1994 A-Spec 500R Single Turbo Build

#101

i would say do a boost leak test. had one on my evo and was down a good 50whp. boost was still reading the same it just doesnt have the same cfm so you lose power. pick up a 4" pvc cap and a coupler at home depot. also get a vavle stem from a car wheel. drill a hole and seal it on there, then put it on your turbo and see if you come up with any leaks. test up to 15-20psi.

#103

Rotary Freak

Thread Starter

iTrader: (4)

Join Date: Aug 2005

Location: US

Posts: 2,150

Likes: 0

Received 0 Likes

on

0 Posts

Thanks everyone for the kind words.

It definitely has been a long journey. I bought the car having owned a FD before but I never touched them mechanically. Now I can be proud to say that I "built" this car with my own hands. To finally be able to enjoy the car and boost it is all I care about at the moment. The high HP numbers will come.

I will be looking at the water injection kit to see why it wasn't working. I am hoping it is a simple fix such as wiring or a dead pump.

With the boost controller, I think I am going to go ahead and leave that unhooked for now and just run on the wastegate spring until Steve comes back again.

I will also check for boost leaks, but again, I'll have to get in touch with Steve to see how conservative he tuned the car. This could possibly be a reason for the "low" HP numbers.

It definitely has been a long journey. I bought the car having owned a FD before but I never touched them mechanically. Now I can be proud to say that I "built" this car with my own hands. To finally be able to enjoy the car and boost it is all I care about at the moment. The high HP numbers will come.

I will be looking at the water injection kit to see why it wasn't working. I am hoping it is a simple fix such as wiring or a dead pump.

With the boost controller, I think I am going to go ahead and leave that unhooked for now and just run on the wastegate spring until Steve comes back again.

I will also check for boost leaks, but again, I'll have to get in touch with Steve to see how conservative he tuned the car. This could possibly be a reason for the "low" HP numbers.

#104

Rotary Freak

Thread Starter

iTrader: (4)

Join Date: Aug 2005

Location: US

Posts: 2,150

Likes: 0

Received 0 Likes

on

0 Posts

I also have a similar set-up as you and right now I'm pushing around 420 rwhp at 13-14psi at 10.7 AFR's. I'd bet the problem is the B10EGV's w/HKS TP... I was down over 100rwhp with those plugs on my dyno day, we immediately swapped them for stock 9's and we were back in business over 400... I know your happy with where you're at right now but imagine another 100 rwhp!

Btw, Steve also tuned my 7 and he was the one who suggested we swap my plugs after being stumped on the first few runs...

Either way, have fun finally going WOT!

Btw, Steve also tuned my 7 and he was the one who suggested we swap my plugs after being stumped on the first few runs...

Either way, have fun finally going WOT!

We are setting up another tune for around March, so I'm going to work on getting the AI and boost controller squared away.

#105

I just saw your response about the 10EGV's. The car prior to me run 10EGVs on water injection with no problems. Steve was actually the one who suggested them to him for his car. I did have a set of 9EQP's as a backup if I was starting to have problems, but Kan didn't see any problems.

We are setting up another tune for around March, so I'm going to work on getting the AI and boost controller squared away.

We are setting up another tune for around March, so I'm going to work on getting the AI and boost controller squared away.

On a side note I just bought R7420's (Greddy plugs) in 9's and 10.5's. I hear a lot of good results with them but they're very pricey. I'm throwing them in with the NGK power wires after I finish my WI...looking to tune to 20psi.

#106

Original Gangster/Rotary!

iTrader: (213)

Pandabear.... (mike right?)....... that's pretty much what I was tuned with and have been running since around March timeframe. It's proved to be a reliable formula for 500 rwhp on the street with pump gas

#107

Rotary Freak

Thread Starter

iTrader: (4)

Join Date: Aug 2005

Location: US

Posts: 2,150

Likes: 0

Received 0 Likes

on

0 Posts

Rich,

For next time around, do you think the car is safe @ 20psi with water injection and 91 octane?

I'm trying to figure out the point of my setup where I can push a good amount of air, but at the same time, not to a "risk break-even" point if that makes sense. At what PSI would you be "uncomfortable" pushing the car.

For next time around, do you think the car is safe @ 20psi with water injection and 91 octane?

I'm trying to figure out the point of my setup where I can push a good amount of air, but at the same time, not to a "risk break-even" point if that makes sense. At what PSI would you be "uncomfortable" pushing the car.

#108

Rich,

For next time around, do you think the car is safe @ 20psi with water injection and 91 octane?

I'm trying to figure out the point of my setup where I can push a good amount of air, but at the same time, not to a "risk break-even" point if that makes sense. At what PSI would you be "uncomfortable" pushing the car.

For next time around, do you think the car is safe @ 20psi with water injection and 91 octane?

I'm trying to figure out the point of my setup where I can push a good amount of air, but at the same time, not to a "risk break-even" point if that makes sense. At what PSI would you be "uncomfortable" pushing the car.

Also, get some real plugs like the iridium NGK R7420 (also sold as Greddy Racing Plugs) or the cheaper platinum NGK R6725. They come in a variety of heat ranges. I use 9 leading and 10 trailing currently but will be trying colder this year since I plan to run a lot of boost.

thewird

#109

Rotary Freak

Thread Starter

iTrader: (4)

Join Date: Aug 2005

Location: US

Posts: 2,150

Likes: 0

Received 0 Likes

on

0 Posts

Thanks!

As I've stated since the beginning of the build, I just want a fun car to drive and make sure it is still safe. If 20psi, even with water injection and all other safety precautions will start to push the safety margins, then I rather play on the safe side.

As I've stated since the beginning of the build, I just want a fun car to drive and make sure it is still safe. If 20psi, even with water injection and all other safety precautions will start to push the safety margins, then I rather play on the safe side.

#110

-Boost leaks

-Exhaust leaks before turbo

-Exhaust restrictions after turbo

-Intake restrictions (I once had a bad intercooler that had a 7psi drop across the core!! Stock twins were reading 20psi at the Y-pipe and 13psi at the UIM!)

-Ignition problems (plugs, coil, etc)

**If you do make changes, please confirm your AFR's when you start testing again**

Then when you cover all that you should set up your boost controller & wastgate to function reliably. I ended up going to a 10psi spring in my TiAl WG to boost 12psi minimum. Originally I had a 13psi spring and was creeping to 17psi by 7,000rpm...never understood why, but I guess it could be port work, manifold design (long runner w/re-routed wastegate), etc...

Good luck man and keep us posted!

.

#111

Rotary Freak

Thread Starter

iTrader: (4)

Join Date: Aug 2005

Location: US

Posts: 2,150

Likes: 0

Received 0 Likes

on

0 Posts

I'm trying to figure if my wastegate/vacuum lines are installed properly.

At the moment, running off just the wastegate spring, I have a vacuum hose running from the side port of the wastegate to the hot side of the turbo piping before my intercooler. I then have the top vacuum line off the wastegate running vented. I first want to verify that this is how we will run the lines for just boosting off the spring.

Second I want to confirm which lines will run into the boost controller solenoid to make sure it's not installed backwards or anything. I have a AEM TruBoost Controller.

At the moment, running off just the wastegate spring, I have a vacuum hose running from the side port of the wastegate to the hot side of the turbo piping before my intercooler. I then have the top vacuum line off the wastegate running vented. I first want to verify that this is how we will run the lines for just boosting off the spring.

Second I want to confirm which lines will run into the boost controller solenoid to make sure it's not installed backwards or anything. I have a AEM TruBoost Controller.

#113

I'm trying to figure if my wastegate/vacuum lines are installed properly.

At the moment, running off just the wastegate spring, I have a vacuum hose running from the side port of the wastegate to the hot side of the turbo piping before my intercooler. I then have the top vacuum line off the wastegate running vented. I first want to verify that this is how we will run the lines for just boosting off the spring.

At the moment, running off just the wastegate spring, I have a vacuum hose running from the side port of the wastegate to the hot side of the turbo piping before my intercooler. I then have the top vacuum line off the wastegate running vented. I first want to verify that this is how we will run the lines for just boosting off the spring.

The poppet valve is held closed by spring tension. Then with a hose hooked to the side port (top port vented), pressure pushes up on the bottom of the diaphragm and opens the poppet valve:

Second I want to confirm which lines will run into the boost controller solenoid to make sure it's not installed backwards or anything. I have a AEM TruBoost Controller.

Port 1 (labeled on the solenoid itself) goes to your pressure source, port 2 goes to the top port of the gate. Port 3 can be vented to atmosphere. You can get the pressure source for port 1 by running a T off the line to the side port, or you can have a separate dedicated line going to the solenoid. In the diagram above, the solenoid is diverting pressure from the side port and applying it to the top port. So less pressure is pushing up on the bottom of the diaphragm while pressure is being applied to the top of the diaphragm to keep the poppet valve closed longer.

#114

Rotary Freak

Thread Starter

iTrader: (4)

Join Date: Aug 2005

Location: US

Posts: 2,150

Likes: 0

Received 0 Likes

on

0 Posts

Ah ok, that helps and explains a lot.

So to reiterate what you just said, if you have a line from the side port to the pressure source and the top port vented, then when turbo spools, the pressure is pushed into the side port of the wastegate diaphram which opens the wastegate up and depending on the spring, it boosts to whatever the spring pressure is.

When you install your boost controller, you run that side port vacuum line into a "T" fitting. From that "T" one line goes to the pressure source, and the other goes to the controller solenoid. From the other side of the solenoid, a line goes to the top port of the wastegate.

The way it works is that the solenoid controls the air flowing to the top port of wastegate. By controlling the air flow to the top port of the wastegate, the wastegate stays closed and higher boost is achieved.

Going to try to sort out my boost controller issue and make sure everything is hooked up correctly.

Thanks again!

So to reiterate what you just said, if you have a line from the side port to the pressure source and the top port vented, then when turbo spools, the pressure is pushed into the side port of the wastegate diaphram which opens the wastegate up and depending on the spring, it boosts to whatever the spring pressure is.

When you install your boost controller, you run that side port vacuum line into a "T" fitting. From that "T" one line goes to the pressure source, and the other goes to the controller solenoid. From the other side of the solenoid, a line goes to the top port of the wastegate.

The way it works is that the solenoid controls the air flowing to the top port of wastegate. By controlling the air flow to the top port of the wastegate, the wastegate stays closed and higher boost is achieved.

Going to try to sort out my boost controller issue and make sure everything is hooked up correctly.

Thanks again!

#116

Rotary Freak

Thread Starter

iTrader: (4)

Join Date: Aug 2005

Location: US

Posts: 2,150

Likes: 0

Received 0 Likes

on

0 Posts

I was able to get my boost controller situation settled I believe.

Went out to test it and with 10% duty cycle, the car is holding around 14-15psi. I checked to see what my hi boost was and it read as high as 16.8psi.

Is it fine for the car to spike like that? Within my boost controller, I have an "alarm boost" setting where if the controller reads 10% greater than what I set my alarm psi, it will turn the solenoid off. At the moment I have it set at 15.5 which means if the gauge reads 17psi, it will cut the solenoid.

Now do you guys believe that this is too high of a "cut-off" safeguard? The reason why I have it high is because I don't want the controller to shut off if the boost just spikes to 17.

I have to do some more testing to compare the peak boost for when I run with the controller off and just running it off the spring.

Steve did tell me that he set the PFC boost fuel cut set at 15psi, so if it sees 1.5psi above that, it will shut the car off.

I just want as many safeguards as possible to protect the engine from any possible damage.

Went out to test it and with 10% duty cycle, the car is holding around 14-15psi. I checked to see what my hi boost was and it read as high as 16.8psi.

Is it fine for the car to spike like that? Within my boost controller, I have an "alarm boost" setting where if the controller reads 10% greater than what I set my alarm psi, it will turn the solenoid off. At the moment I have it set at 15.5 which means if the gauge reads 17psi, it will cut the solenoid.

Now do you guys believe that this is too high of a "cut-off" safeguard? The reason why I have it high is because I don't want the controller to shut off if the boost just spikes to 17.

I have to do some more testing to compare the peak boost for when I run with the controller off and just running it off the spring.

Steve did tell me that he set the PFC boost fuel cut set at 15psi, so if it sees 1.5psi above that, it will shut the car off.

I just want as many safeguards as possible to protect the engine from any possible damage.

#117

Rotary Freak

Thread Starter

iTrader: (4)

Join Date: Aug 2005

Location: US

Posts: 2,150

Likes: 0

Received 0 Likes

on

0 Posts

On another note, I want to know if I should change my boost controller settings. I have the AEM TruBoost which has the following settings:

Display Units - Just selecting Psig, Bar and Kpg - Currently its set at PSI

Scramble Boost - I have no idea what this is. It is supposedly the scramble boost duty cycle - Currently set at 10

Scramble Boost Time - Don't know about this but it's the duration of time the above duty cycle will be effective

Alarm - described in my previous post - Currently set at 15.5

Spring Pressure - I'm supposed to enter my wastegate spring pressure which we believe is a 15psi spring. The TruBoost will keep the boost solenoid open from 1psi until boost exceeds the selected value - Currently this setting is at default of 2psi. Do I need to change this to 15?

Boost Setting - Output duty cycle for setting A - Currently this is set at 10% (the minimum) should this be changed?

Display Units - Just selecting Psig, Bar and Kpg - Currently its set at PSI

Scramble Boost - I have no idea what this is. It is supposedly the scramble boost duty cycle - Currently set at 10

Scramble Boost Time - Don't know about this but it's the duration of time the above duty cycle will be effective

Alarm - described in my previous post - Currently set at 15.5

Spring Pressure - I'm supposed to enter my wastegate spring pressure which we believe is a 15psi spring. The TruBoost will keep the boost solenoid open from 1psi until boost exceeds the selected value - Currently this setting is at default of 2psi. Do I need to change this to 15?

Boost Setting - Output duty cycle for setting A - Currently this is set at 10% (the minimum) should this be changed?

#118

Rotary Freak

Thread Starter

iTrader: (4)

Join Date: Aug 2005

Location: US

Posts: 2,150

Likes: 0

Received 0 Likes

on

0 Posts

Thought I'd give an update.

Boost controller is fixed and water injection is working.

Steve is coming back in March, so I will be getting tuned with my water injection this time.

Going to try and figure out the reason for the "lower numbers"

When I had the car looked over, there seems to be an exhaust leak coming from where my turbo manifold meets my motor. Could this play a large roll?

Boost controller is fixed and water injection is working.

Steve is coming back in March, so I will be getting tuned with my water injection this time.

Going to try and figure out the reason for the "lower numbers"

When I had the car looked over, there seems to be an exhaust leak coming from where my turbo manifold meets my motor. Could this play a large roll?

#121

Rotary Freak

Thread Starter

iTrader: (4)

Join Date: Aug 2005

Location: US

Posts: 2,150

Likes: 0

Received 0 Likes

on

0 Posts

Thought I'd go ahead and give an update on the car.

This past weekend, Steve Kan flew in again and tuned my car. I hadn't changed much with the car since the last tune. Maybe put on 300 miles on the motor, installed brand new OEM manifold gaskets and got my water injection working.

The final numbers ended up being 406rwhp/325rwtq @ 18psi. An increase of 62rwhp/56rwtq and 2psi.

I am pretty happy with the numbers, but in comparing my setup with Rich (we basically have the same exact setups) he is almost 90rwhp more than my setup.

I'm trying to figure out where the bottlenecks of my setup are in stealing power away.

Future things I need to improve:

1. Rewire my fuel pump. Steve said that I am at about 87% duty cycle

2. Order thicker coupers/better clamps/flare IC piping. During the pulls the coupler was blowing off because the IC piping had no flare to clamp to

3. Think about possibly running 50/50 water and meth setup for next tune.

Haven't been able to feel what the extra 60rwhp feels like as it was raining during the day of my tune and I was already breaking loose in 3rd gear just casually driving over to the tune.

I'm excited for some sun!

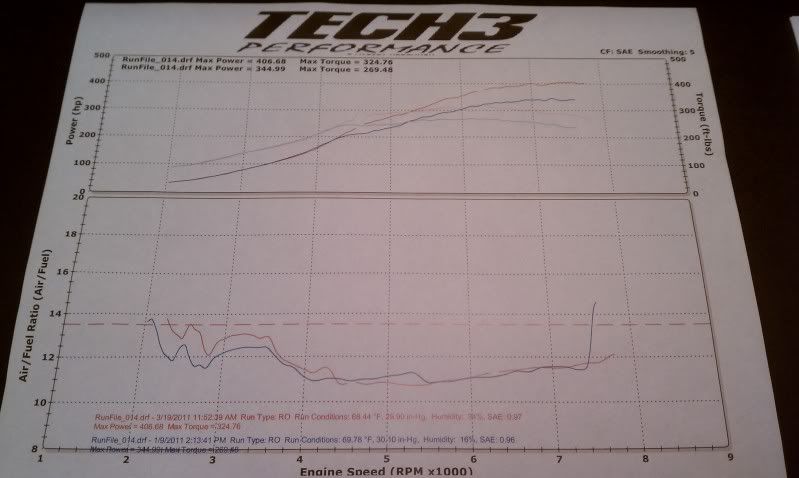

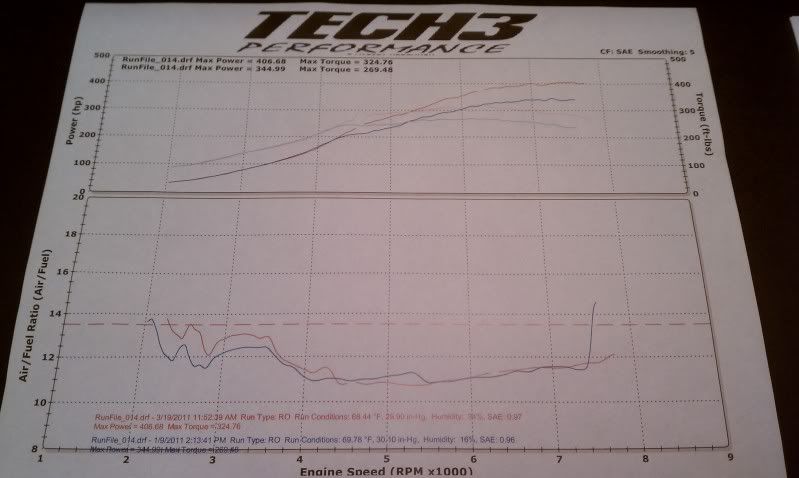

This is showing two results.

Blue is when Steve came in January to tune the car @ 16PSI

Red is the most recent tune @ 18psi with water injection

This past weekend, Steve Kan flew in again and tuned my car. I hadn't changed much with the car since the last tune. Maybe put on 300 miles on the motor, installed brand new OEM manifold gaskets and got my water injection working.

The final numbers ended up being 406rwhp/325rwtq @ 18psi. An increase of 62rwhp/56rwtq and 2psi.

I am pretty happy with the numbers, but in comparing my setup with Rich (we basically have the same exact setups) he is almost 90rwhp more than my setup.

I'm trying to figure out where the bottlenecks of my setup are in stealing power away.

Future things I need to improve:

1. Rewire my fuel pump. Steve said that I am at about 87% duty cycle

2. Order thicker coupers/better clamps/flare IC piping. During the pulls the coupler was blowing off because the IC piping had no flare to clamp to

3. Think about possibly running 50/50 water and meth setup for next tune.

Haven't been able to feel what the extra 60rwhp feels like as it was raining during the day of my tune and I was already breaking loose in 3rd gear just casually driving over to the tune.

I'm excited for some sun!

This is showing two results.

Blue is when Steve came in January to tune the car @ 16PSI

Red is the most recent tune @ 18psi with water injection

#124

I'd Agree with Lance above.. I think you should still run different plugs... greddy's or NGK race plugs.. Still seems a little low.. I was at 463 at 16psi with water meth..and my tune wasn't the best. I think you should still be higher.. But as long as your safe..which im sure steve knows what he's doing.. and your happy with the power then I'd say sort out the little things and get that fair lady of yours out on a road course!!

#125

Full Member

iTrader: (2)

Join Date: Jun 2009

Location: bay area

Posts: 130

Likes: 0

Received 0 Likes

on

0 Posts

It could be that their dyno reads a little bit lower plus the 91 octane might have been a factor. I dynoed at 310whp on their dyno with my 99 spec turbo set up at 14psi and was expecting closer to 350whp+. After the tune with Steve Kan, my car feels really fast for having twins