Custom Strut Tower Brace Progress (FD)

#1

Custom Strut Tower Brace Progress (FD)

EDIT: Added keywords to help people search.

Strut tower bar brace triangulated FD chassis flex

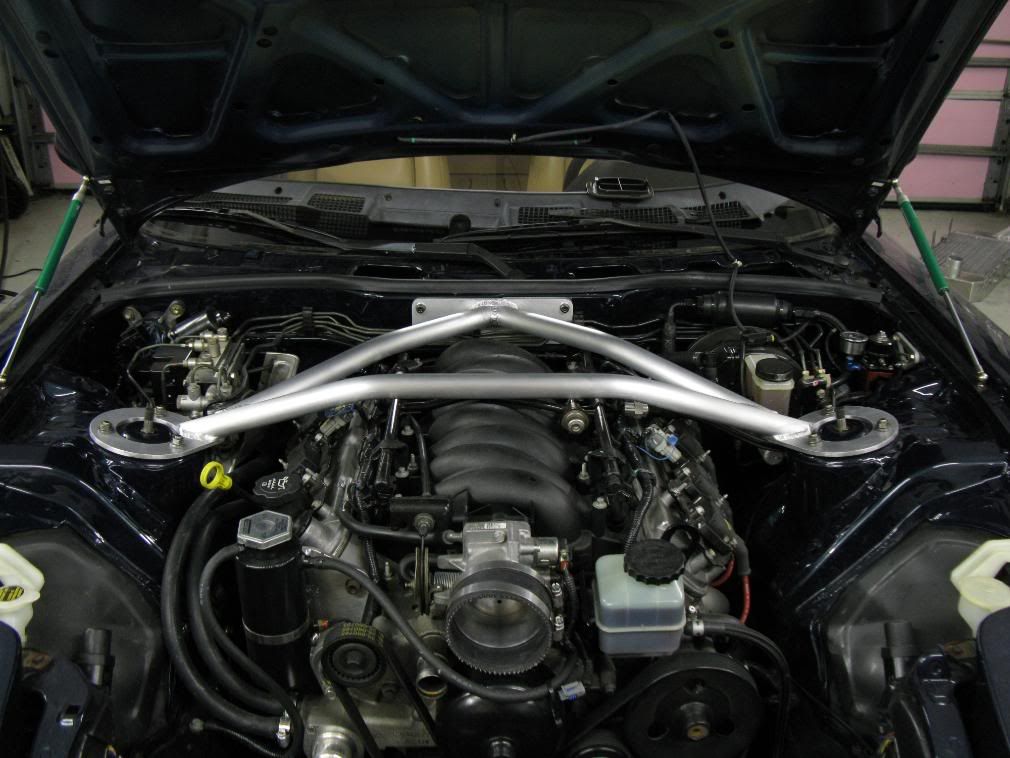

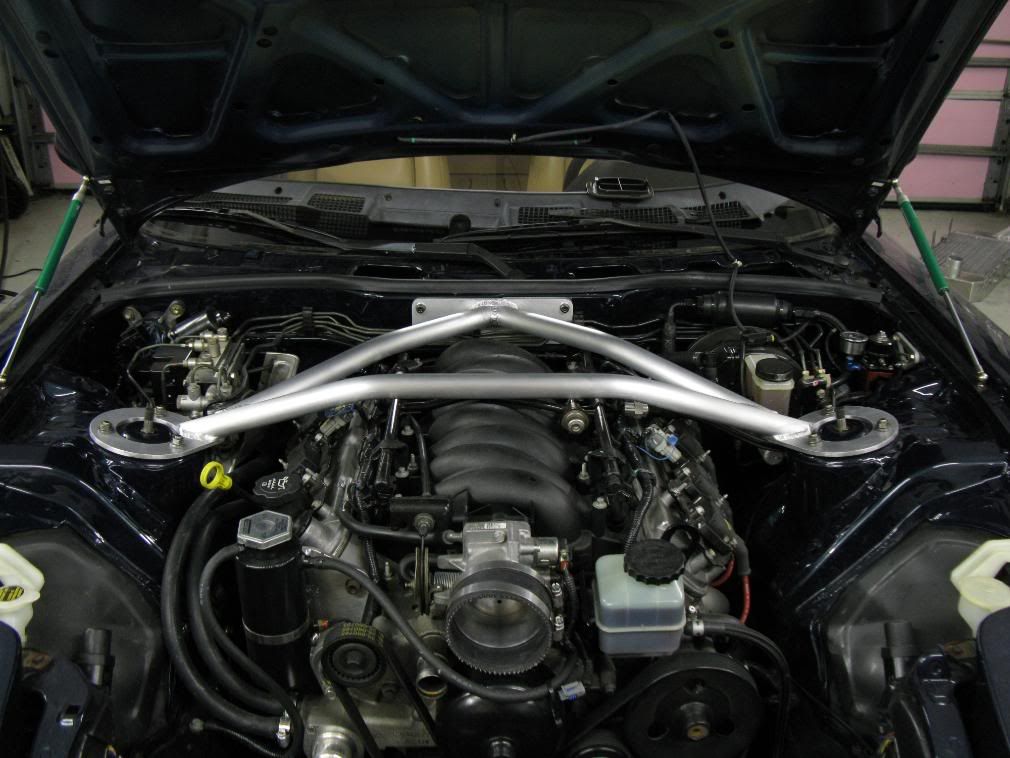

Well I was getting kinda bored with nothing to work on lately so I've been thinking of stuff that I could make for my car. I ended up ordering some parts to start making a front underbody pannel and splitter. While I'm waiting on those parts I figured it start mocking up a front strut tower bar.

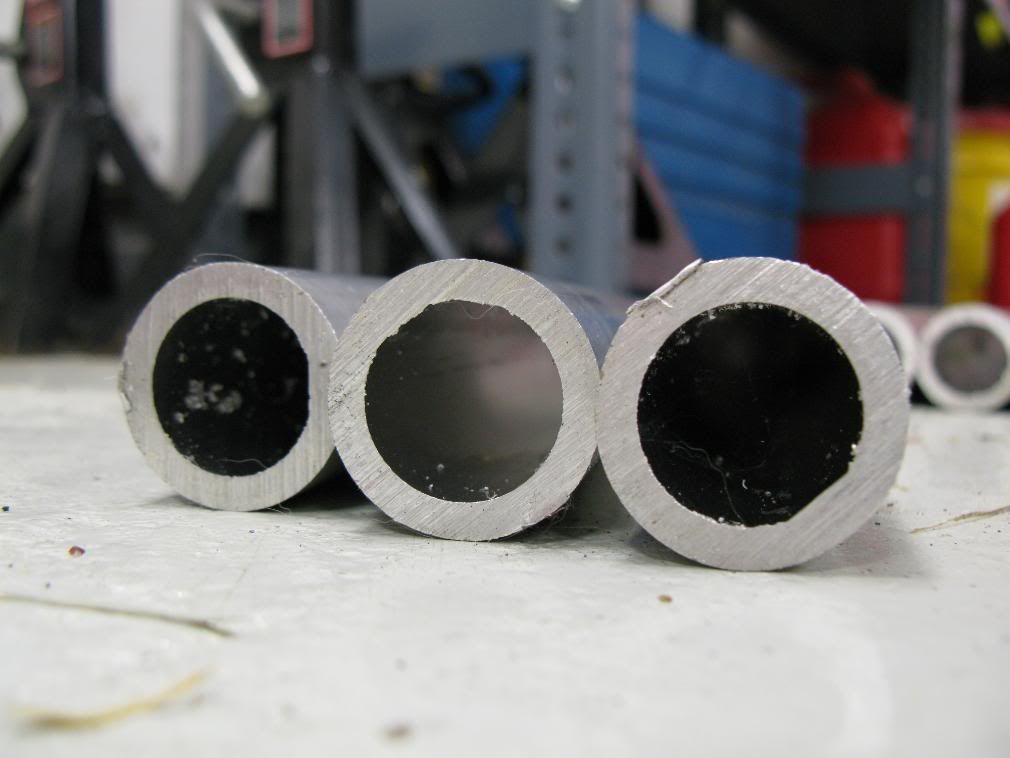

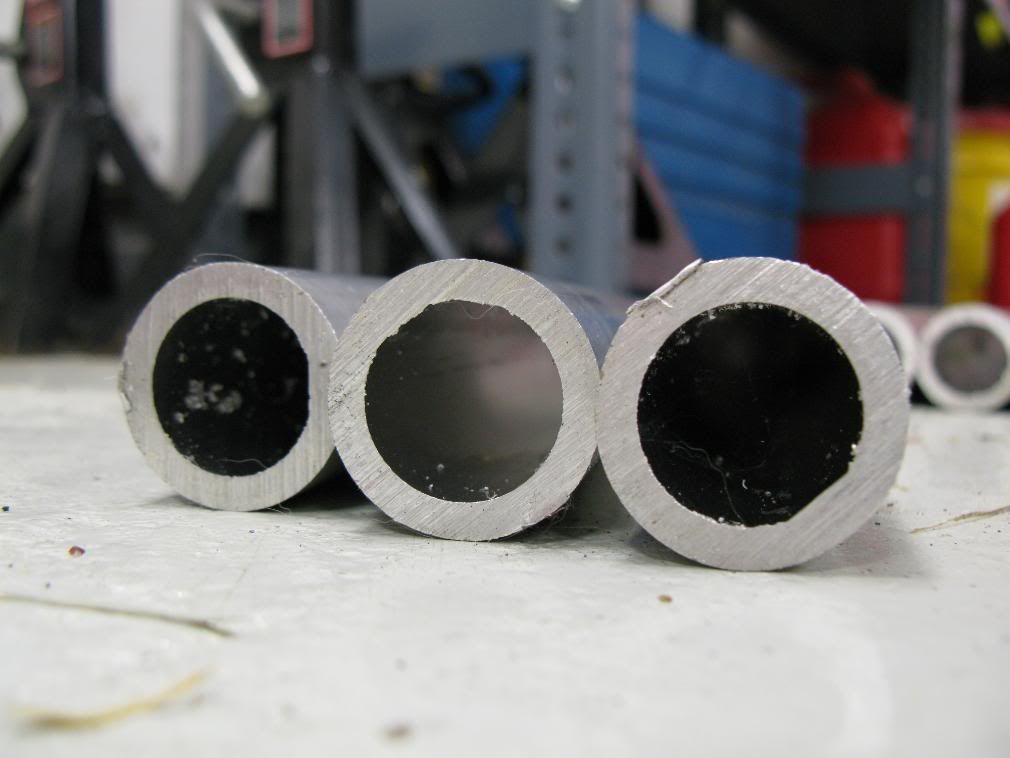

I'm mocking it up with 1" schedule 40 PVC. It ends up being 1.33" OD and 0.133" wall thickness. I'll going to make it using 1" sch 80 AL pipe (6061 T6). I also used some 1/4" foam board for the tower mounts but that will end up being water jet cut from 1/4" 6061-T6 1/4" plate.

I started the mockup using 1.5" aluminum tube but it ended up being too large of an OD. As it sits now, I have ~3/16" clearnace from the hood at the closest, and 5/16" clearance from the LS6 manifold (sorry rotary purists) at the closest point. For the firewall connection I'm going to be using a pretty large 1/4" aluminum plate to spread the load out, bolted to the firewall using 4 10mm bolts, backed with some pretty large washers on the backside. The plate will extend will be approximately 8" long, and go from the top edge of the firewall, down to the lip in the firewall. The pictures show the PVC being cut and taped. On the real version this will be a bent pipe.

The main tube has two 15 degree bends in it to avoid hitting the webing under the hood, and I cannot go less w/o hitting the hood. The bars going to the firewall have a 10 degree bend in them, and that is to clear the fuel rails.

The whole thing will be a single piece welded construction. I looked out of using Chromoly instead of alumnium, but it was heavier, and not as strong. I estimate this piece will weigh in at ~6 lbs when done.

And pics:

For those of you guys that love to pick out everything the background of the pic I'll save you the trouble. Yes, I have a snow shovel in 90 degree weather, a badass pillow in a box, busted *** Z06 titanum exhaust, and a blowgun in my garage.

Strut tower bar brace triangulated FD chassis flex

Well I was getting kinda bored with nothing to work on lately so I've been thinking of stuff that I could make for my car. I ended up ordering some parts to start making a front underbody pannel and splitter. While I'm waiting on those parts I figured it start mocking up a front strut tower bar.

I'm mocking it up with 1" schedule 40 PVC. It ends up being 1.33" OD and 0.133" wall thickness. I'll going to make it using 1" sch 80 AL pipe (6061 T6). I also used some 1/4" foam board for the tower mounts but that will end up being water jet cut from 1/4" 6061-T6 1/4" plate.

I started the mockup using 1.5" aluminum tube but it ended up being too large of an OD. As it sits now, I have ~3/16" clearnace from the hood at the closest, and 5/16" clearance from the LS6 manifold (sorry rotary purists) at the closest point. For the firewall connection I'm going to be using a pretty large 1/4" aluminum plate to spread the load out, bolted to the firewall using 4 10mm bolts, backed with some pretty large washers on the backside. The plate will extend will be approximately 8" long, and go from the top edge of the firewall, down to the lip in the firewall. The pictures show the PVC being cut and taped. On the real version this will be a bent pipe.

The main tube has two 15 degree bends in it to avoid hitting the webing under the hood, and I cannot go less w/o hitting the hood. The bars going to the firewall have a 10 degree bend in them, and that is to clear the fuel rails.

The whole thing will be a single piece welded construction. I looked out of using Chromoly instead of alumnium, but it was heavier, and not as strong. I estimate this piece will weigh in at ~6 lbs when done.

And pics:

For those of you guys that love to pick out everything the background of the pic I'll save you the trouble. Yes, I have a snow shovel in 90 degree weather, a badass pillow in a box, busted *** Z06 titanum exhaust, and a blowgun in my garage.

Last edited by Kevin Doe; 07-07-08 at 12:34 PM.

#4

Bumble Bee RX-3

Join Date: Dec 2005

Location: Palm Harbor, Florida

Posts: 101

Likes: 0

Received 0 Likes

on

0 Posts

nice looking d-bar, some nice .100" gussets with lightening holes or with RX-7, LS-6 logos jetted in them maybe?... with a d-bar setup you should be able to use a lighter bar size and wall, remember there are 2 bars to split and carring the load from each side instead one... engine is solid mounted? otherwise 5/16" may not be enough, and don't let the hood slam as the cushion stop rubbers and skins flex, a little clay on either side of the bars at the closest point and start it up and load the engine with the hood closed, do it lightly at first and check then load more heavily, check clay for squish...

#5

I thougth about going with schedule 40 pipe instead of schedule 80, but the weight difference was only 1.5 lbs. Seemed like a no brainer to go with the thicker wall tubing. I think the 5/16" is more than sufficient, and I made it so large becasue I think a FAST manifold is a little taller. My throttle body is 1/8" from the hood, and it doesn't rub at all. Its a tight fit in there for sure. I'm using poly mounts, so it sits in there pretty securely. It would be pretty cool to get some laser etched logos in there, but then I'm entering ricer territory, a place I am very afraid of. LOL.

#6

Warming the planet.

#7

Bumble Bee RX-3

Join Date: Dec 2005

Location: Palm Harbor, Florida

Posts: 101

Likes: 0

Received 0 Likes

on

0 Posts

Yes would like to see end result...

Just remember it is Ricer when it is shinny useless excess...

1/8" clearance... no bikini babes posing on your hood... : )

Just remember it is Ricer when it is shinny useless excess...

1/8" clearance... no bikini babes posing on your hood... : )

Trending Topics

#8

I got all the pipe bent up. And the plates are all water jetted out. I'll get some pics up soon. I'm gonna start the fabrication here in the next few days I think.

Sadly no bikini babes on my hood. Unless I could convince my 8 month prego wife to get in a bikini and plop on my car. LOL.

Sadly no bikini babes on my hood. Unless I could convince my 8 month prego wife to get in a bikini and plop on my car. LOL.

#9

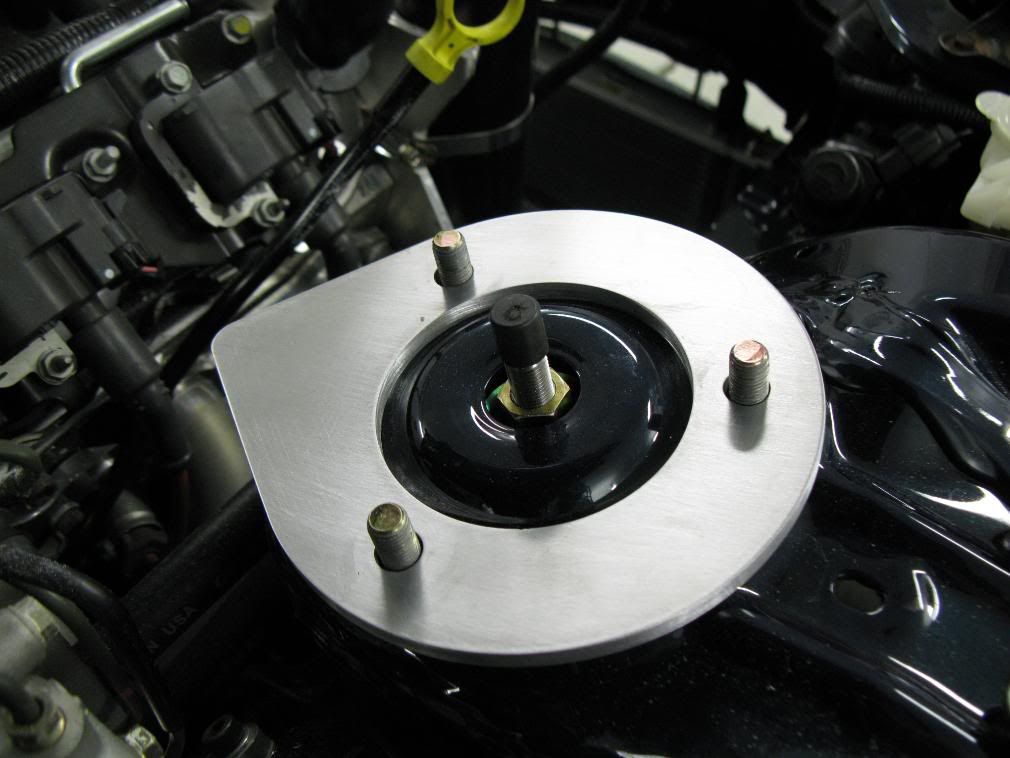

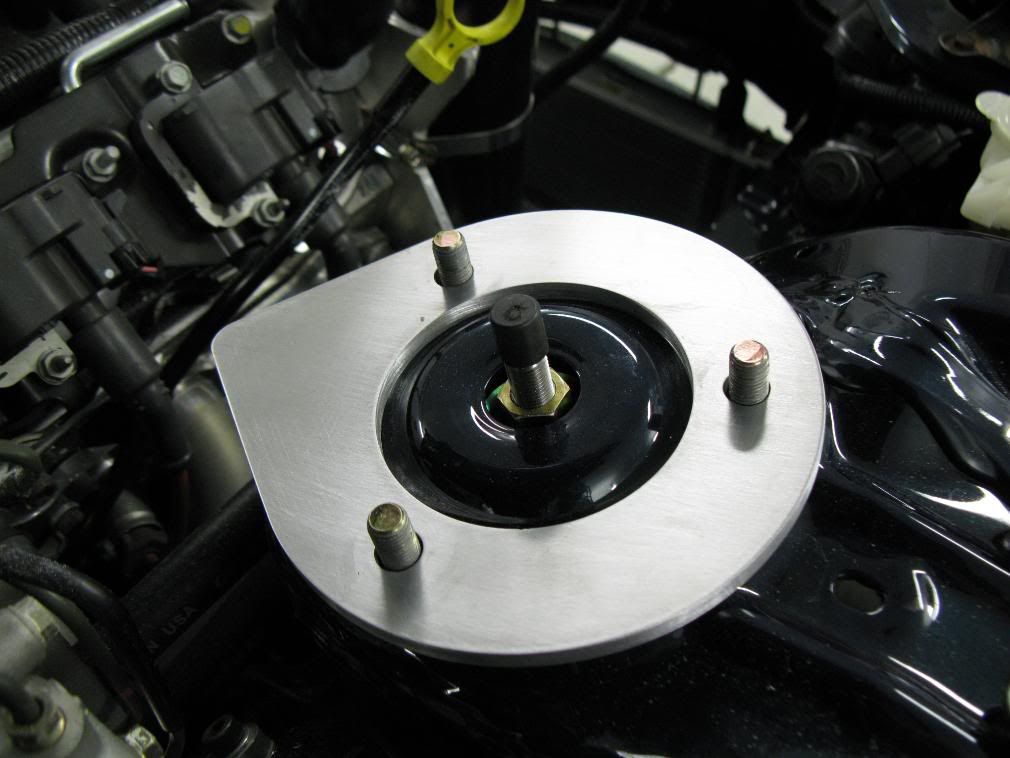

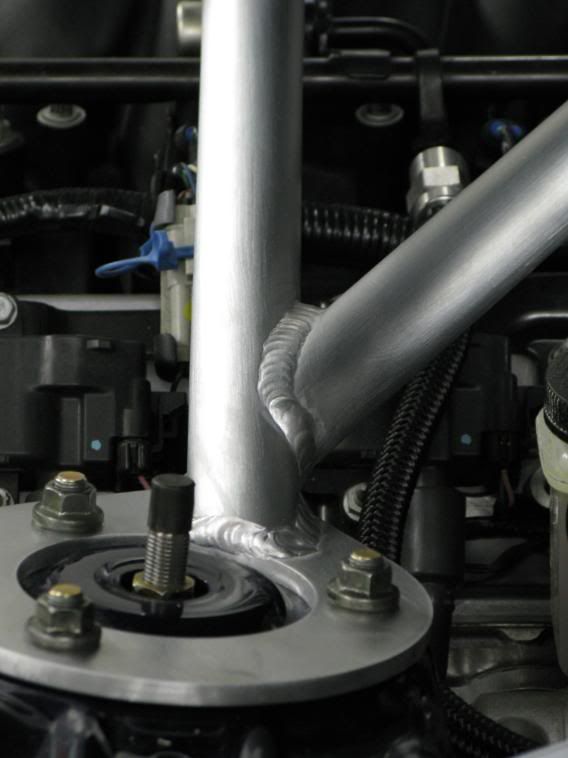

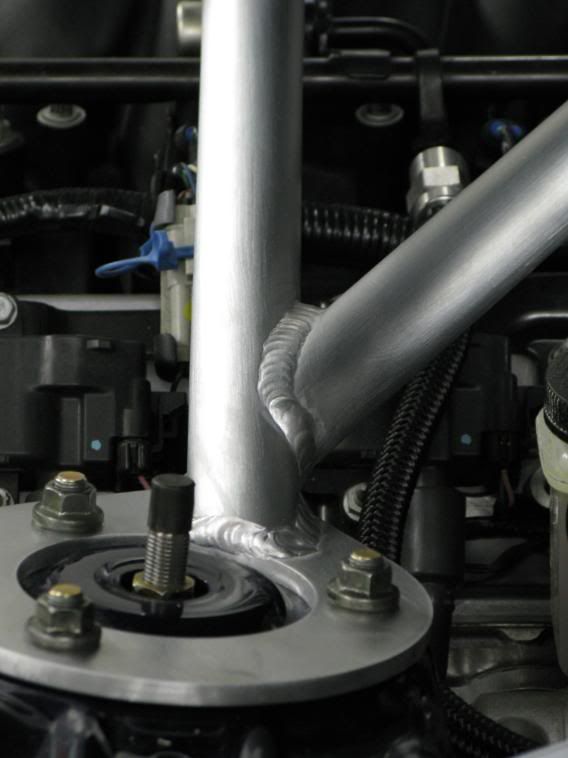

So the plates are all done, and fit well. Time to start some fabrication work on this bitch.

The cutout on the firewall plate is to clear the VIN boss, and make the plate sit flat on the firewall. Dave (JuicedH22) and I machined them, well I basically did, but dave reminded me how to use the mahince since it has been a really long time since I have used a milling machine.

Rob @ Rigid Race Cars here in Cincinnati (actually Williamsburg) bent up my pipe for me, and it turned out really good. Its some heady duty stuff. The pipe is not crushed on the inside of the bend, the dies just made the surface shiny so it appears to be dented.

The cutout on the firewall plate is to clear the VIN boss, and make the plate sit flat on the firewall. Dave (JuicedH22) and I machined them, well I basically did, but dave reminded me how to use the mahince since it has been a really long time since I have used a milling machine.

Rob @ Rigid Race Cars here in Cincinnati (actually Williamsburg) bent up my pipe for me, and it turned out really good. Its some heady duty stuff. The pipe is not crushed on the inside of the bend, the dies just made the surface shiny so it appears to be dented.

#10

Today I made up the strut tower bar from the real deal. It took 10x longer than with the PVC, but all went well. No wasted pieces so thats a plus. All ready to weld tomorrow. I'm gonna have to do some thinking on what order to tack/weld the thing together to prevent warpage and bolt hole misalignment. I only made one change and that was to have the firewall tubes somewhat intersect each other. And onto the pics.

#11

Got it all pretty much finished up today. The only thing left to do is get it coated if I decide to. I"m thinking annodized black, err something. Maybe powercoated satin black. I dunno.

Right now I just brushed it out with some scotch brite pads. Turned out pretty much fantastic.

The first two pics are of the measures I took to prevent flange warpage during welding. If I had not used those, the plates would have wanted to curl up.

Right now I just brushed it out with some scotch brite pads. Turned out pretty much fantastic.

The first two pics are of the measures I took to prevent flange warpage during welding. If I had not used those, the plates would have wanted to curl up.

#15

Rotary Freak

Join Date: Jan 2002

Location: l.a.

Posts: 1,640

Likes: 0

Received 0 Likes

on

0 Posts

there's actually no point in triangulating to the firewall, as the firewall is not that strong. if you want extra rigidity you should punch through the firewall and brace it to the dash bar.

#17

If the force in each beam is really low, it was for one of two reasons. First could be that the chassis is already stiff in that type of torsion. Second could be that the firewall mount it not rigid, and can not apply any significant reaction force and deflects.

If the force in each beam is high, then you can assume that the they are doing their job.

I will report back with real world data in a few weeks or so.

#19

I just picked it up. I took a few classes in college, but nothing of any real substinance. I did steel in that class (TIG). I just took the basic concepts and went from there on my own projects. Now I end up doing a lot of the welding for local car guys projects, so I stay in decent practice.