Power FC Anyone know the Power FC Knock value to voltage definition?

#1

Switched to the AEM awhile ago and would like to set up a Power FC equivalent knock value on my AEM serial gauges. I can define any value to display on the Serial gauge and I am guessing the scale is linear. If it is linear I really just need to know what the max value at 5 volts is and can calculate the rest.

#2

Short answer: there's no way to translate. The knock counts in the PFC don't mean anything specific, and the voltages mentioned in AEM's systems don't mean anything specific either. Higher number means more vibration energy at some unspecified frequency. That's all they mean. How useful that is is just a judgment call. Determining a borderline knock condition is a very subjective thing even when you have every tool available at your disposal: vibration sensors (accelerometer/knock sensor), audible microphones, and combustion pressure sensors.

Detailed answer: Knock sensors and signal processing is a lot more complicated than you think. AEM dumbs it down extremely, and Apex'i dumbs it down even more.

The voltage in the AEM is a somewhat arbitrary value generated by a signal processor inside the ECU. A knock sensor doesn't put out a nice neat 0-5v signal like a temperature sensor. We don't know what frequency the signal processor is looking at, we don't know what the energy level is (power spectral density) that the voltage corresponds to. We don't know how the filtering was done. I suspect AEM bought some off-the-shelf signal processor and really has no idea what that voltage means, except more voltage is probably bad. Similar things can be said about PFC knock counts.

I've posted this in a Subaru forum regarding their OEM knock control system, but I'll repost it here:

"We're all familiar with knock retard in the sense that we understand the ECU pulls timing based on the sensor signal. Allow me to provide a little background on false knock detection from the perspective of the knock sensor frequency signal itself. I can't speak for the FT86 exactly, but I can speak from my experience with knock signal processing on other applications.

When a knock control system is being developed, the engine is typically run at steady state speed and load points in a lab on an engine dyno. A production sensor or lab grade sensor is installed in the intended locations. The engine is then intentionally knocked (often one cylinder at a time) usually just by advancing timing. Then somebody makes some judgment call about the level of knock based on audible sound and cylinder pressure trace on an oscilloscope. It's somewhat subjective, especially for light knock.

So a knock sensor isn't initially used to detect knock... first you knock the engine, then you set up the knock sensor so it can actually detect when it's occuring and its severity. That's the opposite of the way we're all used to thinking: we think, "The knock sensor will tell me how bad the knock is, and the ECU will retard timing in proportion to its severity." But before the knock sensor can do that, the knock sensor had to be "trained" through signal processing settings.

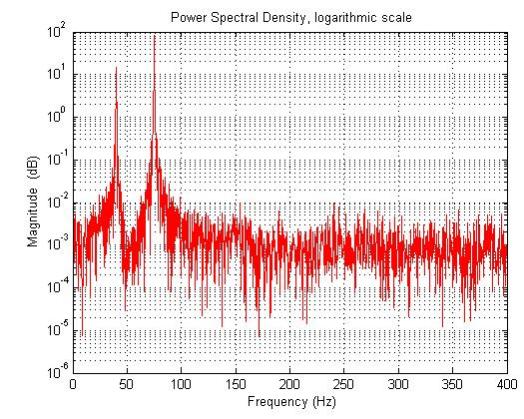

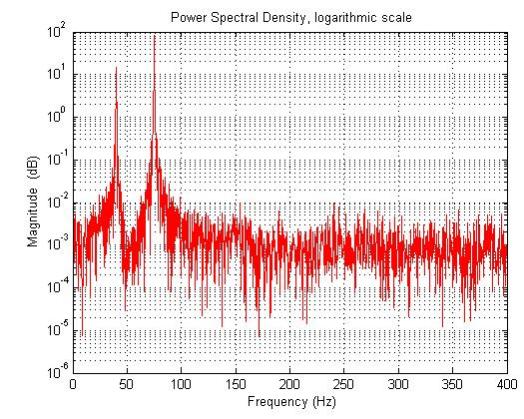

Getting back to early development in a lab: While the engine is knocking the lab data acquisition system averages the sensor signal over some number of combustion cycles. Then it can be post-processed using something like a Matlab tool. You end up with a plot resembling this one I pulled off google images:

What you have here is basically frequency on the X axis, and energy at that frequency on the Y axis.

Whoever is in charge of the knock control system makes a judgment call as to which frequency the ECU will consider "real" knock for a given cylinder. There's a bunch of signal processing done on top of that in the ECU (gain, filter, etc), background noise learning, etc, and out of all that the ECU will judge knock and pull timing. Then it has to be tweaked in the car.

But it all starts with somebody's decision as to what frequency is going to be considered knock, on a stock engine with stock parts. When you change the arrangement of the engine bay by modding, or even drive in a certain way, you can excite certain frequencies on the engine. That frequency can be in the range that the signal processer considers to be knock, whether it actually is knock or not. If the software is tuned to be sensitive enough it could result in timing retard."

Detailed answer: Knock sensors and signal processing is a lot more complicated than you think. AEM dumbs it down extremely, and Apex'i dumbs it down even more.

The voltage in the AEM is a somewhat arbitrary value generated by a signal processor inside the ECU. A knock sensor doesn't put out a nice neat 0-5v signal like a temperature sensor. We don't know what frequency the signal processor is looking at, we don't know what the energy level is (power spectral density) that the voltage corresponds to. We don't know how the filtering was done. I suspect AEM bought some off-the-shelf signal processor and really has no idea what that voltage means, except more voltage is probably bad. Similar things can be said about PFC knock counts.

I've posted this in a Subaru forum regarding their OEM knock control system, but I'll repost it here:

"We're all familiar with knock retard in the sense that we understand the ECU pulls timing based on the sensor signal. Allow me to provide a little background on false knock detection from the perspective of the knock sensor frequency signal itself. I can't speak for the FT86 exactly, but I can speak from my experience with knock signal processing on other applications.

When a knock control system is being developed, the engine is typically run at steady state speed and load points in a lab on an engine dyno. A production sensor or lab grade sensor is installed in the intended locations. The engine is then intentionally knocked (often one cylinder at a time) usually just by advancing timing. Then somebody makes some judgment call about the level of knock based on audible sound and cylinder pressure trace on an oscilloscope. It's somewhat subjective, especially for light knock.

So a knock sensor isn't initially used to detect knock... first you knock the engine, then you set up the knock sensor so it can actually detect when it's occuring and its severity. That's the opposite of the way we're all used to thinking: we think, "The knock sensor will tell me how bad the knock is, and the ECU will retard timing in proportion to its severity." But before the knock sensor can do that, the knock sensor had to be "trained" through signal processing settings.

Getting back to early development in a lab: While the engine is knocking the lab data acquisition system averages the sensor signal over some number of combustion cycles. Then it can be post-processed using something like a Matlab tool. You end up with a plot resembling this one I pulled off google images:

What you have here is basically frequency on the X axis, and energy at that frequency on the Y axis.

Whoever is in charge of the knock control system makes a judgment call as to which frequency the ECU will consider "real" knock for a given cylinder. There's a bunch of signal processing done on top of that in the ECU (gain, filter, etc), background noise learning, etc, and out of all that the ECU will judge knock and pull timing. Then it has to be tweaked in the car.

But it all starts with somebody's decision as to what frequency is going to be considered knock, on a stock engine with stock parts. When you change the arrangement of the engine bay by modding, or even drive in a certain way, you can excite certain frequencies on the engine. That frequency can be in the range that the signal processer considers to be knock, whether it actually is knock or not. If the software is tuned to be sensitive enough it could result in timing retard."

#4

So I was looking through the knock control settings in the AEM Infinity software (I don't think this is in the software for the original EMS).

These are the settings I'm talking about. In the PFC, we have zero idea what signal processing they are using and how that relates to the knock counts reported. In the AEM Infinity, you still have the issue of how you are supposed to set the center frequency. The center frequency issue is part of the reason why you have multiple knock sensors on engines in the first place--one frequency might be strong indicator of knock for one combustion chamber but not for other ones (think piston engines with 2 banks).

As I showed in the plot above, you need a power spectral density plot (fast fourier transform) to help pick it out. And it's a lot easier when you have audible assessment of knock (through a microphone/detcans in controlled environment) or a combustion chamber pressure sensor.

Some of the Rx-7 service manuals have listed 3.5 kHz as the knocking frequency. You can see that's half the default in the AEM Infinity. Well even that was for a stock engine and was certainly a compromise for a system with 1 sensor but 2 rotors. The later Rx-8's actually had one knock sensor for each rotor. We don't know what kind of gain and integrator settings were used in the PFC or stock FD ECU. In the AEM Infinity there is only one setting for gain and integrator, but on modern stock ECUs you will see 3D maps changing the signal processing based on speed and load.

These are the settings I'm talking about. In the PFC, we have zero idea what signal processing they are using and how that relates to the knock counts reported. In the AEM Infinity, you still have the issue of how you are supposed to set the center frequency. The center frequency issue is part of the reason why you have multiple knock sensors on engines in the first place--one frequency might be strong indicator of knock for one combustion chamber but not for other ones (think piston engines with 2 banks).

As I showed in the plot above, you need a power spectral density plot (fast fourier transform) to help pick it out. And it's a lot easier when you have audible assessment of knock (through a microphone/detcans in controlled environment) or a combustion chamber pressure sensor.

Some of the Rx-7 service manuals have listed 3.5 kHz as the knocking frequency. You can see that's half the default in the AEM Infinity. Well even that was for a stock engine and was certainly a compromise for a system with 1 sensor but 2 rotors. The later Rx-8's actually had one knock sensor for each rotor. We don't know what kind of gain and integrator settings were used in the PFC or stock FD ECU. In the AEM Infinity there is only one setting for gain and integrator, but on modern stock ECUs you will see 3D maps changing the signal processing based on speed and load.

Thread

Thread Starter

Forum

Replies

Last Post

streetlegal?

New Member RX-7 Technical

13

03-17-22 02:46 PM

The Shaolin

2nd Generation Specific (1986-1992)

9

09-14-15 07:50 PM

befarrer

Microtech

3

08-22-15 05:52 PM

Frisky Arab

2nd Generation Specific (1986-1992)

13

08-18-15 05:30 PM