Air Flow (CFM) question

#1

Air Flow (CFM) question

Hey everyone, this question is actually about the twin turbo's, but I think I have the best chance of getting it answered here.

A little context...I'm considering a new setup, which I don't believe has ever been done before. I plan to start working on it this winter, but have already started researching and purchasing parts.

I have a few goals for the new setup, one of which is more low end power/torque and better response time than the stock twins in sequential mode. So the information I'm looking for is mostly related to the first turbo in the sequential system, but since i'm looking for information all the way to 6000 rpm, the second turbo will also need to be factored in.

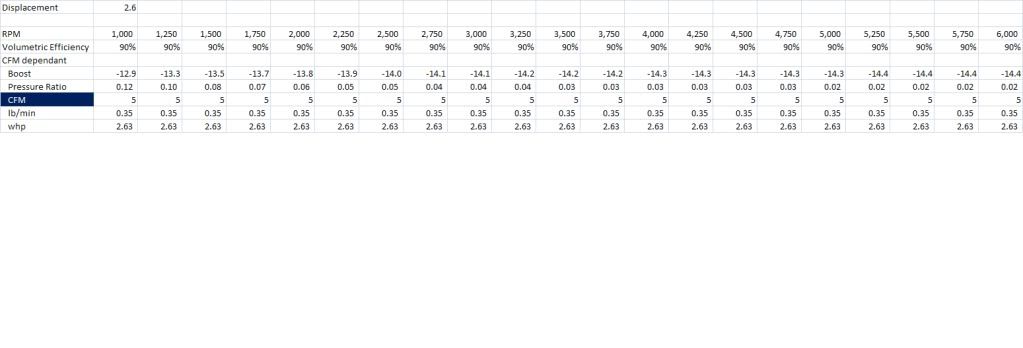

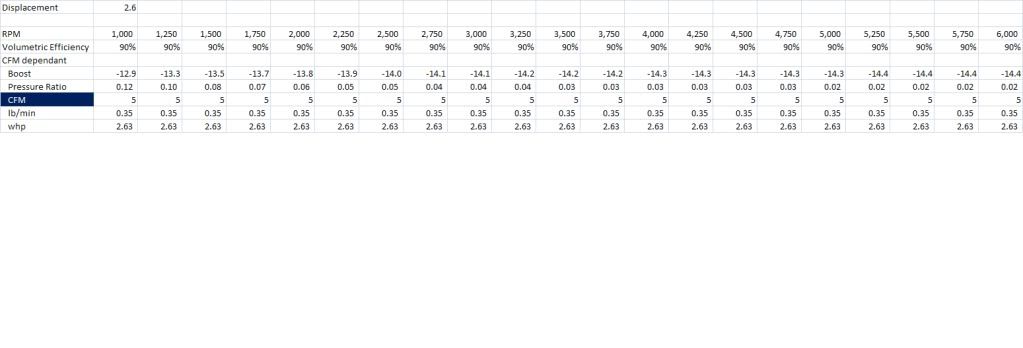

I'm building a calculator in excel to determine what CFM & psi I need at each point along my RPM range, I'll then be sizing my new setup to be in line with that. In order to make sure that i'll reach my low end goal, I need to figure out how much CFM the stock turbos in sequential mode produce at different points in the RPM range.

I know you obviously can't use the calculator in here, what I'm looking for is the information needed to fill out the CFM row.

I think I could probably back into it by taking whp at the different rpm points and reversing the forumla's to calculate CFM. The problem with this is that most dyno charts I've seen don't record whp at the extremely low rpm ranges I'm looking for, (I'm also not sure if my calculator is all that accurate yet)

Thanks in advance.

-Collin

A little context...I'm considering a new setup, which I don't believe has ever been done before. I plan to start working on it this winter, but have already started researching and purchasing parts.

I have a few goals for the new setup, one of which is more low end power/torque and better response time than the stock twins in sequential mode. So the information I'm looking for is mostly related to the first turbo in the sequential system, but since i'm looking for information all the way to 6000 rpm, the second turbo will also need to be factored in.

I'm building a calculator in excel to determine what CFM & psi I need at each point along my RPM range, I'll then be sizing my new setup to be in line with that. In order to make sure that i'll reach my low end goal, I need to figure out how much CFM the stock turbos in sequential mode produce at different points in the RPM range.

I know you obviously can't use the calculator in here, what I'm looking for is the information needed to fill out the CFM row.

I think I could probably back into it by taking whp at the different rpm points and reversing the forumla's to calculate CFM. The problem with this is that most dyno charts I've seen don't record whp at the extremely low rpm ranges I'm looking for, (I'm also not sure if my calculator is all that accurate yet)

Thanks in advance.

-Collin

#2

Rotorhead

Join Date: Feb 2001

Location: Charlottesville, Virginia, USA

Posts: 9,136

Likes: 0

Received 39 Likes

on

33 Posts

Sorry, but this is one of those "you can't get there from here" situations. In order to reverse-engineer the stock system you would need to install test equipment in a stock system and an engine dyno to isolate the variables. I think you would be better off just estimating the engine airflow requirements and then choosing turbos accordingly and adjusting your resluts by changing the A/R as needed. Also, most modern compressor maps are in lbs/min rather than cfm.

The below website shows calculations for lbs/min. There are a few math errors in the examples, but I didn't notice anything wrong with the formulas.

http://www.gnttype.org/techarea/turbo/turboflow.html

The below website shows calculations for lbs/min. There are a few math errors in the examples, but I didn't notice anything wrong with the formulas.

http://www.gnttype.org/techarea/turbo/turboflow.html

#3

Thanks, but if you look at my chart above, it's got lb/min built in as well, so info for either line will do.

I'm not really trying to reverse engineer anything, I just need a rough estimate of the stock sequential system's flow. That way, when I'm picking out the units I need, I'll be sure that they can flow more at the same rpm levels.

I've thought of doing what you mentioned, and just estimating airflow requirements, but can only do this if I have a dyno chart that shows the low rpm whp (most I've seen of the stock system usually don't log until 3k rpm and aren't detailed enough on the axis to allow me to be able to accurately pick out data at each 250 rpm data point).

I'm not really trying to reverse engineer anything, I just need a rough estimate of the stock sequential system's flow. That way, when I'm picking out the units I need, I'll be sure that they can flow more at the same rpm levels.

I've thought of doing what you mentioned, and just estimating airflow requirements, but can only do this if I have a dyno chart that shows the low rpm whp (most I've seen of the stock system usually don't log until 3k rpm and aren't detailed enough on the axis to allow me to be able to accurately pick out data at each 250 rpm data point).

#4

Racing Rotary Since 1983

iTrader: (6)

while i have no stock turbo dyno charts in my file i would be surprised if you couldn't find them.

all my runs start at 2000 rpm in 4th. as far as 250 increments, i suppose you could blow up the dyno chart... i do that often and work in 500 rpm steps.

once you find SAE rwhp it is a simple matter to multiply by 1.92 to get CFM. if you know the AFR you can get brake specific etc.

'shouldn't be difficult.

howard

all my runs start at 2000 rpm in 4th. as far as 250 increments, i suppose you could blow up the dyno chart... i do that often and work in 500 rpm steps.

once you find SAE rwhp it is a simple matter to multiply by 1.92 to get CFM. if you know the AFR you can get brake specific etc.

'shouldn't be difficult.

howard

#5

Thanks Howard, I've been doing a little more digging and found this chart for th 99 twins in sequential mode. Someone commented on the torque being off, but it looks like the hp is pretty decent for the mods he has.

Do you think that from 2k - 3k rpm that the gas is floored (not sure if the super steep section is because the gas pedal wasn't floored yet)? I'm really trying to find an accurate representation of how they produce in the 2-4k rpm range

his mods ...

Here's mine. 338 whp @ 14psi. pumped fuel. 10.7 A/F

Apexi PFC

HKS EVC 6

99spec turbos

denso supra pump

550/1300 injectors (newly cleaned)

NGK iridium 9's all around

NGK Power Cables

HKS Twin Power

HKS RS intake

KS vmount

3" ebay SS downpipe + midpipe

St.May Shotgun exaust

Found this on Page 10 of the 3rd gen dyno sheet section. The forum member is RX7LINK.

Do you think that from 2k - 3k rpm that the gas is floored (not sure if the super steep section is because the gas pedal wasn't floored yet)? I'm really trying to find an accurate representation of how they produce in the 2-4k rpm range

his mods ...

Here's mine. 338 whp @ 14psi. pumped fuel. 10.7 A/F

Apexi PFC

HKS EVC 6

99spec turbos

denso supra pump

550/1300 injectors (newly cleaned)

NGK iridium 9's all around

NGK Power Cables

HKS Twin Power

HKS RS intake

KS vmount

3" ebay SS downpipe + midpipe

St.May Shotgun exaust

Found this on Page 10 of the 3rd gen dyno sheet section. The forum member is RX7LINK.

#6

The reason there are no dyno charts at such low RPM is because no dyno pulls are ever done from 1000 RPM. People generally start around 3k. It's not that the dyno's can't do it, its that people don't do it. If you want a dyno run from 1k RPM, why don't you put your car on the dyno and start it at 1k RPM?

The sharp inclines are usually the time it takes for the turbo's to spool.

thewird

The sharp inclines are usually the time it takes for the turbo's to spool.

thewird

Thread

Thread Starter

Forum

Replies

Last Post

Skeese

Adaptronic Engine Mgmt - AUS

65

03-28-17 03:30 PM

msilvia

3rd Generation Specific (1993-2002)

28

04-14-16 12:58 PM

12abridgeport

1st Generation Specific (1979-1985)

2

08-17-15 06:28 PM