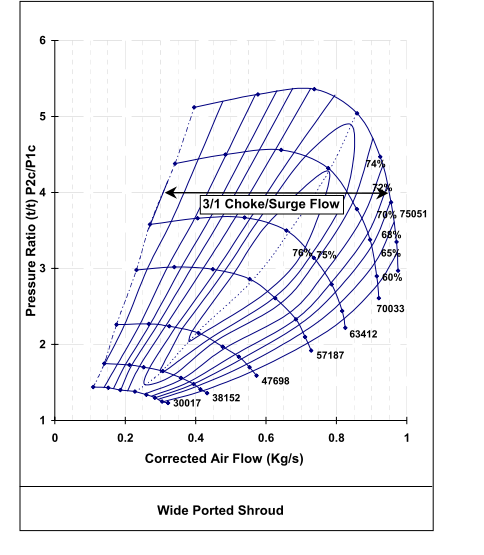

Yes there are a lot of design parameters that haven't been discussed thoroughly. One is the ported shroud. A ported shroud reduces peak efficiency but widens the range between choke and surge. So think of the compressor map expanding along the X axis and decreasing along the Z axis. This is from a Garrett study for diesel applications:

There are also some highly advanced compressor wheels used only on OEM diesel applications right now...

There are also some highly advanced compressor wheels used only on OEM diesel applications right now...

#42

yessir

iTrader: (24)

Join Date: May 2005

Location: Sebring FL

Posts: 722

Likes: 0

Received 0 Likes

on

0 Posts

For years I've been full-throttle flat shifting against the standard rev limiter that cuts fuel, i.e., the injectors, and it works fine; no loss of boost during shifts, no ill effects.

The idea of cutting ignition timing seems to be intended for part-throttle shifts and daily driving--as in the BMW application. If you hard cut the ignition, you'll accumulate a bunch of raw fuel in the exhaust--which tends to go bang.

Moreover, I'm wondering why few have spoke to the OP's point of improving the turbo itself to improve its response. Better materials, and lighter, smaller, more efficient wheels, etc.. Is it just me or am I the only one to think this is relevant? Seems like many, if not most enthusiasts are hellbent on putting a Ferris wheel in their compressor. And perhaps resigned to using a two-step to get it spinning....

There is much to be gained by properly matching the turbo to the real load requirements and optimizing its response. Not only for racing, but especially for those who actually drive their cars--normally, often, and want to enjoy the experience--while still be being fast/quick.

The idea of cutting ignition timing seems to be intended for part-throttle shifts and daily driving--as in the BMW application. If you hard cut the ignition, you'll accumulate a bunch of raw fuel in the exhaust--which tends to go bang.

Moreover, I'm wondering why few have spoke to the OP's point of improving the turbo itself to improve its response. Better materials, and lighter, smaller, more efficient wheels, etc.. Is it just me or am I the only one to think this is relevant? Seems like many, if not most enthusiasts are hellbent on putting a Ferris wheel in their compressor. And perhaps resigned to using a two-step to get it spinning....

There is much to be gained by properly matching the turbo to the real load requirements and optimizing its response. Not only for racing, but especially for those who actually drive their cars--normally, often, and want to enjoy the experience--while still be being fast/quick.

Good stuff, thanks for clarifying that fuel cut is better for flat shifting.

On the 2nd question, improving the turbo itself can be expensive. I'm still dreaming of the day I can afford a nice turbo..... You speak of upgrading the materials. Really the turbo benefits alot from design changes. They have alot of different kinds of "active" turbine housings. Various designs using fins to flapper doors. The Acura MDX has the type with the A/R changing flapper door. I think some newer trucks use the vane type that has fins move inside the turbine to direct more air in to the wheel at low RPMS. Crazy sequential twin set-ups with exhaust backpressure sensors.. They have alot of things that seems better to me, but I'm sure you'll pay for all that stuff.

So I've really started thinking about improving everything around the turbo instead of the turbo itself on account of the pricing of the Active and Ball Bearing turbos.. I mean if you have the correct turbo size anyways. Might be worth it if not..

I been trying to put these three in effect lately.

Shorter, smaller I.D., turbo manifold runners

Larger I.D., shorter, post turbo exhaust

Shorter intercooler piping

#45

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,778

Received 2,563 Likes

on

1,823 Posts

Good stuff, thanks for clarifying that fuel cut is better for flat shifting.

On the 2nd question, improving the turbo itself can be expensive. I'm still dreaming of the day I can afford a nice turbo..... You speak of upgrading the materials. Really the turbo benefits alot from design changes. They have alot of different kinds of "active" turbine housings. Various designs using fins to flapper doors. The Acura MDX has the type with the A/R changing flapper door. I think some newer trucks use the vane type that has fins move inside the turbine to direct more air in to the wheel at low RPMS. Crazy sequential twin set-ups with exhaust backpressure sensors.. They have alot of things that seems better to me, but I'm sure you'll pay for all that stuff.

So I've really started thinking about improving everything around the turbo instead of the turbo itself on account of the pricing of the Active and Ball Bearing turbos.. I mean if you have the correct turbo size anyways. Might be worth it if not..

I been trying to put these three in effect lately.

Shorter, smaller I.D., turbo manifold runners

Larger I.D., shorter, post turbo exhaust

Shorter intercooler piping

On the 2nd question, improving the turbo itself can be expensive. I'm still dreaming of the day I can afford a nice turbo..... You speak of upgrading the materials. Really the turbo benefits alot from design changes. They have alot of different kinds of "active" turbine housings. Various designs using fins to flapper doors. The Acura MDX has the type with the A/R changing flapper door. I think some newer trucks use the vane type that has fins move inside the turbine to direct more air in to the wheel at low RPMS. Crazy sequential twin set-ups with exhaust backpressure sensors.. They have alot of things that seems better to me, but I'm sure you'll pay for all that stuff.

So I've really started thinking about improving everything around the turbo instead of the turbo itself on account of the pricing of the Active and Ball Bearing turbos.. I mean if you have the correct turbo size anyways. Might be worth it if not..

I been trying to put these three in effect lately.

Shorter, smaller I.D., turbo manifold runners

Larger I.D., shorter, post turbo exhaust

Shorter intercooler piping

you're on to something with the smaller manifold runners. the port sleeve is bad on the FC/FD, and it makes the port match odd. the MFR engines (R26B, et all) run 43mm ID headers (2" OD thickwall pipe), and the outlet of the FC/FD engines is 48mm, so imagine the port mismatch....

length i'm not sure about. after the turbo it just needs to be low restriction. and shorter straighter IC piping is better, but the effect is actually pretty small, you have to go way too big on the IC or way too small on the turbo to really make it noticeable

#46

It's the K23 engine. It starts with a single smaller A/R to a larger A/R turbine housing scroll. It's similar to the system on the FC, except the FC has a flap in the manifold instead of the turbo itself.

This is a variable geometry turbo, also known as a variable vane turbo. They became popular on diesel engines about 10 years ago. The angle of the vanes changes which basically adjusts the A/R of the turbine housing. A lot of these turbos run without wastegates.

BMW uses actual compound turbos on SUV diesel engines, where one turbo blows air into another. There is also the "single sequential" turbo which is actually really neat. It's two compressor wheels machined together as one piece. but with two compressor inlets. It bolts up like a single turbo though. It allows the turbo to run at high speeds which increases turbo efficiency. Ford currently uses this on their 6.7 diesel, and it's possible that we may see it on mass produced gas engines. Sequential twins in the same style as the FD have mostly fallen out of favor. Mazda has a new sequential turbo system used on the SkyActive Diesel.

There are also more exotic materials that have been used off and on through the years, like ceramic materials and titanium. There's also ball bearings of course, which reduce the amount of energy lost to friction (slightly increasing horsepower, on paper at least) and increasing transient response.

I think some newer trucks use the vane type that has fins move inside the turbine to direct more air in to the wheel at low RPMS.

Crazy sequential twin set-ups with exhaust backpressure sensors.. They have alot of things that seems better to me, but I'm sure you'll pay for all that stuff.

There are also more exotic materials that have been used off and on through the years, like ceramic materials and titanium. There's also ball bearings of course, which reduce the amount of energy lost to friction (slightly increasing horsepower, on paper at least) and increasing transient response.

#47

yessir

iTrader: (24)

Join Date: May 2005

Location: Sebring FL

Posts: 722

Likes: 0

Received 0 Likes

on

0 Posts

Do you know of any advanced design turbo that would flow enough for around 400-500 on an FC? I'm guessing you'd have to pick through different trucks tills you find one that matches.

Also, I am wondering what you could do to rig in the required eletronics.

Also, I am wondering what you could do to rig in the required eletronics.

#48

yessir

iTrader: (24)

Join Date: May 2005

Location: Sebring FL

Posts: 722

Likes: 0

Received 0 Likes

on

0 Posts

I found some in the $2000-2900 range... for a Garett VNT with 65mm compressor wheel. Dont know if they meant inducer or exducer. The cummings equivalent is also in that ballpark. The flanges for oil and water are all a bit strange. Some of there t4 footprints looked a little off. Not too much of a concern..

With no controller of course.. Im not sure if they make one.. I mean a standalone controller. I found some piggy back electronic that controls the boost pressure and braking force (for j-braking diesel truck stuff) but that was all...

With no controller of course.. Im not sure if they make one.. I mean a standalone controller. I found some piggy back electronic that controls the boost pressure and braking force (for j-braking diesel truck stuff) but that was all...

#50

yessir

iTrader: (24)

Join Date: May 2005

Location: Sebring FL

Posts: 722

Likes: 0

Received 0 Likes

on

0 Posts

Hmm. Even being controlled by air seems hard to work out.. Maybe unless it's powered on exhaust pressure possibly? How would you go about installing an air powered actuator?

For spool up times do you want the vane placement as close to the turbine wheel as possible? After full boost is acquired, the lowest exhaust backpressure as possible while keeping full boost up? So most likely slowly spacing away as the RPM's rise? Can it work somewhat successfully on rpm alone?

For spool up times do you want the vane placement as close to the turbine wheel as possible? After full boost is acquired, the lowest exhaust backpressure as possible while keeping full boost up? So most likely slowly spacing away as the RPM's rise? Can it work somewhat successfully on rpm alone?