Haltech Boost levels different from day to day?

#1

Boost levels different from day to day?

I thought I had my closed loop boost control all figured out, but there seems to be a problem.

I started making lower boost couple days ago for unknown reason, and I remade my base map @ 6 and 9psi on second gear and 12 and 14psi on third gear yesterday @ 75-80*F ambient with closed loop control off. Everything went perfect. I did notice the duty cycles were little higher than what I normally use. Today, I pulled up next to an S4 that was tailing me for a mile and hit a boost cut while building boost which was really irritating. I logged it and I'm now overshooting target boost by 2-3psi. I had left closed loop PID settings at 0 which should turn everything off and left the spool assist off. Only thing different I can think of was ambient temp which was around 60-65*F this morning. EGT is about the same at around 1350*F @WOT.

I checked out the lines and they seem to be in good condition. My duty cycles are 20-27% to achieve 5-14psi. The solenoid is MAC 4 port. Frequency is set at 23Hz.

Any ideas?

I started making lower boost couple days ago for unknown reason, and I remade my base map @ 6 and 9psi on second gear and 12 and 14psi on third gear yesterday @ 75-80*F ambient with closed loop control off. Everything went perfect. I did notice the duty cycles were little higher than what I normally use. Today, I pulled up next to an S4 that was tailing me for a mile and hit a boost cut while building boost which was really irritating. I logged it and I'm now overshooting target boost by 2-3psi. I had left closed loop PID settings at 0 which should turn everything off and left the spool assist off. Only thing different I can think of was ambient temp which was around 60-65*F this morning. EGT is about the same at around 1350*F @WOT.

I checked out the lines and they seem to be in good condition. My duty cycles are 20-27% to achieve 5-14psi. The solenoid is MAC 4 port. Frequency is set at 23Hz.

Any ideas?

#2

If your PID settings are all set to 0 then it will just run off your base duty table (not really closed loop)

The Elite's can be difficult to dial in boost control but essentially you want to set your base duty lower than what it needs so the PID's can bring up the duty to hit the target. If 20% is 5psi and 27% is 14psi it might be tricky to dial in.

The Elite's can be difficult to dial in boost control but essentially you want to set your base duty lower than what it needs so the PID's can bring up the duty to hit the target. If 20% is 5psi and 27% is 14psi it might be tricky to dial in.

#3

If your PID settings are all set to 0 then it will just run off your base duty table (not really closed loop)

The Elite's can be difficult to dial in boost control but essentially you want to set your base duty lower than what it needs so the PID's can bring up the duty to hit the target. If 20% is 5psi and 27% is 14psi it might be tricky to dial in.

The Elite's can be difficult to dial in boost control but essentially you want to set your base duty lower than what it needs so the PID's can bring up the duty to hit the target. If 20% is 5psi and 27% is 14psi it might be tricky to dial in.

Skeese

#4

yea I think you guys are right, and 4 port is good for smaller turbo guys pushing BIG psi numbers like over 30-40psi where being off by a few psi isn't a big deal. If 1-2 psi resolution is desired, I'm inclined to say 4 port isn't the best option.

just to give you an example:

@ ~23% duty cycle = max psi is 11psi

@ ~23.5% duty cycle = 12.5 psi max

@ ~24% duty cycle = overshoots to 14.5 psi which is my cut.

it's not this simple since it's a 2D map based on RPM, but you get the idea.. I have to change the duty cycle by 0.3 - 0.5 rather than an entire integer to get the desired effect

some days I would readjust it because it'll start under or over shooting and I have to either decrease or increase the duty cycle by 1-2%. I think the difference can be attributed to different fuel, amount of oil I'm adding, EGT, ambient temp, who knows?

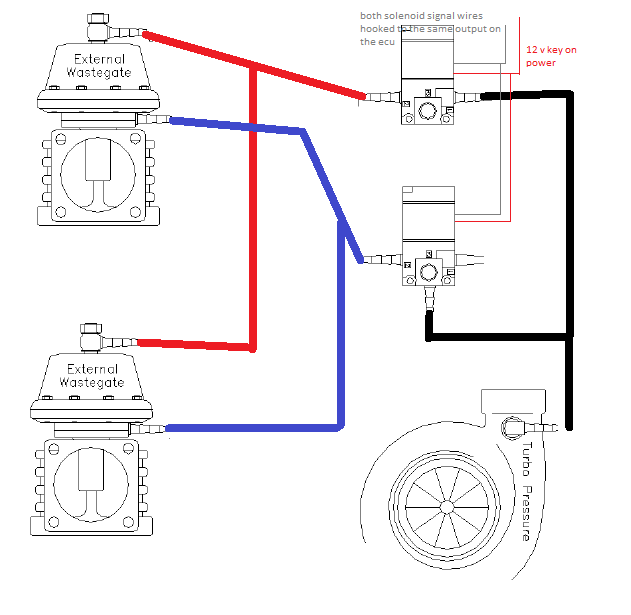

I'm going with dual 3 port set-up. I really like the low psi for 1st and 2nd gear. will report in a few weeks!

just to give you an example:

@ ~23% duty cycle = max psi is 11psi

@ ~23.5% duty cycle = 12.5 psi max

@ ~24% duty cycle = overshoots to 14.5 psi which is my cut.

it's not this simple since it's a 2D map based on RPM, but you get the idea.. I have to change the duty cycle by 0.3 - 0.5 rather than an entire integer to get the desired effect

some days I would readjust it because it'll start under or over shooting and I have to either decrease or increase the duty cycle by 1-2%. I think the difference can be attributed to different fuel, amount of oil I'm adding, EGT, ambient temp, who knows?

I'm going with dual 3 port set-up. I really like the low psi for 1st and 2nd gear. will report in a few weeks!

#5

Banned. I got OWNED!!!

How did you plan on configuring everything? MS Paint time?

I'd want this with a single Dual Port IWG (Turbosmart):

So I think this works for MY setup.

My logic for tuning/safety for this 13bt w/ EFR 9174 is 1st and 2nd gear get something around 8-10psi, 3rd-5th get full boost (whatever the hell that is), and when running pump gas, it drops all 1st-5th to the lower set boost figure (8-10psi). On e85 though, ***** to the wall. Fuckkiiiittt.

Last edited by RGHTBrainDesign; 05-14-17 at 03:41 PM.

#6

I'll report on the finding. who knows... it may not be whole lot better than 4 port in which case I will go with standard 3 port and 10 psi spring, and continue to split flames and backfire in my 1st and 2nd gears as my TCS keeps me in check. I just wanted to avoid having TCS kick in so much regularly. It's fun in the beginning, but it's just obnoxious to those around me.

yea I've been looking for dual port plumbing diagram online, and it has been difficult to find. Haltech can support dual port with 2 x DPO/STEP outputs. It offers basically the same benefit as the 4 port with more useable duty cycle range. That's the theory anyway, but many things in theory don't always translate in real life as we all know

yea I've been looking for dual port plumbing diagram online, and it has been difficult to find. Haltech can support dual port with 2 x DPO/STEP outputs. It offers basically the same benefit as the 4 port with more useable duty cycle range. That's the theory anyway, but many things in theory don't always translate in real life as we all know

#7

Banned. I got OWNED!!!

I'll report on the finding. who knows... it may not be whole lot better than 4 port in which case I will go with standard 3 port and 10 psi spring, and continue to split flames and backfire in my 1st and 2nd gears as my TCS keeps me in check. I just wanted to avoid having TCS kick in so much regularly. It's fun in the beginning, but it's just obnoxious to those around me.

yea I've been looking for dual port plumbing diagram online, and it has been difficult to find. Haltech can support dual port with 2 x DPO/STEP outputs. It offers basically the same benefit as the 4 port with more useable duty cycle range. That's the theory anyway, but many things in theory don't always translate in real life as we all know

yea I've been looking for dual port plumbing diagram online, and it has been difficult to find. Haltech can support dual port with 2 x DPO/STEP outputs. It offers basically the same benefit as the 4 port with more useable duty cycle range. That's the theory anyway, but many things in theory don't always translate in real life as we all know

At this point, I'm already limited on the 2500 Wires, so I might have to cut out some features or spend the money on expansion boxes... So sad. What happened to my luxury!!!

Trending Topics

#9

Banned. I got OWNED!!!

3port MAC-5.4 watt

Frequency (Hz)

10

Approx Duty Range (%)

7-90

Frequency (Hz)

15

Approx Duty Range (%)

10-89

Frequency (Hz)

20

Approx Duty Range (%)

15-86

Frequency (Hz)

25

Approx Duty Range (%)

17-80

Frequency (Hz)

31

Approx Duty Range (%)

20-80

Frequency (Hz)

40

Approx Duty Range (%)

26-68

3 port MAC-C7-HI-FREQ

Frequency (Hz)

31

Approx Duty Range (%)

15-85

Frequency (Hz)

40

Approx Duty Range (%)

17-82

4 port 5.4 watt

Frequency (Hz)

10

Approx Duty Range (%)

9-87

Frequency (Hz)

20

Approx Duty Range (%)

16-70

Frequency (Hz)

30

Approx Duty Range (%)

22-62

Frequency (Hz)

40

Approx Duty Range (%)

25-40

4 port C7-HI-FREQ

Frequency (Hz)

10

Approx Duty Range (%)

6-90

Frequency (Hz)

20

Approx Duty Range (%)

10-80

Frequency (Hz)

30

Approx Duty Range (%)

14-70

#10

That's great data, where did you get it from?

In our experience it also greatly depends on the vehicle and wastegate design / flow.

In our experience it also greatly depends on the vehicle and wastegate design / flow.

3port MAC-5.4 watt

Frequency (Hz)

10

Approx Duty Range (%)

7-90

Frequency (Hz)

15

Approx Duty Range (%)

10-89

Frequency (Hz)

20

Approx Duty Range (%)

15-86

Frequency (Hz)

25

Approx Duty Range (%)

17-80

Frequency (Hz)

31

Approx Duty Range (%)

20-80

Frequency (Hz)

40

Approx Duty Range (%)

26-68

3 port MAC-C7-HI-FREQ

Frequency (Hz)

31

Approx Duty Range (%)

15-85

Frequency (Hz)

40

Approx Duty Range (%)

17-82

4 port 5.4 watt

Frequency (Hz)

10

Approx Duty Range (%)

9-87

Frequency (Hz)

20

Approx Duty Range (%)

16-70

Frequency (Hz)

30

Approx Duty Range (%)

22-62

Frequency (Hz)

40

Approx Duty Range (%)

25-40

4 port C7-HI-FREQ

Frequency (Hz)

10

Approx Duty Range (%)

6-90

Frequency (Hz)

20

Approx Duty Range (%)

10-80

Frequency (Hz)

30

Approx Duty Range (%)

14-70

Frequency (Hz)

10

Approx Duty Range (%)

7-90

Frequency (Hz)

15

Approx Duty Range (%)

10-89

Frequency (Hz)

20

Approx Duty Range (%)

15-86

Frequency (Hz)

25

Approx Duty Range (%)

17-80

Frequency (Hz)

31

Approx Duty Range (%)

20-80

Frequency (Hz)

40

Approx Duty Range (%)

26-68

3 port MAC-C7-HI-FREQ

Frequency (Hz)

31

Approx Duty Range (%)

15-85

Frequency (Hz)

40

Approx Duty Range (%)

17-82

4 port 5.4 watt

Frequency (Hz)

10

Approx Duty Range (%)

9-87

Frequency (Hz)

20

Approx Duty Range (%)

16-70

Frequency (Hz)

30

Approx Duty Range (%)

22-62

Frequency (Hz)

40

Approx Duty Range (%)

25-40

4 port C7-HI-FREQ

Frequency (Hz)

10

Approx Duty Range (%)

6-90

Frequency (Hz)

20

Approx Duty Range (%)

10-80

Frequency (Hz)

30

Approx Duty Range (%)

14-70

#11

Banned. I got OWNED!!!

#12

Thanks for the replies. I tried 10hz in the past. I tried from 10hz upto 40hz. Same result. Lower frequency only widens the usable duty cycle range. It doesn't seem to fix what I think is the real problem: a small change in duty cycle results in a large boost level difference. Again, I think 4 port is perfect if you're looking for 5-40psi boost range. I am inclined to think that as you're climbing up the boost map, your duty cycle sensitivity will decrease as your turbo is being maxed out.

In my experience, these solenoids' on-off time just varies tiny amount day after day. In addition to host of other factors such as AIT and EGT, there are other factors such as voltage fluctuations which will make small differences in the solenoid on-off time with the given pwm input. My personal problem is that my turbo is only about to get into its efficient range at my current boost-cut for 91 octane and in such situation, a small duty cycle change (0.5%) commands large fluctuations (2-4psi) in the actual boost level when using 4 port.

Ideally, I probably should downsize my turbo again to gt40-variant or go back to 3 port, but I like the lower boost option afforded by the 4 port and an option to maxing gt42 on e85 in the future after hosts of other drive terrain upgrades sitting in my garage collecting dust. I think my current wastegate priority is quite good--4psi with 7psi spring which decreases with rpm, so I hope 3 port should solve this current problem.

If someone has a base correction map for boost solenoid duty cycle using tps, AIT, EGT, voltage, etc., I would love to take a look if possible.

In my experience, these solenoids' on-off time just varies tiny amount day after day. In addition to host of other factors such as AIT and EGT, there are other factors such as voltage fluctuations which will make small differences in the solenoid on-off time with the given pwm input. My personal problem is that my turbo is only about to get into its efficient range at my current boost-cut for 91 octane and in such situation, a small duty cycle change (0.5%) commands large fluctuations (2-4psi) in the actual boost level when using 4 port.

Ideally, I probably should downsize my turbo again to gt40-variant or go back to 3 port, but I like the lower boost option afforded by the 4 port and an option to maxing gt42 on e85 in the future after hosts of other drive terrain upgrades sitting in my garage collecting dust. I think my current wastegate priority is quite good--4psi with 7psi spring which decreases with rpm, so I hope 3 port should solve this current problem.

If someone has a base correction map for boost solenoid duty cycle using tps, AIT, EGT, voltage, etc., I would love to take a look if possible.

#13

gents,

I think I figured out my problem with overboosting and underboosting..

did one fix and it's perfect on f'ing default boost PID setting. I'm talking +/- 0.2 psi hold on target boost at 4psi, 8psi, and 14psi. mostly dead-on.

I probably spent $1k in fuel alone to optimize boost control and this single free fix did it. has anyone done closed loop boost control tuning? basically composed of bunch of WOT to third gear (115mph) followed by pulling over to the side of the road in quick successions. After a while, when you think you're stopped, and about to pull the e-brake, you realize you're still going 60mph

anyway, I will gather more data at different ambient temps before I get too excited.

I think I figured out my problem with overboosting and underboosting..

did one fix and it's perfect on f'ing default boost PID setting. I'm talking +/- 0.2 psi hold on target boost at 4psi, 8psi, and 14psi. mostly dead-on.

I probably spent $1k in fuel alone to optimize boost control and this single free fix did it. has anyone done closed loop boost control tuning? basically composed of bunch of WOT to third gear (115mph) followed by pulling over to the side of the road in quick successions. After a while, when you think you're stopped, and about to pull the e-brake, you realize you're still going 60mph

anyway, I will gather more data at different ambient temps before I get too excited.

#15

Banned. I got OWNED!!!

gents,

I think I figured out my problem with overboosting and underboosting..

did one fix and it's perfect on f'ing default boost PID setting. I'm talking +/- 0.2 psi hold on target boost at 4psi, 8psi, and 14psi. mostly dead-on.

I probably spent $1k in fuel alone to optimize boost control and this single free fix did it. has anyone done closed loop boost control tuning? basically composed of bunch of WOT to third gear (115mph) followed by pulling over to the side of the road in quick successions. After a while, when you think you're stopped, and about to pull the e-brake, you realize you're still going 60mph

anyway, I will gather more data at different ambient temps before I get too excited.

I think I figured out my problem with overboosting and underboosting..

did one fix and it's perfect on f'ing default boost PID setting. I'm talking +/- 0.2 psi hold on target boost at 4psi, 8psi, and 14psi. mostly dead-on.

I probably spent $1k in fuel alone to optimize boost control and this single free fix did it. has anyone done closed loop boost control tuning? basically composed of bunch of WOT to third gear (115mph) followed by pulling over to the side of the road in quick successions. After a while, when you think you're stopped, and about to pull the e-brake, you realize you're still going 60mph

anyway, I will gather more data at different ambient temps before I get too excited.

#16

gents,

I think I figured out my problem with overboosting and underboosting..

did one fix and it's perfect on f'ing default boost PID setting. I'm talking +/- 0.2 psi hold on target boost at 4psi, 8psi, and 14psi. mostly dead-on.

I probably spent $1k in fuel alone to optimize boost control and this single free fix did it. has anyone done closed loop boost control tuning? basically composed of bunch of WOT to third gear (115mph) followed by pulling over to the side of the road in quick successions. After a while, when you think you're stopped, and about to pull the e-brake, you realize you're still going 60mph

anyway, I will gather more data at different ambient temps before I get too excited.

I think I figured out my problem with overboosting and underboosting..

did one fix and it's perfect on f'ing default boost PID setting. I'm talking +/- 0.2 psi hold on target boost at 4psi, 8psi, and 14psi. mostly dead-on.

I probably spent $1k in fuel alone to optimize boost control and this single free fix did it. has anyone done closed loop boost control tuning? basically composed of bunch of WOT to third gear (115mph) followed by pulling over to the side of the road in quick successions. After a while, when you think you're stopped, and about to pull the e-brake, you realize you're still going 60mph

anyway, I will gather more data at different ambient temps before I get too excited.

I have

One thing that I've noticed in my case, is that the mac solenoid is affected by heat soak. Something that has cause me to chase my tail, and look at different things. It sucks when you are trying to map the boost control, and and you cant get a constant boost curve!

#18

This little piece of S*** was source of all my boost problems. Obstructive solenoid filter. I took it off and no problems. Basically it is too obstructive to relieve wastegate top side when I'm trying to control overboost. I would overcompensate for such situation in duty map with low % and end with underboosting---neverending cycle. I'm running turbosmart powergate 60, and maybe size of it had something to do with it. If your top side WG volume is small, you may get away with running that stock brass filter. anyway, I even ordered two 3 port solenoid, but I'm keeping them for future projects and not using them anymore. I'm running normal 4 port MAC solenoid.

Here are some symptoms of outflow restriction on the solenoid:

1. likes to overboost when you first hit the target boost.

2. likes to overboost or underboost depending on low or high rpm you start WOT respectively.

Another idea is restrictor pill on feedline but I don't like that idea because I feel that can potentially slow down boost climb with my 7psi spring. and it doesn't actually solve problem of controlling overboost with closed loop control.

well that only took a month of tuning and about a thousand in fuel. all due to that little thing. I know it's blocked because when I tried to blow on it, there is a lot of resistance through it. I probably put a K&N filter on it later.

I'm moving onto water injection. Boost is rock steady and very controllable with haltech and 4 port mac solenoid.

Here are some symptoms of outflow restriction on the solenoid:

1. likes to overboost when you first hit the target boost.

2. likes to overboost or underboost depending on low or high rpm you start WOT respectively.

Another idea is restrictor pill on feedline but I don't like that idea because I feel that can potentially slow down boost climb with my 7psi spring. and it doesn't actually solve problem of controlling overboost with closed loop control.

well that only took a month of tuning and about a thousand in fuel. all due to that little thing. I know it's blocked because when I tried to blow on it, there is a lot of resistance through it. I probably put a K&N filter on it later.

I'm moving onto water injection. Boost is rock steady and very controllable with haltech and 4 port mac solenoid.

Last edited by stickmantijuana; 05-20-17 at 08:57 AM.

#19

This little piece of S*** was source of all my boost problems. Obstructive solenoid filter. I took it off and no problems. Basically it is too obstructive to relieve wastegate top side when I'm trying to control overboost. I would overcompensate for such situation in duty map with low % and end with underboosting---neverending cycle. I'm running turbosmart powergate 60, and maybe size of it had something to do with it. If your top side WG volume is small, you may get away with running that stock brass filter. anyway, I even ordered two 3 port solenoid, but I'm keeping them for future projects and not using them anymore. I'm running normal 4 port MAC solenoid.

Here are some symptoms of outflow restriction on the solenoid:

1. likes to overboost when you first hit the target boost.

2. likes to overboost or underboost depending on low or high rpm you start WOT respectively.

Another idea is restrictor pill on feedline but I don't like that idea because I feel that can potentially slow down boost climb with my 7psi spring. and it doesn't actually solve problem of controlling overboost with closed loop control.

well that only took a month of tuning and about a thousand in fuel. all due to that little thing. I know it's blocked because when I tried to blow on it, there is a lot of resistance through it. I probably put a K&N filter on it later.

I'm moving onto water injection. Boost is rock steady and very controllable with haltech and 4 port mac solenoid.

Here are some symptoms of outflow restriction on the solenoid:

1. likes to overboost when you first hit the target boost.

2. likes to overboost or underboost depending on low or high rpm you start WOT respectively.

Another idea is restrictor pill on feedline but I don't like that idea because I feel that can potentially slow down boost climb with my 7psi spring. and it doesn't actually solve problem of controlling overboost with closed loop control.

well that only took a month of tuning and about a thousand in fuel. all due to that little thing. I know it's blocked because when I tried to blow on it, there is a lot of resistance through it. I probably put a K&N filter on it later.

I'm moving onto water injection. Boost is rock steady and very controllable with haltech and 4 port mac solenoid.

Good info, glad you sort it out!

#22

This little piece of S*** was source of all my boost problems. Obstructive solenoid filter. I took it off and no problems. Basically it is too obstructive to relieve wastegate top side when I'm trying to control overboost. I would overcompensate for such situation in duty map with low % and end with underboosting---neverending cycle. I'm running turbosmart powergate 60, and maybe size of it had something to do with it. If your top side WG volume is small, you may get away with running that stock brass filter. anyway, I even ordered two 3 port solenoid, but I'm keeping them for future projects and not using them anymore. I'm running normal 4 port MAC solenoid.

Here are some symptoms of outflow restriction on the solenoid:

1. likes to overboost when you first hit the target boost.

2. likes to overboost or underboost depending on low or high rpm you start WOT respectively.

Another idea is restrictor pill on feedline but I don't like that idea because I feel that can potentially slow down boost climb with my 7psi spring. and it doesn't actually solve problem of controlling overboost with closed loop control.

well that only took a month of tuning and about a thousand in fuel. all due to that little thing. I know it's blocked because when I tried to blow on it, there is a lot of resistance through it. I probably put a K&N filter on it later.

I'm moving onto water injection. Boost is rock steady and very controllable with haltech and 4 port mac solenoid.

Here are some symptoms of outflow restriction on the solenoid:

1. likes to overboost when you first hit the target boost.

2. likes to overboost or underboost depending on low or high rpm you start WOT respectively.

Another idea is restrictor pill on feedline but I don't like that idea because I feel that can potentially slow down boost climb with my 7psi spring. and it doesn't actually solve problem of controlling overboost with closed loop control.

well that only took a month of tuning and about a thousand in fuel. all due to that little thing. I know it's blocked because when I tried to blow on it, there is a lot of resistance through it. I probably put a K&N filter on it later.

I'm moving onto water injection. Boost is rock steady and very controllable with haltech and 4 port mac solenoid.

this is exactly what the f*ck my engine is doing!

I thought it was the pport yielding inconsistent turbine speeds because of reversion/egt changes per gear/rpm. But now it sounds like you've nailed it down!

Hit from 3k rpm = x boost

Hit from 7k rpm = x+3psi boost

F*CK I can't wait to try it.

#25

(Terraplane)

!!!!!!! Both of them!?

What brand?

Looks like one WG is rich and the other clean.

How was the engine/boost before you discovered this?

What brand?

Looks like one WG is rich and the other clean.

How was the engine/boost before you discovered this?

)

)