itb's and positive "crankcase" ventilation

#1

Isaiah 53.7

Thread Starter

Join Date: Mar 2013

Location: Indiana

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

itb's and positive "crankcase" ventilation

I goofed big and just routed the nipple on the center iron to the charcoal canister, which explains moisture on my dipstick and incredibly gassy smelling oil.

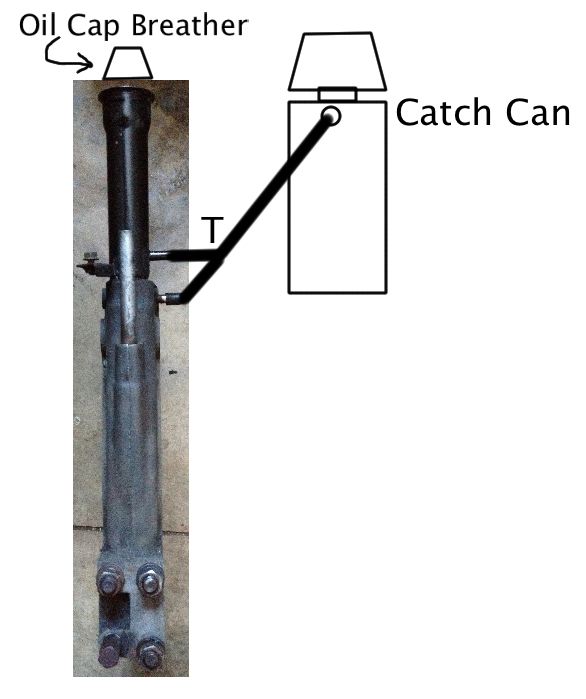

I'm teeing the line connecting the charcoal can and center iron nipple (not oil filler neck nipple) to, eventually, a Saikou Michi catch can to the intake. Obviously, I can't route the line before the throttle bodies since there's no plenum. My questions are;

If I route the line AFTER the throttle bodies, would this be like a vacuum leak and cause a high idle?

How did you get rid of your sump gasses?

I'm teeing the line connecting the charcoal can and center iron nipple (not oil filler neck nipple) to, eventually, a Saikou Michi catch can to the intake. Obviously, I can't route the line before the throttle bodies since there's no plenum. My questions are;

If I route the line AFTER the throttle bodies, would this be like a vacuum leak and cause a high idle?

How did you get rid of your sump gasses?

#3

Isaiah 53.7

Thread Starter

Join Date: Mar 2013

Location: Indiana

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

Don't sweat it if your oil looks fine and your dipstick isn't frothy. I think that's how my engine used to be before I rebuilt it, which is why I routed it so. Now I also have a fresh rebuild with less than 1500 miles. However, I bridgeported mine with a standalone computer with NO efi tuning experience and no friends who like cars let alone wankels! Too rich of a tune sends gasoline to the sump, and from my understanding, bridgies technically don't run too well at idle, making me wonder if that makes the rotors too wet with fuel during little to no load at low rpms. Also makes me wonder if that's why race car drivers are always blipping the throttle...

Needless to say, my engine doesn't want those gasses! Nor does it want my green tuning abilities! Haha

Needless to say, my engine doesn't want those gasses! Nor does it want my green tuning abilities! Haha

#4

Did you say have a tune on that bridgeport? I may have over read it! But that would make sense maybe its almost flooding out at low rpms! I streetported mine with a large pineapple template and it doest like to idle below 900 and it runs really rich right now with out a tune. So that could very well be your problem! You had me scared for a little bit! Haha

#5

Isaiah 53.7

Thread Starter

Join Date: Mar 2013

Location: Indiana

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

Yeah, I still need to tidy up the tune. At first I had the idle set really rich because it gave a super strong bridgeport lope. However, when I leaned it out, it had a softer lope and a higher vacuum reading at idle. When the weather turns, I'll take lots of time to nail the idle and tune. Then dyno time!!!

Anyways, any advice on the sump ventilation from you guys? What am I doing wrong or need to do?

Edit: to better answer your question, newkid, I have a tune that's solid cruising in open loop and able to go wide open up until 7200 rpm where it wants more fuel. Low rpms are finicky with the alpha n tune. One thing I noticed, if it's too rich at light loads, it hiccups... sometimes even at 13.5:1!

Anyways, any advice on the sump ventilation from you guys? What am I doing wrong or need to do?

Edit: to better answer your question, newkid, I have a tune that's solid cruising in open loop and able to go wide open up until 7200 rpm where it wants more fuel. Low rpms are finicky with the alpha n tune. One thing I noticed, if it's too rich at light loads, it hiccups... sometimes even at 13.5:1!

Last edited by Hatchet Jack; 02-02-14 at 08:06 PM.

#7

Isaiah 53.7

Thread Starter

Join Date: Mar 2013

Location: Indiana

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

Good observation. Not a stupid question at all. My injectors are plenty big. I just haven't taken the time to tune that high of rpms. It should sing past 8500, but it's hard tuning with my laptop and driving at the same time! Plus, the noise by that point is all too attractive to the law enforcers.

Trending Topics

#8

Isaiah 53.7

Thread Starter

Join Date: Mar 2013

Location: Indiana

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

I called Mazdatrix, and a gentleman gave me some really good info... he was a super solid guy and great to talk with. Here's some answers:

On their naturally aspirated racing engines, they simply use a vented catch can hooked up to the nipple on the filler neck and cap the center iron nipple.

*If you have a high revving setup, using the nipple on the filler neck is even more important*

-If the lower center iron nipple is used during 10,000+ rpm, oil can make its way up there.

He stated that the sump gasses were routed to the intake from the factory for emission's sake and that he personally wouldn't want them back through the engine. The gasses and vapors should naturally rise to the catch can, given that the catch can is as high as reasonably possible. On turbo applications, it seems to be necessary to have a recirculating catch can due to more pressure on the rotors.

Also, when tuning the idle, tune for what the engine wants; "You're not tuning for sound," he stated. Makes sense...

He also proceeded to say getting my engine professionally tuned is vital, and that a bridged na with itb's should be a really fun setup.

Hope this helps someone else down the road.

On their naturally aspirated racing engines, they simply use a vented catch can hooked up to the nipple on the filler neck and cap the center iron nipple.

*If you have a high revving setup, using the nipple on the filler neck is even more important*

-If the lower center iron nipple is used during 10,000+ rpm, oil can make its way up there.

He stated that the sump gasses were routed to the intake from the factory for emission's sake and that he personally wouldn't want them back through the engine. The gasses and vapors should naturally rise to the catch can, given that the catch can is as high as reasonably possible. On turbo applications, it seems to be necessary to have a recirculating catch can due to more pressure on the rotors.

Also, when tuning the idle, tune for what the engine wants; "You're not tuning for sound," he stated. Makes sense...

He also proceeded to say getting my engine professionally tuned is vital, and that a bridged na with itb's should be a really fun setup.

Hope this helps someone else down the road.

#10

Old [Sch|F]ool

Oil can come out of the center nipple at any RPM. Airflow must use the center nipple as the engine's "inlet" and air must flow out of the oil filler.

On a stock/street port I run an inline PCV valve to the oil filler and the center nipple goes to filtered air. The factory did route the charcoal canister to the center nipple but they were also intending to pull air through, you see? If you have no PCV then you are not pulling air through.

On my bridge port engines, they don't like PCV valves so I cap off the center iron's nipple and just run a breather hose from the oil filler to filtered air.

On a stock/street port I run an inline PCV valve to the oil filler and the center nipple goes to filtered air. The factory did route the charcoal canister to the center nipple but they were also intending to pull air through, you see? If you have no PCV then you are not pulling air through.

On my bridge port engines, they don't like PCV valves so I cap off the center iron's nipple and just run a breather hose from the oil filler to filtered air.

#11

This intrigues me. I too have frothy substances on my dipstick occasionally  . The previous owner of my car installed a catch-can with lines running from the center iron nipple and then to a hard-line coming off the firewall. Is there a better way to run this to eradicate this problem or to remove the can altogether? Car is stock port currently.

. The previous owner of my car installed a catch-can with lines running from the center iron nipple and then to a hard-line coming off the firewall. Is there a better way to run this to eradicate this problem or to remove the can altogether? Car is stock port currently.

. The previous owner of my car installed a catch-can with lines running from the center iron nipple and then to a hard-line coming off the firewall. Is there a better way to run this to eradicate this problem or to remove the can altogether? Car is stock port currently.

. The previous owner of my car installed a catch-can with lines running from the center iron nipple and then to a hard-line coming off the firewall. Is there a better way to run this to eradicate this problem or to remove the can altogether? Car is stock port currently.

#12

Rotary Freak

Oil can come out of the center nipple at any RPM. Airflow must use the center nipple as the engine's "inlet" and air must flow out of the oil filler.

On a stock/street port I run an inline PCV valve to the oil filler and the center nipple goes to filtered air. The factory did route the charcoal canister to the center nipple but they were also intending to pull air through, you see? If you have no PCV then you are not pulling air through.

On my bridge port engines, they don't like PCV valves so I cap off the center iron's nipple and just run a breather hose from the oil filler to filtered air.

On a stock/street port I run an inline PCV valve to the oil filler and the center nipple goes to filtered air. The factory did route the charcoal canister to the center nipple but they were also intending to pull air through, you see? If you have no PCV then you are not pulling air through.

On my bridge port engines, they don't like PCV valves so I cap off the center iron's nipple and just run a breather hose from the oil filler to filtered air.

Just a thought.

Eric

#13

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,778

Received 2,563 Likes

on

1,823 Posts

#15

Old [Sch|F]ool

Don't cap everything. I would (and do) run a hose from the oil filler neck to the air cleaner. Simple way to get filtered air and the engine breathes in all of the blowby gases that it bled out internally. So it's kinda like the engine's lypmhatic system

I've only wished for a catch tank once and that was when the oil was something like 2-3 quarts overfull. The engine tried to correct the issue by blowing oil up into the air cleaner. I thought I blew the engine when it happened...

I've only wished for a catch tank once and that was when the oil was something like 2-3 quarts overfull. The engine tried to correct the issue by blowing oil up into the air cleaner. I thought I blew the engine when it happened...

#16

Isaiah 53.7

Thread Starter

Join Date: Mar 2013

Location: Indiana

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

#17

Old [Sch|F]ool

Running rich all the time for drivability reasons + a 160 degree thermostat with a couple 1/4" holes drilled in it + no PCV system = the oil loads up with fuel and it just sits there instead of getting pulled out by the PCV system. So it dilutes rather rapidly.

i would NOT route the center iron's nipple to anything that wasn't positively moving air INTO the engine. IE unless you have a vacuum source on the oil filler tube. Oil splash from the rotors impinges directly onto that area of the engine and any out-moving air WILL take a whole lot of oil with it.

i would NOT route the center iron's nipple to anything that wasn't positively moving air INTO the engine. IE unless you have a vacuum source on the oil filler tube. Oil splash from the rotors impinges directly onto that area of the engine and any out-moving air WILL take a whole lot of oil with it.

#18

Isaiah 53.7

Thread Starter

Join Date: Mar 2013

Location: Indiana

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

Running rich all the time for drivability reasons + a 160 degree thermostat with a couple 1/4" holes drilled in it + no PCV system = the oil loads up with fuel and it just sits there instead of getting pulled out by the PCV system. So it dilutes rather rapidly.

i would NOT route the center iron's nipple to anything that wasn't positively moving air INTO the engine. IE unless you have a vacuum source on the oil filler tube. Oil splash from the rotors impinges directly onto that area of the engine and any out-moving air WILL take a whole lot of oil with it.

i would NOT route the center iron's nipple to anything that wasn't positively moving air INTO the engine. IE unless you have a vacuum source on the oil filler tube. Oil splash from the rotors impinges directly onto that area of the engine and any out-moving air WILL take a whole lot of oil with it.

From your experience, does idling increase oil dilution from fuel in our bridges? Also, while racing, does your oil level stay about the same compared to light load daily driving?

#19

Old [Sch|F]ool

In my experience it is roughly 1qt/1000mi no matter what. My racing is about 5-10 minutes of "track time" with 2-3 hours of idling in grid, with about 1500-3000mi of daily driving in between, so who knows? (I get about 700-800mi/week on it. I change the oil... a lot.)

#20

Rotary Freak

I still get frothy milkshake every so often at the top of the filler neck, but that is usually from a couple of quick starts and stops when ther engine is cold. If I get the car up to operating temperature, before shutting it down, I never get it. I also change the oil and filter between every race weekend as I notice a degradation of hot idle oil pressures after each race unless I am using Redline Race 40 wt. Then I go 2 race weekends or about 500 miles between changes.

Eric

#21

So, I would really like for this stupid catch can that came with the car to actually be doing something. This is how it is setup currently.

As stated it is routed to the center iron nipple and then jankily connected to this line that smells like fuel and has collected fuel vapors in it. There is nothing connected to the filler neck.

My questions are:

What the hell line is that?

How should I route it now considering I don't have a lot of the stock parts?

As stated it is routed to the center iron nipple and then jankily connected to this line that smells like fuel and has collected fuel vapors in it. There is nothing connected to the filler neck.

My questions are:

What the hell line is that?

How should I route it now considering I don't have a lot of the stock parts?

#22

So are all of you running NA or are any of you turbo? My TII that is finally running is dumping oil out of the VTA filter I have. I have always used a braided hose and extended the hose as high up the firewall as possible and vented it with a small K&N style filter on my NAs. I assumed the same would be fine on this TII, but I was wrong. I have a fair amount of oil splashed unto my firewall now.

The picture posted is how you all are recommending for a turbo setup as well?

The picture posted is how you all are recommending for a turbo setup as well?

#23

Isaiah 53.7

Thread Starter

Join Date: Mar 2013

Location: Indiana

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

Hah. I just now saw these last two posts. Sorry.

I can't really tell from your picture, but the gassy smelling line is probably going to the charcoal canister, right? From what I gathered from Peejay, the nipple on the filler neck went to a PCV valve then to the intake - this creates vacuum throughout the sump to suck in all the fumes/emissions into the intake to burn off... I think.

Just cap the center iron nipple, and route your filler nipple to whatever catchcan you have. Cap the nipple on your charcoal canister where the metal line goes, and discard your metal line. By the way, your charcoal canister isn't a catch can.

Again, sorry I didn't see this sooner.

Turbocharging is a completely different animal. Upon boost, your engine sees a much higher compression ratio than our gutless na's. From what I understand, this creates pressure in your sump due to natural blowby, which can push some oil along with vapors right out of the sump.

This is where we see a can of worms. Some say just getting a catch can is sufficient, so whenever your catch can fills up with oil and gunk, dump it. Some say recirculated oil blowby gunk through a quality catch can is the ticket; just hook it up to your intake tract, drain periodically, and enjoy.

This is coming from a non turbo guy, so the turbo forum would probably be the best place to torment yourself over this. I'll confess, though. I was eyeing a Holset HX40, but then reality kicked in. Have fun!

Just cap the center iron nipple, and route your filler nipple to whatever catchcan you have. Cap the nipple on your charcoal canister where the metal line goes, and discard your metal line. By the way, your charcoal canister isn't a catch can.

Originally Posted by jtbshaw

So are all of you running NA or are any of you turbo? My TII that is finally running is dumping oil out of the VTA filter I have. I have always used a braided hose and extended the hose as high up the firewall as possible and vented it with a small K&N style filter on my NAs. I assumed the same would be fine on this TII, but I was wrong. I have a fair amount of oil splashed unto my firewall now.

The picture posted is how you all are recommending for a turbo setup as well?

The picture posted is how you all are recommending for a turbo setup as well?

Turbocharging is a completely different animal. Upon boost, your engine sees a much higher compression ratio than our gutless na's. From what I understand, this creates pressure in your sump due to natural blowby, which can push some oil along with vapors right out of the sump.

This is where we see a can of worms. Some say just getting a catch can is sufficient, so whenever your catch can fills up with oil and gunk, dump it. Some say recirculated oil blowby gunk through a quality catch can is the ticket; just hook it up to your intake tract, drain periodically, and enjoy.

This is coming from a non turbo guy, so the turbo forum would probably be the best place to torment yourself over this. I'll confess, though. I was eyeing a Holset HX40, but then reality kicked in. Have fun!

#24

Isaiah 53.7

Thread Starter

Join Date: Mar 2013

Location: Indiana

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

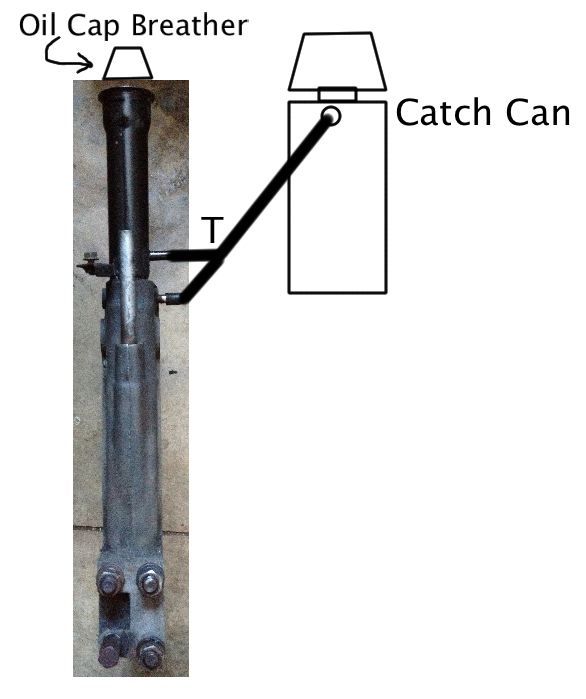

To update; I made a makeshift catchcan out of a mason jar, jb weld, and brass fittings (somehow passed all the tech inspections) shortly after this thread, and routed the filler neck nipple to it. The most fluid I ever saw in it was maybe a 1/2 ounce of gunk after a hefty dyno session in the early spring. Other than that, the jar just houses weird odors. The frothy stuff seems to have gone, but the sump still loads up with fuel, even after leaning out the A/F ratio and advancing the timing, but that's another topic.

I'm still considering a true positive ventilation system utilizing a quality catch can hooked up to each intake runner where I have my brake booster hooked up. Either way, I'm getting rid of the Mason jar, so don't worry.

Here you can see it by the battery, just for reference and to know that it did work at least a little.

I'm still considering a true positive ventilation system utilizing a quality catch can hooked up to each intake runner where I have my brake booster hooked up. Either way, I'm getting rid of the Mason jar, so don't worry.

Here you can see it by the battery, just for reference and to know that it did work at least a little.

#25

Old [Sch|F]ool

Nice results!

I went to an autocross where I got bumped out of tech because I didn't have a catch can for the vent. A salvaged hose and a 20 ounce Pepsi bottle threaded into the brake lines later, I passed tech

Looking at your air filter setup reminded me of this thread: stack filtration ? Speed Talk

And this thread linked inside that one: Foam Sock filters cost me 55bhp - PistonHeads

I went to an autocross where I got bumped out of tech because I didn't have a catch can for the vent. A salvaged hose and a 20 ounce Pepsi bottle threaded into the brake lines later, I passed tech

Looking at your air filter setup reminded me of this thread: stack filtration ? Speed Talk

And this thread linked inside that one: Foam Sock filters cost me 55bhp - PistonHeads