Axle upgrade necessary for road racing? FD3S 4 rotor

#26

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,778

Received 2,564 Likes

on

1,824 Posts

agreed. i'm doing a 3 rotor PP later this year, and i think by the time you load it down to be happy, its going to be going quite fast, my 2 rotor is ok on the street, but we've go no expectations for the 3 rotor.

#27

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,778

Received 2,564 Likes

on

1,824 Posts

i drove my PP back to back with the turbo FC, and there is a large weight difference between the two, but the PP feels stronger everywhere, and there is no waiting for it to spool up or any of that

#28

I've thought over this some more.

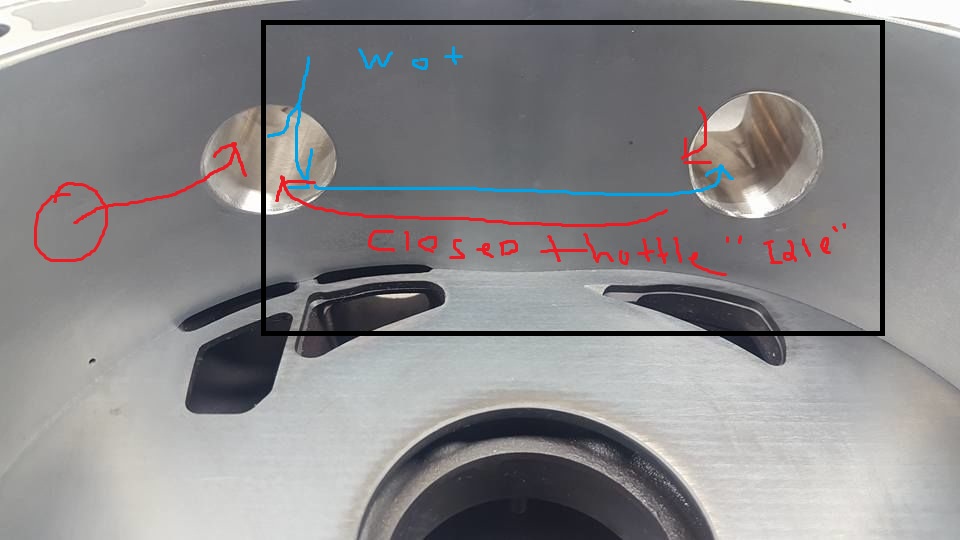

Seems to me like the PPort/Bridgeport bucking issue isn't the port sizing so much as it is your tuning.

If the car has very low resolution, due to map sensor based tuning, with low vacuum and a low range to determine low load, cruise throttle, then fueling will be all over the place as the load changes and vacuum doesn't.

So, if tuned on Throttle Position Input on low load/cruise ranges, rather than MAP sensor, this should help tremendously, no?

Basically, when you apply a little light throttle, on the interstate, to maintain that "cruise", and the car starts bucking, this is because you're near the "idle" vacuum right"? and the car is now applying idle milliseconds to the injectors.

Solution: read the tps to see that its at X percent throttle, apply more fuel and retard timing to stop the bucking.

Summary: at -6 inches of vacuum idle = x milliseconds of fuel, at -6 inches of vacuum on cruise its still x milliseconds = bucking. Fix this by adding more fuel at -6 inches IF TPS is @ Y % throttle

No?

Seems to me like the PPort/Bridgeport bucking issue isn't the port sizing so much as it is your tuning.

If the car has very low resolution, due to map sensor based tuning, with low vacuum and a low range to determine low load, cruise throttle, then fueling will be all over the place as the load changes and vacuum doesn't.

So, if tuned on Throttle Position Input on low load/cruise ranges, rather than MAP sensor, this should help tremendously, no?

Basically, when you apply a little light throttle, on the interstate, to maintain that "cruise", and the car starts bucking, this is because you're near the "idle" vacuum right"? and the car is now applying idle milliseconds to the injectors.

Solution: read the tps to see that its at X percent throttle, apply more fuel and retard timing to stop the bucking.

Summary: at -6 inches of vacuum idle = x milliseconds of fuel, at -6 inches of vacuum on cruise its still x milliseconds = bucking. Fix this by adding more fuel at -6 inches IF TPS is @ Y % throttle

No?

#29

yeap same with above. 13bbp vs 13bpp the pp makes more tourqe everywhere. interesting enough with latest one I have done with rx8 internals(rotors slotted to run conventional seals) it's more streetable even then a bridge. it quite happily cruises at our suburban speed limits of 50km/hr with no throttle modulation. I was blown away had to keep checking what gear I was in lol

#30

Old [Sch|F]ool

I've thought over this some more.

Seems to me like the PPort/Bridgeport bucking issue isn't the port sizing so much as it is your tuning.

If the car has very low resolution, due to map sensor based tuning, with low vacuum and a low range to determine low load, cruise throttle, then fueling will be all over the place as the load changes and vacuum doesn't.

No?

Seems to me like the PPort/Bridgeport bucking issue isn't the port sizing so much as it is your tuning.

If the car has very low resolution, due to map sensor based tuning, with low vacuum and a low range to determine low load, cruise throttle, then fueling will be all over the place as the load changes and vacuum doesn't.

No?

Running richer helps burn the exhaust-diluted air. Running less ignition timing under cruise also helps because you build less manifold vacuum, so less exhaust dilution.

Running without vacuum advance, I could run as lean as 14:1 under highway cruise. But the fuel economy and power sucked. Running with vacuum advance, I had to run at 12:1 to run smoothly but there was a window, it would cruise okay at 55-65mph but slower or faster than that it would buck. Slower than that it wasn't loaded enough because air resistance is the square of speed, faster than that and the engine built too much vacuum and no amount of fuel will solve excess exhaust gases getting pulled up. And the oil dilution from running that rich all the time was crazy! But fuel economy was awesome because the engine was really happy.

So I compromised on timing (kicked it back to stock timing vs. 22-24deg max mechanical) and so the least rich happy running was in the 13-13.5:1ish range... good compromise for fuel economy vs. destroying the oil.

Last edited by peejay; 02-11-16 at 11:32 AM.

#31

Well shoot, I thought I had it figured out lol

What I meant specifically was on MAP based tuning, you'd have KPA/PSI/Inches of hg vs fuel right? So the motor, making less vacuum than a usual rotary, its going to have a smaller range on that MAP scale? Like instead of normally pulling -20inches on cruise or idle its pulling way less.

On a typical engine, seeing -5 inches of vacc, at 3k rpm cruising can be understood as a certain degree of load, which we'd add/subtract fuel at that cell. But with the massive porting, and already less vacuum to begin with, the load can be different at the same cell, demanding differing amounts of fuel based upon throttle position, because manifold pressure isn't as responsive to changes in load. I could have this all totally backwards and no clue of understanding fuel injection. But what I'm getting at is, wouldn't it make most sense to tune on TPS rather than MAP based load??????????????

Guess its time to get ready for the bucking bronco.

What I meant specifically was on MAP based tuning, you'd have KPA/PSI/Inches of hg vs fuel right? So the motor, making less vacuum than a usual rotary, its going to have a smaller range on that MAP scale? Like instead of normally pulling -20inches on cruise or idle its pulling way less.

On a typical engine, seeing -5 inches of vacc, at 3k rpm cruising can be understood as a certain degree of load, which we'd add/subtract fuel at that cell. But with the massive porting, and already less vacuum to begin with, the load can be different at the same cell, demanding differing amounts of fuel based upon throttle position, because manifold pressure isn't as responsive to changes in load. I could have this all totally backwards and no clue of understanding fuel injection. But what I'm getting at is, wouldn't it make most sense to tune on TPS rather than MAP based load??????????????

Guess its time to get ready for the bucking bronco.

Last edited by Monsterbox; 02-11-16 at 12:52 PM.

#32

Here's an excerpt from another member on another forum speaking of this:

"The aux in is a global adjustment on the k, I remember the X having the gas compensation map. I once set it up with zero and full throttle map and tried a 1 bar map, but it didn't work , A p-port makes basically nil for vacuum so on a map sensor it uses about 5 cells, but the fueling needed for 2000 rpm at 15% throttle in 2nd gear is different from 15% throttle at 2000 rpm in 4th. Thats where the second map would come into play. For a turbo p-port, life would be alot easier if in vacuum it referenced Tps, but boost it went to map. "

^so if what he's saying is correct, the load is not being consistently accounted for, 1 value is applied where 2 values are needed, maybe this contributes to the bucking on a map based system?

"The aux in is a global adjustment on the k, I remember the X having the gas compensation map. I once set it up with zero and full throttle map and tried a 1 bar map, but it didn't work , A p-port makes basically nil for vacuum so on a map sensor it uses about 5 cells, but the fueling needed for 2000 rpm at 15% throttle in 2nd gear is different from 15% throttle at 2000 rpm in 4th. Thats where the second map would come into play. For a turbo p-port, life would be alot easier if in vacuum it referenced Tps, but boost it went to map. "

^so if what he's saying is correct, the load is not being consistently accounted for, 1 value is applied where 2 values are needed, maybe this contributes to the bucking on a map based system?

#33

No, the issue here with a motor with a lot of overlap is this.

When the throttle plate is closed/partially open there is not enough airflow coming through the throttle body to feed the expanding intake stroke to atmospheric pressure so a there is a vacuum created (like any engine).

However, because there is a lot of overlap between exhaust and intake strokes the exhaust is available for the expanding intake stroke to "suck up" and fill the intake stroke volume to atmospheric.

Because of the high ratio of exhaust gasses to intake charge in the intake stroke this rotor face has a miss-fire event.

Next this miss-fire chamber is dumped into the exhaust port and instead of just exhaust gasses the expanding intake charge "sucks up" the raw air and fuel along with exhaust gasses.

This however is not a viable enough intake stroke to fire either and there is a miss-fire event again.

Next this miss-fire chamber is dumped into the exhaust port along with the previous miss-fire event and the intake stroke "sucks up" both these miss-fires air/fuel and a little exhaust as well.

Boom, it is enough air with the gas to combust and we have a combustion event.

Next the combustion event dumps its exhaust into the exhaust stroke and the process starts all over.

Braaap, braap, braap (engine firing approximately once every three rotor revolutions).

-----------

There have been ways though up to help this problem by manufacturers who sold p-port rotaries to the public.

The Norton rotary motorcycle used a unique idea to increase carburetor airflow while keeping idle rpms low.

At idle they killed ignition on one rotor so the second firing rotor had more load (ie had to have the throttle plate open more).

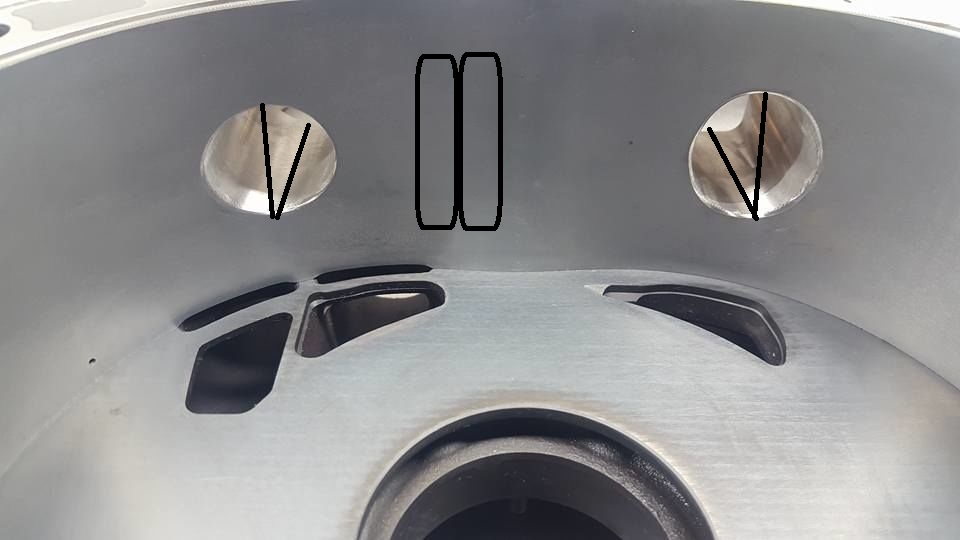

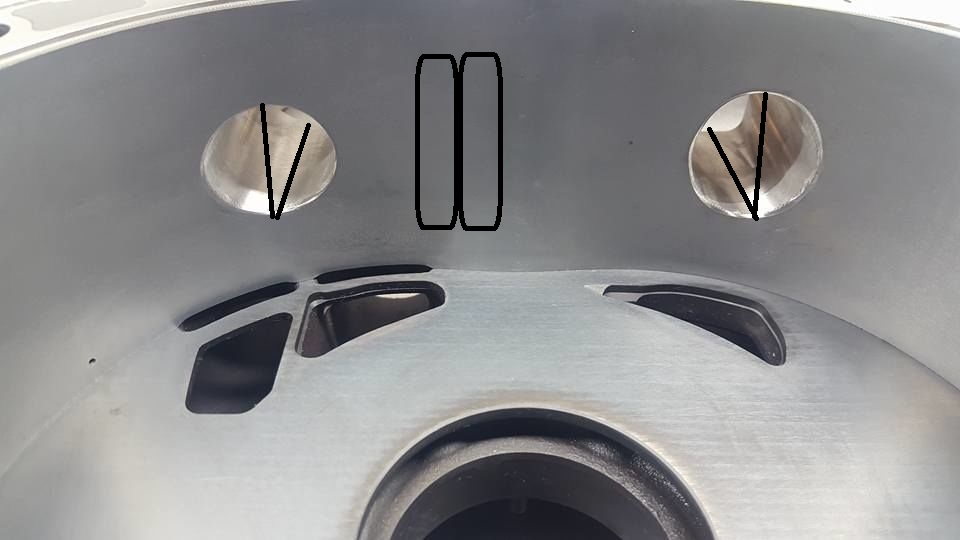

The NSU RO80 used a pinky sized primary carburetor throat and a complimentary shaped p-port (small at the top for the primary, larger at the bottom for seconday) to keep intake velocity up at idle to help bias intake flow over exhaust flow into the intake stroke.

It still braaped some and had ****** (sudden increase in power) so they coupled the motor to a hydraulic torque converter on their manual transaxle.

When the throttle plate is closed/partially open there is not enough airflow coming through the throttle body to feed the expanding intake stroke to atmospheric pressure so a there is a vacuum created (like any engine).

However, because there is a lot of overlap between exhaust and intake strokes the exhaust is available for the expanding intake stroke to "suck up" and fill the intake stroke volume to atmospheric.

Because of the high ratio of exhaust gasses to intake charge in the intake stroke this rotor face has a miss-fire event.

Next this miss-fire chamber is dumped into the exhaust port and instead of just exhaust gasses the expanding intake charge "sucks up" the raw air and fuel along with exhaust gasses.

This however is not a viable enough intake stroke to fire either and there is a miss-fire event again.

Next this miss-fire chamber is dumped into the exhaust port along with the previous miss-fire event and the intake stroke "sucks up" both these miss-fires air/fuel and a little exhaust as well.

Boom, it is enough air with the gas to combust and we have a combustion event.

Next the combustion event dumps its exhaust into the exhaust stroke and the process starts all over.

Braaap, braap, braap (engine firing approximately once every three rotor revolutions).

-----------

There have been ways though up to help this problem by manufacturers who sold p-port rotaries to the public.

The Norton rotary motorcycle used a unique idea to increase carburetor airflow while keeping idle rpms low.

At idle they killed ignition on one rotor so the second firing rotor had more load (ie had to have the throttle plate open more).

The NSU RO80 used a pinky sized primary carburetor throat and a complimentary shaped p-port (small at the top for the primary, larger at the bottom for seconday) to keep intake velocity up at idle to help bias intake flow over exhaust flow into the intake stroke.

It still braaped some and had ****** (sudden increase in power) so they coupled the motor to a hydraulic torque converter on their manual transaxle.

#34

No, the issue here with a motor with a lot of overlap is this.

When the throttle plate is closed/partially open there is not enough airflow coming through the throttle body to feed the expanding intake stroke to atmospheric pressure so a there is a vacuum created (like any engine).

However, because there is a lot of overlap between exhaust and intake strokes the exhaust is available for the expanding intake stroke to "suck up" and fill the intake stroke volume to atmospheric.

Because of the high ratio of exhaust gasses to intake charge in the intake stroke this rotor face has a miss-fire event.

Next this miss-fire chamber is dumped into the exhaust port and instead of just exhaust gasses the expanding intake charge "sucks up" the raw air and fuel along with exhaust gasses.

This however is not a viable enough intake stroke to fire either and there is a miss-fire event again.

Next this miss-fire chamber is dumped into the exhaust port along with the previous miss-fire event and the intake stroke "sucks up" both these miss-fires air/fuel and a little exhaust as well.

Boom, it is enough air with the gas to combust and we have a combustion event.

Next the combustion event dumps its exhaust into the exhaust stroke and the process starts all over.

Braaap, braap, braap (engine firing approximately once every three rotor revolutions).

-----------

There have been ways though up to help this problem by manufacturers who sold p-port rotaries to the public.

The Norton rotary motorcycle used a unique idea to increase carburetor airflow while keeping idle rpms low.

At idle they killed ignition on one rotor so the second firing rotor had more load (ie had to have the throttle plate open more).

The NSU RO80 used a pinky sized primary carburetor throat and a complimentary shaped p-port (small at the top for the primary, larger at the bottom for seconday) to keep intake velocity up at idle to help bias intake flow over exhaust flow into the intake stroke.

It still braaped some and had ****** (sudden increase in power) so they coupled the motor to a hydraulic torque converter on their manual transaxle.

When the throttle plate is closed/partially open there is not enough airflow coming through the throttle body to feed the expanding intake stroke to atmospheric pressure so a there is a vacuum created (like any engine).

However, because there is a lot of overlap between exhaust and intake strokes the exhaust is available for the expanding intake stroke to "suck up" and fill the intake stroke volume to atmospheric.

Because of the high ratio of exhaust gasses to intake charge in the intake stroke this rotor face has a miss-fire event.

Next this miss-fire chamber is dumped into the exhaust port and instead of just exhaust gasses the expanding intake charge "sucks up" the raw air and fuel along with exhaust gasses.

This however is not a viable enough intake stroke to fire either and there is a miss-fire event again.

Next this miss-fire chamber is dumped into the exhaust port along with the previous miss-fire event and the intake stroke "sucks up" both these miss-fires air/fuel and a little exhaust as well.

Boom, it is enough air with the gas to combust and we have a combustion event.

Next the combustion event dumps its exhaust into the exhaust stroke and the process starts all over.

Braaap, braap, braap (engine firing approximately once every three rotor revolutions).

-----------

There have been ways though up to help this problem by manufacturers who sold p-port rotaries to the public.

The Norton rotary motorcycle used a unique idea to increase carburetor airflow while keeping idle rpms low.

At idle they killed ignition on one rotor so the second firing rotor had more load (ie had to have the throttle plate open more).

The NSU RO80 used a pinky sized primary carburetor throat and a complimentary shaped p-port (small at the top for the primary, larger at the bottom for seconday) to keep intake velocity up at idle to help bias intake flow over exhaust flow into the intake stroke.

It still braaped some and had ****** (sudden increase in power) so they coupled the motor to a hydraulic torque converter on their manual transaxle.

So the question is, is there anyway to drive a pport on the interstate with tuning, to overcome the overlap at very low throttle? Driving in a lower gear to increase rpms, would this help at all? Seems like there has to be a happy place RPM where the intake charge has enough momentum to overcome the dilution/backflow. And additionally, like peejay said above, retard the timing, but only in cruise area on a programmable ecu, to the point where the you've effectively lowered the manifold vacuum and increased the load. So basically, datalog the bucking areas, pull timing / increase fuel only in these areas until the reversion is small enough not to misfire???

It sounds like this is going to be a major PITA to drive, like a drag car only. I should have reconsidered PPort earlier, now its time to figure out how to minimize the overlap issue on cruise.

But still, for some reason, it seems like this should be correctable with the proper ecu and tuning techniques.

As stated earlier, the main reasons I originally intended on PPort is the following:

-easier packaging on the manifold design

-maximizing high end power, as the additional 2 rotors should provide plenty of low-end already

-why not go *****-out?

But wow, didn't realize the overlap was that much of an issue.

Last edited by Monsterbox; 02-11-16 at 07:23 PM.

#36

For reference, my full bridge 13B cruising at ~3500 was about 75mph. With the car packed full of tires and spare parts (removed passenger seat so I could get the spare trans and diff in there!), 50% throttle was enough to accelerate past trucks going up some of the steeper hills along I-44 in Missouri. Not downshifting.

That's a two rotor. No forced induction.

Do not underestimate the ability for a high overlap engine to make ridiculous amounts of mid range torque.

That's a two rotor. No forced induction.

Do not underestimate the ability for a high overlap engine to make ridiculous amounts of mid range torque.

Full Bridge, Semi PP Intake And Exhaust Engine Set UP.. - RX8Club.com

also thats what you use a trailer soo much! you make you weight as much as you can plus the drag means you have to be into the throttle.. but hows the mpgs like this??

#40

monster box, you could try a devider, or two ports...

j9fd3s, for me i can drive some hardly streetable cars, but for the purpose of making a PPort streetable, i mean use cruise control on them 800 mile trips in my p port cruiser yes i want to see p port and cruise control work together..

yes i want to see p port and cruise control work together..

j9fd3s, for me i can drive some hardly streetable cars, but for the purpose of making a PPort streetable, i mean use cruise control on them 800 mile trips in my p port cruiser

yes i want to see p port and cruise control work together..

yes i want to see p port and cruise control work together..

Last edited by lastphaseofthis; 02-11-16 at 09:15 PM.

#41

Your making me regret selling my last 4 rotor. Oh well i will have to buy another

.

.As far as pport goes you will always have overlap but in the case of a 2 rotor that has 180 deg phasing the driveability is going to be more choppy. But in a case of a 4 rotor that has 45 deg phasing its not going to be as noticable since you will be fireing more rotors per 360 revolution of the crank shaft. I wouldnt dwell on it too much I think you will be impressed just how streetable it will be during normal driving.

You can also loose torque and move the torque curve depending on port configuration and size.

But I also dont own a running pport 4 rotor (right now) so dont quote me.

#42

My take on it is this.

If I was designing a 1,200rhwhp engine I would make sure it had as easy to drive a powerband as possible so the power was actually accessible.

A side port or even a side port with semi-p-port turbo will have a more easy going powerband than a full p-port turbo and is still easily capable of making the 1,200rwhp goal.

Its just a no brainer to me. I would choose the 1,200rwhp ***** cat over the 1,200rwhp monster.

If I was designing a 1,200rhwhp engine I would make sure it had as easy to drive a powerband as possible so the power was actually accessible.

A side port or even a side port with semi-p-port turbo will have a more easy going powerband than a full p-port turbo and is still easily capable of making the 1,200rwhp goal.

Its just a no brainer to me. I would choose the 1,200rwhp ***** cat over the 1,200rwhp monster.

#43

All preference. Why do what everyone else does. Either way a 4 rotor would be a blast

Heres some food for thought. Drive a cammed out 4cyl.... sucks *** to drive. Take the same cam specs and put it into a v8. The v8 is a totally different animal for dayly driving and easier to drive than the 4 cyl would be.

Heres some food for thought. Drive a cammed out 4cyl.... sucks *** to drive. Take the same cam specs and put it into a v8. The v8 is a totally different animal for dayly driving and easier to drive than the 4 cyl would be.

#44

Well, I appreciate you guys giving some feedback

Its hard to find any information out there on pport engines in general. Rotary world is already a mysterious strange alien territory and those who have gone far in it enough to run pport are few. And its cool to hear experiences for those that have run them.

I personally thought the pport seemed simpler and sounded cooler. Cost wise it was cheaper, and made for much easier packaging. The car isnt really built to be practical or even purpseful in a performance sense, if it were then itwould have an LS v8 lplatform lol. So, if it bucks around, shoots some 2 cycle rich misfire smoke around, and hesitates, it will just have to be adopted as the nature of the car. Lets roll the dice and see how it goes.

Its hard to find any information out there on pport engines in general. Rotary world is already a mysterious strange alien territory and those who have gone far in it enough to run pport are few. And its cool to hear experiences for those that have run them.

I personally thought the pport seemed simpler and sounded cooler. Cost wise it was cheaper, and made for much easier packaging. The car isnt really built to be practical or even purpseful in a performance sense, if it were then itwould have an LS v8 lplatform lol. So, if it bucks around, shoots some 2 cycle rich misfire smoke around, and hesitates, it will just have to be adopted as the nature of the car. Lets roll the dice and see how it goes.

#46

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,778

Received 2,564 Likes

on

1,824 Posts

So the question is, is there anyway to drive a pport on the interstate with tuning, to overcome the overlap at very low throttle? Driving in a lower gear to increase rpms, would this help at all? Seems like there has to be a happy place RPM where the intake charge has enough momentum to overcome the dilution/backflow. .

i've also found that the flywheel weight matters, mine is light, and it is really picky about AFR's. my friend used a stock flywheel, and except for the idle, you'd never know it was ported

a have a friend of a friend with a turbo P port, 800ps, so its possible, i just wouldn't do it myself, NA is huge fun.

#47

Old [Sch|F]ool

Driving in a lower gear decreases load on the engine and it runs worse. The stuttering rotary is not a function of low RPM, it is a function of low load. They will run smooth at 700rpm with enough load and they will stutter on a 9000rpm free-rev.

The only nice benefit of more RPM is that the engine has enough rotational inertia that you can cruise while stuttering without hammering your U-joints and gears apart. This is why a heavy flywheel makes bridge and peripheral port engines more street drivable, they can stutter all they want and it won't feel like you're driving a jackhammer.

Seems like there has to be a happy place RPM where the intake charge has enough momentum to overcome the dilution/backflow.

This is why high overlap engines suck at low throttle openings and move a lot of air at high openings. And why exhaust tuning becomes extremely critical. Exhaust (lack of) restriction and pipe tuning are what make the intake ports move air.

And why "street port" engines have minimal overlap, and why the RX-8 has NONE. Less sensitivity to exhaust restriction, and change dilution becomes a lot more predictable.

Last edited by peejay; 02-12-16 at 06:15 AM.

#48

Makes sense that the larger 4 rotor will be a space shuttle by the time throttle is opened up enough to get rid of the vacuum in the manifold.

Wish there was some sort of way to bypass air into the engine, via a solenoid or something, to reduce vacuum, and help stop the exhaust pull-up, without accelerating the engine

Wish there was some sort of way to bypass air into the engine, via a solenoid or something, to reduce vacuum, and help stop the exhaust pull-up, without accelerating the engine

#49

Wish there was some sort of way to bypass air into the engine, via a solenoid or something, to reduce vacuum, and help stop the exhaust pull-up, without accelerating the engine

There is, but its not easy to implement.

Mazda might do this on the new 16X if the Mazda3 EV generator is an indication. There have been rumors of such.

Direct Homogeneous Charge Compression Ignition or even Homogeneous Charge Spark Ignition.

Basically, this is running the rotary as a Diesel with no throttle plate creating vacuum at low load. The Homogeneous Charge allows the engine to run at extremely lean AFRs (thus idle/low rpm at "WOT") while lowering the usual NOx emissions from doing so.

------------

You could get creative with some more conventional methods taking cues from what other manufacturers of p-port rotaries have done.

For instance, to increase load at idle/ low load you could get a high amp alternator and braking resistors for loading the engine up (might want Gilmer drive to alt pulley).

Or you could get more complex and shut down 2 rotors at idle/low load.

These would help idle and cruise street-ability.

They won't help the overall unpredictable turbo p-port power band though.

-------------

You could also try exhaust throttling instead of intake throttling. I haven't heard anyone try this yet, so I don't know if it would work.

It is possible there would not be excessive exhaust reversion if the intake is free even as exhaust manifold pressure rises. This is because there is a strong siphon between the exhaust and the intake created by the two sides of the rotor across the apex seal. However, a siphon still needs flow and not just pressure to work.

You could ask a friend with a p-port to hold the throttle WOT while you blocked the exhaust with a block of wood or something to see if you could get the rpms down smoothly.

Anyone want to try this for the sake of my curiosity?

There is, but its not easy to implement.

Mazda might do this on the new 16X if the Mazda3 EV generator is an indication. There have been rumors of such.

Direct Homogeneous Charge Compression Ignition or even Homogeneous Charge Spark Ignition.

Basically, this is running the rotary as a Diesel with no throttle plate creating vacuum at low load. The Homogeneous Charge allows the engine to run at extremely lean AFRs (thus idle/low rpm at "WOT") while lowering the usual NOx emissions from doing so.

------------

You could get creative with some more conventional methods taking cues from what other manufacturers of p-port rotaries have done.

For instance, to increase load at idle/ low load you could get a high amp alternator and braking resistors for loading the engine up (might want Gilmer drive to alt pulley).

Or you could get more complex and shut down 2 rotors at idle/low load.

These would help idle and cruise street-ability.

They won't help the overall unpredictable turbo p-port power band though.

-------------

You could also try exhaust throttling instead of intake throttling. I haven't heard anyone try this yet, so I don't know if it would work.

It is possible there would not be excessive exhaust reversion if the intake is free even as exhaust manifold pressure rises. This is because there is a strong siphon between the exhaust and the intake created by the two sides of the rotor across the apex seal. However, a siphon still needs flow and not just pressure to work.

You could ask a friend with a p-port to hold the throttle WOT while you blocked the exhaust with a block of wood or something to see if you could get the rpms down smoothly.

Anyone want to try this for the sake of my curiosity?