Door Box Lid and Door Panel Plastic

#51

Full Member

Join Date: Dec 2005

Location: clermont, georgia

Posts: 238

Likes: 0

Received 0 Likes

on

0 Posts

I plan on replacing the screws with black oxide allen heads, also countersunk. If you wanted to make one yourself it could be easily done with hand tools, just drill the ends for machine screws to substiture for hinge pins instead of turning down the rod on a lathe, and file the tapered flat on the rod instead of milling it. To bend the sheet, round off a bit of hardwood and clamp it in a vise together with the metal and use a soft hammer to form the sheet over the curved wood. If you don't want the screw heads, just use some JB weld; put the pin in the door, and slide it backwards into position, put a tiny bit of jbweld on the flat, and get the cover position right. when that small amount of jb weld has cured, open the cover and put a nice fillet in for a full strength bond.

tom

tom

#52

GB List Here -> CLICK

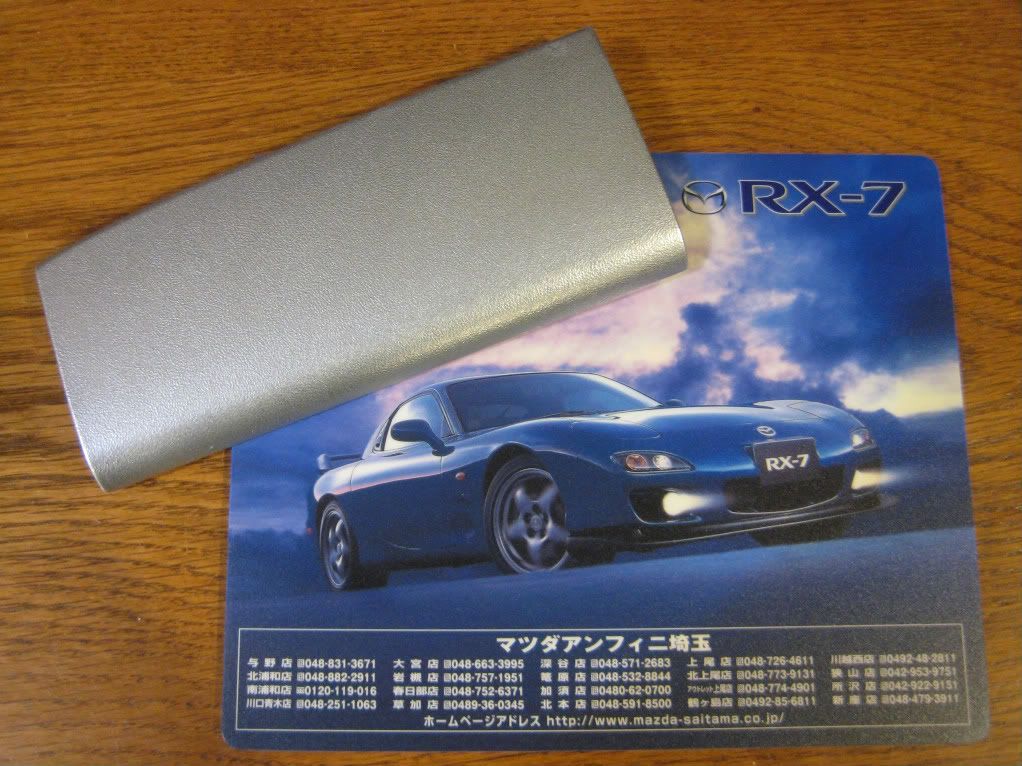

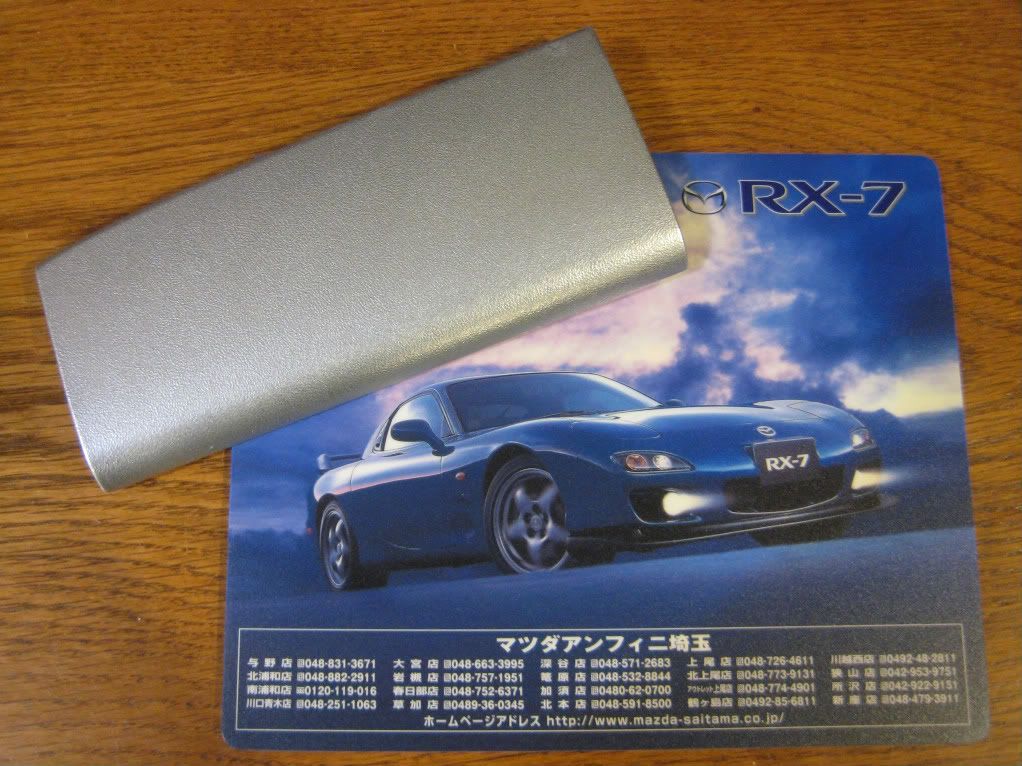

We've started a list for interested parties, and have a prototype that will be finished sometime this week. We realize this part may not look as complicated as the passneger door handle we previously made, but retaining the factory texture on such a large piece is not particularly easy. We feel however that it is well worth the cost increase to identically match the stock piece, as the lid sits inbetween two existing plastic pieces. Please see the included pictures of the handle we currently produce, as it is representitive of what the map pocket cover will look like. The aesthetics and fitment are 100% identical to stock, but will last longer than the car

If desired, we can produce this piece in raw aluminum, or any anodized finish, however for a 100% identical match we highly suggest our proprietary coating which is extremely durable, and identically matches the stock finish. Seeing as the map pocket cover is sandwiched in between two other plastic trim pieces, a non matching finish such as hard anodized, black anodized, raw, non-matching paint, will look ridiculous (IMHO). Our OEM-match coating, along with our specialized casting process will produce a piece indistinguishable from the stock plastic, yet will permanently fix the known problem that occurs on many of our cars. New mounting hardware as well as replacement felt on the inside of the lid will also be included. We need twice the number of people currently signed up to make this piece a reality, so please sign up if you are seriously interested.

(IMHO). Our OEM-match coating, along with our specialized casting process will produce a piece indistinguishable from the stock plastic, yet will permanently fix the known problem that occurs on many of our cars. New mounting hardware as well as replacement felt on the inside of the lid will also be included. We need twice the number of people currently signed up to make this piece a reality, so please sign up if you are seriously interested.

Lastly, as this part is extremely costly to produce, we are producing the map lid pocket not for profit. Yes, you heard correct. The tooling and individual casting part-cost required to make this piece identical to stock (the only way we would make it) is extremely high. We talked it over and decided that it would be more important to create an identical reproduction for the FD community, than to try to turn a buck off it. We exist directly because of support from the FD community, and are not only here to create kick *** FD parts, but also to support the FD community as a whole... and doing a part here and there in which we simply break even fits with our philosophy for creating nothing but the best parts for the FD. (If we can get a few thumbs up's in the process from other forum members, we're happy campers). We really want these lids in our own FD's, and we hope you do as well.

-SBG

PS This piece (and all of our current parts) are proudly made in the USA, in state of the art facilities (aside from the HID projectors which are made by hand, by us, in a non-state-of-the-art facility )

)

We've started a list for interested parties, and have a prototype that will be finished sometime this week. We realize this part may not look as complicated as the passneger door handle we previously made, but retaining the factory texture on such a large piece is not particularly easy. We feel however that it is well worth the cost increase to identically match the stock piece, as the lid sits inbetween two existing plastic pieces. Please see the included pictures of the handle we currently produce, as it is representitive of what the map pocket cover will look like. The aesthetics and fitment are 100% identical to stock, but will last longer than the car

If desired, we can produce this piece in raw aluminum, or any anodized finish, however for a 100% identical match we highly suggest our proprietary coating which is extremely durable, and identically matches the stock finish. Seeing as the map pocket cover is sandwiched in between two other plastic trim pieces, a non matching finish such as hard anodized, black anodized, raw, non-matching paint, will look ridiculous

Lastly, as this part is extremely costly to produce, we are producing the map lid pocket not for profit. Yes, you heard correct. The tooling and individual casting part-cost required to make this piece identical to stock (the only way we would make it) is extremely high. We talked it over and decided that it would be more important to create an identical reproduction for the FD community, than to try to turn a buck off it. We exist directly because of support from the FD community, and are not only here to create kick *** FD parts, but also to support the FD community as a whole... and doing a part here and there in which we simply break even fits with our philosophy for creating nothing but the best parts for the FD. (If we can get a few thumbs up's in the process from other forum members, we're happy campers). We really want these lids in our own FD's, and we hope you do as well.

-SBG

PS This piece (and all of our current parts) are proudly made in the USA, in state of the art facilities (aside from the HID projectors which are made by hand, by us, in a non-state-of-the-art facility

)

)

__________________

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

Last edited by SakeBomb Garage; 03-19-11 at 10:42 PM.

#55

Dibs on what? Please shoot us a PM or email regarding the passenger handle, but lets keep this thread on track for the map-lid... the handles were just posted as an example of what the finish on the map-lid would look like.

We should have an update sometime early today I hope

-Heath

We should have an update sometime early today I hope

-Heath

__________________

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

#56

Here are a few pictures of our one-off prototype (raw). The finished product will be made in 93 and 94 finishes, and offered raw or coated in our proprietary coating which is extremely durable, and identically matches the interior plastics (see example of handle below).

Raw -> click here

Coated -> click here

The good: My door (personally) is forever fixed

The bad: This is not a production piece. To create the tooling to reproduce these in large quantities is extremely expensive (many many thousands). It's still cheaper than plastic injection tooling but those parts are made in the thousands, not hundreds, or tens. As a result we need around 70 people on board to make a GB happen (at least)... this is for us to break even. At this point our intention is not to do this for profit, but to simply get enough members together to produce the tooling and sell it at cost for the GB members. We are looking at the $250-ish range before paypal, and shipping etc (with 70 members). If we have less interest, the additional cost would have to be distributed amongst the interested members which would drive the cost up considerably for each part.... so... we need more people to make this happen. If the numbers start increasing we can begin taking deposits or payments to put this piece in production.

Please click HERE to sign up ! And please pass the word along to FD buddies etc... with enough people we can make this happen!

Raw -> click here

Coated -> click here

The good: My door (personally) is forever fixed

The bad: This is not a production piece. To create the tooling to reproduce these in large quantities is extremely expensive (many many thousands). It's still cheaper than plastic injection tooling but those parts are made in the thousands, not hundreds, or tens. As a result we need around 70 people on board to make a GB happen (at least)... this is for us to break even. At this point our intention is not to do this for profit, but to simply get enough members together to produce the tooling and sell it at cost for the GB members. We are looking at the $250-ish range before paypal, and shipping etc (with 70 members). If we have less interest, the additional cost would have to be distributed amongst the interested members which would drive the cost up considerably for each part.... so... we need more people to make this happen. If the numbers start increasing we can begin taking deposits or payments to put this piece in production.

Please click HERE to sign up ! And please pass the word along to FD buddies etc... with enough people we can make this happen!

__________________

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

#57

posted in another thread, but I felt like it directly related to the current GB's going into effect, so I'm reposting here:

"It shouldn't.... we just need more people on board is the thing. $250 is conservative. The "competition" claims they will be selling them for ~$200 (and hard anodizing will not match the factory finish) and has yet to produce anything. We've got a track record for making perfectly fitting and perfectly matching pieces. Without numbers, our hands are tied and we can't make this piece.

Ask yourself, if company A) makes and sells a part at cost, and company B) Has the part produced over seas and insists on turning a profit on it.... are the parts equal? does quality suffer? Are their parts being machined for a specialized bolt to fix the problem caused by the roll pin and plastic pivot? Do they require you to reuse (if you even still have it) the plastic pivots on the ends?

I insist that everyone interested go to their own door box, take a look at the design, and then ask the questions needed to insure that the piece they are buying (or will buy) fixes the design flaws in the original piece. I've spend a lot of time with multiple broken door box lids and know what the design flaws are. The fix for this part is MUCH more involved than simply making an identical replica in aluminum.... seriously. Is company X going to address those design flaws? Roll pin, plastic pivots, shrinkage of 1mm per 4" linear casting (the piece is about 8" length, and will be ~2mm shorter if directly cast), and the finish.

Our part looks identical but will be (from a functionality standpoint) redesigned and fixed. In addition to the more expensive casting process to retain the factory look/finish, we are doing additional work behind the scenes to fix the flaws in this part. Our part (if we can get enough people together to make it at cost) will NOT be equal to the part from company X... I assure you

-Heath "

Ask yourself, if company A) makes and sells a part at cost, and company B) Has the part produced over seas and insists on turning a profit on it.... are the parts equal? does quality suffer? Are their parts being machined for a specialized bolt to fix the problem caused by the roll pin and plastic pivot? Do they require you to reuse (if you even still have it) the plastic pivots on the ends?

I insist that everyone interested go to their own door box, take a look at the design, and then ask the questions needed to insure that the piece they are buying (or will buy) fixes the design flaws in the original piece. I've spend a lot of time with multiple broken door box lids and know what the design flaws are. The fix for this part is MUCH more involved than simply making an identical replica in aluminum.... seriously. Is company X going to address those design flaws? Roll pin, plastic pivots, shrinkage of 1mm per 4" linear casting (the piece is about 8" length, and will be ~2mm shorter if directly cast), and the finish.

Our part looks identical but will be (from a functionality standpoint) redesigned and fixed. In addition to the more expensive casting process to retain the factory look/finish, we are doing additional work behind the scenes to fix the flaws in this part. Our part (if we can get enough people together to make it at cost) will NOT be equal to the part from company X... I assure you

-Heath "

__________________

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

#59

If you are willing to pay $500 a piece, and send in your original, sure we can make em

. The process used to make the prototype piece can't be used for multiple copies unfortunately, and the original is destroyed in the process (which is ok as I have multiple non-broken covers I've scrounged up over the years cause they keep breaking). The prototype was made to figure out the re-design changes needed to fix the problems that cause the lid (or pocket) to break. The issues that *we* addressed are:

. The process used to make the prototype piece can't be used for multiple copies unfortunately, and the original is destroyed in the process (which is ok as I have multiple non-broken covers I've scrounged up over the years cause they keep breaking). The prototype was made to figure out the re-design changes needed to fix the problems that cause the lid (or pocket) to break. The issues that *we* addressed are:-the roll pin (replacement in this case)

-plastic pivots used on either end (deleted)

-the stress induced by the flat spring (fixed with removal of roll pin/slop)

-shrinkage in the casting (accounted for in our redesign)

-identical look

__________________

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

#61

That prototype looks like a very well made piece. Also can see how this will match nicely with the interior so kudos to you guys.

I would have been in on this but just fixed mine for 25 cents or the cost of a screw. I think I was lucky though as the only part that broke on mine with the plastic that held the pin in place. I drilled out the hole and used a screw to fix it. Monster Garage complete!

Anyway, there's no telling how long that will last so I still might pick up one of these.

I would have been in on this but just fixed mine for 25 cents or the cost of a screw. I think I was lucky though as the only part that broke on mine with the plastic that held the pin in place. I drilled out the hole and used a screw to fix it. Monster Garage complete!

Anyway, there's no telling how long that will last so I still might pick up one of these.