Bullseye S480

#28

Banned. I got OWNED!!!

Join Date: Dec 2007

Location: paradise Florida

Posts: 946

Likes: 0

Received 0 Likes

on

0 Posts

#29

Correction: A properly sized "exhaust side" can and will help with the "spool up". But it has more to do with the balance between the wheels.

I agree with you on the balance in between , I've seen ppl go with a good size A/R and the hot side small it spool at a really low rpm by mid rpm band it stop producing viseversa to big exhaust no low end only at top end of the rpm's

-J

I agree with you on the balance in between , I've seen ppl go with a good size A/R and the hot side small it spool at a really low rpm by mid rpm band it stop producing viseversa to big exhaust no low end only at top end of the rpm's

-J

#30

I can't tell you the exact % of increase, but I will say that I'm sure I know why BW did it and IN THIS CASE it probably is more efficiant. But, just because a compressor has more blades doesn't make it better. In a lot of cases it makes it worse. It has to do more with the shape, pitch and angle of the blades and how they work together not only with one another but also with the housing/inlet.

-J

-J

Consider the BW 80mm comp wheel, if the blade had the same blade cross sectional area as the Garrett (80mm comp wheel) blade and the compressor wheels were rotating at the same speed the flow (from each blade) would be the same (if they both have the same inducer and exducer diameters). Therefore if additional blades were added the flow would increase (this is a fact). But, this all changes with the efficiency of the compressor wheel at the determined rotational speed. Increasing comp wheel rotation reduces efficiency! Changing the blade configurations (as you mentioned) may or may not increase efficiency (depends on the initial design, at what speed you want it to be most efficient). Additional blades reduce efficiency at higher rotational speeds. At some particular speed (most probably at lower rotational speeds, where there would have the greatest flow difference, to mid range speeds), the S480 comp wheel would have ~25% more flow because of the additional blades.

If you don't believe me please speak to an engineer at garrett and they will tell you the same thing

#31

If the exhaust (the exhaust manifold, turbo housing AR andthe turbo wheel was the same) the S480 turbo would spool a little quicker because of the additional airflow (larger wheel more air)

Last edited by pmr eng; 11-21-08 at 07:20 PM.

#32

Ultimately flow is governed by the cross sectional area of the blades (nothing else)

Consider the BW 80mm comp wheel, if the blade had the same blade cross sectional area as the Garrett (80mm comp wheel) blade and the compressor wheels were rotating at the same speed the flow (from each blade) would be the same (if they both have the same inducer and exducer diameters). Therefore if additional blades were added the flow would increase (this is a fact). But, this all changes with the efficiency of the compressor wheel at the determined rotational speed. Increasing comp wheel rotation reduces efficiency! Changing the blade configurations (as you mentioned) may or may not increase efficiency (depends on the initial design, at what speed you want it to be most efficient). Additional blades reduce efficiency at higher rotational speeds. At some particular speed (most probably at lower rotational speeds, where there would have the greatest flow difference, to mid range speeds), the S480 comp wheel would have ~25% more flow because of the additional blades.

If you don't believe me please speak to an engineer at garrett and they will tell you the same thing

Consider the BW 80mm comp wheel, if the blade had the same blade cross sectional area as the Garrett (80mm comp wheel) blade and the compressor wheels were rotating at the same speed the flow (from each blade) would be the same (if they both have the same inducer and exducer diameters). Therefore if additional blades were added the flow would increase (this is a fact). But, this all changes with the efficiency of the compressor wheel at the determined rotational speed. Increasing comp wheel rotation reduces efficiency! Changing the blade configurations (as you mentioned) may or may not increase efficiency (depends on the initial design, at what speed you want it to be most efficient). Additional blades reduce efficiency at higher rotational speeds. At some particular speed (most probably at lower rotational speeds, where there would have the greatest flow difference, to mid range speeds), the S480 comp wheel would have ~25% more flow because of the additional blades.

If you don't believe me please speak to an engineer at garrett and they will tell you the same thing

Let me ask you this: At what comressor speed do the added blades make the unit "25%" more efficient? Are you running that boost level? Are you even going to be at the place in the comp. map that you'll benifit from this amazing "25%" gain? I highly doubt it.

Also, "increasing comp wheel rotation" does NOT reduce efficiency. It does past a point but that statment can't be an absolute.

Haha no need for me to call garrett bud, I know.....

#33

Let me ask you this: At what comressor speed do the added blades make the unit "25%" more efficient? Are you running that boost level? Are you even going to be at the place in the comp. map that you'll benifit from this amazing "25%" gain? I highly doubt it.

Also, "increasing comp wheel rotation" does NOT reduce efficiency. It does past a point but that statment can't be an absolute.

Haha no need for me to call garrett bud, I know.....

Also, "increasing comp wheel rotation" does NOT reduce efficiency. It does past a point but that statment can't be an absolute.

Haha no need for me to call garrett bud, I know.....

Have you ever seen a centrifugal belt driven supercharger and the amount of blades the impeller has? Well I can tell you they have alot >8 why, because their rotational speed is much less then a turbocharger

Ok, see the speeds, 84000, 91000, 100000rpm and the efficiency, 79%-70%

You can see an deduction in efficiency with an increase in speed

#34

blades. You see 2 or 3 usually. Also think @ a boat prop. I think the high

speed boats use fewer blades, more for low end pull. I have no data and

am just contemplating. Another thing that comes into play is pitch- I mean

are the blades the same pitch on these two turbos?- unlikely.

#35

Junior Member

iTrader: (34)

Join Date: Nov 2004

Location: AZ

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

I agree, think about an airplane prop- if this is true, you would have 8 or 10

blades. You see 2 or 3 usually. Also think @ a boat prop. I think the high

speed boats use fewer blades, more for low end pull. I have no data and

am just contemplating. Another thing that comes into play is pitch- I mean

are the blades the same pitch on these two turbos?- unlikely.

blades. You see 2 or 3 usually. Also think @ a boat prop. I think the high

speed boats use fewer blades, more for low end pull. I have no data and

am just contemplating. Another thing that comes into play is pitch- I mean

are the blades the same pitch on these two turbos?- unlikely.

#36

I agree, think about an airplane prop- if this is true, you would have 8 or 10

blades. You see 2 or 3 usually. Also think @ a boat prop. I think the high

speed boats use fewer blades, more for low end pull. I have no data and

am just contemplating. Another thing that comes into play is pitch- I mean

are the blades the same pitch on these two turbos?- unlikely.

blades. You see 2 or 3 usually. Also think @ a boat prop. I think the high

speed boats use fewer blades, more for low end pull. I have no data and

am just contemplating. Another thing that comes into play is pitch- I mean

are the blades the same pitch on these two turbos?- unlikely.

Must impellers are very similar in their configurations

Last edited by pmr eng; 11-22-08 at 07:25 PM.

#37

#38

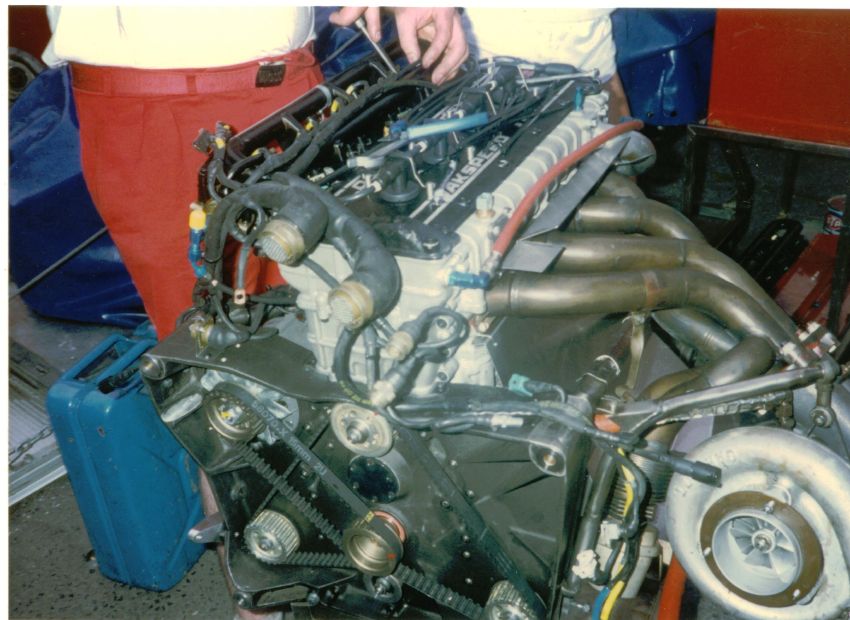

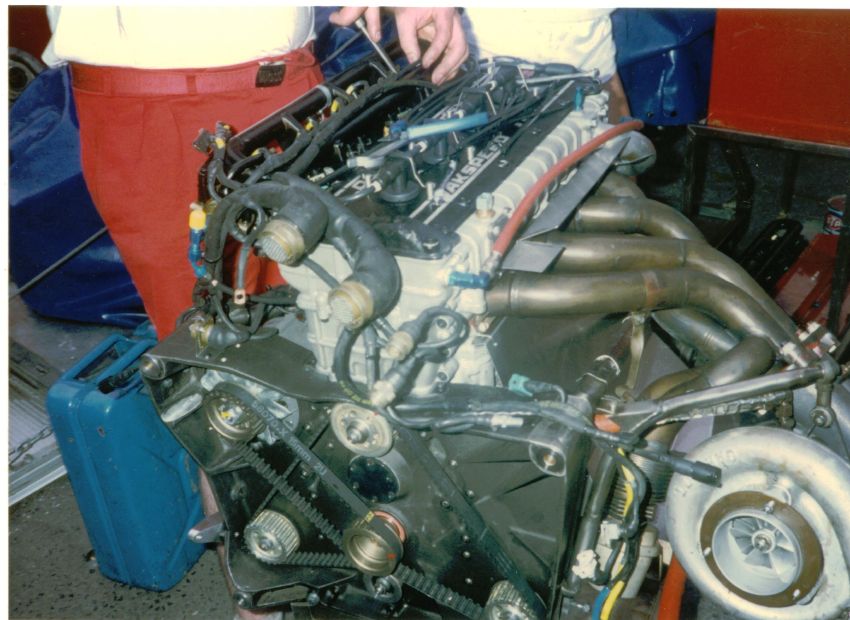

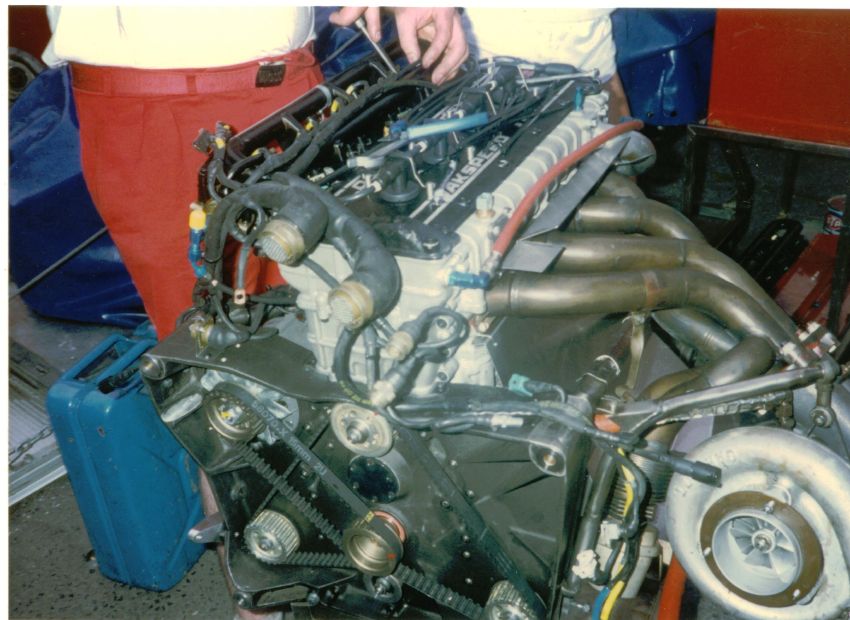

Plain and simple answer is the more blades a comp wheel has and the thicker the blades, the less a wheel will flow. So a 6 blade versus a 8 blade wheel of the same design the 6 blade will outflow the 8 blade counterpart. Only thing is the 8 blade design will move the air sooner per 1 rev of the shaft up to a certain X shaft speed. Their is a reason why the Formula 1 turbos of the 80's ran 3 and 4 blade design and not 8-10 blades. They were limited to a certain inducer size and had to design a charger to move the most amount of air with that limited inducer size. The only problem with less blades, is that it will make a compressor map more narrow, but a formula 1 car operated at a very high rpm and narrow range during racing that the limited blade count did not effect driveability.

#40

Only thing is the 8 blade design will move the air sooner per 1 rev of the shaft up to a certain X shaft speed.

Their is a reason why the Formula 1 turbos of the 80's ran 3 and 4 blade design and not 8-10 blades. They were limited to a certain inducer size and had to design a charger to move the most amount of air with that limited inducer size. The only problem with less blades, is that it will make a compressor map more narrow, but a formula 1 car operated at a very high rpm and narrow range during racing that the limited blade count did not effect driveability

They never ran 3-4 blades (well I haven't seen any)

The turbo F1 engines ran very high boost, they had 6-7 blades

Here is the proof,

Honda 6 blades

BMW 6 blades

TAG- Porsche 7 blades

For further F1 information check out this great site

http://www.gurneyflap.com

#41

I have never found any tubo that have more compressor blades to outflow more than one with less in the same given dimension and that's not base on what I've read form the internet either. Actual testing at 50 to 70 psi most 7 blades fall short way below that and 8 blades are not even considered for that application.

It's well known fact to those who have actual experience that more blades equals more/broader airfow at lower than at higher speeds. More blades give a wider compressor map.

It's well known fact to those who have actual experience that more blades equals more/broader airfow at lower than at higher speeds. More blades give a wider compressor map.

Last edited by crispeed; 11-28-08 at 01:23 AM.

#42

These wheels will not hold boost period. They are not airtight(or anything close to it for that matter). If they are generating pressure greater than the pressure present in the intake plenum(on the engine side of the compressor) then the boost is not leaking or going anywhere. Not to mention: more blades means more holes through which boost would "escape" (though not in any applicable anecdote).

This is a very hard situation to explain but to put it simply: After a certain point additional blades will only screw themselves over. The more blades on the inducer the less opportunity each blade has to grab additional air due to the low pressure area created in the wake of the preceeding blade. More blades can only be smaller and thus cannot push the air with as much force as a wider blade.

With fewer blades at any given RPM mother nature will have more time to erase the "vacuum" created by the preceeding blade. Thus there will be more air to grab and wider blades to push it harder than a design with more blades. This design fails to take advantage of a "low" rpm situation where air is abundant.

#43

more blades means more holes through which boost would "escape"

Since the gap between each blade is larger with the 6 blade wheel, than there is a likely hood of greater chance for the air to escape with the 6 blade wheel?

This is a very hard situation to explain but to put it simply: After a certain point additional blades will only screw themselves over. The more blades on the inducer the less opportunity each blade has to grab additional air due to the low pressure area created in the wake of the preceeding blade. More blades can only be smaller and thus cannot push the air with as much force as a wider blade.

I mentioned that before

With fewer blades at any given RPM mother nature will have more time to erase the "vacuum" created by the preceeding blade. Thus there will be more air to grab and wider blades to push it harder than a design with more blades. This design fails to take advantage of a "low" rpm situation where air is abundant.

I agree the less blades are more efficient at higher speeds

#44

I have never found any tubo that have more compressor blades to outflow more than one with less in the same given dimension and that's not base on what I've read form the internet either. Actual testing at 50 to 70 psi most 7 blades fall short way below that and 8 blades are not even considered for that application.

It's well known fact to those who have actual experience that more blades equals more/broader airfow at lower than at higher speeds. More blades give a wider compressor map.

It's well known fact to those who have actual experience that more blades equals more/broader airfow at lower than at higher speeds. More blades give a wider compressor map.

Your practical experience can't be questioned

If that's the case then I take your word for it, that is if the inducer and exducer dimensions were the same

The larger the difference between the inducer and exducer diameters, the greater the ability for the compressor wheel to hold more pressure more efficiently

#45

adiabaticly inefficient

Join Date: Aug 2001

Location: nw houston,TX or w. hollywood,CA

Posts: 386

Likes: 0

Received 0 Likes

on

0 Posts

I have never found any tubo that have more compressor blades to outflow more than one with less in the same given dimension and that's not base on what I've read form the internet either. Actual testing at 50 to 70 psi most 7 blades fall short way below that and 8 blades are not even considered for that application.

It's well known fact to those who have actual experience that more blades equals more/broader airfow at lower than at higher speeds. More blades give a wider compressor map.

It's well known fact to those who have actual experience that more blades equals more/broader airfow at lower than at higher speeds. More blades give a wider compressor map.

all the info i needed

#46

A 8 blade compressor wheel will hold higher boost/pressure better than any 6 blade wheel period! Why because the additional blades hold the pressure better, not allowing the air to escape. A 6 blade wheel may or may not outflow a 8 blades depends on the circumstances, comp wheel speed the biggest factor

I agree!

You are wrong there!

They never ran 3-4 blades (well I haven't seen any)

The turbo F1 engines ran very high boost, they had 6-7 blades

Here is the proof,

Honda 6 blades

BMW 6 blades

TAG- Porsche 7 blades

For further F1 information check out this great site

http://www.gurneyflap.com

I agree!

You are wrong there!

They never ran 3-4 blades (well I haven't seen any)

The turbo F1 engines ran very high boost, they had 6-7 blades

Here is the proof,

Honda 6 blades

BMW 6 blades

TAG- Porsche 7 blades

For further F1 information check out this great site

http://www.gurneyflap.com

#47

I don't know why ppl are concern about the wheel having 6 ,7 blades and the 8 blade this that . I dont see anything bad about the Borgwarner desing at all its been proven on many cars .

Here are some Dyno vids of car running the S480 !

http://www.grs-motorsports.com/notic...carolina/3.wmv

http://www.grs-motorsports.com/notic...carolina/4.wmv

http://www.grs-motorsports.com/notic...carolina/6.wmv

http://www.grs-motorsports.com/notic...carolina/5.wmv

Here are some Dyno vids of car running the S480 !

http://www.grs-motorsports.com/notic...carolina/3.wmv

http://www.grs-motorsports.com/notic...carolina/4.wmv

http://www.grs-motorsports.com/notic...carolina/6.wmv

http://www.grs-motorsports.com/notic...carolina/5.wmv

#48

#49

I don't know why ppl are concern about the wheel having 6 ,7 blades and the 8 blade this that . I dont see anything bad about the Borgwarner desing at all its been proven on many cars .

Here are some Dyno vids of car running the S480 !

http://www.grs-motorsports.com/notic...carolina/3.wmv

http://www.grs-motorsports.com/notic...carolina/4.wmv

http://www.grs-motorsports.com/notic...carolina/6.wmv

http://www.grs-motorsports.com/notic...carolina/5.wmv

Here are some Dyno vids of car running the S480 !

http://www.grs-motorsports.com/notic...carolina/3.wmv

http://www.grs-motorsports.com/notic...carolina/4.wmv

http://www.grs-motorsports.com/notic...carolina/6.wmv

http://www.grs-motorsports.com/notic...carolina/5.wmv

For what I payed and the power I'm after, the turbo is more than adequate

I will definately be looking to upgrade the turbo to a much larger one, when funds become available and I start chasing the need for more power

I wish 13BT_Starlet all the best and success with his S480 8 blade turbocharger!

Thread

Thread Starter

Forum

Replies

Last Post

Viking War Hammer

Single Turbo RX-7's

20

07-28-08 10:53 AM