13b-re swap in to my FC

#1

13b-re swap in to my FC

OK, so I got the 13bre long block for 400 bucks and it looks like it's gonna be a runner ( I hope it doesn't smoke)

I am going to put it in my S4 FC and as most of you know the motor mounts seem to be the biggest hurdle. So I decided to make my own.

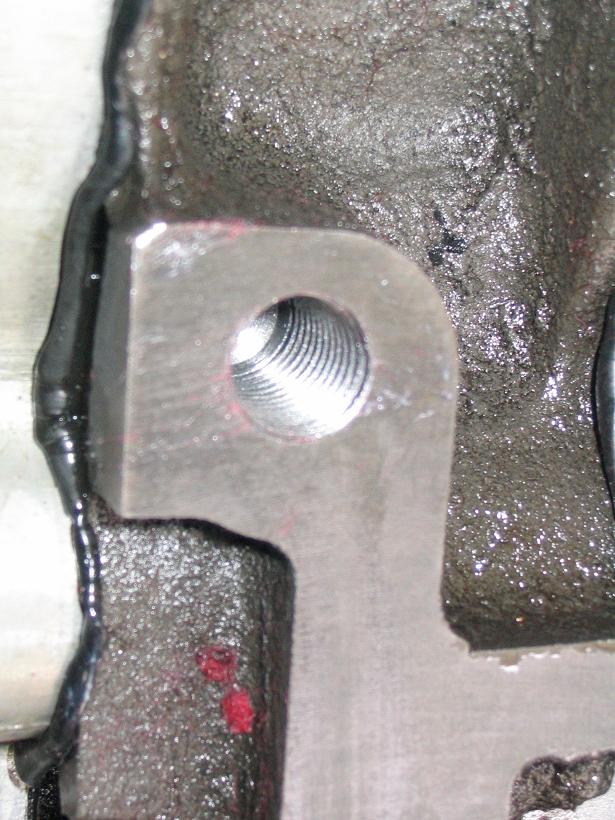

I will use the S4 oil pan and S4 aluminum passenger side mount. At first I was going to drill and tap all three holes on the bottom of the block; but soon realized I overlooked the fact that the Cosmo mounting holes on the side of the block wouldn’t leave me enough material to tap threads into.

After much head banging I decided to modify the aluminum mount to work. I will drill and tap the hole farthest in the block and then weld a piece of aluminum (in the shape of an L) on the aluminum mount to match the two mounting holes in the Cosmo block. Here are a few pictures of what I am doing.

I am going to put it in my S4 FC and as most of you know the motor mounts seem to be the biggest hurdle. So I decided to make my own.

I will use the S4 oil pan and S4 aluminum passenger side mount. At first I was going to drill and tap all three holes on the bottom of the block; but soon realized I overlooked the fact that the Cosmo mounting holes on the side of the block wouldn’t leave me enough material to tap threads into.

After much head banging I decided to modify the aluminum mount to work. I will drill and tap the hole farthest in the block and then weld a piece of aluminum (in the shape of an L) on the aluminum mount to match the two mounting holes in the Cosmo block. Here are a few pictures of what I am doing.

#3

multipersonality disorder

Join Date: Feb 2002

Location: so. cal

Posts: 5,656

Likes: 0

Received 0 Likes

on

0 Posts

first off--even if the motor does smoke, 400 is a great price, even for a core.

if you're welding somethign like that up, you're probably competant enough to just make some new mounts from scratch and keep the cosmo pan, though.

if you're welding somethign like that up, you're probably competant enough to just make some new mounts from scratch and keep the cosmo pan, though.

Trending Topics

#8

Originally Posted by Apathy

Thats nice. I didnt have any equipment so I just forked out the money for premade speedmachine brackets and was done with it.

#9

Some pics of the driver side motor mount

I bought 5 bucks worth of 1/8th inch steel plate 7" x 7"

Then proceeded to cut the back part of the factory mount off.

I will then weld it to the newly fabricated 7"x7" back plate.

I will have my welder TIG weld it along with the Aluminum passanger side mount

Then proceeded to cut the back part of the factory mount off.

I will then weld it to the newly fabricated 7"x7" back plate.

I will have my welder TIG weld it along with the Aluminum passanger side mount

#10

Last few shots before getting it welded. After buying the materials, tap, and drill bit as well as welding I will probably spent $50.00 making them and invested about 5 hours total time. Most of that time making measurments

Last edited by BASTARD; 06-02-06 at 09:31 PM.

#11

multipersonality disorder

Join Date: Feb 2002

Location: so. cal

Posts: 5,656

Likes: 0

Received 0 Likes

on

0 Posts

looks nice and you did a great job, but why go through all that trouble instead of just buying the mounting brackets? and why use an inferior fc oil pan?

#12

Originally Posted by GUITARJUNKIE28

looks nice and you did a great job, but why go through all that trouble instead of just buying the mounting brackets? and why use an inferior fc oil pan?

As far as the FC oil pan I have never had a problem with it. I will be driving this car as it was intened to be driven... on the road, daily.

Ok, So I want a few extra ponies and I will occasionally smoke the tires and i have a bad habit of driving at speed in excess of 145MPH , but I am not a Drag racer or a road racer and therefore dont really feel as tho I am taxing the oil system in that capacity. However if I do get to that point, I still have the oil pan on the shelf and can make changes later.

#14

multipersonality disorder

Join Date: Feb 2002

Location: so. cal

Posts: 5,656

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by BASTARD

I didn't buy prefab mounts becuase i can do it myself for a fraction the cost. Yeah, ok you can argue the whole time is money so the time i spent fabricating would cost lets say $80.00 X 5 hours = 400.oo bucks... but since i am not in the fabrication business I don't charge myself for the labor.

As far as the FC oil pan I have never had a problem with it. I will be driving this car as it was intened to be driven... on the road, daily.

Ok, So I want a few extra ponies and I will occasionally smoke the tires and i have a bad habit of driving at speed in excess of 145MPH , but I am not a Drag racer or a road racer and therefore dont really feel as tho I am taxing the oil system in that capacity. However if I do get to that point, I still have the oil pan on the shelf and can make changes later.

As far as the FC oil pan I have never had a problem with it. I will be driving this car as it was intened to be driven... on the road, daily.

Ok, So I want a few extra ponies and I will occasionally smoke the tires and i have a bad habit of driving at speed in excess of 145MPH , but I am not a Drag racer or a road racer and therefore dont really feel as tho I am taxing the oil system in that capacity. However if I do get to that point, I still have the oil pan on the shelf and can make changes later.

now if you're planning on usint the pinapple aluminum pan or something along those lines, i can totally see going through the extra trouble for ll this.

#15

Originally Posted by GUITARJUNKIE28

hey man, i wasn't trying to insult you. i think you did a great job. if you cna drill and tap the iron, then fab up everything else, you obviously have enough skill to fab up a mount from scratch that will bolt to the cosmo housings.

now if you're planning on usint the pinapple aluminum pan or something along those lines, i can totally see going through the extra trouble for ll this.

now if you're planning on usint the pinapple aluminum pan or something along those lines, i can totally see going through the extra trouble for ll this.

... I do have the ability to fab mounts from scratch... and I thought about it. but for whatever reason I decided to go this route.. probably because it's the road less traveled and it was cheap... what can I say, I'm a cheap bastard...I hope it works out.

... I do have the ability to fab mounts from scratch... and I thought about it. but for whatever reason I decided to go this route.. probably because it's the road less traveled and it was cheap... what can I say, I'm a cheap bastard...I hope it works out. And to be honset I have thought about making my own pan I dont think it would be that difficult...

you can use a solid plate of aluminum; any thickness you like. If you think you can gain some rigidity from a thick plate of aluminum for the high HP cars then you could use 1/4 plate (or thicker???). Cut the shape and needed holes for the dip stick, sump, and drainage and then weld a box on the bottom side with a drain plug

#17

multipersonality disorder

Join Date: Feb 2002

Location: so. cal

Posts: 5,656

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by BASTARD

no insult taken  ... I do have the ability to fab mounts from scratch... and I thought about it. but for whatever reason I decided to go this route.. probably because it's the road less traveled and it was cheap... what can I say, I'm a cheap bastard...I hope it works out.

... I do have the ability to fab mounts from scratch... and I thought about it. but for whatever reason I decided to go this route.. probably because it's the road less traveled and it was cheap... what can I say, I'm a cheap bastard...I hope it works out.

And to be honset I have thought about making my own pan I dont think it would be that difficult...

you can use a solid plate of aluminum; any thickness you like. If you think you can gain some rigidity from a thick plate of aluminum for the high HP cars then you could use 1/4 plate (or thicker???). Cut the shape and needed holes for the dip stick, sump, and drainage and then weld a box on the bottom side with a drain plug

... I do have the ability to fab mounts from scratch... and I thought about it. but for whatever reason I decided to go this route.. probably because it's the road less traveled and it was cheap... what can I say, I'm a cheap bastard...I hope it works out.

... I do have the ability to fab mounts from scratch... and I thought about it. but for whatever reason I decided to go this route.. probably because it's the road less traveled and it was cheap... what can I say, I'm a cheap bastard...I hope it works out. And to be honset I have thought about making my own pan I dont think it would be that difficult...

you can use a solid plate of aluminum; any thickness you like. If you think you can gain some rigidity from a thick plate of aluminum for the high HP cars then you could use 1/4 plate (or thicker???). Cut the shape and needed holes for the dip stick, sump, and drainage and then weld a box on the bottom side with a drain plug

well reguardless of what way you decided to do it, you did some good work there

WNT2CREALPAIN, i've got an RE supplier for $1200 hit me up in pm and i'll give you the number to the place.

#19

Did i mention I was making my fuel rail too?... yes those are -10 and yes maybe over kill but i figured if im gonna spend the money might as well do it big. My idea was to maintain a constant 1/2 I.D. once the fuel reached the fuel rail. I will be running 750 primaries and 1680 secondary injectors. As you can see I still need to make the primary rail mount.

#20

Well, after weeks of doing nothing I finaly got the motor in the car. The TB elbow was kind of a PITA, but turned out nice and so was the new intercooler pipe. All in all I am very happy so far with the fit.

I have also decided to run premix for now to get by the EOMP hassles.

As of now the only thing left is the TPS (which is almost ready to mount), the alternator and the CAS... all which are easily installed, but I am waiting until I get my self fusing tape to wrap my Haltec harness.

I have also decided to run premix for now to get by the EOMP hassles.

As of now the only thing left is the TPS (which is almost ready to mount), the alternator and the CAS... all which are easily installed, but I am waiting until I get my self fusing tape to wrap my Haltec harness.

#23

Im Doing This Swap, But Running The Stock Twins. I Have A 20b Intercooler That I Want To Run As A Front Mount. If I Need That Throttle Body Elbow Will You Be Willing To Make Me One? IM ALSO IN CALI, SOUTH BAY

#24

Originally Posted by rotarydelight

Im Doing This Swap, But Running The Stock Twins. I Have A 20b Intercooler That I Want To Run As A Front Mount. If I Need That Throttle Body Elbow Will You Be Willing To Make Me One? IM ALSO IN CALI, SOUTH BAY

I think you will be fine with the stock elbow... the only reason i cut down the stock one was becuase I was already running 3" pipe from my intercooler from the previous installation. If i was doing this the first time... I would use the stock one just as it came off the Cosmo and stick to the 2.5" tubing...

here's a picture of the previous install.. that had a completely custom TB elbow I made

as far as making a TB elbow for you, I suppose I could... but it would require you to provide me with the parts and pieces needed to do it... which would be a TB elbow from a cosmo and a 3" 90 bend off ebay plus labor for the welding which i sub out and if you wanted a bead rolled on the end I would also have to sub that out... one thing i dont do is polish stuff

BTW... Im in the East Bay as in Nor Cal