New dyno runs of PP engine

#1

Senior Member

Thread Starter

New dyno runs of PP engine

Just came back from a long day dyno a PP 13B rallycross engine for a Norwegian customer. Some short specs: 77 block hardened plates, clearanced and balanced 9:2 rotors,Hurley 3 mm 2 piece seals,44 mm min dia in rotor housing MFR port timing with weld up conical port with no steel sleeve,Weber 51 IDA with 120 mm air horns, direct fire ignition with BUR9EQ plugs and headers same as the WR 314 hp engine with 750 mm length and 54 mm Idia with 250 mm tapered cone. After a short break in we begin to pull the engine on DR Ernies Superflow 901 bench. After nearly 30 pull we had these fine numbers coming up. Numbers are STP 300 rpm corrected.

6000 rpm 211.3 hp 185 ft.lb

7000 rpm 267.1 hp 200.4 ft.lb

8000 rpm 313 hp 205.5 ft.lb

8500 rpm 325.2 hp 201 ft.lb peak power. 7500 peak torque 210.3 ft.lb

We tested a 300 mm 54 mm Idia headers also but lost almost 20 hp.

Ended up with 44 mm chokes compared to 43 mm, that lost 2 hp at 6000 rpm but gained 4 hp at peak power 8500 rpm. Split was first 5 deg but with 2 deg in split we found a few hp. As usual F7 tubes, and 250 main and 125 air jets was the final fuel set up. Now we got to find a good air filter for this engine so that only clean air is entering the engine. Oh we used Shell V Power 99 unleaded fuel with 1% premix. The engine is coming to the engine bay of an old Beetle that shall compete in 2 event in September. Some pictures and graphs will hopefully be up this weekend.

Lasse

6000 rpm 211.3 hp 185 ft.lb

7000 rpm 267.1 hp 200.4 ft.lb

8000 rpm 313 hp 205.5 ft.lb

8500 rpm 325.2 hp 201 ft.lb peak power. 7500 peak torque 210.3 ft.lb

We tested a 300 mm 54 mm Idia headers also but lost almost 20 hp.

Ended up with 44 mm chokes compared to 43 mm, that lost 2 hp at 6000 rpm but gained 4 hp at peak power 8500 rpm. Split was first 5 deg but with 2 deg in split we found a few hp. As usual F7 tubes, and 250 main and 125 air jets was the final fuel set up. Now we got to find a good air filter for this engine so that only clean air is entering the engine. Oh we used Shell V Power 99 unleaded fuel with 1% premix. The engine is coming to the engine bay of an old Beetle that shall compete in 2 event in September. Some pictures and graphs will hopefully be up this weekend.

Lasse

The following users liked this post:

sharingan 19 (05-22-21)

#3

Good numbers congrats. I got a couple of questions for you. 8500rpm's seems a little low for a pport motor. Did you go any further than that? Also, with the lower compression rotors did you have to add more timing? One more. Have you ever tried using larger chokes than 44mm? I'm running 48mm in my 12a bridgeport. You should make alot more peak hp with larger chokes.

#4

Senior Member

Thread Starter

The powerband from 8-9000 rpm was all over 300 hp over that 1000 rpm spread but peak was at 8500 rpm. Seems that the carb with 120 mm air horns and the 750 mm header was a good power/torque combo. Most MFR port timed PP engines i built peaked from 8200 to 8700 rpm but the WR motor 327 hp@9300 rpm had 45 mm idia intake and a little more overlap and some mm later closing. This engine need more tuning to get it's full potential. Seems with a 44 mm idia, the engine likes 43-44 mm chokes in all the engines i built. But bridge and streetported engines can make more hp with largers chokes. The timing was 22-23 degree, same as the WR engine. Also the exhaust temp was around 1500 deg F.

/Lasse

/Lasse

#5

The powerband from 8-9000 rpm was all over 300 hp over that 1000 rpm spread but peak was at 8500 rpm. Seems that the carb with 120 mm air horns and the 750 mm header was a good power/torque combo. Most MFR port timed PP engines i built peaked from 8200 to 8700 rpm but the WR motor 327 hp@9300 rpm had 45 mm idia intake and a little more overlap and some mm later closing. This engine need more tuning to get it's full potential. Seems with a 44 mm idia, the engine likes 43-44 mm chokes in all the engines i built. But bridge and streetported engines can make more hp with largers chokes. The timing was 22-23 degree, same as the WR engine. Also the exhaust temp was around 1500 deg F.

/Lasse

/Lasse

#7

Senior Member

Thread Starter

I think the low EGTs is becausse of 4 coil sequential ignition. I have used ProSpark direct fire for 10 years now and mostly have 1450 to 1550F temps. When using distributor i had some times over 1800F temps! The last 2 engines i built seems to like A/F 13.0-13.5. The engines really screams when pushing them to 9000 rpm...

/Lasse

/Lasse

Trending Topics

#8

I think the low EGTs is becausse of 4 coil sequential ignition. I have used ProSpark direct fire for 10 years now and mostly have 1450 to 1550F temps. When using distributor i had some times over 1800F temps! The last 2 engines i built seems to like A/F 13.0-13.5. The engines really screams when pushing them to 9000 rpm...

/Lasse

/Lasse

#11

Exhaust Manifold Leak

Old thread, really nice numbers I must say. care to give us a hint of port timing used? especially exhaust opening? With the old MFR spec of around 73-74° opening we where stuck at 270 hp, even with 50 and 52mm intake ports.

#14

You might consider dropping to 9.4:1 CR rotors.

Unlike in a piston engine the rotary has to balance the power gain from raising the compression ratio with the power lost to pumping loss pushing the expanding combustion charge from the trailing side of the rotor housing minor axis through the rotor slot to the leading side of the minor axis.

The pumping losses will be higher at higher RPM.

You may have already noticed tuning that you can make more HP in the high RPM lowering the timing advance.

The '70s Mazda Factory Race 13Bs used specially cast 9.4:1 CR rotors and made 300bhp.

Now, a counterpoint to this argument is the Lemans R26B used higher 10:1 CR.

However, it is worth noting that 2 decades later the R26B made 515kw or 690bhp. Less bhp per rotor than the '70s 9.4 CR MFR 13Bs despite its many performance advances.

My belief is Mazda's raising the R26B CR was along with many of its other advances an attempt to raise efficiency (and so HP and MPG) under the curve even if at a slight detriment to high RPM peak efficiency.

R26B power peaked before its low 9,000rpm redline.

In Mazda's production cars the raised CR provided better throttle response as well as the better HP and MPG under the curve where the engines are usually used.

In production trim they are not close to the limits of BHP imposed by pumping losses at high RPM anyways- as you have shown.

Anyways, just my opinion and something to consider. If you are building a 13B for racing you might as well build it how Mazda did... 9.4 CR rotors.

R26B was a whole 'nother beast for a different purpose (that is now performed by diesels since the rotary was banned in LeMans).

Unlike in a piston engine the rotary has to balance the power gain from raising the compression ratio with the power lost to pumping loss pushing the expanding combustion charge from the trailing side of the rotor housing minor axis through the rotor slot to the leading side of the minor axis.

The pumping losses will be higher at higher RPM.

You may have already noticed tuning that you can make more HP in the high RPM lowering the timing advance.

The '70s Mazda Factory Race 13Bs used specially cast 9.4:1 CR rotors and made 300bhp.

Now, a counterpoint to this argument is the Lemans R26B used higher 10:1 CR.

However, it is worth noting that 2 decades later the R26B made 515kw or 690bhp. Less bhp per rotor than the '70s 9.4 CR MFR 13Bs despite its many performance advances.

My belief is Mazda's raising the R26B CR was along with many of its other advances an attempt to raise efficiency (and so HP and MPG) under the curve even if at a slight detriment to high RPM peak efficiency.

R26B power peaked before its low 9,000rpm redline.

In Mazda's production cars the raised CR provided better throttle response as well as the better HP and MPG under the curve where the engines are usually used.

In production trim they are not close to the limits of BHP imposed by pumping losses at high RPM anyways- as you have shown.

Anyways, just my opinion and something to consider. If you are building a 13B for racing you might as well build it how Mazda did... 9.4 CR rotors.

R26B was a whole 'nother beast for a different purpose (that is now performed by diesels since the rotary was banned in LeMans).

#15

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,796

Received 2,574 Likes

on

1,830 Posts

the S5 SAE paper explains the higher compression thus; i will paraphrase, but the cast rotors were 9.4 +/- 0.3. the S5 rotors are 9.7 +/- 0.03. so the 9.7's are just at the high end of the previous variance.

i do agree though that higher compression doesn't see gains, i think we get fooled that the number is 9 instead of 12 or something. there is a small effect where having lower compression = more space for air and fuel mix = more power. the high power japanese builds use 8.5 rotors machined to 8.3.

i do agree though that higher compression doesn't see gains, i think we get fooled that the number is 9 instead of 12 or something. there is a small effect where having lower compression = more space for air and fuel mix = more power. the high power japanese builds use 8.5 rotors machined to 8.3.

#16

the S5 SAE paper explains the higher compression thus; i will paraphrase, but the cast rotors were 9.4 +/- 0.3. the S5 rotors are 9.7 +/- 0.03. so the 9.7's are just at the high end of the previous variance.

Good info!

Now, can we assume the lighter MFR precision "lost wax" cast rotors are more precise in their CR since the precision of casting is what allowed them to be cast thinner and thus lighter?

Do you have info on the progression of 13B/13G MFR rotor CR?

It seems to me they kept 9.4:1 CR for long.

I believe the 1984-87 757B Lemans chassis 13G 3rotor used 9.4:1 rotors.

I do not know the CR of the 1988-89 767B Lemans chassis 13J 4rotor. This was mazda's early attempt to provide a broad power band with 2 stage length induction.

there is a small effect where having lower compression = more space for air and fuel mix = more power. the high power japanese builds use 8.5 rotors machined to 8.3.

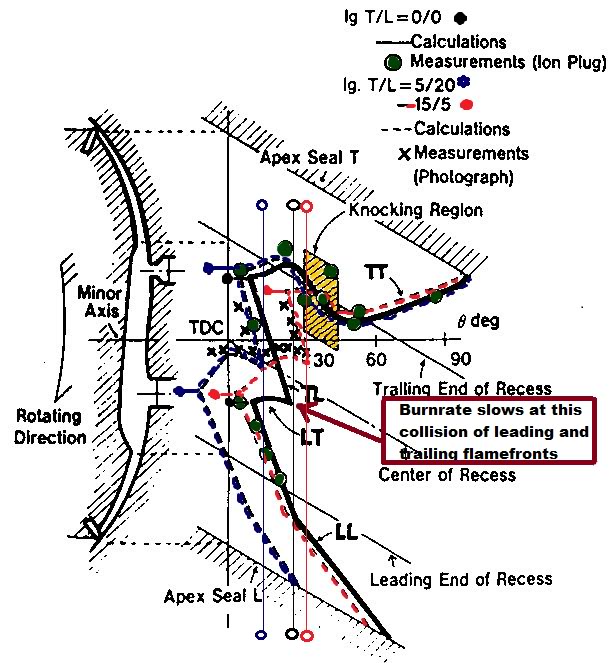

I really do think it has more to do with pumping loss across the minor axis than a larger combustion tub. It is a hard concept to grasp without rotating the engine parts.

It would be great to plot flame front propagation speed from the Leading plug to distance across the rotor tub to the Trailing side to see where ignition advance has to be limited to per RPM to avoid Leading pocket air/fuel charge expansion.

It is clear that power gains from Trailing split (retard from Leading ignition) are caused by limiting the pumping losses from expanding Trailing pocket gasses across the minor axis.

Good info!

Now, can we assume the lighter MFR precision "lost wax" cast rotors are more precise in their CR since the precision of casting is what allowed them to be cast thinner and thus lighter?

Do you have info on the progression of 13B/13G MFR rotor CR?

It seems to me they kept 9.4:1 CR for long.

I believe the 1984-87 757B Lemans chassis 13G 3rotor used 9.4:1 rotors.

I do not know the CR of the 1988-89 767B Lemans chassis 13J 4rotor. This was mazda's early attempt to provide a broad power band with 2 stage length induction.

there is a small effect where having lower compression = more space for air and fuel mix = more power. the high power japanese builds use 8.5 rotors machined to 8.3.

I really do think it has more to do with pumping loss across the minor axis than a larger combustion tub. It is a hard concept to grasp without rotating the engine parts.

It would be great to plot flame front propagation speed from the Leading plug to distance across the rotor tub to the Trailing side to see where ignition advance has to be limited to per RPM to avoid Leading pocket air/fuel charge expansion.

It is clear that power gains from Trailing split (retard from Leading ignition) are caused by limiting the pumping losses from expanding Trailing pocket gasses across the minor axis.

#19

Exhaust Manifold Leak

Mine figures where measured at the wheel but tyre rolling losses are measured with the known inertia of the 48'rollers during the roll out after the pull and then added to the measured wheel power. therefore figures are estimated at the flywheel. distract 10-15hp for wheel power.

#20

"Elusive, not deceptive!”

I really do think it has more to do with pumping loss across the minor axis than a larger combustion tub. It is a hard concept to grasp without rotating the engine parts.

It would be great to plot flame front propagation speed from the Leading plug to distance across the rotor tub to the Trailing side to see where ignition advance has to be limited to per RPM to avoid Leading pocket air/fuel charge expansion.

It is clear that power gains from Trailing split (retard from Leading ignition) are caused by limiting the pumping losses from expanding Trailing pocket gasses across the minor axis.

#21

Old [Sch|F]ool

This is something I've been considering ever since people started trying RX-8 rotors and found that they made the same or less power as the 9.7 rotors, and then a year or two later a Noted Engine Builder put together a 13B bridge port with TII rotors that made low-mid 300s HP with ignition timing in the 10 degree range (so leaving a lot on the table)

I don't think the power losses at high RPM have anything to do with trying to move a burning charge, and more simply having to move the air past the pinch whether it is burning (expanding) or not.

I don't think the power losses at high RPM have anything to do with trying to move a burning charge, and more simply having to move the air past the pinch whether it is burning (expanding) or not.

#22

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,796

Received 2,574 Likes

on

1,830 Posts

[quote]Do you have info on the progression of 13B/13G MFR rotor CR?

It seems to me they kept 9.4:1 CR for long.[quote]

as far as i know they were 9.4 with a 3mm carbon seal up to the 13J-MM(M?) when they switched to ceramic. at some point they were running different bearing sizes too, they called it the 20B, but its with a ZR part number prefix.

#23

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,796

Received 2,574 Likes

on

1,830 Posts

i do think that airflow inside the engine would make a good next design study, as we've come a long way from the previous test equipment

#24

Peejay

I don't think the power losses at high RPM have anything to do with trying to move a burning charge, and more simply having to move the air past the pinch whether it is burning (expanding) or not.

That is a good point, as experimenting with different timing and split would solve the former issue.

Just reading the 1982 IMSA GTO 13Bs were rated at 310bhp for the carby version and 330bhp for the fuel injected.

9.4:1 rotors.

Maybe you feel like being our grand experimenter Rub20B and make a 9.4:1 rotating assembly (I know co$t) and dyno that with only tuning changes made to the motor?

Maybe to really make the point go down to the lighter S5 turbo FD 9.0:1 CR rotors.

I believe there has been a street port S5 TII motor that did about 230rhpw chassis dyno and a stock 13BREW with turbos removed which did about the same. Pretty good for side port motors.

Even heard of a mild streetport 8.5:1 CR rotor (ground down to 8.2:1 CR) that did 216rwhp/160ftlbs on chassis dyno.

I don't think the power losses at high RPM have anything to do with trying to move a burning charge, and more simply having to move the air past the pinch whether it is burning (expanding) or not.

That is a good point, as experimenting with different timing and split would solve the former issue.

Just reading the 1982 IMSA GTO 13Bs were rated at 310bhp for the carby version and 330bhp for the fuel injected.

9.4:1 rotors.

Maybe you feel like being our grand experimenter Rub20B and make a 9.4:1 rotating assembly (I know co$t) and dyno that with only tuning changes made to the motor?

Maybe to really make the point go down to the lighter S5 turbo FD 9.0:1 CR rotors.

I believe there has been a street port S5 TII motor that did about 230rhpw chassis dyno and a stock 13BREW with turbos removed which did about the same. Pretty good for side port motors.

Even heard of a mild streetport 8.5:1 CR rotor (ground down to 8.2:1 CR) that did 216rwhp/160ftlbs on chassis dyno.

#25

Exhaust Manifold Leak

Ok, might give it a try. too bad i have now a renesis rotating assembly and 2 piece ianetties ready to be balancced to go into the engine with RB housings. 9.4 rotors could be better for combustion point of view (bigger bathud for combustion to take place), but theyre haevy and I dont have a cnc machine to lighten them. 9.0 TII rotors or FD would be the easy solution for me, I have plenty of those and they grooves never wear out on TII engines as long as they dont get driven till a seal takes a crap with minor detonation.

altough still I first really need to make 300 at the flywheel with my 9.7 setup. I can surely agree that making 350 or more is asked to much for a novice like me. but at least I would like to obtain 300. I will dyno my engine in the coming weeks. if it doesnt work out I might try bigger diameter header and maybe a 55m IDA throttle body with ms2 and 2 injectors to replace the 51mm IDA just to see if there might be the restriction..

altough still I first really need to make 300 at the flywheel with my 9.7 setup. I can surely agree that making 350 or more is asked to much for a novice like me. but at least I would like to obtain 300. I will dyno my engine in the coming weeks. if it doesnt work out I might try bigger diameter header and maybe a 55m IDA throttle body with ms2 and 2 injectors to replace the 51mm IDA just to see if there might be the restriction..