oil catch can to AN or not?

#1

oil catch can to AN or not?

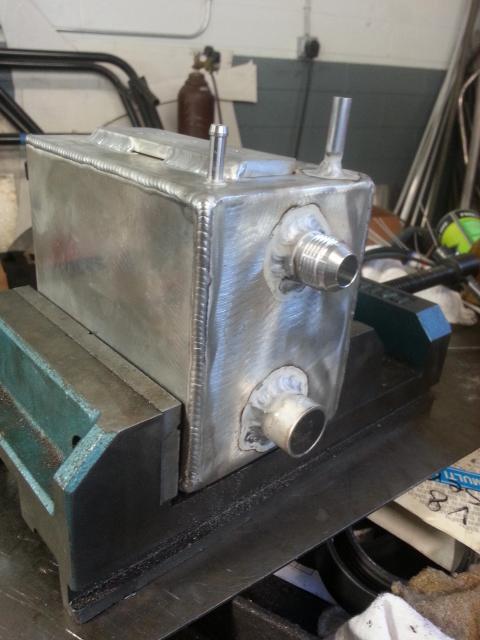

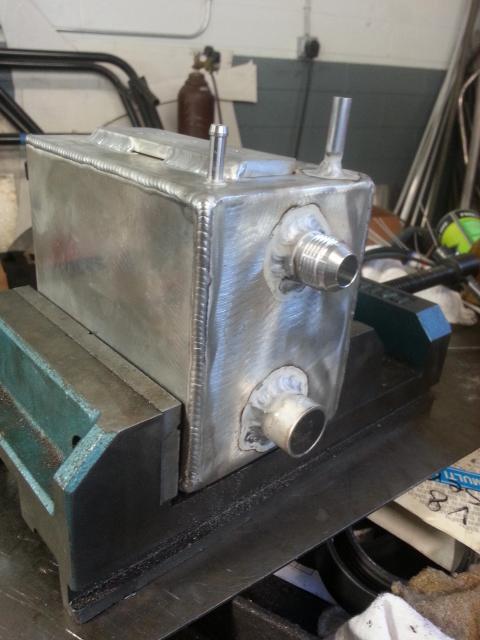

i have a s4 t2, I was going to make my baffled oil catch can, but my buddy had a spare laying around. Here is the pic

So I will be modifying my 13bt oil filler neck with a 5/8" opening. I will be using this catch can for that, the line off the center iron, and my evap line.

I'm torn between spending the money on nice an fittings, or just welding on tubes. If I did weld on -10 at the can, -10 at the oil filler neck blah blah blah, I'll be spending an extra $70 but look bitchin. What do you think about capping off the center iron vent and just runnin the bigger vent on the oil fill? I would save some money if I did.

Or I can just weld on tubing and use hose and clamps which would cost me close to nothing, and look ok, and get the job done.

Anyone with opinion or suggestions on which way to go, sizes?

So I will be modifying my 13bt oil filler neck with a 5/8" opening. I will be using this catch can for that, the line off the center iron, and my evap line.

I'm torn between spending the money on nice an fittings, or just welding on tubes. If I did weld on -10 at the can, -10 at the oil filler neck blah blah blah, I'll be spending an extra $70 but look bitchin. What do you think about capping off the center iron vent and just runnin the bigger vent on the oil fill? I would save some money if I did.

Or I can just weld on tubing and use hose and clamps which would cost me close to nothing, and look ok, and get the job done.

Anyone with opinion or suggestions on which way to go, sizes?

#2

there isn't really any point of making the center iron vent bigger, but you want to keep it, it's a really good vent.

you want any other vents as large as you can.

I run the 5/16" (maybe 3/8")? center vent and a -10AN off my oil fill to a catch can and don't have any issues.

you want any other vents as large as you can.

I run the 5/16" (maybe 3/8")? center vent and a -10AN off my oil fill to a catch can and don't have any issues.

#3

I was chasing an issue, and as a test, I ended up capping the center iron nipple, and welding 2 -10 an fittings to the oil filler neck. Things improved GREATLY after that.

If venting is the issue, it doesnt matter if you do it with AN fittings, or welded ports and rubber hoses.

If venting is the issue, it doesnt matter if you do it with AN fittings, or welded ports and rubber hoses.

#5

I thought I would share some of my progress for my oil catch can project. I went with -10 an fittings for the oil filler neck to the oil catch can , but the center iron vent and the fuel tank vent I just used a hose.

Here is the drain. it's a weld in -6 bung with a -6 cap

I will be using a clamp on breather filter with a 1" opening. My oil filler neck is modified for a -10, so I welded a -10 male fitting. The center iron vent is about a 5/16" nipple, so I welded a 5/16" tube on there. The fuel vent is just a nipple I had laying around so I just drilled and tapped for that

Since I don't have a lot of the stock stuff, the ill neck doesn't need to be 2 piece or be that crazy shape, so I cut it and made it with less angles, welded the -10 male fitting to it. The tube the -10 is welded to is cut at an angle to minimize the amount of oil going into it when I add oil. The only problem now is I might have to pour my oil in the engine slower. I hope not.

painted

I'll post pics of my mounting and plumbing after I finish that

Here is the drain. it's a weld in -6 bung with a -6 cap

I will be using a clamp on breather filter with a 1" opening. My oil filler neck is modified for a -10, so I welded a -10 male fitting. The center iron vent is about a 5/16" nipple, so I welded a 5/16" tube on there. The fuel vent is just a nipple I had laying around so I just drilled and tapped for that

Since I don't have a lot of the stock stuff, the ill neck doesn't need to be 2 piece or be that crazy shape, so I cut it and made it with less angles, welded the -10 male fitting to it. The tube the -10 is welded to is cut at an angle to minimize the amount of oil going into it when I add oil. The only problem now is I might have to pour my oil in the engine slower. I hope not.

painted

I'll post pics of my mounting and plumbing after I finish that

Thread

Thread Starter

Forum

Replies

Last Post

troym55

3rd Generation Specific (1993-2002)

23

05-25-16 12:42 PM

tiger18

3rd Generation Specific (1993-2002)

9

09-03-15 08:27 PM