Defined Autoworks 4-rotor kit group buy!

#1

Finally after much development we are proud to announce our 4 rotor kit group buy!

Never before has a company based in the U.S. offered such a service. I have already kick started the process and have enough of the complex parts on the shelf to build 4 sets of 4-rotor engines.

Why go with Defined Autoworks?

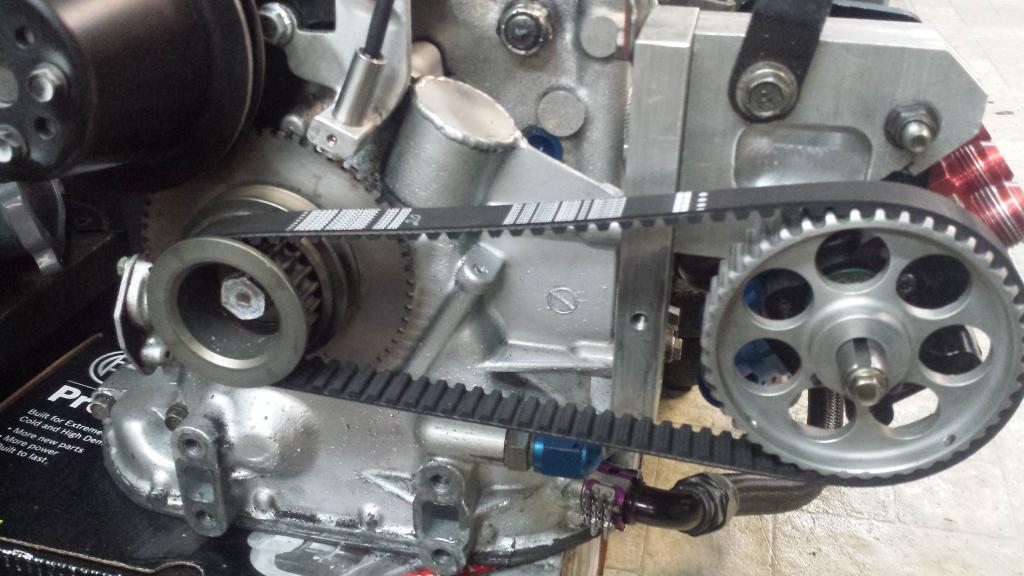

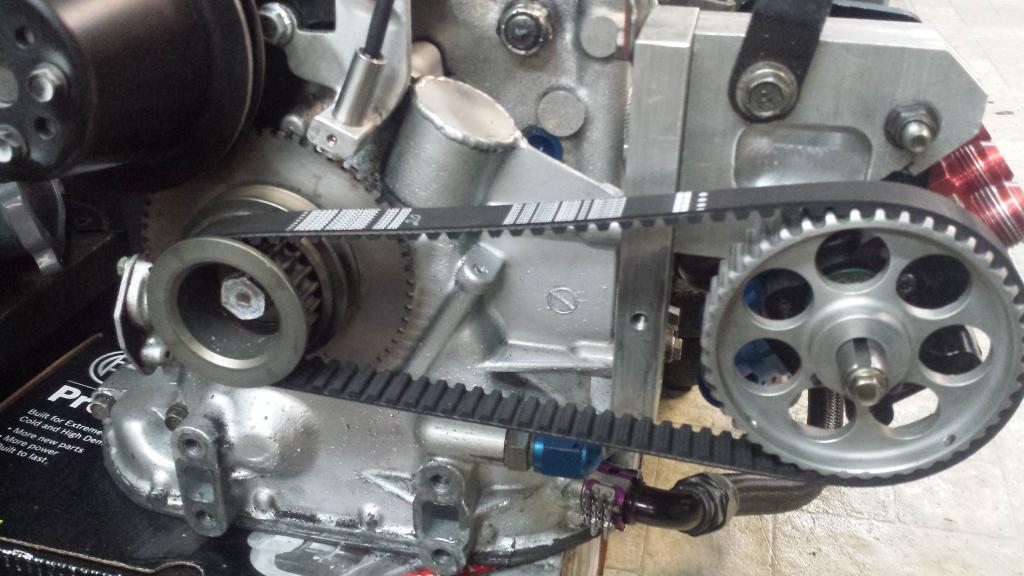

My personal 4-rotor has been running flawlessly while being beaten on the racetrack at over 10,000rpm without skipping a beat. Making over 610rwhp (720+hp) its currently one of the highest documented 4-rotors naturally aspirated.

Why go to a place that has never even built a 4-rotor? Why go to a place that has never even raced and tested a 4 rotor sucessfully? Those are the good questions to ask.

The infamous build video-

Being in the U.S. gains another massive advantage, no more shipping of your valuable parts overseas. Shipping round trip of four cast iron housings is over $2500.

This cost is saved and the risk of damage or customs withholding your parts eliminated.

4-rotors are complex machines, and the undertaking not for the faint of heart. I'm sure there will be many questions and I welcome all to help explain what is being offered or what else is needed. Anyone involved in this group buy will get technical support from me personally. While this is not a unlimited amount of time, I will assist in the general assembly or advice from my years building multi rotor motors.

Additional items to compliment the 4-rotor kits-

We are a one stop shop. I build and fabricate custom drysump kits that will out-flow the mazda comp units. The regulator is externally adjustable and the length of the engine is reduced.

Also offered is fully cnc made slide throttle setup. Provides the best power and flow of any intake. Fully roller bearing supported and reliable.

Lastly if anyone wants other 4-rotor parts, such as full p-port housings or lightened rotors, anything can be provided from A-Z. Full builds and complete engines are no issue.

Only part not in stock is the 4-rotor eccentric shaft due to the cost. Wait for this item is 2-6 months.

4-rotor kit pricing-

2 person group buy $9200

3 person group buy $8700

4 person group buy $8200

5 person group buy $7700

6+ person group buy $7500

Things needed to be sent in-

Two front stationary gears, One 86+ front counterweight, Two intermediate irons to be modified, will need front and rear cast iron plate for center line machining.

Slide throttle assembly pricing-

2 person group buy $3900

3 person group buy $3400

4+ person group buy $3000

Defined Auto Competition drysump setup

2 person group buy $5000

3 person group buy $4800

4+ person group buy $4200

4-rotor slide throttle

Drysump system

Never before has a company based in the U.S. offered such a service. I have already kick started the process and have enough of the complex parts on the shelf to build 4 sets of 4-rotor engines.

Why go with Defined Autoworks?

My personal 4-rotor has been running flawlessly while being beaten on the racetrack at over 10,000rpm without skipping a beat. Making over 610rwhp (720+hp) its currently one of the highest documented 4-rotors naturally aspirated.

Why go to a place that has never even built a 4-rotor? Why go to a place that has never even raced and tested a 4 rotor sucessfully? Those are the good questions to ask.

The infamous build video-

Being in the U.S. gains another massive advantage, no more shipping of your valuable parts overseas. Shipping round trip of four cast iron housings is over $2500.

This cost is saved and the risk of damage or customs withholding your parts eliminated.

4-rotors are complex machines, and the undertaking not for the faint of heart. I'm sure there will be many questions and I welcome all to help explain what is being offered or what else is needed. Anyone involved in this group buy will get technical support from me personally. While this is not a unlimited amount of time, I will assist in the general assembly or advice from my years building multi rotor motors.

Additional items to compliment the 4-rotor kits-

We are a one stop shop. I build and fabricate custom drysump kits that will out-flow the mazda comp units. The regulator is externally adjustable and the length of the engine is reduced.

Also offered is fully cnc made slide throttle setup. Provides the best power and flow of any intake. Fully roller bearing supported and reliable.

Lastly if anyone wants other 4-rotor parts, such as full p-port housings or lightened rotors, anything can be provided from A-Z. Full builds and complete engines are no issue.

Only part not in stock is the 4-rotor eccentric shaft due to the cost. Wait for this item is 2-6 months.

4-rotor kit pricing-

2 person group buy $9200

3 person group buy $8700

4 person group buy $8200

5 person group buy $7700

6+ person group buy $7500

Things needed to be sent in-

Two front stationary gears, One 86+ front counterweight, Two intermediate irons to be modified, will need front and rear cast iron plate for center line machining.

Slide throttle assembly pricing-

2 person group buy $3900

3 person group buy $3400

4+ person group buy $3000

Defined Auto Competition drysump setup

2 person group buy $5000

3 person group buy $4800

4+ person group buy $4200

4-rotor slide throttle

Drysump system

#2

MECP Certified Installer

I am curious...

Is the need for sending in the front and rear plates along with the intermediate plates so that you don't have to use the insanely expensive mazda parts? I am guessing from the pics the side ports are getting a good dose of devcon.

Also, why the machining of the end plates and stat gears?

I can in now flipping way afford this, but the inner engineer in me is very curious and I am sure others would like to know as well. Hell, it might be a selling point to some.

Is the need for sending in the front and rear plates along with the intermediate plates so that you don't have to use the insanely expensive mazda parts? I am guessing from the pics the side ports are getting a good dose of devcon.

Also, why the machining of the end plates and stat gears?

I can in now flipping way afford this, but the inner engineer in me is very curious and I am sure others would like to know as well. Hell, it might be a selling point to some.

#4

Is the need for sending in the front and rear plates along with the intermediate plates so that you don't have to use the insanely expensive mazda parts?

Nope, for the center line boring.

Mazda used two bearings only for the 2 rotors so any line between 2 points is perfectly straight and low tolerances are fine. Once you add more points (bearings) you have to correct Mazda's low tolerances to make all bearings perfectly in line.

The 20B gets away without this because of the design of the multi piece eccentric shaft coupling, but it took Mazda a while to get this right with multi rotors and indeed there was a recall for it on early production 20Bs. On a production car you have to be able to slap replacement parts together and have it work, so tolerances are looser.

You can make a more rigid/true eccentric shaft than the 20B design if you use higher tolerances through line boring and different shaft coupling.

Though, it is interesting that this 4 rotor design is still like Mazda's 2 rotor +1 +1. I presume having two journals at either end of the middle of the 2 rotor style eccentric shaft is enough to thwart its flexing and the middle bearing is unnecessary.

Two front stationary gears, One 86+ front counterweight, Two intermediate irons to be modified, will need front and rear cast iron plate for center line machining.

Nope, for the center line boring.

Mazda used two bearings only for the 2 rotors so any line between 2 points is perfectly straight and low tolerances are fine. Once you add more points (bearings) you have to correct Mazda's low tolerances to make all bearings perfectly in line.

The 20B gets away without this because of the design of the multi piece eccentric shaft coupling, but it took Mazda a while to get this right with multi rotors and indeed there was a recall for it on early production 20Bs. On a production car you have to be able to slap replacement parts together and have it work, so tolerances are looser.

You can make a more rigid/true eccentric shaft than the 20B design if you use higher tolerances through line boring and different shaft coupling.

Though, it is interesting that this 4 rotor design is still like Mazda's 2 rotor +1 +1. I presume having two journals at either end of the middle of the 2 rotor style eccentric shaft is enough to thwart its flexing and the middle bearing is unnecessary.

Two front stationary gears, One 86+ front counterweight, Two intermediate irons to be modified, will need front and rear cast iron plate for center line machining.

#5

MECP Certified Installer

Is the need for sending in the front and rear plates along with the intermediate plates so that you don't have to use the insanely expensive mazda parts?

Nope, for the center line boring.

Mazda used two bearings only for the 2 rotors so any line between 2 points is perfectly straight and low tolerances are fine. Once you add more points (bearings) you have to correct Mazda's low tolerances to make all bearings perfectly in line.

The 20B gets away without this because of the design of the multi piece eccentric shaft coupling, but it took Mazda a while to get this right with multi rotors and indeed there was a recall for it on early production 20Bs. On a production car you have to be able to slap replacement parts together and have it work, so tolerances are looser.

You can make a more rigid/true eccentric shaft than the 20B design if you use higher tolerances through line boring and different shaft coupling.

Though, it is interesting that this 4 rotor design is still like Mazda's 2 rotor +1 +1. I presume having two journals at either end of the middle of the 2 rotor style eccentric shaft is enough to thwart its flexing and the middle bearing is unnecessary.

Two front stationary gears, One 86+ front counterweight, Two intermediate irons to be modified, will need front and rear cast iron plate for center line machining.

Nope, for the center line boring.

Mazda used two bearings only for the 2 rotors so any line between 2 points is perfectly straight and low tolerances are fine. Once you add more points (bearings) you have to correct Mazda's low tolerances to make all bearings perfectly in line.

The 20B gets away without this because of the design of the multi piece eccentric shaft coupling, but it took Mazda a while to get this right with multi rotors and indeed there was a recall for it on early production 20Bs. On a production car you have to be able to slap replacement parts together and have it work, so tolerances are looser.

You can make a more rigid/true eccentric shaft than the 20B design if you use higher tolerances through line boring and different shaft coupling.

Though, it is interesting that this 4 rotor design is still like Mazda's 2 rotor +1 +1. I presume having two journals at either end of the middle of the 2 rotor style eccentric shaft is enough to thwart its flexing and the middle bearing is unnecessary.

Two front stationary gears, One 86+ front counterweight, Two intermediate irons to be modified, will need front and rear cast iron plate for center line machining.

#7

In the 20b, you have to either use 20b/REW irons + the thick middle so port sizes are all the same, or block off the side ports, use thin middle irons and do a peripheral port.

How do you solve that problem with this so all 4 rotors have equal port sizes? (sorry if this is a dumb question)

How do you solve that problem with this so all 4 rotors have equal port sizes? (sorry if this is a dumb question)

Trending Topics

#8

MECP Certified Installer

#9

In the 20b, you have to either use 20b/REW irons + the thick middle so port sizes are all the same, or block off the side ports, use thin middle irons and do a peripheral port. How do you solve that problem with this so all 4 rotors have equal port sizes? (sorry if this is a dumb question)

#10

How do you solve that problem with this so all 4 rotors have equal port sizes? (sorry if this is a dumb question)

Its not a dumb question.

If you want side port engine instead of peripheral port engine you can use old 12 "tall port" intermediate plates (along with GSL-SE rotor housings for the coolant o-ring groove in the right spot) that have larger runners for primaries in the intermediate plate that will be able to be ported to match 13B GSL-SE 4 port end plates.

Or you could use 13BREW end plates and 13BRE intermediate plates and probably get things to flow evenly- those 13BRE port runners are pretty big.

Work on a flow bench could get things just right in either scenario.

Or you could remember a 4 rotor has no practical purpose so you can give up a bit of consumer friendly-ness and build it as a Peripheral port race engine and make more power.

Its not a dumb question.

If you want side port engine instead of peripheral port engine you can use old 12 "tall port" intermediate plates (along with GSL-SE rotor housings for the coolant o-ring groove in the right spot) that have larger runners for primaries in the intermediate plate that will be able to be ported to match 13B GSL-SE 4 port end plates.

Or you could use 13BREW end plates and 13BRE intermediate plates and probably get things to flow evenly- those 13BRE port runners are pretty big.

Work on a flow bench could get things just right in either scenario.

Or you could remember a 4 rotor has no practical purpose so you can give up a bit of consumer friendly-ness and build it as a Peripheral port race engine and make more power.

#12

How do you solve that problem with this so all 4 rotors have equal port sizes? (sorry if this is a dumb question)

Its not a dumb question.

If you want side port engine instead of peripheral port engine you can use old 12 "tall port" intermediate plates (along with GSL-SE rotor housings for the coolant o-ring groove in the right spot) that have larger runners for primaries in the intermediate plate that will be able to be ported to match 13B GSL-SE 4 port end plates.

Or you could use 13BREW end plates and 13BRE intermediate plates and probably get things to flow evenly- those 13BRE port runners are pretty big.

Work on a flow bench could get things just right in either scenario.

Or you could remember a 4 rotor has no practical purpose so you can give up a bit of consumer friendly-ness and build it as a Peripheral port race engine and make more power.

Its not a dumb question.

If you want side port engine instead of peripheral port engine you can use old 12 "tall port" intermediate plates (along with GSL-SE rotor housings for the coolant o-ring groove in the right spot) that have larger runners for primaries in the intermediate plate that will be able to be ported to match 13B GSL-SE 4 port end plates.

Or you could use 13BREW end plates and 13BRE intermediate plates and probably get things to flow evenly- those 13BRE port runners are pretty big.

Work on a flow bench could get things just right in either scenario.

Or you could remember a 4 rotor has no practical purpose so you can give up a bit of consumer friendly-ness and build it as a Peripheral port race engine and make more power.

Thread

Thread Starter

Forum

Replies

Last Post

rx8volks

Canadian Forum

0

08-11-15 10:30 PM